Rheological and Aging Properties of Composite Modified Bitumen by Styrene–Butadiene–Styrene and Desulfurized Crumb Rubber

Abstract

:1. Introduction

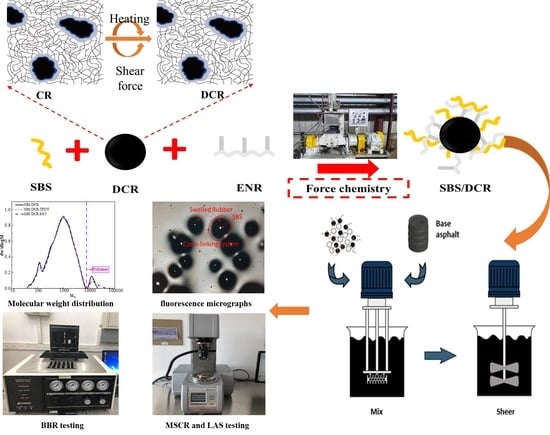

2. Methods

2.1. Materials and Preparation

2.2. Aging Method

2.3. Fluorescence Intensity Measurement

2.4. Molecular Distribution Analysis Using Gel Permeation Chromatography

2.5. Multiple Stress Creep Recovery Test

2.6. Linear Amplitude Scanning Test

2.7. Bending Beam Rheometer Test

3. Results and Discussion

3.1. Fluorescence Microscopy (FM) Analysis of SBS and DCR in Bitumen

3.2. Molecular Distribution Analysis with GPC

3.3. Multiple Stress Creep Recovery Results

3.4. Linear Amplitude Scanning Test Results

3.5. Low-Temperature Performance

3.6. Analysis of and Anti-aging Properties

4. Conclusions

- (1)

- The fluorescence micrographs confirmed that the DCR and SBS modifiers in SBS/DCRMB had been vulcanized and produced a three-dimensional network structure under the action of sulfur. Moreover, using GPC to analyze the molecular distribution of SBS/DCRMB shows only two regions (residual asphalt and polymer), which further indicates that a crosslinking reaction occurred between the polymers of SBS/DCRMB.

- (2)

- GPC testing results indicated that the introduction of DCR in SBS/DCRMB significantly improved the thermal oxygen anti-aging ability, and the results of the LAS and MSCR test also indicated the same pattern.

- (3)

- The MSCR testing results illustrated that DCR could effectively improve the elastic properties and decrease the viscous parts of asphalt. Furthermore, the three-dimensional polymer network structure formed by DCR and SBS plays a significant role in the high-temperature properties.

- (4)

- DCR enhanced the resistance to fatigue cracking of SBS/DCRMB and combination with the GPC test results, shows that the influence of aging on the fatigue life of SBSMB was mainly the result of the hardening of residual asphalt. In contrast, the fatigue performance loss of SBS/DCRMB was primarily caused by the condensation of the polymer part and the disintegration of the polymer network structure.

- (5)

- According to the stiffness modulus and creep rate results of the BBR test, the temperature sensitivity and anti-aging properties of SBS/DCRMB were significantly better than those of SBSMB.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Conflicts of Interest

References

- Yilmaz, M.; Yalcin, E. The effects of using different bitumen modifiers and hydrated lime together on the properties of hot mix asphalts. Road Mater. Pavement Des. 2016, 17, 499–511. [Google Scholar] [CrossRef]

- Chen, J.S.; Liao, M.C.; Shiah, M.S. Asphalt modified by styrene-butadiene-styrene triblock copolymer: Morphology and model. J. Mater. Civ. Eng. 2002, 14, 224–229. [Google Scholar] [CrossRef] [Green Version]

- Wu, S.-p.; Pang, L.; Mo, L.-t.; Chen, Y.-c.; Zhu, G.-j. Influence of aging on the evolution of structure, morphology and rheology of base and SBS modified bitumen. Constr. Build. Mater. 2009, 23, 1005–1010. [Google Scholar] [CrossRef]

- Dong, F.; Fan, W.; Yang, G.; Wei, J.; Luo, H.; Wu, M.; Zhang, Y. Dispersion of SBS and its Influence on the Performance of SBS Modified Asphalt. J. Test. Eval. 2014, 42, 1073–1080. [Google Scholar] [CrossRef]

- Dong, Z.J.; Zhou, T.; Luan, H.; Williams, R.C.; Wang, P.; Leng, Z. Composite modification mechanism of blended bio-asphalt combining styrene-butadiene-styrene with crumb rubber: A sustainable and environmental-friendly solution for wastes. J. Clean Prod. 2019, 214, 593–605. [Google Scholar] [CrossRef]

- Lee, S.-J.; Akisetty, C.K.; Amirkhanian, S.N. The effect of crumb rubber modifier (CRM) on the performance properties of rubberized binders in HMA pavements. Constr. Build. Mater. 2008, 22, 1368–1376. [Google Scholar] [CrossRef]

- Wang, H.; Liu, X.; Apostolidis, P.; Scarpas, T. Review of warm mix rubberized asphalt concrete: Towards a sustainable paving technology. J. Clean Prod. 2018, 177, 302–314. [Google Scholar] [CrossRef] [Green Version]

- Lo Presti, D. Recycled Tyre Rubber Modified Bitumens for road asphalt mixtures: A literature review. Constr. Build. Mater. 2013, 49, 863–881. [Google Scholar] [CrossRef]

- Lundy, J.R.; Hicks, R.G.; Zhou, H. Ground Rubber Tires in Asphalt-Concrete Mixtures—Three Case Histories. In Use of Waste Materials in Hot-Mix Asphalt; Waller, H.F., Ed.; ASTM International: West Conshohocken, PA, USA, 1993; Volume 1193, pp. 262–275. [Google Scholar]

- Mull, M.A.; Stuart, K.; Yehia, A. Fracture resistance characterization of chemically modified crumb rubber asphalt pavement. J. Mater. Sci. 2002, 37, 557–566. [Google Scholar] [CrossRef]

- Ye, Z.G.; Zhang, Y.Z.; Kong, X.M. Modification of bitumen with desulfurized crumb rubber in the present of reactive additives. J. Wuhan Univ. Technol. Mater. Sci. Ed. 2005, 20, 95–97. [Google Scholar]

- He, L.; Ma, Y.; Huang, X.; Ma, T. Research on Performance and Microstructure of Desulfurized Rubber Asphalt. J. Build. Mater. 2012, 15, 227–231. [Google Scholar]

- Subhy, A.; Lo Presti, D.; Airey, G. An investigation on using pre-treated tyre rubber as a replacement of synthetic polymers for bitumen modification. Road Mater. Pavement Des. 2015, 16, 245–264. [Google Scholar] [CrossRef] [Green Version]

- Singh, B.; Kumar, L.; Gupta, M.; Chauhan, M.; Chauhan, G.S. Effect of activated crumb rubber on the properties of crumb rubber-modified bitumen. J. Appl. Polym. Sci. 2013, 129, 2821–2831. [Google Scholar] [CrossRef]

- Liang, M.; Xin, X.; Fan, W.; Ren, S.; Shi, J.; Luo, H. Thermo-stability and aging performance of modified asphalt with crumb rubber activated by microwave and TOR. Mater. Des. 2017, 127, 84–96. [Google Scholar] [CrossRef]

- Li, B.; Zhou, J.; Zhang, Z.; Yang, X.; Wu, Y. Effect of Short-Term Aging on Asphalt Modified Using Microwave Activation Crumb Rubber. Mater 2019, 12, 1039. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Cao, D.; Zhang, H. Study on the Mechanism and Properties of Activated Crumb Rubber Modified Asphalt. Advan Mater Resear. 2011, 239, 191–196. [Google Scholar] [CrossRef]

- Wang, H.; You, Z.; Mills-Beale, J.; Hao, P. Laboratory evaluation on high temperature viscosity and low temperature stiffness of asphalt binder with high percent scrap tire rubber. Constr. Build. Mater. 2012, 26, 583–590. [Google Scholar] [CrossRef]

- Navarro, F.J.; Partal, P.; Martinez-Boza, F.; Gallegos, C. Influence of crumb rubber concentration on the rheological behavior of a crumb rubber modified bitumen. Energy Fuels 2005, 19, 1984–1990. [Google Scholar] [CrossRef]

- Nejad, F.M.; Aghajani, P.; Modarres, A.; Firoozifar, H. Investigating the properties of crumb rubber modified bitumen using classic and SHRP testing methods. Constr. Build. Mater. 2012, 26, 481–489. [Google Scholar] [CrossRef]

- Liang, M.; Ren, S.S.; Sun, C.J.; Zhang, J.Z.; Jiang, H.G.; Yao, Z.Y. Extruded Tire Crumb-Rubber Recycled Polyethylene Melt Blend as Asphalt Composite Additive for Enhancing the Performance of Binder. J. Mater. Civ. Eng. 2020, 32, 10. [Google Scholar] [CrossRef]

- Yidirim, Y. Polymer modified asphalt binders. Constr. Build. Mater. 2007, 21, 66–72. [Google Scholar] [CrossRef]

- Kodrat, I.; Sohn, D.; Hesp, S.A.M. Comparison of polyphosphoric acid-modified asphalt binders with straight and polymer-modified materials. Transp. Res. Rec. 2007, 1998, 47–55. [Google Scholar] [CrossRef]

- Tan, Y.Q.; Guo, M.; Cao, L.P.; Zhang, L. Performance optimization of composite modified asphalt sealant based on rheological behavior. Constr. Build. Mater. 2013, 47, 799–805. [Google Scholar] [CrossRef]

- Xiang, L.; Cheng, J.; Kang, S. Thermal oxidative aging mechanism of crumb rubber/SBS composite modified asphalt. Constr. Build. Mater. 2015, 75, 169–175. [Google Scholar] [CrossRef]

- Javier Lopez-Moro, F.; Candelas Moro, M.; Hernandez-Olivares, F.; Witoszek-Schultz, B.; Alonso-Fernandez, M. Microscopic analysis of the interaction between crumb rubber and bitumen in asphalt mixtures using the dry process. Constr. Build. Mater. 2013, 48, 691–699. [Google Scholar] [CrossRef]

- Zhang, F.; Hu, C. The research for structural characteristics and modification mechanism of crumb rubber compound modified asphalts. Constr. Build. Mater. 2015, 76, 330–342. [Google Scholar] [CrossRef]

- Fu, Q.; Xu, G.; Chen, X.; Zhou, J.; Sun, F. Rheological properties of SBS/CR-C composite modified asphalt binders in different aging conditions. Constr. Build. Mater. 2019, 215, 1–8. [Google Scholar] [CrossRef]

- Wang, S.; Zhao, X.; Wang, Q. Rheological and Structural Evolution of Rubberized Asphalts under Weathering. J. Mater. Civ. Eng. 2017, 29, 04017180. [Google Scholar] [CrossRef]

- ASTM D5/D5M-20. Standard Test Method for Penetration of Bituminous Materials; ASTM International: West Conshohocken, PA, USA, 2020; Available online: www.astm.org (accessed on 5 September 2021).

- ASTM D36-06. Standard Test Method for Softening Point of Bitumen (Ring-and-Ball Apparatus); ASTM International: West Conshohocken, PA, USA, 2006; Available online: www.astm.org (accessed on 5 September 2021).

- ASTM D113-17. Standard Test Method for Ductility of Asphalt Materials; ASTM International: West Conshohocken, PA, USA, 2017; Available online: www.astm.org (accessed on 5 September 2021).

- ASTM D2872-97. Standard Test Method for Effect of Heat and Air on a Moving Film of Asphalt (Rolling Thin-Film Oven Test); ASTM International: West Conshohocken, PA, USA, 1997; Available online: www.astm.org (accessed on 5 September 2021).

- ASTM D92-16. Standard Test Method for Flash and Fire Points by Cleveland Open Cup Tester; ASTM International: West Conshohocken, PA, USA, 2016; Available online: www.astm.org (accessed on 5 September 2021).

- ASTM D1754/D1754M-09. Standard Test Method for Effect of Heat and Air on Asphaltic Materials (Thin-Film Oven Test); ASTM International: West Conshohocken, PA, USA, 2009; Available online: www.astm.org (accessed on 5 September 2021).

- ASTM D6531-00. Standard Test Method for Relative Tinting Strength of Aqueous Ink Systems by Instrumental Measurement; ASTM International: West Conshohocken, PA, USA, 2019; Available online: www.astm.org (accessed on 5 September 2021).

- Buisine, J.; Buisine, J.M.; Joly, G.; Eladlani, A.; Such, C.; FARCAS, F.; Ramond, G.; Claudy, P.; Letoffe, J.M.; King, G.N.; et al. Thermodynamic behavior and physicochemical analysis of eight SHRP bitumens. Transp. Res. Rec. 1993, 1386, 1–9. [Google Scholar]

- Daly, W.H.; Qui Chiu, Z.; Negulescu, I. Preparation and characterization of asphalt-modified polyethylene blends. Transp. Res. Rec. 1993, 1391, 56. [Google Scholar]

- D’Angelo, J.; Dongre, R. Practical Use of Multiple Stress Creep and Recovery Test Characterization of Styrene-Butadiene-Styrene Dispersion and Other Additives in Polymer-Modified Asphalt Binders. Transp. Res. Rec. 2009, 2126, 73–82. [Google Scholar] [CrossRef]

- Hao, G.R.; Huang, W.D.; Yuan, J.; Tang, N.P.; Xiao, F.P. Effect of aging on chemical and rheological properties of SBS modified asphalt with different compositions. Constr. Build. Mater. 2017, 156, 902–910. [Google Scholar] [CrossRef]

- Themeli, A.; Chailleux, E.; Farcas, F.; Chazallon, C.; Migault, B. Molecular weight distribution of asphaltic paving binders from phase-angle measurements. Road Mater. Pavement Des. 2015, 16, 228–244. [Google Scholar] [CrossRef]

- Wang, H.; Liu, X.; Apostolidis, P.; Scarpas, T. Rheological Behavior and Its Chemical Interpretation of Crumb Rubber Modified Asphalt Containing Warm-Mix Additives. Transp. Res. Rec. 2018, 2672, 337–348. [Google Scholar] [CrossRef]

- AASHTO T350. Multiple Stress Creep Recovery(MSCR) Test of Asphalt Binder Using a Dynamic Shear Rheometer (DSR); AASHTO: Washington, DC, USA, 2016. [Google Scholar]

- AASHTO TP101. Standard Method of Test for Estimating Fatigue Resistance of Asphalt Binders Using the Linear Amplitude Sweep; AASHTO: Washington, DC, USA, 2012. [Google Scholar]

- ASTM D7643-16. Standard Practice for Determining the Continuous Grading Temperatures and Continuous Grades for PG Graded Asphalt Binders; ASTM International: West Conshohocken, PA, USA, 2016; Available online: www.astm.org (accessed on 5 September 2021).

- Wekumbura, C.; Stastna, J.; Zanzotto, L. Destruction and recovery of internal structure in polymer-modified asphalts. J. Mater. Civ. Eng. 2007, 19, 227–232. [Google Scholar] [CrossRef]

- Golalipour, A.; Bahia, H.U.; Tabatabaee, H.A. Critical Considerations toward Better Implementation of the Multiple Stress Creep and Recovery Test. J. Mater. Civ. Eng. 2017, 29, 7. [Google Scholar] [CrossRef]

- Zhou, Z.; Gu, X.Y.; Dong, Q.; Ni, F.J.; Jiang, Y.X. Rutting and fatigue cracking performance of SBS-RAP blended binders with a rejuvenator. Constr. Build. Mater. 2019, 203, 294–303. [Google Scholar] [CrossRef]

- Ren, S.S.; Liu, X.Y.; Fan, W.Y.; Qian, C.D.; Nan, G.Z.; Erkens, S. Investigating the effects of waste oil and styrene-butadiene rubber on restoring and improving the viscoelastic, compatibility, and aging properties of aged asphalt. Constr. Build. Mater. 2021, 269, 19. [Google Scholar] [CrossRef]

- Wang, R.; Xu, G.; Chen, X.H.; Zhou, W.B.; Zhang, H.Y. Evaluation of aging resistance for high-performance crumb tire rubber compound modified asphalt. Constr. Build. Mater. 2019, 218, 497–505. [Google Scholar] [CrossRef]

| Properties | Unit | Test Results | Test Method | ||

|---|---|---|---|---|---|

| Neat | SBS | SBS/DCR | |||

| Penetration (25 °C, 100g, 5 s) | (0.1 mm) | 68.9 | 58.9 | 72.4 | ASTM D5 [30] |

| Softening point (ring and ball method) | °C | 47.2 | 66.5 | 85.8 | ASTM D36 [31] |

| Ductility (15 °C, 5 cm/s) | Cm | >100 | -- | -- | ASTM D113 [32] |

| Ductility (5 °C, 5 cm/s) | Cm | -- | 20.4 | 44.5 | ASTM D113 [32] |

| Change in mass TFOT | % | −0.2 | −0.11 | −0.08 | ASTM D2872 [33] |

| Flashpoint, Cleveland open cup | °C | 289 | 291 | 310 | ASTM D92 [34] |

| Binder Type | Aging Conditions | Mn | Mw | Mn/Mw |

|---|---|---|---|---|

| SBSMB | Virgin | 850 | 2270 | 2.67 |

| TFOT | 885 | 2303 | 2.60 | |

| PAV-20 h | 928 | 2354 | 2.54 | |

| SBS/DCRMB | Virgin | 860 | 2577 | 3.00 |

| TFOT | 884 | 2664 | 3.01 | |

| PAV-20 h | 910 | 2790 | 3.07 |

| Binder Type | Aging Conditions | C1 | C2 | A | B | ||

|---|---|---|---|---|---|---|---|

| SBS | Virgin | 0.050 | 0.473 | 3,142,334 | 2.894 | 1.447 | 0.236 |

| TFOT | 0.059 | 0.496 | 1,856,421 | 2.888 | 1.444 | 0.258 | |

| PAV-20 h | 0.066 | 0.521 | 1,533,497 | 2.922 | 1.461 | 0.318 | |

| SBS/DCR | Virgin | 0.058 | 0.490 | 8,010,102 | 2.978 | 1.489 | 0.199 |

| TFOT | 0.054 | 0.504 | 5,165,232 | 3.026 | 1.513 | 0.210 | |

| PAV-20 h | 0.050 | 0.513 | 3,456,893 | 3.042 | 1.521 | 0.249 |

| Modified Asphalt | MAI, % | JDAI, % | TLAI, % | NfAI, % (Strain = 1%) |

|---|---|---|---|---|

| SBSMB-TFOT | 2.63 | 12.13 | 11.67 | 45.7 |

| SBS/DCRMB-TFOT | 0.33 | 6.75 | 5.72 | 14.0 |

| SBSMB-PAV | 4.87 | 32.67 | 56.63 | 80.6 |

| SBS/DCRMB-PAV | 2.33 | 20.47 | 28.4 | 63.0 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xu, G.; Yu, Y.; Yang, J.; Wang, T.; Kong, P.; Chen, X. Rheological and Aging Properties of Composite Modified Bitumen by Styrene–Butadiene–Styrene and Desulfurized Crumb Rubber. Polymers 2021, 13, 3037. https://doi.org/10.3390/polym13183037

Xu G, Yu Y, Yang J, Wang T, Kong P, Chen X. Rheological and Aging Properties of Composite Modified Bitumen by Styrene–Butadiene–Styrene and Desulfurized Crumb Rubber. Polymers. 2021; 13(18):3037. https://doi.org/10.3390/polym13183037

Chicago/Turabian StyleXu, Gang, Yunhong Yu, Jingyao Yang, Tianling Wang, Peipei Kong, and Xianhua Chen. 2021. "Rheological and Aging Properties of Composite Modified Bitumen by Styrene–Butadiene–Styrene and Desulfurized Crumb Rubber" Polymers 13, no. 18: 3037. https://doi.org/10.3390/polym13183037