The Influence of Neem Oil and Its Glyceride on the Structure and Characterization of Castor Oil-Based Polyurethane Foam

Abstract

:1. Introduction

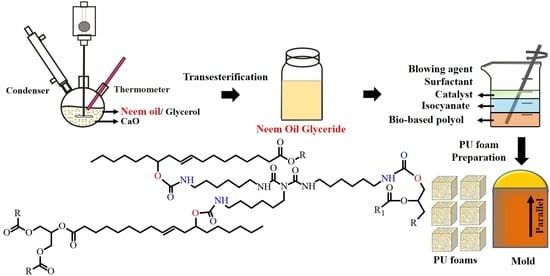

2. Materials and Methods

2.1. Materials

2.2. Basic Properties of Plant Oils and Isocyanate

2.3. Preparation of Bio-Based PU Foams

2.4. Properties of Neem Oil-Based PU Foams

2.4.1. Density

2.4.2. FTIR

2.4.3. Optical Micrograph

2.4.4. Mechanical Properties

2.4.5. Water and Chemicals Resistance

2.4.6. TG Analysis

2.4.7. Statistical Analyses

3. Results and Discussion

3.1. Basic Properties of Plant Oils and Isocyanate

3.2. The Basic Properties and Pore Structure of PU Foams

3.3. FTIR Spectra for PU Foams

3.4. Mechanical Properties of PU Foams

3.5. Water and Solvents Resistance of PU Foams

3.6. Thermal Properties of PU Foams

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Vale, M.; Mateus, M.M.; Galhano dos Santos, R.; Nieto de Castro, C.; de Schrijver, A.; Bordado, J.C.; Marques, A.C. Replacement of petroleum-derived diols by sustainable biopolyols in one component polyurethane foams. J. Clean. Prod. 2019, 212, 1036–1043. [Google Scholar] [CrossRef]

- Engels, H.W.; Pirkl, H.G.; Albers, R.; Albach, R.W.; Krause, J.; Hoffmann, A.; Casselmann, H.; Dormish, J. Polyurethanes: Versatile materials and sustainable problem solvers for today’s challenges. Angew. Chem. Int. Ed. 2013, 52, 9422–9441. [Google Scholar] [CrossRef]

- Agrawal, A.; Kaur, R.; Walia, R.S. PU foam derived from renewable sources: Perspective on properties enhancement: An overview. Eur. Polym. J. 2017, 95, 255–274. [Google Scholar] [CrossRef]

- Hejna, A.; Kirpluks, M.; Kosmela, P.; Cabulis, U.; Haponiuk, J.; Piszczyk, Ł. The influence of crude glycerol and castor oil-based polyol on the structure and performance of rigid polyurethane-polyisocyanurate foams. Ind. Crop. Prod. 2017, 95, 113–125. [Google Scholar] [CrossRef]

- Kurańska, M.; Prociak, A. The influence of rapeseed oil-based polyols on the foaming process of rigid polyurethane foams. Ind. Crop. Prod. 2016, 89, 182–187. [Google Scholar] [CrossRef]

- Liang, H.; Wang, S.; He, H.; Wang, M.; Liu, L.; Lu, J.; Zhang, Y.; Zhang, C. Aqueous anionic polyurethane dispersions from castor oil. Ind. Crop. Prod. 2018, 122, 182–189. [Google Scholar] [CrossRef]

- Yousuf, A. Biodiesel from lignocellulosic biomass—Prospects and challenges. Waste Manag. 2012, 32, 2061–2067. [Google Scholar] [CrossRef]

- Ashraful, A.M.; Masjuki, H.H.; Kalam, M.A.; Rizwanul Fattah, I.M.; Imtenan, S.; Shahir, S.A.; Mobarak, H.M. Production and comparison of fuel properties, engine performance, and emission characteristics of biodiesel from various non-edible vegetable oils: A review. Energy Convers. Manag. 2014, 80, 202–228. [Google Scholar] [CrossRef]

- Saha, P.; Khomlaem, C.; Aloui, H.; Kim, B.S. Biodegradable polyurethanes based on castor oil and poly (3-hydroxybutyrate). Polymers 2021, 13, 1387. [Google Scholar] [CrossRef]

- Borrero-López, A.M.; Valencia, C.; Blánquez, A.; Hernández, M.; Eugenio, M.E.; Franco, J.M. Cellulose pulp- and castor oil-based polyurethanes for lubricating applications: Influence of streptomyces action on barley and wheat straws. Polymers 2020, 12, 2822. [Google Scholar] [CrossRef] [PubMed]

- Gurunathan, T.; Mohanty, S.; Nayak, S.K. Isocyanate terminated castor oil-based polyurethane prepolymer: Synthesis and characterization. Prog. Org. Coat. 2015, 80, 39–48. [Google Scholar] [CrossRef]

- Chen, Y.C.; Tai, W. Castor oil-based polyurethane resin for low-density composites with bamboo charcoal. Polymers 2018, 10, 1100. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Ogunniyi, D.S. Castor oil: A vital industrial raw material. Bioresour. Technol. 2006, 97, 1086–1091. [Google Scholar] [CrossRef] [PubMed]

- Lee, J.H.; Kim, S.H.; Oh, K.W. Bio-based polyurethane foams with castor oil based multifunctional polyols for improved compressive properties. Polymers 2021, 13, 576. [Google Scholar] [CrossRef] [PubMed]

- Mutlu, H.; Meier, M.A.R. Castor oil as a renewable resource for the chemical industry. Eur. J. Lipid Sci. Technol. 2010, 112, 10–30. [Google Scholar] [CrossRef]

- Chaudhari, A.B.; Anand, A.; Rajput, S.D.; Kulkarni, R.D.; Gite, V.V. Synthesis, characterization and application of azadirachta indica juss (neem oil) fatty amides (aijfa) based polyurethanes coatings: A renewable novel approach. Prog. Org. Coat. 2013, 76, 1779–1785. [Google Scholar] [CrossRef]

- Chaudhari, A.; Gite, V.; Rajput, S.; Mahulikar, P.; Kulkarni, R. Development of eco-friendly polyurethane coatings based on neem oil polyetheramide. Ind. Crop. Prod. 2013, 50, 550–556. [Google Scholar] [CrossRef]

- Marathe, R.; Tatiya, P.; Chaudhari, A.; Lee, J.; Mahulikar, P.; Sohn, D.; Gite, V. Neem acetylated polyester polyol—renewable source based smart pu coatings containing quinoline (corrosion inhibitor) encapsulated polyurea microcapsules for enhance anticorrosive property. Ind. Crop. Prod. 2015, 77, 239–250. [Google Scholar] [CrossRef]

- Das, P.; Sharma, N.; Puzari, A.; Kakati, D.K.; Devi, N. Synthesis and characterization of neem (azadirachta indica) seed oil-based alkyd resins for efficient anticorrosive coating application. Polym. Bull. 2021, 78, 457–479. [Google Scholar] [CrossRef]

- Członka, S.; Bertino, M.F.; Kośny, J.; Strąkowska, A.; Masłowski, M.; Strzelec, K. Linseed oil as a natural modifier of rigid polyurethane foams. Ind. Crop. Prod. 2018, 115, 40–51. [Google Scholar] [CrossRef]

- Mehta, P.S.; Mehta, A.S.; Mehta, S.J.; Makhijani, A.B. Bhopal tragedy’s health effects: A review of methyl isocyanate toxicity. JAMA 1990, 264, 2781–2787. [Google Scholar] [CrossRef]

- Salmon, A.G.; Kerr Muir, M.; Andersson, N. Acute toxicity of methyl isocyanate: A preliminary study of the dose response for eye and other effects. Br. J. Ind. Med. 1985, 42, 795–798. [Google Scholar] [CrossRef] [Green Version]

- Hsieh, C.C.; Chen, Y.C. Synthesis of bio-based polyurethane foam modified with rosin using an environmentally-friendly process. J. Clean. Prod 2020, 276, 124203. [Google Scholar] [CrossRef]

- Chaudhari, A.; Kulkarni, R.; Mahulikar, P.; Sohn, D.; Gite, V. Development of PU coatings from neem oil based alkyds prepared by the monoglyceride route. J. Am. Oil Chem. Soc. 2015, 92, 733–741. [Google Scholar] [CrossRef]

- Lee, W.J.; Yu, C.Y.; Chen, Y.C. Preparation and characteristics of polyurethane made with polyhydric alcohol-liquefied rice husk. J. Appl. Polym. Sci. 2018, 135, 45910. [Google Scholar] [CrossRef]

- Zhang, Y.; Yan, R.; Ngo, T.-d.; Zhao, Q.; Duan, J.; Du, X.; Wang, Y.; Liu, B.; Sun, Z.; Hu, W.; et al. Ozone oxidized lignin-based polyurethane with improved properties. Eur. Polym. J. 2019, 117, 114–122. [Google Scholar] [CrossRef]

- Harikrishnan, G.; Khakhar, D.V. Effect of monomer temperature on foaming and properties of flexible polyurethane foams. J. Appl. Polym. Sci. 2007, 105, 3439–3443. [Google Scholar] [CrossRef]

- Choe, E.; Min, D.B. Mechanisms and factors for edible oil oxidation. Compr. Rev. Food Sci. Food Saf. 2006, 5, 169–186. [Google Scholar] [CrossRef]

- Chang, C.W.; Lu, K.T. Linseed-oil-based waterborne uv/air dual-cured wood coatings. Prog. Org. Coat. 2013, 76, 1024–1031. [Google Scholar] [CrossRef]

- Zhou, W.; Jia, P.; Zhou, Y.; Zhang, M. Preparation and characterization of tung oil-based flame retardant polyols. Chin. J. Chem. Eng. 2018, 26, 2664–2671. [Google Scholar] [CrossRef]

- Allauddin, S.; Narayan, R.; Raju, K.V.S.N. Synthesis and properties of alkoxysilane castor oil and their polyurethane/urea–silica hybrid coating films. Acs Sustain. Chem. Eng. 2013, 1, 910–918. [Google Scholar] [CrossRef]

- Zhang, J.; Hori, N.; Takemura, A. Influence of NCO/OH ratio on preparation of four agricultural wastes liquefied polyols based polyurethane foams. Polym. Degrad. Stab. 2020, 179, 109256. [Google Scholar] [CrossRef]

- Silva, B.B.R.; Santana, R.M.C.; Forte, M.M.C. A solventless castor oil-based PU adhesive for wood and foam substrates. Int. J. Adhes. Adhes. 2010, 30, 559–565. [Google Scholar] [CrossRef]

- Tilly, J.C.; Pervaje, A.K.; Inglefield, D.L.; Santiso, E.E.; Spontak, R.J.; Khan, S.A. Spectroscopic and rheological cross-analysis of polyester polyol cure behavior: Role of polyester secondary hydroxyl content. ACS Omega 2019, 4, 932–939. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Lin, W.T.; Lee, W.J. Effects of the NCO/OH molar ratio and the silica contained on the properties of waterborne polyurethane resins. Colloids Surf. Phys. Eng. Asp. 2017, 522, 453–460. [Google Scholar] [CrossRef]

- Hamilton, A.R.; Thomsen, O.T.; Madaleno, L.A.O.; Jensen, L.R.; Rauhe, J.C.M.; Pyrz, R. Evaluation of the anisotropic mechanical properties of reinforced polyurethane foams. Compos. Sci. Technol. 2013, 87, 210–217. [Google Scholar] [CrossRef] [Green Version]

- Gómez-Fernández, S.; Ugarte, L.; Calvo-Correas, T.; Peña-Rodríguez, C.; Corcuera, M.A.; Eceiza, A. Properties of flexible polyurethane foams containing isocyanate functionalized kraft lignin. Ind. Crop. Prod. 2017, 100, 51–64. [Google Scholar] [CrossRef]

- Dolomanova, V.; Rauhe, J.C.M.; Jensen, L.R.; Pyrz, R.; Timmons, A.B. Mechanical properties and morphology of nano-reinforced rigid pu foam. J. Cell. Plast. 2011, 47, 81–93. [Google Scholar] [CrossRef]

- Septevani, A.A.; Evans, D.A.C.; Martin, D.J.; Annamalai, P.K. Hybrid polyether-palm oil polyester polyol based rigid polyurethane foam reinforced with cellulose nanocrystal. Ind. Crop. Prod. 2018, 112, 378–388. [Google Scholar] [CrossRef]

- Caglayan, C.; Osken, I.; Ataalp, A.; Turkmen, H.S.; Cebeci, H. Impact response of shear thickening fluid filled polyurethane foam core sandwich composites. Compos. Struct. 2020, 243, 112171. [Google Scholar] [CrossRef]

- Wadekar, M.; Eevers, W.; Vendamme, R. Influencing the properties of ligninPU films by changing copolyol chain length, lignin content and nco/oh mol ratio. Ind. Crop. Prod. 2019, 141, 111655. [Google Scholar] [CrossRef]

- Chattopadhyay, D.K.; Webster, D.C. Thermal stability and flame retardancy of polyurethanes. Prog. Polym. Sci. 2009, 34, 1068–1133. [Google Scholar] [CrossRef]

- Dutta, S.; Karak, N. Effect of the NCO/OH ratio on the properties of mesua ferrea l. Seed oil-modified polyurethane resins. Polym. Int. 2006, 55, 49–56. [Google Scholar] [CrossRef]

- Ferreira, P.; Pereira, R.; Coelho, J.F.J.; Silva, A.F.M.; Gil, M.H. Modification of the biopolymer castor oil with free isocyanate groups to be applied as bioadhesive. Int. J. Biol. Macromol. 2007, 40, 144–152. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Malik, M.; Kaur, R. Mechanical and thermal properties of castor oil–based polyurethane adhesive: Effect of TiO2 filler. Adv. Polym. Tech. 2018, 37, 24–30. [Google Scholar] [CrossRef]

- Gu, R.; Konar, S.; Sain, M. Preparation and characterization of sustainable polyurethane foams from soybean oils. J. Am. Oil Chem. Soc. 2012, 89, 2103–2111. [Google Scholar] [CrossRef]

| Code | NCO/OH | Raw Materials (Parts by Weight) | ||||||

|---|---|---|---|---|---|---|---|---|

| Polyol | Isocyanate | Surfactant 2 | Catalyst 2 | Blowing Agent 2 | ||||

| Castor Oil | NOG 1 | Neem Oil | ||||||

| N1-0 | 1.0 | 100 | 0 | - | 49 | 4.0 | 4.0 | 4.0 |

| N1-1 | 100 | 6 | - | 54 | 4.3 | 4.3 | 4.3 | |

| N1-2 | 100 | 13 | - | 61 | 4.5 | 4.5 | 4.5 | |

| N2-0 | 1.5 | 100 | 0 | - | 73 | 4.0 | 4.0 | 4.0 |

| N2-1 | 100 | 6 | - | 81 | 4.3 | 4.3 | 4.3 | |

| N2-2 | 100 | 13 | - | 92 | 4.5 | 4.5 | 4.5 | |

| N3-0 | 2.0 | 100 | 0 | - | 98 | 4.0 | 4.0 | 4.0 |

| N3-1 | 100 | 6 | - | 109 | 4.3 | 4.3 | 4.3 | |

| N3-2 | 100 | 13 | - | 122 | 4.5 | 4.5 | 4.5 | |

| O1-2 | 1.3 | 100 | - | 13 | 61 | 4.5 | 4.5 | 4.5 |

| O2-2 | 1.9 | 100 | - | 13 | 92 | 4.5 | 4.5 | 4.5 |

| O3-2 | 2.5 | 100 | - | 13 | 122 | 4.5 | 4.5 | 4.5 |

| Code | Acid Value (mg KOH/g) | Hydroxyl Value (mg KOH/g) | Mw 2 (g/mol) | Mn 3 (g/mol) | Polydispersity (Mw/Mn) | Average Hydroxyl Content (mmol/g) |

|---|---|---|---|---|---|---|

| Castor oil | 2.1 ± 0.1 | 150.9 ± 4.6 | 1181 4 | 1150 4 | 1.0 | 2.7 |

| Neem oil | 7.2 ± 0 | 7.2 ± 0 | 1125 | 602 | 1.9 | 0.1 |

| NOG 1 | 2.3 ± 0.2 | 283.8 ± 5.0 | 1134 | 707 | 1.6 | 5.1 |

| Code | Relative Absorption Intensity * | |||

|---|---|---|---|---|

| Bonded Urethane (1686 cm−1) | Bonded Urea (1640 cm−1) | Amide II (1523 cm−1) | Amide III (1258 cm−1) | |

| N1-0 | 1.75 | 0.30 | 1.32 | 1.37 |

| N1-1 | 1.74 | 0.84 | 1.57 | 1.43 |

| N1-2 | 2.32 | 1.15 | 2.19 | 1.75 |

| N2-0 | 1.55 | 0.35 | 1.23 | 1.23 |

| N2-1 | 2.03 | 0.87 | 1.83 | 1.53 |

| N2-2 | 2.42 | 1.20 | 2.29 | 1.85 |

| N3-0 | 1.54 | 0.66 | 1.32 | 1.32 |

| N3-1 | 2.07 | 1.01 | 1.86 | 1.55 |

| N3-2 | 2.40 | 1.21 | 2.28 | 1.80 |

| O1-2 | 1.28 | 0.66 | 1.17 | 1.19 |

| O2-2 | 1.84 | 0.98 | 1.76 | 1.47 |

| O3-2 | 1.81 | 1.10 | 1.81 | 1.48 |

| Code | I | I’ | II | T10 3 (°C) | Char Yield 4 (%) | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Onset | Peak | WL 1 | PH 2 | Onset | Peak | WL | PH | Onset | Peak | WL | PH | |||

| (°C) | (°C) | (%) | (%/min) | (°C) | (°C) | (%) | (%/min) | (°C) | (°C) | (%) | (%/min) | |||

| N1-0 | 275 | 310 | 36.6 | 5.8 | 355 | 360 | 17.1 | 4.7 | 445 | 484 | 26.2 | 4.6 | 290 | 10.9 |

| N1-1 | 267 | 312 | 38.7 | 6.0 | 350 | 361 | 20.0 | 4.8 | 432 | 474 | 27.7 | 4.7 | 285 | 8.2 |

| N1-2 | 272 | 318 | 43.2 | 6.3 | 351 | 360 | 22.2 | 4.6 | 433 | 466 | 24.8 | 4.8 | 284 | 8.1 |

| O1-2 | 273 | 321 | 41.1 | 6.6 | 358 | 366 | 18.1 | 4.1 | 436 | 463 | 26.5 | 4.2 | 286 | 9.6 |

| N3-0 | 278 | 320 | 61.2 | 9.4 | - | - | - | - | 432 | 468 | 21.9 | 4.5 | 286 | 12.7 |

| N3-1 | 281 | 321 | 60.3 | 9.6 | - | - | - | - | 430 | 473 | 21.9 | 4.8 | 286 | 8.0 |

| N3-2 | 285 | 322 | 60.6 | 10.9 | - | - | - | - | 423 | 474 | 27.1 | 3.6 | 283 | 7.4 |

| O3-2 | 293 | 330 | 57.3 | 8.5 | - | - | - | - | 430 | 467 | 25.0 | 4.5 | 286 | 4.9 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liao, Y.-H.; Su, Y.-L.; Chen, Y.-C. The Influence of Neem Oil and Its Glyceride on the Structure and Characterization of Castor Oil-Based Polyurethane Foam. Polymers 2021, 13, 2020. https://doi.org/10.3390/polym13122020

Liao Y-H, Su Y-L, Chen Y-C. The Influence of Neem Oil and Its Glyceride on the Structure and Characterization of Castor Oil-Based Polyurethane Foam. Polymers. 2021; 13(12):2020. https://doi.org/10.3390/polym13122020

Chicago/Turabian StyleLiao, Yi-Han, You-Lin Su, and Yi-Chun Chen. 2021. "The Influence of Neem Oil and Its Glyceride on the Structure and Characterization of Castor Oil-Based Polyurethane Foam" Polymers 13, no. 12: 2020. https://doi.org/10.3390/polym13122020