Latest Advances in Waste Plastic Pyrolytic Catalysis

Abstract

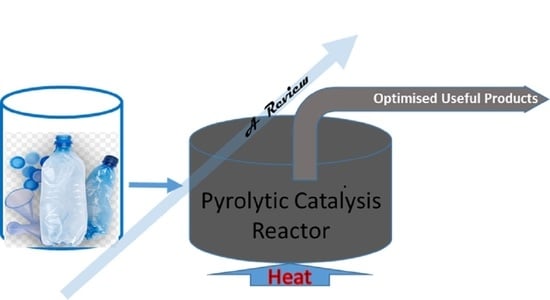

:1. General Introduction

2. Catalyst and Non-Catalyst Use

Some Other Influential Factors

3. Catalytic Pyrolysis

3.1. Heterogeneous Catalysts and Pyrolysis

3.2. Homogeneous Catalysts and Pyrolysis

3.3. Biocatalysts and their Reactions

4. Common Waste Plastic Pyrolytic Products

Functional Implications & Recommendations of This Literature

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| HDPE | High Density Polyethylene |

| LDPE | Low Density Polyethylene |

| PE | Polyethylene |

| PP | Polypropylene |

| PS | Polystyrene |

| PVC | Polyvinyl Chloride |

| PET | Polyethylene Terephthalate |

| CO | Carbon-monoxide |

| CO2 | Carbon dioxide |

| MSW | Municipal Solid Wastes |

| MWPs | Municipal Waste Plastics |

| TCT | Thermo-Chemical Treatment |

| WP | Waste Plastics |

| WPCP | Waste Plastic Catalytic Pyrolysis |

| WPP | Waste Plastic Pyrolysis |

| HCs | Hydrocarbons |

| WPTP | Waste Plastic Thermal Pyrolysis |

| TA-NZ | Thermally Activated Modified Natural Zeolite |

| GC-MS | Gas Chromatography–Mass Spectrometry |

| FT-IR | Fourier Transform Infrared |

| MMO | Methane Monooxygenase |

| HCl | Hydrogen Chloride |

References

- Pyrolysisadvocacy, (n.d). Pyrolysis Explained. Available online: https://www.pyrolysisadvocacy.com/pyrolysis-explained (accessed on 7 January 2020).

- Demirbas, A. Pyrolysis of municipal plastic waste for recovery of gasoline-range hydrocarbons. J. Anal. Appl. Pyrolysis 2004, 72, 97–102. [Google Scholar] [CrossRef]

- Zafar, S. Pyrolysis of Municipal Wastes. BioEnergy Consult Powering a Greener Future. 29 July 2020. Available online: https://www.bioenergyconsult.com/pyrolysis-of-municipal-waste/ (accessed on 27 November 2021).

- Britannica. “Catalyst”. Chemistry. 2019. Available online: https://www.britannica.com/science/catalyst (accessed on 9 January 2020).

- Butler, E.; Devlin, G.; Meier, D.; McDonnell, K. A review recent laboratory research and commercial developments in fast pyrolysis and upgrading. Renew. Sust. Energ. Rev. 2011, 15, 4171–4186. [Google Scholar] [CrossRef] [Green Version]

- Abnisa, F.; Daud, W.M.A.W. A review on co-pyrolysis of biomass: An optional technique to obtain a high-grade pyrolysis oil. Energy Convers. Manag. 2014, 87, 71–85. [Google Scholar] [CrossRef]

- Pyrolab (n.d). Sequential Pyrolysis. Available online: https://www.pyrolab.com/pyrolysis-methods/sequential-pyrolysis (accessed on 16 July 2021).

- Syamsiro, M.; Saptoadi, H.; Norsujianto, T.; Noviasri, P.; Cheng, S.; Alimuddin, Z.; Yoshikawaa, K. Fuel Oil Production from Municipal Plastic Wastes in Sequential Pyrolysis and Catalytic Reforming Reactors. 2014. Available online: https://www.sciencedirect.com/science/article/pii/S1876610214002288 (accessed on 9 September 2021).

- Aguado, J.; Serrano, D.P.; Escola, J.M. Catalytic Upgrading of Plastic Wastes. In Feedstock Recycling and Pyrolysis of Waste Plastics; Scheirs, J., Kaminsky, W., Eds.; John Wiley & Sons, Ltd.: Mostoles, Spain, 2006; pp. 73–110. [Google Scholar]

- Aguado, J.; Serrano, D.P.; Vicente, G.; Sánchez, N. Enhanced production of an alpha;-olefins by thermal degradation of High-Density Polyethylene (HDPE) in decalin solvent: Effect of the reaction time and temperature. Ind. Eng. Chem. Res. 2007, 46, 3497–3504. [Google Scholar] [CrossRef]

- Guado, J.; Serrano, D.P.; Escola, J.M.; Garagorri, E.; Fernandez, J.A. Catalytic conversion of polyolefins into fuels over zeolite beta. Polym. Degrad. Stab. 2000, 69, 11–16. [Google Scholar]

- Aguado, J.; Serrano, D.P.; Escola, J.M.; Garagorri, E. Catalytic conversion of low-density polyethylene using a continuous screw kiln reactor. Catal. Today 2002, 75, 257–262. [Google Scholar] [CrossRef]

- Clark, J. The Effect of Catalysts on Reaction Rates. 2002. Available online: https://chem.libretexts.org/Bookshelves/Inorganic_Chemistry/Supplemental_Modules_and_Websites_(Inorganic_Chemistry)/Catalysis/The_Effect_of_a_Catalyst_on_Rate_of_Reaction (accessed on 14 February 2021).

- Lee, K.-H. Thermal and Catalytic Degradation of Waste HDPE. Feedstock Recycling and Pyrolysis of Waste Plastics, 1st ed.; Wiley: New York, NY, USA, 2006. [Google Scholar]

- Bridgwater, A. Fast pyrolysis of biomass for the production of liquids. In Biomass Combustion Science, Technology and Engineering; Woodhead Publishing Series in Energy; Woodhead: Cambridge, UK, 2013; pp. 130–171. [Google Scholar]

- Fulekar, M.H. Nanotechnology Importance and Applications, 1st ed.; I.K. International Publishing House: New Delhi, India, 2010. [Google Scholar]

- Gao, F. Pyrolysis of Waste Plastics into Fuels. Ph.D. Thesis, University of Canterbury, Christchurch, New Zealand, 2010. [Google Scholar]

- Beltrame, P.L.; Carniti, P.; Audisio, G.; Bertini, F. Catalytic degradation of polymers: Part II Degradation of polyethylene. Polym. Degrad. Stabil. 1989, 26, 209–220. [Google Scholar] [CrossRef]

- Sarker, M.; Rashid, M.M.; Molla, M. Abundant High-Density Polyethylene (HDPE-2) Turns into Fuel by Using of HZSM-5 Catalyst. J. Fundam. Renew. Energy Appl. 2011, 1, R110201. [Google Scholar] [CrossRef]

- Murata, K.; Sato, K.; Sakata, Y. Effect of pressure on thermal degradation of polyethylene. J. Anal. Appl. Pyrolysis 2004, 71, 569–589. [Google Scholar] [CrossRef]

- Mastral, F.J.; Esperanza, E.; Garcı’a, P.; Juste, M. Pyrolysis of high-density polyethylene in a fluidised bed reactor. Influ. Temp. Resid. Time. J. Anal. Appl. Pyrolysis 2002, 63, 1–15. [Google Scholar] [CrossRef]

- Yansaneh, O.Y.; Zein, S.H. Recent Advances on Waste Plastic Thermal Pyrolysis: A Critical Overview. Processes 2022, 10, 332. [Google Scholar] [CrossRef]

- Miandad, R.; Rehan, M.; Barakat, M.A.; Aburiazaiza, A.S.; Khan, H.; Ismail, I.M.I.; Dhavamani, J.; Gardy, J.; Hassanpour, A.; Nizami, A.S. Catalytic Pyrolysis of Plastic Waste: Moving Toward Pyrolysis Based Biorefineries. Front. Energy Res. 2019, 7, 27. [Google Scholar] [CrossRef] [Green Version]

- Lee, K.H.; Shin, D.H. Effect of steam on coking in the non-catalytic pyrolysis of naphtha components. Korean J. Chem. Eng. 2004, 21, 252–256. [Google Scholar] [CrossRef]

- Marcilla, A.; Beltrán, M.I.; Hernández, F.; Navarro, R. HZSM5 and HUSY deactivation during the catalytic pyrolysis of polyethylene. Appl. Catal. A Gen. 2004, 278, 3743. [Google Scholar] [CrossRef]

- Achilias, D.S. Chemical Recycling of Poly(Methyl Methacrylate) by Pyrolysis. Potential use of the Liquid Fraction as a Raw Material for the Reproduction of the Polymer. Eur. Polym. J. 2007, 43, 2564–2575. [Google Scholar] [CrossRef]

- Helt, J.E.; Agrawal, R.K.; Myles, K.M. Pyrolysis of Municipal Solid Waste. Annual Report, July 1984–June 1985, Argonne National Laboratory, ANL/CNSV-45. 1984. Available online: https://www.osti.gov/biblio/7255421-pyrolysis-municipal-solid-wasteannual-report-july-june (accessed on 5 March 2021).

- Matayeva, A.; Basile, F.; Cavani, F.; Bianchi, D.; Chiaberge, S. Development of Upgraded Bio-Oil via Liquefaction and Pyrolysis. Stud. Surf. Sci. Catal. 2019, 178, 231–256. [Google Scholar]

- Wang, S.; Lee, W.J.; Li, C.; Kuan, B.; Burke, N.; Patel, J. The pyrolysis of natural gas: A study of carbon deposition and the suitability of reactor materials. Aiche J. 2019, 65, 1035–1046. [Google Scholar] [CrossRef]

- Liao, Z.-P.; Liu, Y.-J. Status of plastics processing industry and suggestions on its development. Modern Chem. Ind. 2000, 20, 5–8. (In Chinese) [Google Scholar]

- Khan, M.Z.H.; Sultana, M.; Al-Mamun, M.R.; Hasan, M.R. Pyrolytic Waste Plastic Oil and Its Diesel Blend: Fuel Characterization. J. Environ. Public Health 2016, 2016, 7869080. [Google Scholar] [CrossRef] [Green Version]

- Ahmad, I.; Khan, M.I.; Khan, H.; Ishaq, M.; Khan, R.; Gul, K.; Ahmad, W. Pyrolysis of HDPE into fuel like products: Evaluating catalytic performance of plain and metal oxides impregnated waste brick kiln dust. J. Anal. Appl. Pyrolysis 2017, 124, 195–203. [Google Scholar] [CrossRef]

- Tiwary, P.; Guria, C. Effect of metal oxide catalysts on degradation of waste polystyrene in hydrogen at elevated temperature and pressure in benzene solution. J. Polym. Environ. 2010, 18, 298–307. [Google Scholar] [CrossRef]

- Manos, G.; Garforth, A.; Dwyer, J. Catalytic degradation of high-density polyethylene over different zeolitic structures. Ind. Eng. Chem. Res. 2000, 39, 1198–1202. [Google Scholar] [CrossRef]

- Wallis, M.; Bhatia, S.K. Kinetic study of the thermal degradation of high-density polyethylene. Polym. Degrad. Stabil. 2006, 91, 1476–1483. [Google Scholar] [CrossRef]

- Sharratt, P.N.; Lin, Y.H.; Garforth, A.A.; Dwyer, J. Investigation of the catalytic pyrolysis of high-density polyethylene over a HZSM-5 catalyst in a laboratory fluidized-bed reactor. Ind. Eng. Chem. Res. 1997, 36, 5118–5124. [Google Scholar] [CrossRef]

- Zhao, X.; Zhan, L.; Xie, B.; Gao, B. Products derived from waste plastics (PC, HIPS, ABS, PP and PA6) via hydrothermal treatment: Characterization and potential applications. Chemosphere 2018, 207, 742–752. [Google Scholar] [CrossRef]

- Ludlow-Palafox, C.; Chase, H.A. Microwave-induced pyrolysis of plastic wastes. Ind. Eng. Chem. Res. 2001, 40, 4749–4756. [Google Scholar] [CrossRef]

- Simon, C.M.; Kaminsky, W.; Schlesselmann, B. Pyrolysis of polyolefins with steam to yield olefins. J. Anal. Appl. Pyrolysis 1996, 38, 75–87. [Google Scholar] [CrossRef]

- Serrano, D.P.; Aguado, J.; Escola, J.M.; Garag, E. Conversion of low-density polyethylene into petrochemical feedstocks using a continuous screw kiln reactor. J. Anal. Appl. Pyrolysis 2001, 58–59, 789–801. [Google Scholar] [CrossRef]

- Porter, E.A. Distillation. 2011. Available online: https://www.thermopedia.com/content/703/ (accessed on 5 March 2021).

- Treybal, R.E. Mass Transfer Operations, 3rd ed.; McGraw-Hill: New York, NY, USA, 1980; pp. 387–389, 410–412. Available online: http://www.separationprocesses.com/Distillation/DT_Chp04n3.htm (accessed on 3 October 2020).

- Buekens, A. Introduction to Feedstock Recycling of Plastics. In Feedstock Recycling and Pyrolysis of Waste Plastics; Scheirs, J., Kaminsky, W., Eds.; John Wiley & Sons, Ltd.: Brussels, Belgium, 2006; pp. 3–41. [Google Scholar]

- Wilhoit, R.C.; Zwolinski, B.J. Handbook of Vapor Pressures and Heats of Vaporization of Hydrocarbons and Related Compounds; Publication No. 101; Thermodynamics Research Center: College Station, TX, USA, 1971; p. 337. [Google Scholar]

- Moses, K. Production and Characterization of Liquid Fuel from Mixed Plastic Wastes Using Catalytic Pyrolysis. Master’s Thesis, Makerere University, Kampala, Uganda, 2014. [Google Scholar]

- Vogt, P.F.; Gerulis, J.J. Amines, Aromatic. In Ullmann’s Encyclopedia of Industrial Chemistry; Wiley: Hoboken, NJ, USA, 2000. [Google Scholar] [CrossRef]

- Miskolczi, N.; Bartha, L.; Deak, G.; Jover, B.; Kallo, D. Thermal and thermo-catalytic degradation of high-density polyethylene waste. J. Anal. Appl. Pyrolysis 2004, 72, 235–242. [Google Scholar] [CrossRef]

- Lee, K.-H. Pyrolysis of Waste Polystyrene and High-Density Polyethylene. In Material Recycling—Trends and Perspectives; In Tech: London, UK, 2012; ISBN 978-953-51-0327-1. [Google Scholar]

- Marcilla, A.; GarcÃa-Quesada, J.C.; Sánchez, S.; Ruiz, R. Study of the catalytic pyrolysis behaviour of polyethylene polypropylene mixtures. J. Anal. Appl. Pyrolysis 2005, 74, 38792. [Google Scholar] [CrossRef]

- Miskolczi, N.; Bartha, L.; Deak, G.Y. Thermal degradation of polyethylene and polystyrene from the packaging industry over different catalysts. Polym. Degrad. Stab. 2006, 91, 517–526. [Google Scholar] [CrossRef]

- Buekens, A.G.; Huang, H. Catalytic plastics cracking for recovery of gasoline- range hydrocarbons from municipal plastic wastes. Resour. Conserv. Recy. 1998, 23, 163–181. [Google Scholar] [CrossRef]

- Milne, B.J.; Behie, L.A.; Berruti, F. Recycling of waste plastics by ultrapyrolysis using an internally circulating fluidized bed reactor. J. Anal. Appl. Pyrolysis 1999, 51, 157–166. [Google Scholar] [CrossRef]

- Adnan, A.; Shah, J.; Jan, M.R. Thermo-catalytic pyrolysis of polystyrene in the presence of zinc bulk catalysts. J. Taiwan Inst. Chem. Eng. 2014, 45, 2494–2500. [Google Scholar] [CrossRef]

- DieselNet. Catalyst Fundamentals. DieselNet. Revision 2000.11a. 2000. Available online: https://dieselnet.com/tech/cat_fund.php#:~:text=It%20is%20important%20to%20recognize,the%20kinetics%20of%20reaching%20equilibrium (accessed on 14 August 2020).

- Farnetti, E.; Monte, R.D.; Kašpar, J. Homogeneous and Heterogeneous Catalysis. In Inorganic and Bio-Inorganic Chemistry—(n.d.); ©Encyclopedia of Life Support Systems (EOLSS); University of Trieste: Trieste, Italy, 2010; Volume II. [Google Scholar]

- Foist, L. Heterogeneous and Homogeneous Catalysts. Available online: https://study.com/academy/lesson/heterogeneous-homogeneous-catalysts.html (accessed on 5 March 2021).

- Pera, L.M.; Baigori, M.D.; Pandey, A.; Castro, G.R. Biocatalysis. In Industrial Biorefineries & White Biotechnology; Elsevier: Amsterdam, The Netherlands, 2015; pp. 391–408. [Google Scholar]

- Wang, L.; Luo, G.-H.; Li, Q. Progress of waste plastics pyrolysis. Chem. Ind. Eng. Program 2003, 22, 130–134. [Google Scholar]

- Salaudeen, S.A.; Arku, P.; Dutta, A. Plastics to Energy; Elsevier: Amsterdam, The Netherlands, 2019. [Google Scholar]

- Ivanova, S.; Gumerova, E.; Minsker, K.; Zaikov, G.; Berlin, A. Selective catalytic degradation of polyolefins. Prog. Polym. Sci. 1990, 15, 193–215. [Google Scholar] [CrossRef]

- Adnan; Shah, J.; Jan, M.R. Effect of polyethylene terephthalate on the catalytic pyrolysis of polystyrene: Investigation of the liquid products. J. Taiwan Inst. Chem. Eng. 2015, 51, 96–102. [Google Scholar] [CrossRef]

- Chai, Y.; Gao, N.; Wang, M.; Wu, C. H2 production from co-pyrolysis/gasification of waste plastics and biomass under novel catalyst Ni-CaO-C. Chem. Eng. J. 2020, 382, 122947. [Google Scholar] [CrossRef]

- Wu, S.L.; Kuo, J.H.; Wey, M.Y. Thermaldegradation of waste plastics in a two-stage pyrolysis-catalysis reactor overcore-shell type catalyst. J. Anal. Appl. Pyrolysis 2019, 142, 104641. [Google Scholar] [CrossRef]

- Westerhaus, F.A.; Jagadeesh, R.V.; Wienhöfer, G.; Pohl, M.-M.; Radnik, J.; Surkus, A.-E.; Rabeah, J.; Junge, K.; Junge, H.; Nielsen, M.; et al. Heterogenized cobalt oxide catalysts for nitroarene reduction by pyrolysis of molecularly defined complexes. Nat. Chem. 2013, 5, 537–543. [Google Scholar] [CrossRef]

- Maesen, T. The Zeolite Scene—An Overview, 3rd revised ed.; Introduction to Zeolite Science and Practice; Centi, G., Ed.; Elsevier: Richmond, CA, USA, 2007; Volume 1, pp. 1–12. [Google Scholar]

- ACS Publications. Catalyst bulk phase may play role in oxidation. Chem. Eng. News 1967, 45, 50–53. [Google Scholar] [CrossRef]

- Barrer, R.M. Synthesis of Zeolites; Elsevier: Portoroz, Slovenia, 1985. [Google Scholar]

- Faravelli, T.; Bozzano, G.; Scassa, C.; Perego, M.; Fabini, S.; Ranzi, E.; Dente, M. Gas product distribution from polyethylene pyrolysis. J. Anal. Appl. Pyrolysis 1999, 52, 87–103. [Google Scholar] [CrossRef]

- Kim, S. Pyrolysis kinetics of waste PVC pipe. Waste Manag. 2001, 21, 609–616. [Google Scholar] [CrossRef]

- Obeid, F.; Zeaiter, J.; Ala’a HAl-Muhtaseb, A.H.; Bouhadir, K. Thermo-catalytic pyrolysis of waste polyethylene bottles in a packed bed reactor with different bed materials and catalysts. Energy Convers. Manag. 2014, 85, 1–6. [Google Scholar] [CrossRef]

- Mansur, D.; Simanungkalit, S.P.; Fitriady, M.A.; Safitri, D. Liquefaction of plastic for fuel production and application of volcanic ash as catalyst. Aip Conf. Proc. 2018, 2024, 020001. [Google Scholar]

- Jan, M.R.; Shah, J.; Gulab, H. Catalytic degradation of waste high-density polyethylene into fuel products using BaCO3 as a catalyst. Fuel Process. Technol. 2010, 91, 1428–1437. [Google Scholar] [CrossRef]

- Jan, M.R.; Shah, J.; Gulab, H. Catalytic conversion of waste high-density polyethylene into useful hydrocarbons. Fuel 2013, 105, 595–602. [Google Scholar]

- Jan, M.R.; Shah, J.; Gulab, H. Characterization of Thermo-Catalytic Degradation Products of Waste High-Density Polyethylene Using GC-MS (An Environmental Waste as Feedstock Chemicals). J. Chem. Soc. Pak. 2015, 37, 1256–1268. [Google Scholar]

- Miandad, R.; Barakat, M.A.; Rehan, M.; Aburiazaiza, A.S.; Ismail, I.M.I.; Nizami, A.S. Plastic waste to liquid oil through catalytic pyrolysis using natural and synthetic zeolite catalysts. Waste Manag. 2017, 69, 66–78. [Google Scholar] [CrossRef]

- Shah, J.; Jan, M.R.; Mabood, F.; Jabeen, F. Catalytic pyrolysis of LDPE leads to valuable resource recovery and reduction of waste problems. Energy Convers. Manag. 2010, 51, 2791–2801. [Google Scholar] [CrossRef]

- Huo, E.; Lei, H.; Liu, C.; Zhang, Y.; Xin, L.; Zhao, Y.; Qian, M.; Zhang, Q.; Lin, X.; ChenxiWang, C.; et al. Jet fuel and hydrogen produced from waste plastics catalytic pyrolysis with activated carbon and MgO. Sci. Total Environ. 2020, 727, 138411. [Google Scholar] [CrossRef] [PubMed]

- Ahmad, I.; Khan, M.I.; Khan, H.; Ishaq, M.; Tariq, R.; Gul, K.; Ahmad, W. Pyrolysis Study of Polypropylene and Polyethylene into Premium Oil Products. Int. J. Green Energy 2015, 12, 663–671. [Google Scholar] [CrossRef]

- Chukwuneke, C.; Sylvester, O.; Kubor, K.; Lagre, S.; Siebert, J.; Uche, O.; Agboola, B.; Okoro, L.; Jahng, W.J. Synthesis of C5-C22 Hydrocarbon Fuel from Ethylene-Based Polymers. Int. J. Sci. Eng. Res. 2014, 5, 805–809. [Google Scholar] [CrossRef]

- Sarker, M.; Rashid, M.M.; Rahman, M.S. Thermal Conversion of Polymer Wastes (LDPE) into Hydrocarbon Diesel Fuel without Cracking Catalysts. Int. J. Pure Appl. Sci. Technol. 2012, 11, 36. [Google Scholar]

- Mabood, F.; Jan, M.R.; Shah, J.; Jabeen, F.; Hussain, Z. Catalytic conversion of waste low-density polyethylene into fuel oil. J. Iran. Chem. Res. 2010, 3, 121–131. [Google Scholar]

- Roozbehani, B.; Motevassel, M.; Mirdrikvand, M.; Moqadam, S.I.; Kharaghani, A. Gasoline production from a polymeric urban disposal mixture using silica–alumina catalyst. Clean Technol. Environ. Policy 2016, 19, 123–136. [Google Scholar] [CrossRef]

- Fivga, A.; Dimitriou, I. Pyrolysis of plastic waste for production of heavy fuel substitute: A techno-economic assessment. Energy 2018, 149, 865–874. [Google Scholar] [CrossRef]

- Liu, Y.; Qian, J.; Wang, J. Pyrolysis of polystyrene waste in a fluidized-bed reactor to obtain styrene monomer and gasoline fraction. Fuel Processing Technol. 2000, 63, 45–55. [Google Scholar] [CrossRef]

- Rezvanipour, M.; Hesari, F.A.; Pazouki, M. Catalytic Pyrolysis of General-Purpose PolyStyrene Using Red Mud as a Catalyst. Materials and Energy Research Center, Meshkin Dasht, Karaj, Ira. Iran. J. Chem. Eng. 2014, 11, 10–20. [Google Scholar]

- López, A.; de Marco, I.; Caballero, B.M.; Laresgoiti, M.F.; Adrados, A. Influence of time and temperature on pyrolysis of plastic wastes in a semi-batch reactor. Chem. Eng. J. 2011, 173, 62–71. [Google Scholar] [CrossRef]

- Lumen Learning, (n.d). Homogeneous Catalysis. Introduction to Chemistry. Available online: https://courses.lumenlearning.com (accessed on 5 March 2021).

- Keane, M.A. Catalytic Processing of Waste Polymer Composites. Management, Recycling and Reuse of Waste Composites; Woodhead Publishing Series in Composites Science and Engineering; Woodhead: Cambridge, UK, 2010; pp. 122–151. [Google Scholar]

- Wang, Y.-F.; Liang, Y.; Wu, Y.-F.; Yang, J.; Zhang, X.; Cai, D.; Peng, X.; Kurmoo, M.; Zeng, M.-H. In Situ Pyrolysis Tracking and Real-Time Phase Evolution: From a Binary Zinc Cluster to Supercapacitive Porous Carbon. Angew. Chem. Int. Ed. 2020, 59, 13232–13237. [Google Scholar] [CrossRef] [PubMed]

- Liu, J.; Liu, J.; Shi, F.; Hu, S.; Jiang, S.; Liu, S.; Liu, D.; Tian, X. Transition metal and co-pyrolysis. Bio Resources. J. Solid. State Chem. 2019, 275, 8–15. [Google Scholar] [CrossRef]

- Park, S.; Bang, Y.; Han, S.J.; Yoo, J.; Song, J.H.; Song, J.C.; Song, I.K. Hydrogen Production by Steam Reforming of Liquefied Natural Gas (LNG) over Mesoporous Nickel-Iron-Alumina Catalyst. J. Mol. Catal. A Chem. 2015, 410, 74–80. [Google Scholar] [CrossRef]

- Dorcheh, A.S.; Abbasi, M.H. Silica aerogel; synthesis, properties and characterisation. J. Master Process. Technol. 2008, 199, 10–26. [Google Scholar] [CrossRef]

- Kakaei, S.; Khameneh, E.S.; Hosseini, M.H.; Moharreri, M.M. A modified ionic liquid clay to remove heavy metals from water: Investigating its catalytic activity. Int. J. Environ. Sci. Technol. 2020, 17, 2043–2058. [Google Scholar] [CrossRef] [Green Version]

- Casella, L. Comprehensive Inorganic Chemistry II—From Elements to Applications, 2nd ed.; Comprehensive Inorganic Chemistry II. Volume Editor’s Introduction; Elsevier: Amsterdam, The Netherlands, 2013; pp. xxxvii–xxxviii. [Google Scholar]

- Dhawane, S.H.; Halder, G. Synthesis of Catalyst Support from Waste Biomass for Impregnation of Catalysts in Biofuel Production. In Advances in Feedstock Conversion Technologies for Alternative Fuels and Bioproducts; Elsevier: Amsterdam, The Netherlands, 2019; pp. 199–220. [Google Scholar]

- Kirimura, K.; Ishii, Y. Enzymatic Kolbe–Schmitt Reaction for the Syntheses of Value-Added Compounds. In Future Directions in Biocatalysis, 2nd ed.; Elsevier: Amsterdam, The Netherlands, 2017; pp. 135–147. [Google Scholar]

- Ali, O.M.; Mamat, R.; Rasul, M.G.; Najafi, G. Potential of Biodiesel as Fuel for Diesel Engine. In Clean Energy for Sustainable Development—Comparisons and Contrasts of New Approaches; Elsevier: Amsterdam, The Netherlands, 2017; pp. 557–590. [Google Scholar]

- Melgarejo-Torres, R.; Pérez-Vega, S.B.; Rivera-Arredondo, V.M.; Che-Galicia, G. Multiphase bioreactors in the pharmaceutical industry. In Advances in Chemical Engineering; Academic Press: Cambridge, MA, USA, 2019. [Google Scholar]

- Uragami, T.; Chakraborty, S.; Piemonte, V.; Paola, L.D. Biocatalytic membrane reactors: Principles, preparation and biotechnological, pharmaceutical and medical applications. In Handbook of Membrane Reactors—Reactor Types and Industrial Applications; Woodhead Publishing Series in Energy: Sawston, UK, 2013; Volume 2, pp. 846–887. [Google Scholar]

- Muthudineshkumar, R.; Anand, R. Anaerobic digestion of various feedstocks for second-generation biofuel production. In Advances in Eco-Fuels for a Sustainable Environment; Woodhead Publishing: Sawston, UK, 2019. [Google Scholar]

- Wilding, M.; Micklefield, J. Synthetic Methods VI—Enzymatic and Semi-Enzymatic in Comprehensive Chirality; Elsevier BV: Amsterdam, The Netherlands, 2012. [Google Scholar]

- Pinheiro, B.B.; dos Santos, K.P.; Rios, N.S.; Macedo, A.C.; dos Santos, J.C.S.; Gonçalves, L.R.B. Enzymatic Reactions and Biocatalytic Processes- in Reference Module in Chemistry. Mol. Sci. Chem. Eng. 2019. [Google Scholar] [CrossRef]

- Street, A.; Zydenbos, S. Analysis of the Christchurch Mixed Municipal Waste Stream—1 July 2003 to 30 June 2004; City Water & Waste Unit, Christchurch City Council: Christchurch, New Zealand, 2007; p. 6. [Google Scholar]

- UN Environment Report. Banning Single-Use Plastic: Lessons and Experiences from Countries. 2018. Available online: https://www.unep.org/interactive/beat-plastic-pollution/ (accessed on 17 September 2020).

- Smith, L. Plastic Waste; Briefing Paper Number 08515; House of Commons Library: London, UK, 2021. [Google Scholar]

- Pandey, U.; Stormyr, J.A.; Hassani, A.; Jaiswal, R.; Haugen, H.H.; Britt, M.E. Pyrolysis of Plastic Waste to Environmentally Friendly Products. In Energy Production and Management in the 21st Century IV 61; Moldestad University of South-Eastern Norway: Kongsberg, Norway, 2020; p. 61. [Google Scholar]

- Jeong, J.S.; Kim, K.W.; An, K.H.; Kim, B.J. Fast recovery process of carbon fibers from waste carbon fibers-reinforced thermoset plastics. J. Environ. Manag. 2019, 247, 816–821. [Google Scholar] [CrossRef]

- Ma, J.; Shi, L.; Shi, Y.; Luo, S.; Xu, J. Pyrolysis of polymethylsilsesquioxane. J. Appl. Polym. Sci. 2002, 85, 1077–1086. [Google Scholar] [CrossRef]

- Kumar, S.; Panda, A.K.; Singh, R.K. A review on tertiary recycling of high-density polyethylene to fuel. Resour. Conversat. Recycl. 2008, 55, 893–910. [Google Scholar] [CrossRef]

- Jung, S.H.; Cho, M.H.; Kang, B.S.; Kim, J.S. Pyrolysis of a fraction of waste polypropylene and polyethylene for the recovery of BTX aromatics using a fluidized bed reactor. Fuel Process. Technol. 2010, 91, 277–284. [Google Scholar] [CrossRef]

- Sophonrat, N.; Sandström, L.; Zaini, I.N.; Yangaa, W. Stepwise Pyrolysis of Mixed Plastics and Paper for Separation of Oxygenated and Hydrocarbon Condensates; Department of Materials Science and Engineering, KTH Royal Institute of Technology: Stockholm, Sweden, 2018; Available online: www.elsevier.com/locate/apenergy (accessed on 9 May 2021).

- Muhammad, C.C.; Onwudili, J.A.; Williams, P.T. Thermal degradation of real-world waste plastics and simulated mixed plastics in a two-stage pyrolysis-catalysis reactor for fuel. Energy Fuels 2015, 29, 2601–2609. [Google Scholar] [CrossRef]

- Horvat, N.; Ng, F.T.T. Tertiary polymer recycling: Study of polyethylene thermolysis as a first step to synthetic diesel fuel. Fuel 1999, 78, 459–470. [Google Scholar] [CrossRef]

- Singh, R.K.; Ruj, B. Time and temperature depended fuel gas generation from pyrolysis of real world municipal plastic waste. Fuel 2016, 174, 164–171. [Google Scholar] [CrossRef]

- Sharma, B.K.; Moser, B.R.; Vermillion, K.E.; Doll, K.M.; Rajagopalan, N. Production, characterisation and fuel properties of alternative diesel fuel from pyrolysis of waste plastic grocery bags. Fuel Process. Technol. 2014, 122, 79–90. [Google Scholar] [CrossRef]

- Scott, D.S.; Czernik, S.R.; Piskorz, J.; Radlein, D.S.A. Fast pyrolysis of plastic wastes. Energy Fuel 1990, 4, 407–411. [Google Scholar] [CrossRef]

- McCaffrey, W.C.; Cooper, D.G.; Kamal, M.R. Tertiary recycling of polyethylene: Mechanism of liquid production from polyethylene by thermolysis/reactive distillation. Polym. Deg. Stab. 1998, 62, 513–521. [Google Scholar] [CrossRef]

- McCaffrey, W.C.; Cooper, D.G.; Kamal, M.R. The effect of short-chain branching on the thermolysis/reactive distillation of polyethylene. J. App. Polym. Sci. 1999, 73, 1415–1421. [Google Scholar] [CrossRef]

- Hartulistiyoso, E.; Sigiro, F.A.; Yulianto, M. Temperature distribution of the plastics Pyrolysis process to produce fuel at 450 °C. Proc. Environ. Sci. 2015, 28, 234–241. [Google Scholar] [CrossRef] [Green Version]

- Cepeliogullar, O.; Putun, A.E. Utilization of two different types of plastic wastes from daily and industrial life. J. Selcuk. Univ. Nat. Appl. Sci. 2013, 2, 694–706. [Google Scholar]

- Fakhrhoseini, S.M.; Dastanian, M. Predicting pyrolysis products of PE, PP, and PET using NRTL activity coefficient model. J. Chem. 2013, 2013, 487676. [Google Scholar] [CrossRef]

- Chen, Z.; Wu, D.; Chen, L.; Ji, M.; Zhang, J.; Du, Y.; Wu, Z. The fast co-pyrolysis study of PVC and biomass for disposing of solid wastes and resource utilization in N2 and CO2. Process Saf. Environ. Prot. 2021, 150, 489–496. [Google Scholar] [CrossRef]

- Wang, C.; Jiang, Z.; Song, Q.; Liao, M.; Weng, J.; Gao, R.; Zhao, M.; Chen, Y.; Chen, G. Investigation on hydrogen-rich syngas production from catalytic co-pyrolysis of polyvinyl chloride (PVC) and wastepaper blends. Energy 2021, 232, 121005. [Google Scholar] [CrossRef]

- Ye, L.; Li, T.; Hong, L. Co-pyrolysis of Fe3O4-poly(vinyl chloride) (PVC) mixtures: Mitigation of chlorine emissions during PVC recycling. Waste Manag. 2021, 126, 832–842. [Google Scholar] [CrossRef] [PubMed]

- Uzoejinwa, B.B.; He, X.; Wang, S.; Abomohra, A.E.l.-F.; Hu, Y.; Wang, Q. Co-pyrolysis of biomass and waste plastics as a thermochemical conversion technology for high-grade biofuel production: Recent progress and future directions elsewhere worldwide. Energy Convers. Manag. 2018, 163, 468–492. [Google Scholar] [CrossRef]

- Al-Salem, S.M.; Antelava, A.; Constantinou, A.; Manos, G.; Dutta, A. A review on thermal and catalytic pyrolysis of plastic solid waste (PSW). Environ. Manag. J. 2017, 197, 177–198. [Google Scholar] [CrossRef]

- Adrados, A.; Marco, I.D.; Caballero, B.M.; López, A.; Laresgoiti, M.F.; Torres, A. Pyrolysis of plastic packaging waste: A comparison of plastic residuals from material recovery facilities with simulated plastic waste. Waste Manag. 2012, 32, 826–832. [Google Scholar] [CrossRef]

- Kaminsky, W.; Predel, M.; Sadiki, A. Feedstock recycling of polymers by pyrolysis in a fluidised bed. Polym. Degrad. Stab. 2004, 85, 1045–1050. [Google Scholar] [CrossRef]

- Kim, S.S.; Kim, S. Pyrolysis characteristics of polystyrene and polypropylene in a stirred batch reactor. Chem. Eng. J. 2004, 98, 53–60. [Google Scholar] [CrossRef]

- Marcilla, A.; Beltran, M.I.; Conesa, J.A. Catalyst addition in polyethylene pyrolysis—Thermogravimetric study. J. Anal. Appl. Pyrolysis 2001, 58, 117–126. [Google Scholar] [CrossRef]

- Demirbas, A. Recent advances in biomass conversion technologies. Energy Educ. Sci. Technol. 2000, 6, 19–41. [Google Scholar]

| Waste Plastics | Equipment | Catalyst Used | Process Parameters | Product Yield | Others | Reference |

|---|---|---|---|---|---|---|

| Expanded waste PS | Pyrex batch reactor | Zinc bulk catalysts (Zn, ZnO and ZnCl2); Zinc metal catalyst | Thermo-catalytic pyrolysis. 1:0.2 feed to catalyst ratio. 450 °C pyrolysis temperature and 120 min reaction time | Liquid product (96.73 ± 0.12 wt.% with 2.47 wt.% toluene, 1.16 wt.% ethylbenzene, 47.96 wt.% styrene monomer and 1.90 wt.% α-methylstyrene) | Fractional distillation was utilised and found with further thermal pyrolysis plus cyclization and recombination reactions | [53] |

| Influence and reactivity of PET on PS | Quartz glass reactor | 20% Al-(Al2O3) catalyst | 1:0–1:0.3 feed to catalyst ratio. 250–500 °C pyrolysis temperature. 20–90 min reaction time | Benzene, styrene, α-methylstyrene, biphenyl, indene, naphthalene, naphthalene derivatives and terphenyls, among others and some oxygenated compounds such as 4-hydroxy-4-methyl, 2-pentanone, acetophenone, 2-buten-1-one, 1-phenyl and 1,2-propanediol, 3-benzyloxy-1,2-diacetyl, among others were identified | Triplicate analysis | [61] |

| Plastics and biomass | Two-stage fixed bed reactor | (Ni-CaO-C) | Co-pyrolysis/gasification. About 10 mg of samples were heated at the rate of 10 °C/min from room temperature to 800 °C, and the temperature was kept stable at 800 °C for 10 min before decreasing | Hydrogen production (86.74 mol% and 115.33 mmol/g) and low (CO2) concentration (7.31 mol%) in the gaseous products | [62] | |

| PE | A two-stage pyrolysis-catalysis reactor | Core-shell catalyst (Ni-Ce@SiO2) | The highest quantum of hydrogen was attained when the catalyst: plastic weight ratio was 1.0, and the catalytic reaction temperature was at 800 °C. | Hydrogen | [63] | |

| PE | Autoclave | Volcanic ash | Temp-range (200–350 °C), pres. 1–10 kg/cm2 | 200 °C (solid bottom layer), 250 °C (plastic liquefaction oil-consisting of two layers; bottom layer showed more concentration), 300 °C (homogeneous yellow clear oil- for greater than 10 min and at 350 °C for 0–60 min) | Liquefaction method | [71] |

| HDPE | Batch Pyrex glass reactor | (BaCO3) (powdered) | 450 °C pyrolysis temperature, 0.1 catalyst/plastic ratio with a reaction time of 120 min at which point the oil collected at optimum conditions | Gasoline, kerosene, and diesel | Fractional distillation | [72] |

| HDPE | (CaCO3) | Various parameters scuh as temperature, catalyst to plastic ratio (cat/pol) and reaction time were explored to find out optimum reaction conditions | Gasoline, kerosene or diesel oil | Fractional distillation at different temperatures. The ASTM distillation study | [73] | |

| HDPE | (MgCO3) | Higher hydrocarbons and catalytic oil | GC-MS to determine their detailed composition | [74] | ||

| PS, PP, PE & their mixtures | Small pilot scale reactor | Natural zeolite and then synthetic zeolite catalysts | 450 °C pyrolysis temperature and 75 min reaction time | Liquid oils (like conventional diesel) | [75] | |

| LDPE | Batch pyrex glass reactor | A wide range of acidic and basic catalysts like calciumcarbide, silica, alumina, zincoxide and magnesiumoxide | Heating rate of 40 °C/min. Actual pyrolysis temperature (350–450 °C) | Oil yield, wax, and gases | Conditions such as temperature, catalyst weight and reaction time were optimized in order to achieve maximum conversion into chemicals that could be used for feedstock | [76] |

| LDPE | Activated carbon and (MgO) | Jet fuel and hydrogen | This work described a convenient, efficient, and economical to produce jet fuel and hydrogen | [77] | ||

| HDPE | Fibre glass reactor | (HZSM-5) | Reaction temperature between 370 °C and 420 °C and a reaction time of 240 min | Gaseous products in the range of C1–C4. Liquid fuel produced (alkanes, some alkene groups resembling aliphatic groups, and some aromatic groups are yielded as well | To obtain the hydrocarbon fuels, the gross heat of combustion was 123,845 BTU/gal, API gravity was 53.70° API and sulphur contained 3.05 ppm | [19] |

| PP and HDPE | Steel micro reactor | Non-sweeping nitrogen atmosphere | 250 to 400 °C but maximum yield attained at 300 °C for PP and 350 °C for HDPE | Liquid, gas and residue for PP and HDPE each | FTIR and GC-MS utilised to analyse the liquefactions | [78] |

| HDPE | Packed bed reactor | Sodium hydroxide, HUSY and HBeta zeolite | Inert atmosphere at 450 °C | Liquid, paraffins (6C44), olefins (6C22), aromatics (6C14) and alcohols (C16 and C17) | Thermal and catalytic cracking techniques | [70] |

| PEs | Batch Pyrex round-bottom glass | Metal oxide catalysts, including Ca(OH)2, (ZnO) and (Al2O3) | 200 °C reaction temperature. Catalyst-to polymer ratios from 1:1 to 1:5 | Liquid fuel | GC-MS), HPLC, FT-IR, and EA used for the analysis | [79] |

| LDPE | Steel reactor | Without any cracking catalyst, in the presence of oxygen and closed system | 800 gm sample, 20–430 °C (to liquefaction), 260–290 °C for diesel grade fuel distribution | Diesel Fuel | DSC, GC-MS and FT-IR analysis used for result characterisations | [80] |

| LDPE | Batch reactor | Calcium carbide | Atmospheric pressure | Liquid fuel- 12.0 + 0.2% at 673K, gas 13.36 + 0.32% and char. Maximum conversion into liquid product 69.73% was acquired at about 350 °C | Column chromatography and fractional distillation method was used to collect the samples and then characterised with the support of FT-IR spectroscopy | [81] |

| Polymer mixture | Semi-batch laboratory reactor | Silica–alumina | 430 °C, catalyst to polymer ratio 40%. Isothermal and constant pressure conditions. | Gasoline | Arrhenius’s Law, a kinetic model was established for the determination of the reaction kinetic parameters | [82] |

| Mixed plastic wastes | Batch system | Silica-alumina synthesized catalysts and application of sodium carbonate to reduce the emission of dioxins in the environment | The main variables during the production process were contact time and temperature | Liquid fuel. | The HCs ranged from (C8H18) to (C25H54) for all samples obtained. @risk software was utilised in order to predict the scenarios of its applicability. The simulation showed a right match with the regular diesel. | [45] |

| Municipal plastic wastes, MPW | Review | Thermal and catalytic cracking | Gasoline-range hydrocarbons | MSW collection, classification and pre-treatment at the front end, and hydrocarbon distillation and purification at the tail end were complementary to plastic pyrolysis | [50] | |

| Plastic Wastes | A modelled pyrolysis plant | Determination of the economic feasibility of the capacity of the modelled plant | A scaling-up analysis | Heavy fuel oil substitute or as raw material by the petrochemical industry | Additionally, a sensitivity analysis was performed showing that the fuel production rate was the most sensitive parameter for the 100 kg/h plant, as well as the scaled-up plants | [83] |

| PS | Fluidized-bed reactor | 20/40 mesh quartz sand as the fluidization medium | Optimal results were attained at 450–700 °C pyrolysis temperature with nitrogen as the carrier gas | Gasoline and styrene monomer | A substantial discussion was made with regards to the recycling of higher boiling point fractions | [84] |

| General-Purpose PS | Unstirred semi-batch stainless steel reactor | Red mud | The catalytic degradation gradually started from about 175 up to 400 °C. Nitrogen atmosphere (air free) | Kerosene | GC-MS analysis was used to characterise the condensed liquid organic compounds | [85] |

| Mixture of plastics more like MPW | Semi batch reactor | Red mud and (ZSM-5) zeolite | 500 and 440 °C pyrolysis temperature for red mud and (ZSM-5) zeolite, respectively | liquid and gaseous fuels | Red mud required higher temperatures than (ZSM-5) zeolite to exert a catalytic effect in pyrolysis since similar results to those obtained without catalyst were obtained at 440 °C, while at 500 °C a higher yield of gases and a greater proportion of aromatics in the liquids was obtained. | [86] |

| Waste Plastics | Pyrolytic Products | References |

|---|---|---|

| PE, PP, PS | 1-alkenes, n-alkanes, and α, ω-dialkenes ranging from C1 to C45+; methyl-oligomers; liquid fuel | [43] |

| Expanded PS waste | Liquid products | [53] |

| PS | Liquid oil | [23] |

| Plastics and biomass | Hydrogen (H2) (energy carrier) | [62] |

| PE | Hydrogen (H2) (energy carrier) | [63] |

| PE | Fuel-like products | [70] |

| PE | Liquefaction oil | [72] |

| PP and PE | Fuel oil [with Benzene, Toluene and Xylene (BTX) aromatics as core targets] | [110] |

| PE and PS | Wax | [111] |

| PE, PP and PS | Heavy fuel oil substitute or as raw material | [83] |

| PE or PP or PS | Char | [112] |

| HDPE | Gasoline, kerosene, and diesel | [72] |

| HDPE | Gasoline, kerosene, and diesel | [73] |

| HDPE | Higher hydrocarbons and catalytic oil | [74] |

| HDPE | Pyrolysis oil | [113] |

| PS, PP, PE & their mixtures | Liquid oils (like conventional diesel) | [75] |

| MPW | Pyrolytic gas | [114] |

| MPW | Diesel and gasoline | [8] |

| LDPE | A complex mixture of alkanes, alkenes, carbonyl group (aldehydes, ketones, aromatic compounds) and substituted aromatic compounds like phenols | [76] |

| HDPE | Gaseous products in the range of C1–C4, liquid fuel | [19] |

| PP and HDPE | Liquid fuel and gas | [115] |

| HDPE | Liquid for chemical feedstock or fuel, paraffins, olefins, aromatics and alcohols (hexadecanol and heptadecanol) | [70] |

| HDPE | Pyrolysis oil | [115] |

| PE | Low molecular weight liquid fuel | [79] |

| PE | Pyrolysis oil | [116] |

| PE | Pyrolysis oil | [50] |

| PE | Pyrolysis oil | [18] |

| LDPE and HDPE | Liquid fuel | [117,118] |

| LDPE | Diesel | [80] |

| LDPE | Liquid fuel and gas | [81] |

| Polymer mixture | Gasoline | [82] |

| Mixed waste plastics | Liquid fuel | [45] |

| MPW | Gasoline | [50] |

| PS | Gasoline and styrene monomer | [84] |

| Reclaimed plastic bottles, PET | Gaseous materials | [119] |

| PET | Gaseous materials | [120] |

| PET | Gaseous materials | [121] |

| PVC and biomass | Nitrogen (N2) and Carbondioxide (CO2) | [122] |

| PVC and wastepaper | Hydrogen (H2) | [123] |

| PVC and (Fe3O4) | Chlorine emission mitigation | [124] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yansaneh, O.Y.; Zein, S.H. Latest Advances in Waste Plastic Pyrolytic Catalysis. Processes 2022, 10, 683. https://doi.org/10.3390/pr10040683

Yansaneh OY, Zein SH. Latest Advances in Waste Plastic Pyrolytic Catalysis. Processes. 2022; 10(4):683. https://doi.org/10.3390/pr10040683

Chicago/Turabian StyleYansaneh, Osman Y., and Sharif H. Zein. 2022. "Latest Advances in Waste Plastic Pyrolytic Catalysis" Processes 10, no. 4: 683. https://doi.org/10.3390/pr10040683