The Impacts of Bio-Based and Synthetic Hydrogels on Soil Hydraulic Properties: A Review

Abstract

:1. Introduction

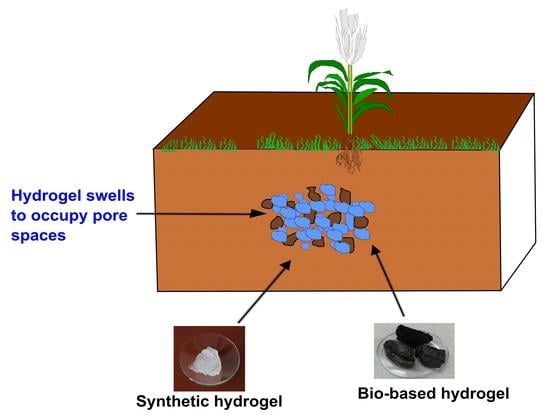

1.1. Hydrogels

1.2. Swelling Characteristic of Hydrogels

2. Impacts of the Application of Hydrogels on Soil Hydraulic Properties

2.1. Impact of Hydrogels on Soil Water Retention

2.1.1. Impact of Bio-Based Hydrogels on Soil Water Retention

2.1.2. Impact of Synthetic-Based Hydrogels on Soil Water Retention

2.1.3. Impact of Hydrogels on Plant Available Water Capacity (PAWC)

2.2. Impact of Hydrogels on Saturated Hydraulic Conductivity

2.2.1. Impact of Bio-Based Hydrogels on Saturated Hydraulic Conductivity

2.2.2. Impact of Synthetic-Based Hydrogels on Saturated Hydraulic Conductivity

2.2.3. How Does Application of Hydrogel Affect Saturated Hydraulic Conductivity?

2.3. Impact of Hydrogel Application on Unsaturated Hydraulic Conductivity

2.4. Impact of Hydrogels on Soil Water Infiltration

2.5. Impact of Hydrogels on Soil Water Evaporation

2.6. Summary of How Hydrogels Influence Soil Hydraulic Properties

3. Important Factors to Consider When Applying Hydrogels to Influence Soil Hydraulic Properties

- (i)

- The swelling capacity of a hydrogel in aqueous solutions and in soil is an important indicator of performance. The swelling capacity of a hydrogel enables the hydrogel to absorb and expel water from its environment [33]. From this review, the swelling capacity of a hydrogel directly affects all the soil hydraulic properties discussed. Since hydrogels will have to be in the presence of soil to influence soil hydraulic properties, it is worth quantifying the swelling capacity of the hydrogel when confined in soil. A hydrogel with a higher swelling capacity will absorb more water in soil which increases water retained in the soil. The increase in surface area of the hydrogel with swelling also impedes the downward movement of water, thus decreasing hydraulic conductivity and soil water infiltration. Higher swelling in hydrogels also leads to higher water storage, which reduces evaporation when hydrogels are placed at an appropriate depth in soil.

- (ii)

- Swelling characteristics when confined under soil pressure impacts hydraulic properties. An ideal hydrogel should be able to withstand the pressure exerted by the surrounding soil. Hydrogels should be designed to be able to absorb water causing it to swell, changing the shape, mass, and volume of the hydrogel in the process, even at depth within the soil. According to Misiewicz et al. (2020), during the swelling of hydrogels, the hydrogel-soil mixture exerts pressure on the top layer of the soil. Due to this pressure exerted by the hydrogel during swelling, the hydrogel can repeatedly absorb and release water in soil against the pressure exerted by the soil. Misiewicz et al. (2020) further explains that the cause of the pressure exerted by the hydrogel during swelling depends on the available soil pore volume and the grain size distribution of the hydrogel. Similarly, Louf et al. [117] demonstrated that in a three-dimensional granular medium, e.g., soil, the extent of swelling in a hydrogel depends on the antagonistic competition between the force exerted by the hydrogel osmotic pressure and the force exerted by the surrounding soil. While these studies [93,117,118] tested the swelling behavior of synthetic hydrogels (polyacrylamide and acylate-based) hydrogels, there are currently no studies that examine these questions for bio-based hydrogels. It is possible that differences in the mechanical strength between bio-based and synthetic hydrogels could influence the pressure the hydrogel can withstand in soil. According to Ahmed [21], synthetic hydrogels possess a higher mechanical strength than bio-based hydrogels, which could be advantageous in withstanding pressure. The challenge thus lies in synthesizing hydrogels with optimized mechanical strength with improved elasticity, that allows the hydrogel to swell.

4. Future Research Needs

- Additional studies are needed to understand how the particle size distribution of bio-based hydrogels affects soil hydraulic properties. From this review, only one study, Abdallah [57], tested the impact of particle size of a synthetic polyacrylamide hydrogel on soil water retention properties. However, to better understand how new bio-based hydrogels could be tuned to improve certain soil properties, it is important to quantify the specific particle size ranges of bio-based hydrogels. Investigators can then start to determine the relationship between particle size and the hydrogel’s ability to swell in different soils, which has been shown to affect several hydraulic properties like soil water retention and hydraulic conductivity.

- The particle density of hydrogels can affect soil physical properties, such as porosity and bulk density, which in turn affects how water moves through soil. Studies that investigate how the particle density of various hydrogels affect soil physical properties will help in the development of hydrogels with specific properties that improve soil hydraulic properties. In addition, when comparing the swelling characteristics of various hydrogels at different concentration, it is essential that the hydrogels have similar particle densities. A hydrogel with a high density will have a different swelling characteristic, compared to one with a low density. Therefore, to make accurate comparisons between hydrogels, the particle densities should be determined.

- Most studies tend to test the effects of hydrogel on sandy soils. Though the impacts of hydrogel application to finer soils, such as clay and silt, are currently not definitive, there is value in investigating the impact of hydrogels over a large range of soil textures.

- Most studies in literature currently apply hydrogel in powdered or granular form by mixing with soil. More research into different application methods to ascertain the effectiveness of those methods, e.g., spraying in liquid form, applying hydrogels in swollen form, or applying hydrogels in dry solid form, is needed. Some investigators suggest that the hydrogels should be applied after they have been swelled. Studies are needed to quantify the benefit of applying swollen hydrogels and, if useful, to determine how to effectively apply swollen hydrogels.

- There are limited studies on the impacts of hydrogels on soil unsaturated hydraulic conductivity (K). Most studies concentrate on the effects of hydrogels on saturated hydraulic conductivity and in laboratory experiments, likely due to the ease of measuring Ks compared to K. However, under field conditions, soils will mostly be unsaturated, thus more research is needed to understand how hydrogels affect K.

- When hydrogels are applied to soil, the surrounding soil tends to exert a force against the hydrogel, hence reducing the hydrogel’s swelling capacity. Research is needed to design hydrogels that can withstand the various biotic, abiotic, and mechanical stresses that soil exerts on hydrogels over at least one growing season.

- Once a complete data set is established, a predictive mathematical model can be developed to summarize our understanding of the effects of the hydrogels on soil hydraulic properties. For example, can we predict the concentration of hydrogels that when applied to a specific soil decreases/increases Ks? This information will increase the usefulness of this knowledge so, for example, farmers know the amount of hydrogel to apply when a particular soil is used to grow a crop. Secondly, if that range of suitable hydrogel application is obtained, is it system dependent e.g., hydrogel type, soil type, climate, soil temperature, or can that recommended range be generalized to all hydrogels and soil types?

5. Summary and Conclusions

- Both synthetic and bio-based hydrogels were effective at increasing soil water retention when applied within a range of 0.1 to 1% hydrogel (w/w). Though the increase in water retention was definitive in sandy soils, few studies tested other soil textures.

- The impact of hydrogels on saturated hydraulic conductivity (Ks) was found to be the most inconsistent. Studies on the effect of bio-based hydrogels on Ks were fewer than for synthetic hydrogels. Bio-based hydrogels were found to decrease Ks by up to 60% in sandy soils. The overwhelming evidence for a decrease in Ks was with synthetic hydrogels. The high swelling capacity of synthetic hydrogels stores more water initially when water starts infiltrating soil, reducing the amount of water percolating into the deeper layers and hence decreasing Ks. Unsaturated hydraulic conductivity (K) was found to decrease at lower matric suctions and increased at higher matric suctions. However, few studies exist that investigate the impact of hydrogels on K.

- The application of synthetic hydrogels mostly reduced soil water infiltration by up to 90%. Only one study was found to measure the impacts of bio-based hydrogel on soil water infiltration, which also confirmed a decrease in infiltration. Hydrogels alter soil structure decreasing the number of drainage pores and retaining water.

- Like soil water infiltration, hydrogel application mostly decreased soil evaporation as soil water is bound to the hydrogel, reducing how much water is lost to the atmosphere. Hydrogels near the soil surface can also increase evaporation by storing water making it easy for stage one of evaporation to occur.

- In conclusion, the performance of both synthetic and bio-based hydrogels on soil hydraulic properties will depend on the type of hydrogel, soil texture, application rate, particle size distribution of the hydrogel, the swelling capacity of the hydrogel, the location of placement, and how these properties vary over time.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Peppas, N. Hydrogels in pharmaceutical formulations. Eur. J. Pharm. Biopharm. 2000, 50, 27–46. [Google Scholar] [CrossRef]

- Slaughter, B.V.; Khurshid, S.S.; Fisher, O.Z.; Khademhosseini, A.; Peppas, N.A. Hydrogels in regenerative medicine. Adv. Mater. 2009, 21, 3307–3329. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Amine, K.M.; Champagne, C.P.; Salmieri, S.; Britten, M.; St-Gelais, D.; Fustier, P.; Lacroix, M. Effect of palmitoylated alginate microencapsulation on viability of Bifidobacterium longum during freeze-drying. LWT Food Sci. Technol. 2014, 56, 111–117. [Google Scholar] [CrossRef] [Green Version]

- Al-Darby, A.M. The hydraulic properties of a sandy soil treated with gel-forming soil conditioner. Soil Technol. 1996, 9, 15–28. [Google Scholar] [CrossRef]

- Prakash, S.; Vasudevan, S.; Banerjee, A.; Joe, A.C.; Geetha, K.N.; Mani, S.K. Sustainable Irrigation through Application of Hydrogel: A Review. Alinteri J. Agric. Sci. 2021, 36, 38–52. [Google Scholar] [CrossRef]

- Thakur, V.K.; Thakur, M.K. Hydrogels: Recent Advances; Springer: Gateway East, Singapore, 2018. [Google Scholar]

- Chirani, N.; Gritsch, L.; Motta, F.L.; Fare, S. History and applications of hydrogels. J. Biomed. Sci. 2015, 4, 1–23. [Google Scholar]

- Buwalda, S.J. Bio-based composite hydrogels for biomedical applications. Multifunct. Mater. 2020, 3, 022001. [Google Scholar] [CrossRef]

- Hecht, H.; Srebnik, S. Structural Characterization of Sodium Alginate and Calcium Alginate. Biomacromolecules 2016, 17, 2160–2167. [Google Scholar] [CrossRef]

- Song, B.; Liang, H.; Sun, R.; Peng, P.; Jiang, Y.; She, D. Hydrogel synthesis based on lignin/sodium alginate and application in agriculture. Int. J. Biol. Macromol. 2020, 144, 219–230. [Google Scholar] [CrossRef]

- Luo, T.; Hao, Y.; Wang, C.; Jiang, W.; Ji, X.; Yang, G.; Chen, J.; Janaswamy, S.; Lyu, G. Lignin Nanoparticles and Alginate Gel Beads: Preparation, Characterization and Removal of Methylene Blue. Nanomaterials 2022, 12, 176. [Google Scholar] [CrossRef]

- Adjuik, T.A.; Nokes, S.E.; Montross, M.D. Evaluating the feasibility of using lignin–alginate beads with starch additive for entrapping and releasing Rhizobium spp. J. Appl. Polym. Sci. 2022, e53181. [Google Scholar] [CrossRef]

- Duquette, D.; Dumont, M.-J. Comparative studies of chemical crosslinking reactions and applications of bio-based hydrogels. Polym. Bull. 2019, 76, 2683–2710. [Google Scholar] [CrossRef]

- Meng, Y.; Lu, J.; Cheng, Y.; Li, Q.; Wang, H. Lignin-based hydrogels: A review of preparation, properties, and application. Int. J. Biol. Macromol. 2019, 135, 1006–1019. [Google Scholar] [CrossRef] [PubMed]

- Passauer, L. Highly swellable lignin hydrogels: Novel materials with interesting properties. In Functional Materials from Renewable Sources; ACS Publications: Washington, DC, USA, 2012; pp. 211–228. [Google Scholar]

- Meng, Y.; Liu, X.; Li, C.; Liu, H.; Cheng, Y.; Lu, J.; Zhang, K.; Wang, H. Super-swelling lignin-based biopolymer hydrogels for soil water retention from paper industry waste. Int. J. Biol. Macromol. 2019, 135, 815–820. [Google Scholar] [CrossRef]

- Adjuik, T.A.; Nokes, S.E.; Montross, M.D.; Walton, R.; Wendroth, O. Laboratory Determination of the Impact of Incorporated Alkali Lignin-Based Hydrogel on Soil Hydraulic Conductivity. Water 2022, 14, 2516. [Google Scholar] [CrossRef]

- Kopeček, J. Hydrogel biomaterials: A smart future? Biomaterials 2007, 28, 5185–5192. [Google Scholar] [CrossRef] [Green Version]

- Bashir, S.; Hina, M.; Iqbal, J.; Rajpar, A.H.; Mujtaba, M.A.; Alghamdi, N.A.; Wageh, S.; Ramesh, K.; Ramesh, S. Fundamental Concepts of Hydrogels: Synthesis, Properties, and Their Applications. Polymers 2020, 12, 2702. [Google Scholar] [CrossRef]

- Rizwan, M.; Gilani, S.R.; Durani, A.I.; Naseem, S. Materials diversity of Hydrogel: Synthesis, polymerization process and soil conditioning properties in agricultural field. J. Adv. Res. 2021, 33, 15–40. [Google Scholar] [CrossRef]

- Ahmed, E.M. Hydrogel: Preparation, characterization, and applications: A review. J. Adv. Res. 2015, 6, 105–121. [Google Scholar] [CrossRef] [Green Version]

- Akhtar, M.F.; Hanif, M.; Ranjha, N.M. Methods of synthesis of hydrogels. A review. Saudi Pharm. J. 2016, 24, 554–559. [Google Scholar] [CrossRef] [Green Version]

- Bouranis, D.L.; Theodoropoulos, A.G.; Drossopoulos, J.B. Designing synthetic polymers as soil conditioners. Commun. Soil Sci. Plant Anal. 1995, 26, 1455–1480. [Google Scholar] [CrossRef]

- Garbowski, T.; Bar-Michalczyk, D.; Charazińska, S.; Grabowska-Polanowska, B.; Kowalczyk, A.; Lochyński, P. An overview of natural soil amendments in agriculture. Soil Tillage Res. 2023, 225, 105462. [Google Scholar] [CrossRef]

- Suresh, R.; Prasher, S.O.; Patel, R.M.; Qi, Z.; Elsayed, E.; Schwinghamer, T.; Ehsan, A.M. Super Absorbent Polymer and Irrigation Regime Effects on Growth and Water Use Efficiency of Container-Grown Cherry Tomatoes. Trans. ASABE 2018, 61, 523–531. [Google Scholar] [CrossRef]

- Islam, M.R.; Mao, S.; Alam, A.M.S.; Eneji, A.E.; Hu, Y.; Xue, X. A Lysimeter Study for Leaching Losses, Sustainable Fertilization, and Growth Responses of Corn (Zea mays L.) Following Soil Amendment with a Water-Saving Superabsorbent Polymer. Appl. Eng. Agric. 2011, 27, 757–764. [Google Scholar] [CrossRef]

- Lentz, R.D.; Kincaid, D.C. Polyacrylamide Treatments for Reducing Seepage in Soil-Lined Reservoirs: A Field Evaluation. Trans. ASABE 2008, 51, 535–544. [Google Scholar] [CrossRef] [Green Version]

- Andry, H.; Yamamoto, T.; Irie, T.; Moritani, S.; Inoue, M.; Fujiyama, H. Water retention, hydraulic conductivity of hydrophilic polymers in sandy soil as affected by temperature and water quality. J. Hydrol. 2009, 373, 177–183. [Google Scholar] [CrossRef]

- Hou, X.; Li, Y.; Pan, Y.; Jin, Y.; Xiao, H. Controlled release of agrochemicals and heavy metal ion capture dual-functional redox-responsive hydrogel for soil remediation. Chem. Commun. 2018, 54, 13714–13717. [Google Scholar] [CrossRef]

- Zhou, G.; Luo, J.; Liu, C.; Chu, L.; Crittenden, J. Efficient heavy metal removal from industrial melting effluent using fixed-bed process based on porous hydrogel adsorbents. Water Res. 2018, 131, 246–254. [Google Scholar] [CrossRef]

- Bashan, Y.; Hernandez, J.-P.; Leyva, L.A.; Bacilio, M. Alginate microbeads as inoculant carriers for plant growth-promoting bacteria. Biol. Fertil. Soils 2002, 35, 359–368. [Google Scholar] [CrossRef]

- Mohawesh, O.; Durner, W. Effects of Bentonite, Hydrogel and Biochar Amendments on Soil Hydraulic Properties from Saturation to Oven Dryness. Pedosphere 2019, 29, 598–607. [Google Scholar] [CrossRef]

- Blanco, A.; González, G.; Casanova, E.; Pirela, M.E.; Briceño, A. Mathematical Modeling of Hydrogels Swelling Based on the Finite Element Method. Sci. Res. 2013, 04, 161–170. [Google Scholar] [CrossRef]

- Isık, B.; Kıs, M. Preparation and determination of swelling behavior of poly(acrylamide-co-acrylic acid) hydrogels in water. J. Appl. Polym. Sci. 2004, 94, 1526–1531. [Google Scholar] [CrossRef]

- Ghobashy, M.M. Superabsorbent. In Hydrogels; Haider, S., Haider, A., Eds.; InTech: London, UK, 2018. [Google Scholar]

- Masaro, L.; Zhu, X. Physical models of diffusion for polymer solutions, gels and solids. Prog. Polym. Sci. 1999, 24, 731–775. [Google Scholar] [CrossRef]

- Zhou, Y.; Jin, L. Hydrolysis-induced large swelling of polyacrylamide hydrogels. Soft Matter 2020, 16, 5740–5749. [Google Scholar] [CrossRef] [PubMed]

- Passauer, L.; Fischer, K.; Liebner, F. Preparation and physical characterization of strongly swellable oligo (oxyethylene) lignin hydrogels. Holzforschung 2011, 65, 309–317. [Google Scholar] [CrossRef]

- Aalaie, J.; Rahmatpour, A.; Vasheghani-Farahani, E. Rheological and swelling behavior of semi-interpenetrating networks of polyacrylamide and scleroglucan. Polym. Adv. Technol. 2009, 20, 1102–1106. [Google Scholar] [CrossRef]

- Saha, A.; Sekharan, S.; Manna, U. Superabsorbent hydrogel (SAH) as a soil amendment for drought management: A review. Soil Tillage Res. 2020, 204, 104736. [Google Scholar] [CrossRef]

- Dinu, M.V.; Dragan, E.S. Macroporous Hydrogels: Preparation, Properties, and Applications. In Hydrogels; Springer: Berlin/Heidelberg, Germany, 2018; pp. 51–85. [Google Scholar]

- Zhang, M.; Cheng, Z.; Zhao, T.; Liu, M.; Hu, M.; Li, J. Synthesis, Characterization, and Swelling Behaviors of Salt-Sensitive Maize Bran–Poly(acrylic acid) Superabsorbent Hydrogel. J. Agric. Food Chem. 2014, 62, 8867–8874. [Google Scholar] [CrossRef]

- Zhang, J.; Liu, R.; Li, A.; Wang, A. Preparation, swelling behaviors and application of polyacrylamide/attapulgite superabsorbent composites. Polym. Adv. Technol. 2006, 17, 12–19. [Google Scholar] [CrossRef]

- Feng, Q.; Li, J.; Cheng, H.; Chen, F.; Xie, Y. Synthesis and Characterization of Porous Hydrogel Based on Lignin and Polyacrylamide. BioResources 2014, 9, 4369–4381. [Google Scholar] [CrossRef] [Green Version]

- Alkhasha, A.; Al-Omran, A.; Aly, A. Effects of Biochar and Synthetic Polymer on the Hydro-Physical Properties of Sandy Soils. Sustainability 2018, 10, 4642. [Google Scholar] [CrossRef]

- Durner, W.; Flühler, H. Soil hydraulic properties. In Encyclopedia of Hydrological Sciences; Anderson, M.G., Ed.; John Wiley & Sons, Ltd: West Sussex, UK, 2006; pp. 1104–1119. [Google Scholar]

- Van Genuchten, M.T.; Pachepsky, Y.A. Hydraulic properties of unsaturated soils. In Encyclopedia of Agrophysics; Gliński, J., Horabik, J., Lipiec, J., Eds.; Springer: Dordrecht, The Netherlands, 2011; pp. 368–376. [Google Scholar]

- Behera, S.; Mahanwar, P.A. Superabsorbent polymers in agriculture and other applications: A review. Polym.-Plast. Technol. Mater. 2020, 59, 341–356. [Google Scholar] [CrossRef]

- Tomadoni, B.; Salcedo, M.; Mansilla, A.; Casalongué, C.; Alvarez, V. Macroporous alginate-based hydrogels to control soil substrate moisture: Effect on lettuce plants under drought stress. Eur. Polym. J. 2020, 137, 109953. [Google Scholar] [CrossRef]

- Cannazza, G.; Cataldo, A.; De Benedetto, E.; Demitri, C.; Madaghiele, M.; Sannino, A. Experimental Assessment of the Use of a Novel Superabsorbent polymer (SAP) for the Optimization ofWater Consumption in Agricultural Irrigation Process. Water 2014, 6, 2056–2069. [Google Scholar] [CrossRef] [Green Version]

- Kalinoski, R.M.; Shi, J. Hydrogels derived from lignocellulosic compounds: Evaluation of the compositional, structural, mechanical and antimicrobial properties. Ind. Crops Prod. 2019, 128, 323–330. [Google Scholar] [CrossRef]

- Li, X.; Pan, X. Hydrogels based on hemicellulose and lignin from lignocellulose biorefinery: A mini-review. J. Biobased Mater. Bioenergy 2010, 4, 289–297. [Google Scholar] [CrossRef]

- Ostrand, M.S.; Desutter, T.M.; Daigh, A.L.M.; Limb, R.F.; Steele, D.D. Superabsorbent polymer characteristics, properties, and applications. Agrosystems Geosci. Environ. 2020, 3, e20074. [Google Scholar] [CrossRef]

- Wendroth, O.; Zhang, X.; Reyes, J.; Knott, C. Irrigation: Basics and principles of an approach involving soil moisture measurements. In A Comprehensive Guide to Soybean Management in Kentucky; University of Kentucky: Lexington, KY, USA, 2018. [Google Scholar]

- Abedi-Koupai, J.; Sohrab, F.; Swarbrick, G. Evaluation of Hydrogel Application on Soil Water Retention Characteristics. J. Plant Nutr. 2008, 31, 317–331. [Google Scholar] [CrossRef]

- Ehlers, W.; Goss, M. Water Dynamics in Plant Production; CABI: Wallingford, UK, 2016. [Google Scholar]

- Abdallah, A.M. The effect of hydrogel particle size on water retention properties and availability under water stress. Int. Soil Water Conserv. Res. 2019, 7, 275–285. [Google Scholar] [CrossRef]

- Banedjschafie, S.; Durner, W. Water retention properties of a sandy soil with superabsorbent polymers as affected by aging and water quality. J. Plant Nutr. Soil Sci. 2015, 178, 798–806. [Google Scholar] [CrossRef]

- Montesano, F.F.; Parente, A.; Santamaria, P.; Sannino, A.; Serio, F. Biodegradable Superabsorbent Hydrogel IncreasesWater Retention Properties of Growing Media and Plant Growth. Agric. Agric. Sci. Procedia 2015, 4, 451–458. [Google Scholar] [CrossRef]

- Bhardwaj, A.K.; Shainberg, I.; Goldstein, D.; Warrington, D.N.; Levy, G.J. Water Retention and Hydraulic Conductivity of Cross-Linked Polyacrylamides in Sandy Soils. Soil Sci. Soc. Am. J. 2007, 71, 406–412. [Google Scholar] [CrossRef]

- El-Tohamy, W.A.; El-Abagy, H.M.; Ahmed, E.M.; Aggor, F.S.; Hawash, S.I. Application of super absorbent hydrogel poly (acrylate/acrylic acid) for water conservation in sandy soil. Trans. Egypt. Soc. Chem. Eng. 2014, 40, 1–8. [Google Scholar]

- Dehkordi, K.D. Effect of superabsorbent polymer on soil and plants on steep surfaces. Water Environ. J. 2018, 32, 158–163. [Google Scholar] [CrossRef]

- Demitri, C.; Scalera, F.; Madaghiele, M.; Sannino, A.; Maffezzoli, A. Potential of cellulose-based superabsorbent hydrogels as water reservoir in agriculture. Int. J. Polym. Sci. 2013, 2013, 435073. [Google Scholar] [CrossRef] [Green Version]

- Narjary, B.; Aggarwal, P.; Singh, A.; Chakraborty, D.; Singh, R. Water availability in different soils in relation to hydrogel application. Geoderma 2012, 187–188, 94–101. [Google Scholar] [CrossRef]

- Narjary, B.; Aggarwal, P. Evaluation of soil physical quality under amendments and hydrogel applications in a soybean–wheat cropping system. Commun. Soil Sci. Plant Anal. 2014, 45, 1167–1180. [Google Scholar] [CrossRef]

- Hu, Y.; Guo, N.; Hill, R.L.; Wu, S.; Dong, Q.G.; Ma, P. Effects of the combined application of biomaterial amendments and polyacrylamide on soil water and maize growth under deficit irrigation. Can. J. Soil Sci. 2019, 99, 182–194. [Google Scholar] [CrossRef]

- Garrison, T.; Murawski, A.; Quirino, R. Bio-Based Polymers with Potential for Biodegradability. Polymers 2016, 8, 262. [Google Scholar] [CrossRef]

- Mikkelsen, R.L. Using hydrophilic polymers to control nutrient release. Fertil. Res. 1994, 38, 53–59. [Google Scholar] [CrossRef]

- Akhter, J.; Mahmood, K.; Malik, K.A.; Mardan, A.; Ahmad, M.; Iqbal, M.M. Effects of hydrogel amendment on water storage of sandy loam and loam soils and seedling growth of barley, wheat and chickpea. Plant Soil Environ. 2004, 50, 463–469. [Google Scholar] [CrossRef] [Green Version]

- Bai, W.; Zhang, H.; Liu, B.; Wu, Y.; Song, J. Effects of super-absorbent polymers on the physical and chemical properties of soil following different wetting and drying cycles. Soil Use Manag. 2010, 26, 253–260. [Google Scholar] [CrossRef]

- Liao, R.; Wu, W.; Ren, S.; Yang, P. Effects of Superabsorbent Polymers on the Hydraulic Parameters and Water Retention Properties of Soil. J. Nanomater. 2016, 2016, 1–11. [Google Scholar] [CrossRef] [Green Version]

- Saha, A.; Rattan, B.; Sekharan, S.; Manna, U. Quantifying the interactive effect of water absorbing polymer (WAP)-soil texture on plant available water content and irrigation frequency. Geoderma 2020, 368, 114310. [Google Scholar] [CrossRef]

- Abrisham, E.S.; Jafari, M.; Tavili, A.; Rabii, A.; Zare Chahoki, M.A.; Zare, S.; Egan, T.; Yazdanshenas, H.; Ghasemian, D.; Tahmoures, M. Effects of a super absorbent polymer on soil properties and plant growth for use in land reclamation. Arid Land Res. Manag. 2018, 32, 407–420. [Google Scholar] [CrossRef] [Green Version]

- Shahid, S.A.; Qidwai, A.A.; Anwar, F.; Ullah, I.; Rashid, U. Improvement in the Water Retention Characteristics of Sandy Loam Soil Using a Newly Synthesized Poly(acrylamide-co-acrylic Acid)/AlZnFe2O4 Superabsorbent Hydrogel Nanocomposite Material. Molecules 2012, 17, 9397–9412. [Google Scholar] [CrossRef]

- Alkhasha, A.; Al-Omran, A. Evaluating the Effects of Biochar and SAP Polymer on Soil Physical Quality Indices. Commun. Soil Sci. Plant Anal. 2020, 51, 1123–1135. [Google Scholar] [CrossRef]

- Al-Humaid, A.I.; Moftah, A.E. Effects of Hydrophilic Polymer on the Survival of Buttonwood Seedlings Grown Under Drought Stress. J. Plant Nutr. 2007, 30, 53–66. [Google Scholar] [CrossRef]

- Zhao, W.; Hu, J.; Cui, Z.; Dou, P.; Fan, Y. Effects of superabsorbent polymers on the vertical infiltration of soil water with sand mulching. Environ. Earth Sci. 2019, 78, 648. [Google Scholar] [CrossRef]

- Lentz, R.D. Long-term water retention increases in degraded soils amended with cross-linked polyacrylamide. Agron. J. 2020, 112, 2569–2580. [Google Scholar] [CrossRef]

- Agaba, H.; Baguma Orikiriza, L.J.; Osoto Esegu, J.F.; Obua, J.; Kabasa, J.D.; Hüttermann, A. Effects of hydrogel amendment to different soils on plant available water and survival of trees under drought conditions. Clean–Soil Air Water 2010, 38, 328–335. [Google Scholar] [CrossRef]

- Agaba, H.; Orikiriza, L.; Obua, J.; Kabasa, J.; Worbes, M.; Hüttermann, A. Hydrogel amendment to sandy soil reduces irrigation frequency and improves the biomass of Agrostis stolonifera. Agric. Sci. 2011, 2, 544–550. [Google Scholar] [CrossRef]

- Leciejewski, P. The effect of hydrogel additives on the water retention curve of sandy soil from forest nursery in Julinek. J. Water Land Dev. 2009, 13, 239–247. [Google Scholar] [CrossRef]

- Geesing, D.; Schmidhalter, U. Influence of sodium polyacrylate on the water-holding capacity of three different soils and effects on growth of wheat. Soil Use Manag. 2006, 20, 207–209. [Google Scholar] [CrossRef]

- Zhuang, W.; Li, L.; Liu, C. Effects of sodium polyacrylate on water retention and infiltration capacity of a sandy soil. Springer Plus 2013, 2 (Suppl. 1), S11. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Abobatta, W. Impact of hydrogel polymer in agricultural sector. Adv. Agric. Environ. Sci. Open Access 2018, 1, 59–64. [Google Scholar] [CrossRef]

- Yang, L.; Yang, Y.; Chen, Z.; Guo, C.; Li, S. Influence of super absorbent polymer on soil water retention, seed germination and plant survivals for rocky slopes eco-engineering. Ecol. Eng. 2014, 62, 27–32. [Google Scholar] [CrossRef]

- Lal, R.; Shukla, M.K. Principles of Soil Physics; CRC Press: Boca Raton, FL, USA, 2004. [Google Scholar]

- Smagin, A.V.; Sadovnikova, N.B.; Shnyrev, N.A.; Kokoreva, A.A.; Sidorova, M.A. Saturated and unsaturated hydraulic conductivity of synthetic gel structures in coarse textured soil substrates. IOP Conf. Ser. Earth Environ. Sci. 2019, 368, 012048. [Google Scholar] [CrossRef]

- Hussien, R.A.; Donia, A.M.; Atia, A.A.; El-Sedfy, O.F.; El-Hamid, A.R.A.; Rashad, R.T. Studying some hydro-physical properties of two soils amended with kaolinite-modified cross-linked poly-acrylamides. Catena 2012, 92, 172–178. [Google Scholar] [CrossRef]

- Han, Y.; Yu, X.; Yang, P.; Li, B.; Xu, L.; Wang, C. Dynamic study on water diffusivity of soil with super-absorbent polymer application. Environ. Earth Sci. 2013, 69, 289–296. [Google Scholar] [CrossRef]

- Levy, G.; Smith, H.J.C.; Agassi, M.J.S. Soil, Water temperature effect on hydraulic conductivity and infiltration rate of soils. South Afr. J. Plant Soil 1988, 6, 240–244. [Google Scholar] [CrossRef] [Green Version]

- Wei, Y.; Durian, D.J. Rain water transport and storage in a model sandy soil with hydrogel particle additives. Eur. Phys. J. E 2014, 37, 97. [Google Scholar] [CrossRef] [PubMed]

- Lejcuś, K.; Śpitalniak, M.; Dąbrowska, J. Swelling Behaviour of Superabsorbent Polymers for Soil Amendment under Different Loads. Polymers 2018, 10, 271. [Google Scholar] [CrossRef] [PubMed]

- Misiewicz, J.; Lejcuś, K.; Dąbrowska, J.; Marczak, D. The Characteristics of Absorbency Under Load (AUL) for Superabsorbent and Soil Mixtures. Sci. Rep. 2019, 9, 18098. [Google Scholar] [CrossRef] [Green Version]

- Jury, W.A.; Horton, R. Soil Physics, 6th ed.; John Wiley & Sons: Hoboken, NJ, USA, 2004. [Google Scholar]

- Blanco-Canqui, H. Biochar and soil physical properties. Soil Sci. Soc. Am. J. 2017, 81, 687–711. [Google Scholar] [CrossRef] [Green Version]

- Kirkham, M.B. Principles of Soil and Plant Water Relations; Academic Press: Cambridge, MA, USA, 2014. [Google Scholar]

- Sihag, P.; Tiwari, N.; Ranjan, S. Prediction of cumulative infiltration of sandy soil using random forest approach. J. Appl. Water Eng. Res. 2018, 7, 118–142. [Google Scholar] [CrossRef]

- Guo, J.; Shi, W.; Wen, L.; Shi, X.; Li, J. Effects of a super-absorbent polymer derived from poly-γ-glutamic acid on water infiltration, field water capacity, soil evaporation, and soil water-stable aggregates. Arch. Agron. Soil Sci. 2019, 66, 1627–1638. [Google Scholar] [CrossRef]

- Lentz, R.D. Inhibiting Water Infiltration into Soils with Cross-linked Polyacrylamide: Seepage Reduction for Irrigated Agriculture. Soil Sci. Soc. Am. J. 2007, 71, 1352–1362. [Google Scholar] [CrossRef]

- Reddy, K.S.; Vijayalakshmi; Maruthi, V.; Nemichandrappa; Umesha, B. Influence of Super Absorbent Polymers on Infiltration Characteristics of Alfisols in Semi-Arid Region. Indian J. Dryland Agric. Res. Dev. 2015, 30, 11. [Google Scholar] [CrossRef] [Green Version]

- Shuttleworth, W.J. Evaporation. In Handbook of Hydrology; Maidment, D.R., Ed.; McGraw-Hill, Inc.: New York, NY, USA, 1993; pp. 4.1–4.53. [Google Scholar]

- Rose, D. Water movement in porous materials III: Evaporation of water from soil. J. Phys. D Appl. Phys. 1968, 1, 1779. [Google Scholar] [CrossRef]

- Idso, S.B.; Reginato, R.J.; Jackson, R.D.; Kimball, B.A.; Nakayama, F.S. The Three Stages of Drying of a Field Soil. Soil Sci. Soc. Am. J. 1974, 38, 831–837. [Google Scholar] [CrossRef]

- Yu, J.; Shi, J.; Dang, P.; Mamedov, A.; Shainberg, I.; Levy, G. Soil and polymer properties affecting water retention by superabsorbent polymers under drying conditions. Soil Sci. Soc. Am. J. 2012, 76, 1758–1767. [Google Scholar] [CrossRef]

- Yang, L.; Han, Y.; Yang, P.; Wang, C.; Yang, S.; Kuang, S.; Yuan, H.; Xiao, C. Effects of superabsorbent polymers on infiltration and evaporation of soil moisture under point source drip irrigation. Irrig. Drain. 2015, 64, 275–282. [Google Scholar] [CrossRef]

- Zhao, W.; Cao, T.; Dou, P.; Sheng, J.; Luo, M. Effect of various concentrations of superabsorbent polymers on soil particle-size distribution and evaporation with sand mulching. Sci. Rep. 2019, 9, 3511. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Taban, M.; Movahedi Naeini, S. Effect of aquasorb and organic compost amendments on soil water retention and evaporation with different evaporation potentials and soil textures. Commun. Soil Sci. Plant Anal. 2006, 37, 2031–2055. [Google Scholar] [CrossRef]

- Yu, J.; Shi, J.; Ma, X.; Dang, P.; Yan, Y.; Mamedov, A.I.; Shainberg, I.; Levy, G.J. Superabsorbent polymer properties and concentration effects on water retention under drying conditions. Soil Sci. Soc. Am. J. 2017, 81, 889–901. [Google Scholar] [CrossRef] [Green Version]

- Koupai, J.A.; Eslamian, S.S.; Kazemi, J.A. Enhancing the available water content in unsaturated soil zone using hydrogel, to improve plant growth indices. Ecohydrol. Hydrobiol. 2008, 8, 67–75. [Google Scholar] [CrossRef]

- Sarmah, D.; Karak, N. Biodegradable superabsorbent hydrogel for water holding in soil and controlled-release fertilizer. J. Appl. Polym. Sci. 2020, 137, 48495. [Google Scholar] [CrossRef]

- Hayat, R.; Ali, S. Water absorption by synthetic polymer (Aquasorb) and its effect on soil properties and tomato yield. Int. J. Agric. Biol. 2004, 6, 998–1002. [Google Scholar]

- Baran, A.; Zaleski, T.; Kulikowski, E.; Wieczorek, J. Hydrophysical and Biological Properties of Sandy Substrata Enriched with Hydrogel. Pol. J. Environ. Stud. 2015, 24, 2355–2362. [Google Scholar] [CrossRef]

- Salim, S.A. Effect of Water-retaining Agent (Sky Gel) on Soil Physical Properties, Growth, Yield and Water Use Efficiency of Wheat (Triticum aestivum L.) Plant. J. Biol. Chem. 2015, 6, 1. [Google Scholar]

- Śpitalniak, M.; Lejcuś, K.; Dąbrowska, J.; Garlikowski, D.; Bogacz, A. The Influence of a Water Absorbing Geocomposite on Soil Water Retention and Soil Matric Potential. Water 2019, 11, 1731. [Google Scholar] [CrossRef] [Green Version]

- Kashkuli, H.A.; Zohrabi, N. The Effect of superabsorbent polymers on the water holding capacity and water potential of Karkhe Noor sandy soils. Int. J. Sci. Res. Knowl. 2013, 1, 317. [Google Scholar] [CrossRef]

- Sivapalan, S. Effect of polymer on soil water holding capacity and plant water use efficiency. In Proceedings of the 10th Australian Agronomy Conference, Hobart, Australia, 29 January–1 February 2001. [Google Scholar]

- Louf, J.-F.; Lu, N.B.; O’Connell, M.G.; Cho, H.J.; Datta, S.S. Under pressure: Hydrogel swelling in a granular medium. Sci. Adv. 2021, 7, eabd2711. [Google Scholar] [CrossRef] [PubMed]

- Misiewicz, J.; Głogowski, A.; Lejcuś, K.; Marczak, D. The Characteristics of Swelling Pressure for Superabsorbent Polymer and Soil Mixtures. Materials 2020, 13, 5071. [Google Scholar] [CrossRef]

| Reference | Type of Study | Soil Textures | Hydrogel Application Rate | Hydrogel Used | Water Retention | Ks | Soil Water Infiltration | Evaporation |

|---|---|---|---|---|---|---|---|---|

| 1. Abdallah [57] | Lab and greenhouse study | Sandy soil | 0.3 and 0% (w/w) | WaterSorb (WS) (Synthetic) | Gravimetric water content increased by 260% | Decreased 38.9–68.8% | N/A | N/A |

| 2. Abedi-Koupai et al. [55] | Lab | Sandy loam, Loamy, and Clay | 2, 4, 6, and 8 g hydrogel/kg soil | PR3005A and Tarawat A100 (Synthetic) | Available water content increased 180% in clay and 220–320% in loamy and sandy loam | N/A | N/A | N/A |

| 3. Agaba et al. [79] | Greenhouse | Sand, Sandy loam, Loam, Silt loam and Clay | 0, 0.2, and 0.4% (w/w) | Luquasorb hydrogel, a powder type of potassium polyacrylate (Synthetic) | Plant available water increased 300% in sand, 200% in silt loam | N/A | N/A | N/A |

| 4. Agaba et al. [80] | Greenhouse | Sandy soil | 0, 0.2, and 0.4% (w/w) | Luquasorb hydrogel, a powder type of potassium polyacrylate (Synthetic) | 100% increase in retained water in top 25 cm of soil | N/A | N/A | N/A |

| 5. Akhter et al. [69] | Potted study in lab | Sandy loam, and Loam | 0.1, 0.2 and 0.3% (w/w) | Acrylamide-based hydrogel (Synthetic) | Increased soil water content at field capacity by 17–46% in sandy loam and 23–50% in loam | N/A | N/A | N/A |

| 6. Bai et al. [70] | Lab and potted study | Sandy clay loam | 0, 0.05, 0.1, 0.2 and 0.3% (w/w) | Polyacrylate/polyacrylamide-based hydrogels (Synthetic) | Relative soil moisture increased 6.2–32.8% | N/A | N/A | N/A |

| 7. Cannazza et al. [50] | Greenhouse potted study | Red soil (Clay soil) and white soil | 0, 0.2, 0.5, 1.0 and 1.5% (w/w) | Cellulose-based hydrogel (Bio-based) | Increased water retention by 50% | N/A | N/A | N/A |

| 8. Koupai et al. [109] | Lab and field study | Sandy loam and Clay | 4 and 6 g/kg soil | Superab A200 (Synthetic) | Available water content increased by 230% | N/A | N/A | N/A |

| 9. Leciejewski [81] | Lab study | Loamy sand | 0.02, 0.08, 0.17, and 0.25% (w/w) | Potassium polyacrylate-based hydrogel (Synthetic) | Soil water increased by 200–250% | N/A | N/A | N/A |

| 10. Liao et al. [71] | Potted in lab | Sandy loam | 0, 0.01, 0.03, 0.06% | Polyacrylamide and acrylic acid-based hydrogel (Synthetic) | Soil water content increased by 2.7–26.5% | N/A | N/A | N/A |

| 11. Montesano et al. [59] | Lab study | Sandy soil | 0, 0.5, 1 and 2% (w/w) | Cellulose-based hydrogel (Bio-based) | Increased soil water content at FC by 400% | N/A | N/A | N/A |

| 12. Sarmah & Karak [110] | Lab study | Silty and Sandy | 0.1 and 0.25% | Starch based hydrogel (Bio-based) | Water holding capacity increased by 120% | N/A | N/A | N/A |

| 13. Saha et al. [72] | Lab study | Fine sand, Silt loam and Clay | 0, 0.1, 0.2, and 0.4% (w/w) | Stockosorb, acrylic-based polymer with acrylamide cross-linking. (Synthetic) | Plant available water capacity increased by 120–330% in fine sand | N/A | N/A | N/A |

| 14. Abrisham et al. [73] | Field study | Sandy loam | 0, 1, and 3 g hydrogel/dm−3 of soil | Stockosorb, an acrylamide/acrylic acid copolymer potassium Salt. (Synthetic) | Available water content increased by 21.5% | N/A | Soil water infiltration decreased by 21.5% | N/A |

| 15. Bhardwaj et al. [60] | Lab study | Sandy soil | 0, 0.5, 2.5, and 5.0 g hydrogel/kg of soil | Cross-linked acrylamide or acrylic acid copolymers (Synthetic) | Increased | Decreased then an increase with time | N/A | N/A |

| 16. Andry et al. [28] | Lab study | Sandy soil | 0, 0.1, and 0.2% (w/w) | Carboxymethylcellulose (bio-based) and isopropyl acrylamide (Synthetic) | Available water content increased by 400–500% | Increased | N/A | N/A |

| 17. Lentz [78] | Potted study and lab study | Degraded calcareous Silt loam | 0.25 or 0.5% dry weight (5.6 or 11.2 Mg ha−1) | Polyacrylamide copolymer and polyacrylic acid-potassium salt hydrogels. (Synthetic) | Plant available water increased by 42% | N/A | N/A | N/A |

| 18. Shahid et al. [74] | Lab study | Sandy loam soil | 0.1, 0.2, 0.3 and 0.4% (w/w) | Poly (Acrylamide-co-acrylic acid)/AlZnFe2O4 nanocomposite hydrogels (Synthetic) | Water retention at field capacity increased by 60–100% | Decreased by 16–63%. | N/A | N/A |

| 19. Hayat & Ali [111] | Lab and potted greenhouse study | Sandy loam | 0, 0.25, 0.5, 0.75, 1.00, 1.25, and 1.50% (w/w) | Aquasorb (Synthetic) | Soil moisture content increased by 30–850% | N/A | N/A | N/A |

| 20. Yu et al. [104] | Lab | Loamy sand, Sandy Loam, Sandy clay loam and Clay loam | 0.5% (w/w) | WOTE, GNKH, PR3005S, and BJ-210 lXM (Synthetic) | Water absorption capacity increased by two orders of magnitude | N/A | N/A | Decreased evaporation up to 338% after 7 h of drying |

| 21. Banedjschafie & Durner [58] | Lab | Sand | 0, 0.3, 0.6, and 1% w/w | Superab A200 (Synthetic) | Plant available water increased by 18% | N/A | N/A | N/A |

| 22. Baran et al. [112] | Lab | Loamy sand and Sand | 0, 0.2, 0.6, 1%, and 2% (w/w) | AgroaquaGel (Synthetic) | Increased maximum water capacity by 32–69% | N/A | N/A | N/A |

| 23. Demitri et al. [63] | Lab and greenhouse | Red soil | 0.2, 0.5, and 1% (w/w) | Cellulose-based hydrogel (Bio-based) | Increased | N/A | N/A | N/A |

| 24. Geesing [82] | Lab | Loam, Silty clay loam and Sandy loam | 0, 1, 3, or 5 g/L of soil | Sodium polyacrylate (Synthetic) | Increased only at rate > 3 g/L | N/A | N/A | N/A |

| 25. Hu et al. [66] | Lab | Sandy loam | 0, 2 and 4 (t/ha) | Biomaterials and polyacrylamide (Synthetic and bio-based) | Soil water content increased by 12.1–23.4% | Increased 91–122%. | N/A | N/A |

| 26. Dehkordi [62] | Greenhouse | Sandy soil | 0,0.20, 0.40 and 0.6% (w/w) | Superab A200 (Synthetic) | Soil water retention increased 175–375% | N/A | N/A | Evaporation rate decreased by 80% on the third day |

| 27. Narjary et al. [64] | Lab | Sand, alluvial Sandy loam, red Sandy loam and black Clay | 0, 0.7, and 0.5% (w/w) | Pusa, a polyacrylate cellulose-based hydrogel. (Bio-based) | Soil water content increased by 400% in sandy soil at soil pressures of 10–100 kPa. | Decreased by 118, 708, and 95% in sand, red sandy loam and alluvial sandy soil, respectively | N/A | N/A |

| 28. Narjary & Aggarwal [65] | Field* | Sandy loam | 0, 2.5, and 5 (kg/ha) | Pusa, a polyacrylate cellulose-based hydrogel. (Bio-based) | Plant available water capacity increased by 6–8% | Decreased 45–60% | N/A | N/A |

| 29. Salim [113] | Lab and field | Sandy loam | 0, 4, 8, and 12% (w/w) | Sky Gel, copolymer of acrylic acid and sodium acrylic acid (Synthetic) | Water holding capacity increased by 63.2–302.8% | N/A | N/A | N/A |

| 30. Śpitalniak et al. [114] | Lab | Coarse sand, Loamy sand, and Sandy loam | Water absorbent geocomposite (Synthetic) | Soil water retention increased by 54.8–191.6% | N/A | N/A | N/A | |

| 31. Zhao et al. [77] | Lab | Sandy loam | 0,0.1, 0.2, 0.5, and 1% (w/w) | Acrylamide -based hydrogel (Synthetic) | Soil water content increased by 0.76–3.74% | N/A | Mean infiltration rate decreased by 9–51.5% | N/A |

| 32. Alkhasha et al. [45] | Lab | Loamy sand | 0, 0.2, 0.4, 0.6, and 0.8% (w/w) | PagriSap (polyacrylamide-based hydrogel) (Synthetic) | Soil moisture increased by 2.49–5.53% | Decreased 31.4–71.4% | Cumulative infiltration increased from 9.32–21.87% | The 0.2% treatment decreased cumulative evaporation by 10.77% while 0.4–0.8% decreased cumulative evaporation by 6.87–14.86% |

| 33. Alkhasha & Al-Omran [75] | Lab | Sandy loam | 0, 0.2, 0.4, 0.6, and 0.8% (w/w) | PagriSap (polyacrylamide- based hydrogel) (Synthetic) | Soil water content increased by 3.3% | N/A | N/A | N/A |

| 34. Al-Humaid & Moftah [76] | Field | Sandy soil | 0.1%, 0.2%, 0.4% or 0.6% (w/w) | Stockosorb K400, a cross-linked polyacrylamide (Synthetic) | Soil water content increased by 13.3–300% | N/A | N/A | N/A |

| 35. Zhuang et al. [83] | Lab | Sandy soil | 0, 0.08, 0.2, 0.5 and 1% | Sodium polyacrylate (Synthetic) | Maximum water supply quantity increased by 45.61–318.89% | Decreased by 42.53–96.5%. | Decreased | N/A |

| 36. Song et al. [10] | Lab | Sandy loam soil | 0, 0.375, 0.650, 0.975% (w/w) | Lignin-based sodium alginate hydrogel (Bio-based) | Maximum water holding capacity in soil increased by 2.98–8.96% | Decreased 63.2–89.5% | N/A | N/A |

| 37. Passauer et al. [38] | Lab | Coarse silica | 0, 0.1, 0.25, and 0.5% (w/w) | Lignin-based hydrogel (Bio-based) | Soil water content increased by 300–400% | N/A | N/A | N/A |

| 38. Kashkuli & Zohrabi [115] | Lab | Sandy soil | 0, 0.03, 0.06, 0.08, 0.2, and 0.4% (w/w) | Super AB A200 and Herbasorb (Synthetic) | Soil available water increased 350 and 320% | N/A | N/A | N/A |

| 39. Sivapalan [116] | Lab | Sandy | 0, 0.03 and 0.07% (w/w) | ALCOSORB® 400 (anionic acrylic copolymer) (Synthetic) | Soil water retention increased 23 and 95% | N/A | N/A | N/A |

| 40. Han et al. [89] | Lab | Sandy loam | ASC or PAM in soil at a mass ratio of 1:2000 (SAP:soil) | Acrylate Sodium Co-polymers (ASC) and Polyacrylamides (PAM) (Synthetic) | N/A | Decrease then an increase with time | N/A | N/A |

| 41. Hussein et al. [88] | Lab | Sandy and Sandy clay loam | 0.5, 1.0 and 2.0% (wt/wt) | Poly (acrylic acid)-co-acrylamide hydrogel (Synthetic) | N/A | Decreased by 53.68–87.18% with lower rates (0.5 and 1%) and an increase by 107.6–516.3% at 2% | N/A | N/A |

| 42. Smagin et al. [87] | Lab | Silty sand | 0.01 to 0.3 % (w/w) | Technical polyacrylamide (PAA) hydrogel and a co-polymer of acrylamide and (sodium acrylate (Synthetic) | N/A | Decreased by 200–800% | N/A | N/A |

| 43. Mohawesh & Durner [32] | Lab | Sandy soil | 0.1, 0.25, and 0.5% (w/w) | Luquasorb (Synthetic) | Soil water content increased up to 86.9% | Decreased by 300% | N/A | N/A |

| 44. Guo et al. [98] | Lab | Sandy loam | 0, 0.05, 0.10, 0.15, and 0.20% (w/w) | Poly-γ-glutamic acid-based hydrogel (Bio-based) | Soil water content at FC increased by 8.7–58.3% | N/A | Cumulative infiltration decreased 32.4–52.0% | Cumulative evaporation increased 17.1–25.3% |

| 45. Lentz [99] | Lab | Silt loam, Loam, Loamy sand, and Clay loam | 0, 0.25, and 0.5% (w/w) | Polyacrylamide hydrogel (Synthetic) | N/A | N/A | Decreased infiltration by 84–97% | N/A |

| 46. Reddy et al. [100] | Lab | Sandy loam | 0, 0.25, 0.75, 1.25 and 1.75% | RDW-W, RDW-I, RDW-W and RDW-F (Synthetic) | N/A | N/A | Maximum reduction of 90% in steady state infiltration | N/A |

| 47. Yang et al. [105] | Lab | Sand, loam, Silt | 0.6% (w/w) | Acrylic sodium copolymer (Synthetic) | N/A | N/A | Decrease and increase | Decreased |

| 48. Zhao et al. [106] | Lab | Sandy loam | 0, 0.2, 0.5 and 1% (w/w) | Polyacrylamide and acrylic acid-based hydrogel (Synthetic) | N/A | N/A | N/A | Decreased by 0.3–14% at 20 cm on day 30 |

| 49. Taban et al. [107] | Lab | Loam and Loamy sand | 0.14 and 0.7% (w/w) | Aquasorb PR3005A, a salt copolymer polyacrylamide (Synthetic) | N/A | N/A | N/A | Decreased about 31.25% after 2500 h |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Adjuik, T.A.; Nokes, S.E.; Montross, M.D.; Wendroth, O. The Impacts of Bio-Based and Synthetic Hydrogels on Soil Hydraulic Properties: A Review. Polymers 2022, 14, 4721. https://doi.org/10.3390/polym14214721

Adjuik TA, Nokes SE, Montross MD, Wendroth O. The Impacts of Bio-Based and Synthetic Hydrogels on Soil Hydraulic Properties: A Review. Polymers. 2022; 14(21):4721. https://doi.org/10.3390/polym14214721

Chicago/Turabian StyleAdjuik, Toby A., Sue E. Nokes, Michael D. Montross, and Ole Wendroth. 2022. "The Impacts of Bio-Based and Synthetic Hydrogels on Soil Hydraulic Properties: A Review" Polymers 14, no. 21: 4721. https://doi.org/10.3390/polym14214721