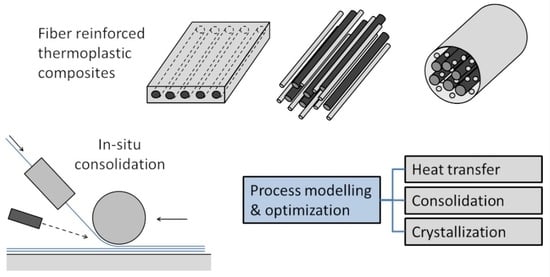

Review: Filament Winding and Automated Fiber Placement with In Situ Consolidation for Fiber Reinforced Thermoplastic Polymer Composites

Abstract

:1. Introduction

2. Manufacturing of FRTP Composites

2.1. Automated Fiber Placement

2.2. Filament Winding

3. Materials

4. Heat Sources for In Situ Consolidation

5. Modeling Heat Transfer

6. Modeling FRTP Consolidation

6.1. Consolidation of Prepreg Tapes

6.1.1. Intimate Contact Model

6.1.2. Autohesion Model

6.1.3. Bonding Model

6.2. Consolidation of Commingled Yarns

- is the viscosity of the thermoplastic matrix dependent on the temperature through an Arhennius law,

- is maximum fiber volume content (0.83 for carbon fibers [88]),

- is the pressure dependent fiber volume content,

- is the radius of the reinforcement fiber,

- is the applied pressure,

- is the atmospheric pressure, and

- is the transverse permeability constant through the fibers.

6.3. Consolidation of Powder Impregnated Fibers

7. Modeling Crystallization and Other Aspects of FRTP In Situ Consolidation

8. Studies on Factors Affecting In Situ Consolidation Quality

9. Future Perspectives

10. Concluding Remarks

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Boon, Y.D.; Joshi, S.C.; Ong, L.S. Interfacial bonding between CFRP and mechanically-treated aluminum liner surfaces for risers. Compos. Struct. 2018, 188, 374–386. [Google Scholar] [CrossRef]

- Ishikawa, T.; Amaoka, K.; Masubuchi, Y.; Yamamoto, T.; Yamanaka, A.; Arai, M.; Takahashi, J. Overview of automotive structural composites technology developments in Japan. Compos. Sci. Technol. 2018, 155, 221–246. [Google Scholar] [CrossRef]

- Bhudolia, S.K.; Perrotey, P.; Joshi, S.C. Experimental investigation on suitability of carbon fibre thin plies for racquets. Proc. Inst. Mech. Eng. Part P J. Sports Eng. Technol. 2015, 230, 64–72. [Google Scholar] [CrossRef]

- Arhant, M.; Davies, P. 2-Thermoplastic matrix composites for marine applications. In Marine Composites; Pemberton, R., Summerscales, J., Graham-Jones, J., Eds.; Woodhead Publishing: Cambridge, UK, 2019; pp. 31–53. [Google Scholar]

- Mahieux, C.A. Cost effective manufacturing process of thermoplastic matrix composites for the traditional industry: The example of a carbon-fiber reinforced thermoplastic flywheel. Compos. Struct. 2001, 52, 517–521. [Google Scholar] [CrossRef]

- Arhant, M.; Briançon, C.; Burtin, C.; Davies, P. Carbon/Polyamide 6 thermoplastic composite cylinders for deep sea applications. Compos. Struct. 2019, 212, 535–546. [Google Scholar] [CrossRef] [Green Version]

- Khennane, A. 8-Filament winding processes in the manufacture of advanced fibre-reinforced polymer (FRP) composites. In Advanced Fibre-Reinforced Polymer (FRP) Composites for Structural Applications; Bai, J., Ed.; Woodhead Publishing: Cambridge, UK, 2013; pp. 187–206. [Google Scholar]

- Beland, S. High Performance Thermoplastic Resins and Their Composites; Noyes Data Corporation: Park Ridge, NJ, USA, 1990. [Google Scholar]

- Chang, I.Y.; Lees, J.K. Recent development in thermoplastic composites: A review of matrix systems and processing methods. J. Thermoplast. Compos. Mater. 1988, 1, 277–296. [Google Scholar] [CrossRef]

- Fernández, I.; Blas, F.; Frövel, M. Autoclave forming of thermoplastic composite parts. J. Mater. Process. Technol. 2003, 143–144, 266–269. [Google Scholar] [CrossRef]

- Sherwood, J.A.; Fetfatsidis, K.A.; Gorczyca, J.L. 6-Fabric thermostamping in polymer matrix composites. In Manufacturing Techniques for Polymer Matrix Composites (PMCs); Advani, S.G., Hsiao, K.-T., Eds.; Woodhead Publishing: Cambridge, UK, 2012; pp. 139–181. [Google Scholar]

- Kozaczuk, K. Automated fiber placement systems overview. Trans. Inst. Aviat. 2016, 4, 52–59. [Google Scholar] [CrossRef]

- Denkena, B.; Schmidt, C.; Weber, P. Automated fiber placement head for manufacturing of innovative aerospace stiffening structures. Procedia Manuf. 2016, 6, 96–104. [Google Scholar] [CrossRef] [Green Version]

- Peeters, D.; Clancy, G.; Oliveri, V.; O’Higgins, R.; Jones, D.; Weaver, P.M. Concurrent design and manufacture of a thermoplastic composite stiffener. Compos. Struct. 2019, 212, 271–280. [Google Scholar] [CrossRef]

- He, K.; Nie, H.; Yan, C. The intelligent composite panels manufacturing technology based on tape-laying automatic system. Procedia CIRP 2016, 56, 610–613. [Google Scholar] [CrossRef] [Green Version]

- Sacco, C.; Baz Radwan, A.; Anderson, A.; Harik, R.; Gregory, E. Machine learning in composites manufacturing: A case study of automated fiber placement inspection. Compos. Struct. 2020, 250, 112514. [Google Scholar] [CrossRef]

- Croft, K.; Lessard, L.; Pasini, D.; Hojjati, M.; Chen, J.; Yousefpour, A. Experimental study of the effect of automated fiber placement induced defects on performance of composite laminates. Compos. Part A Appl. Sci. Manuf. 2011, 42, 484–491. [Google Scholar] [CrossRef] [Green Version]

- Nguyen, M.H.; Vijayachandran, A.A.; Davidson, P.; Call, D.; Lee, D.; Waas, A.M. Effect of automated fiber placement (AFP) manufacturing signature on mechanical performance of composite structures. Compos. Struct. 2019, 228, 111335. [Google Scholar] [CrossRef]

- Zhang, P.; Sun, R.; Zhao, X.; Hu, L. Placement suitability criteria of composite tape for mould surface in automated tape placement. Chin. J. Aeronaut. 2015, 28, 1574–1581. [Google Scholar] [CrossRef] [Green Version]

- Oromiehie, E.; Prusty, B.G.; Compston, P.; Rajan, G. Automated fibre placement based composite structures: Review on the defects, impacts and inspections techniques. Compos. Struct. 2019, 224, 110987. [Google Scholar] [CrossRef]

- Dhinakaran, V.; Surendar, K.V.; Hasunfur Riyaz, M.S.; Ravichandran, M. Review on study of thermosetting and thermoplastic materials in the automated fiber placement process. Mater. Today Proc. 2020, 27, 812–815. [Google Scholar] [CrossRef]

- Gonzalez Henriquez, R.; Mertiny, P. 3.21 Filament winding applications. In Comprehensive Composite Materials II; Beaumont, P.W.R., Zweben, C.H., Eds.; Elsevier: Oxford, UK, 2018; pp. 556–577. [Google Scholar]

- Bhudolia, S.; Fischer, S.; He, P.; Yue, C.Y.; Joshi, S.C.; Yang, J. Design, manufacturing and testing of filament wound composite risers for marine and offshore applications. Mater. Sci. Forum 2015, 813, 337–343. [Google Scholar]

- Sorrentino, L.; Anamateros, E.; Bellini, C.; Carrino, L.; Corcione, G.; Leone, A.; Paris, G. Robotic filament winding: An innovative technology to manufacture complex shape structural parts. Compos. Struct. 2019, 220, 699–707. [Google Scholar] [CrossRef]

- Beck, B.; Tawfik, H.; Haas, J.; Park, Y.B.; Henning, F. Automated 3D skeleton winding process for continuous-fiber-reinforcements in structural thermoplastic components. In Advances in Polymer Processing 2020, Proceedings of the International Symposium on Plastics Technology, Aachen, Germany, 10 March 2020; Springer: Berlin/Heidelberg, Germany, 2020; pp. 150–161. [Google Scholar]

- Wiegand, N.; Mäder, E. Commingled yarn spinning for thermoplastic/glass fiber composites. Fibers 2017, 5, 26. [Google Scholar] [CrossRef] [Green Version]

- Boon, Y.D.; Joshi, S.C. A review of methods for improving interlaminar interfaces and fracture toughness of laminated composites. Mater. Today Commun. 2020, 22, 100830. [Google Scholar] [CrossRef]

- Gabrion, X.; Placet, V.; Trivaudey, F.; Boubakar, L. About the thermomechanical behaviour of a carbon fibre reinforced high-temperature thermoplastic composite. Compos. Part B Eng. 2016, 95, 386–394. [Google Scholar] [CrossRef] [Green Version]

- Mack, J.; Schledjewski, R. 7-Filament winding process in thermoplastics. In Manufacturing Techniques for Polymer Matrix Composites (PMCs); Advani, S.G., Hsiao, K.-T., Eds.; Woodhead Publishing: Cambridge, UK, 2012; pp. 182–208. [Google Scholar]

- Volk, M.; Wong, J.; Arreguin, S.; Bar, C.; Schmuck, F.; Ermanni, P. Thermoplastic composite materials for high voltage insulator applications. In Proceedings of the ECCM18—18th European Conference on Composite Materials, Athens, Greece, 25–28 June 2018. [Google Scholar]

- Iannone, V.; Barile, M.; Lecce, L. Automated fabrication of hybrid thermoplastic prepreg material to be processed by in-situ consolidation automated fiber placement process. MATEC Web Conf. 2018, 188, 01024. [Google Scholar] [CrossRef]

- Friedrich, K. Commingled yarns and their use for composites. In Polypropylene: An A–Z Reference; Karger-Kocsis, J., Ed.; Springer: Dordrecht, The Netherlands, 1999; pp. 81–89. [Google Scholar]

- Bernet, N.; Michaud, V.; Bourban, P.E.; Månson, J.A.E. Commingled yarn composites for rapid processing of complex shapes. Compos. Part A Appl. Sci. Manuf. 2001, 32, 1613–1626. [Google Scholar] [CrossRef]

- Thomann, U.I.; Ermanni, P. The influence of yarn structure and processing conditions on the laminate quality of stampformed carbon and thermoplastic polymer fiber commingled yarns. J. Thermoplast. Compos. Mater. 2004, 17, 259–283. [Google Scholar] [CrossRef]

- Lionetto, F.; Dell’Anna, R.; Montagna, F.; Maffezzoli, A. Modeling of continuous ultrasonic impregnation and consolidation of thermoplastic matrix composites. Compos. Part A Appl. Sci. Manuf. 2016, 82, 119–129. [Google Scholar] [CrossRef]

- Wong, J.C.H.; Blanco, J.M.; Ermanni, P. Filament winding of aramid/PA6 commingled yarns with in situ consolidation. J. Thermoplast. Compos. Mater. 2017, 31, 465–482. [Google Scholar] [CrossRef]

- Vodermayer, A.M.; Kaerger, J.C.; Hinrichsen, G. Manufacture of high performance fibre-reinforced thermoplastics by aqueous powder impregnation. Compos. Manuf. 1993, 4, 123–132. [Google Scholar] [CrossRef]

- Goud, V.; Alagirusamy, R.; Das, A.; Kalyanasundaram, D. Dry electrostatic spray coated towpregs for thermoplastic composites. Fibers Polym. 2018, 19, 364–374. [Google Scholar] [CrossRef]

- Henninger, F.; Friedrich, K. Thermoplastic filament winding with online-impregnation. Part A: Process technology and operating efficiency. Compos. Part A Appl. Sci. Manuf. 2002, 33, 1479–1486. [Google Scholar] [CrossRef]

- Henninger, F.; Hoffmann, J.; Friedrich, K. Thermoplastic filament winding with online-impregnation. Part B. Experimental study of processing parameters. Compos. Part A Appl. Sci. Manuf. 2002, 33, 1684–1695. [Google Scholar] [CrossRef]

- Grouve, W.J.B.; Warnet, L.L.; Rietman, B.; Visser, H.A.; Akkerman, R. Optimization of the tape placement process parameters for carbon–PPS composites. Compos. Part A Appl. Sci. Manuf. 2013, 50, 44–53. [Google Scholar] [CrossRef]

- Agarwal, V.; McCullough, R.L.; Schultz, J.M. The thermoplastic laser-assisted consolidation process-mechanical and microstructure characterization. J. Thermoplast. Compos. Mater. 1996, 9, 365–380. [Google Scholar] [CrossRef]

- Funck, R.; Neitzel, M. Improved thermoplastic tape winding using laser or direct-flame heating. Compos. Manuf. 1995, 6, 189–192. [Google Scholar] [CrossRef]

- Yassin, K.; Hojjati, M. Processing of thermoplastic matrix composites through automated fiber placement and tape laying methods:A review. J. Thermoplast. Compos. Mater. 2018, 31, 1676–1725. [Google Scholar] [CrossRef]

- Tafreshi, O.A.; Hoa, S.V.; Shadmehri, F.; Hoang, D.M.; Rosca, D. Determination of convective heat transfer coefficient for automated fiber placement (AFP) for thermoplastic composites using hot gas torch. Adv. Manuf. Polym. Compos. Sci. 2020, 6, 86–100. [Google Scholar] [CrossRef]

- Rizzolo, R.H.; Walczyk, D.F. Ultrasonic consolidation of thermoplastic composite prepreg for automated fiber placement. J. Thermoplast. Compos. Mater. 2015, 29, 1480–1497. [Google Scholar] [CrossRef]

- Lauke, B.; Friedrich, K. Evaluation of processing parameters of thermoplastic composites fabricated by filament winding. Compos. Manuf. 1993, 4, 93–101. [Google Scholar] [CrossRef]

- Hoa, S.V.; Hoang, M.D.; Simpson, J. Manufacturing procedure to make flat thermoplastic composite laminates by automated fibre placement and their mechanical properties. J. Thermoplast. Compos. Mater. 2017, 30, 1693–1712. [Google Scholar] [CrossRef]

- Romagna, J.; Ziegmann, G.; Flemming, M. Thermoplastic filament winding—An experimental investigation of the on-line consolidation of poly(ether imide) fit preforms. Compos. Manuf. 1995, 6, 205–210. [Google Scholar] [CrossRef]

- Deden, D.; Bruckner, F.; Brandt, L.; Fischer, F. Comparison of heat sources for automated dry fibre placement: Xenon flashlamp vs. infrared heating. In Proceedings of the 22nd International Conference on Composites Materials ICCM22, Melbourne, Australia, 11–16 August 2019. [Google Scholar]

- Comer, A.J.; Ray, D.; Obande, W.O.; Jones, D.; Lyons, J.; Rosca, I.; O’ Higgins, R.M.; McCarthy, M.A. Mechanical characterisation of carbon fibre—PEEK manufactured by laser-assisted automated-tape-placement and autoclave. Compos. Part A Appl. Sci. Manuf. 2015, 69, 10–20. [Google Scholar] [CrossRef]

- Stokes-Griffin, C.M.; Compston, P. The effect of processing temperature and placement rate on the short beam strength of carbon fibre–PEEK manufactured using a laser tape placement process. Compos. Part A Appl. Sci. Manuf. 2015, 78, 274–283. [Google Scholar] [CrossRef]

- Stokes-Griffin, C.M.; Kollmannsberger, A.; Compston, P.; Drechsler, K. The effect of processing temperature on wedge peel strength of CF/PA6 laminates manufactured in a laser tape placement process. Compos. Part A Appl. Sci. Manuf. 2019, 121, 84–91. [Google Scholar] [CrossRef]

- Stokes-Griffin, C.M.; Compston, P. A combined optical-thermal model for near-infrared laser heating of thermoplastic composites in an automated tape placement process. Compos. Part A Appl. Sci. Manuf. 2015, 75, 104–115. [Google Scholar] [CrossRef]

- Bhudolia, S.K.; Gohel, G.; Leong, K.F.; Islam, A. Advances in ultrasonic welding of thermoplastic composites: A review. Materials 2020, 13, 1284. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Chu, Q.; Li, Y.; Xiao, J.; Huan, D.; Zhang, X.; Chen, X. Processing and characterization of the thermoplastic composites manufactured by ultrasonic vibration-assisted automated fiber placement. J. Thermoplast. Compos. Mater. 2017, 31, 339–358. [Google Scholar] [CrossRef]

- Dell’Anna, R.; Lionetto, F.; Montagna, F.; Maffezzoli, A. Lay-Up and consolidation of a composite pipe by in situ ultrasonic welding of a thermoplastic matrix composite tape. Materials 2018, 11, 786. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Heraeus Noblelight. humm3®—Intelligent Heat for Automated Fibre Placement (AFP). Available online: https://www.heraeus.com/en/hng/products_and_solutions/arc_and_flash_lamps/humm3/humm3.html (accessed on 29 April 2020).

- Nguyen, C.; Kolbe, A.; Bans, C. Application of lightning strike protection on thermoplastic structures by automated fiber placement. In Proceedings of the 5th International Conference and Exhibition on Thermoplastic Composites ITHEC, Bremen, Germany, 13–14 October 2020. [Google Scholar]

- Whitaker, S. Fundamental Principles of Heat Transfer; Pergamon Press Inc.: Elmsford, NY, USA, 1977. [Google Scholar]

- Sonmez, F.O.; Hahn, H.T. Modeling of heat transfer and crystallization in thermoplastic composite tape placement process. J. Thermoplast. Compos. Mater. 1997, 10, 198–240. [Google Scholar] [CrossRef]

- Weiler, T.; Emonts, M.; Wollenburg, L.; Janssen, H. Transient thermal analysis of laser-assisted thermoplastic tape placement at high process speeds by use of analytical solutions. J. Thermoplast. Compos. Mater. 2017, 31, 311–338. [Google Scholar] [CrossRef]

- Stokes-Griffin, C.M.; Compston, P.; Matuszyk, T.I.; Cardew-Hall, M.J. Thermal modelling of the laser-assisted thermoplastic tape placement process. J. Thermoplast. Compos. Mater. 2013, 28, 1445–1462. [Google Scholar] [CrossRef]

- Baho, O.; Ausias, G.; Grohens, Y.; Férec, J. Simulation of laser heating distribution for a thermoplastic composite: Effects of AFP head parameters. Int. J. Adv. Manuf. Technol. 2020, 110, 2105–2117. [Google Scholar] [CrossRef]

- Venkateshan, S.P. Heat Transfer, 3rd ed.; ANE Books Pvt. Ltd.: New Delhi, India; Springer: Cham, Switzerland, 2021. [Google Scholar]

- Liu, X.L.; Han, Z.Y.; Zhao, Z.Y.; Sun, S.Z. Thermal analysis of cylindrical molds using thermoplastic composite during robotic fiber placement. J. Phys. Conf. Ser. 2021, 1765, 012023. [Google Scholar] [CrossRef]

- Cao, Z.; Dong, M.; Liu, K.; Fu, H. Temperature field in the heat transfer process of PEEK thermoplastic composite fiber placement. Materials 2020, 13, 4417. [Google Scholar] [CrossRef]

- Tafreshi, O.A.; Hoa, S.V.; Shadmehri, F.; Hoang, D.M.; Rosca, D. Heat transfer analysis of automated fiber placement of thermoplastic composites using a hot gas torch. Adv. Manuf. Polym. Compos. Sci. 2019, 5, 206–223. [Google Scholar] [CrossRef] [Green Version]

- Zacherl, L.; Shadmehri, F.; Rother, K. Determination of convective heat transfer coefficient for hot gas torch (HGT)-assisted automated fiber placement (AFP) for thermoplastic composites. J. Thermoplast. Compos. Mater. 2021. [Google Scholar] [CrossRef]

- Agarwal, V.; Guçeri, S.I.; McCullough, R.L.; Schultz, J.M. Thermal characterization of the laser-assisted consolidation process. J. Thermoplast. Compos. Mater. 1992, 5, 115–135. [Google Scholar] [CrossRef]

- Kollmannsberger, A.; Lichtinger, R.; Hohenester, F.; Ebel, C.; Drechsler, K. Numerical analysis of the temperature profile during the laser-assisted automated fiber placement of CFRP tapes with thermoplastic matrix. J. Thermoplast. Compos. Mater. 2017, 31, 1563–1586. [Google Scholar] [CrossRef]

- Song, X. Modeling of Thermoplastic Composite Filament Winding. Master’s Thesis, Virginia Polytechnic Institute and State University, Blacksburg, VA, USA, 2000. [Google Scholar]

- Fricke, D.; Fischer, F. Process simulation of the in-situ automated fiber placement process for thermoplastic composites. In Proceedings of the SAMPE Europe Conference, Amsterdam, The Netherlands, 30 September–1 October 2020. [Google Scholar]

- Dara, P.H.; Loos, A.C. Thermoplastic Matrix Composite Processing Model; Center for Composite Materials and Structures, Virginia Polytechnic Institute and State University: Blacksburg, VA, USA, 1985. [Google Scholar]

- Loos, A.C.; Dara, P.H. Processing of thermoplastic matrix composites. In Review of Progress in Quantitative Nondestructive Evaluation; Springer: Boston, MA, USA, 1987; pp. 1257–1265. [Google Scholar]

- Lee, W.I.; Springer, G.S. A model of the manufacturing process of thermoplastic matrix composites. J. Compos. Mater. 1987, 21, 1017–1055. [Google Scholar] [CrossRef]

- Mantell, S.C.; Springer, G.S. Manufacturing process models for thermoplastic composites. J. Compos. Mater. 1992, 26, 2348–2377. [Google Scholar] [CrossRef]

- Yang, F.; Pitchumani, R. A fractal Cantor set based description of interlaminar contact evolution during thermoplastic composites processing. J. Mater. Sci. 2001, 36, 4661–4671. [Google Scholar] [CrossRef]

- Stokes-Griffin, C.M.; Compston, P. Investigation of sub-melt temperature bonding of carbon-fibre/PEEK in an automated laser tape placement process. Compos. Part A Appl. Sci. Manuf. 2016, 84, 17–25. [Google Scholar] [CrossRef]

- Yang, F.; Pitchumani, R. Healing of thermoplastic polymers at an interface under nonisothermal conditions. Macromolecules 2002, 35, 3213–3224. [Google Scholar] [CrossRef]

- Boiko, Y.M.; Guérin, G.; Marikhin, V.A.; Prud’homme, R.E. Healing of interfaces of amorphous and semi-crystalline poly(ethylene terephthalate) in the vicinity of the glass transition temperature. Polymer 2001, 42, 8695–8702. [Google Scholar] [CrossRef]

- De Gennes, P.G. Reptation of a polymer chain in the presence of fixed obstacles. J. Chem. Phys. 1971, 55, 572–579. [Google Scholar] [CrossRef]

- Kim, Y.H.; Wool, R.P. A theory of healing at a polymer-polymer interface. Macromolecules 1983, 16, 1115–1120. [Google Scholar] [CrossRef]

- Wool, R.P.; Yuan, B.-L.; McGarel, O.J. Welding of polymer interfaces. Polym. Eng. Sci. 1989, 29, 1340–1367. [Google Scholar] [CrossRef]

- Yang, F.; Pitchumani, R. Nonisothermal healing and interlaminar bond strength evolution during thermoplastic matrix composites processing. Polym. Compos. 2003, 24, 263–278. [Google Scholar] [CrossRef]

- Bernet, N.; Michaud, V.; Bourban, P.E.; Manson, J.A.E. An impregnation model for the consolidation of thermoplastic composites made from commingled yarns. J. Compos. Mater. 1999, 33, 751–772. [Google Scholar] [CrossRef]

- Klinkmüller, V.; Um, M.K.; Steffens, M.; Friedrich, K.; Kim, B.S. A new model for impregnation mechanisms in different GF/PP commingled yarns. Appl. Compos. Mater. 1994, 1, 351–371. [Google Scholar] [CrossRef]

- Gutowski, T.G.; Cai, Z.; Bauer, S.; Boucher, D.; Kingery, J.; Wineman, S. Consolidation experiments for laminate composites. J. Compos. Mater. 1987, 21, 650–669. [Google Scholar] [CrossRef]

- Ye, L.; Friedrich, K.; Kästel, J. Consolidation of GF/PP commingled yarn composites. Appl. Compos. Mater. 1994, 1, 415–429. [Google Scholar] [CrossRef]

- Gebart, B.R. Permeability of unidirectional reinforcements for RTM. J. Compos. Mater. 1992, 26, 1100–1133. [Google Scholar] [CrossRef]

- Ye, L.; Klinkmuller, V.; Friedrich, K. Impregnation and consolidation in composites made of GF/PP powder impregnated bundles. J. Thermoplast. Compos. Mater. 1992, 5, 32–48. [Google Scholar] [CrossRef]

- Steggall-Murphy, C.; Simacek, P.; Advani, S.G.; Yarlagadda, S.; Walsh, S. A model for thermoplastic melt impregnation of fiber bundles during consolidation of powder-impregnated continuous fiber composites. Compos. Part A Appl. Sci. Manuf. 2010, 41, 93–100. [Google Scholar] [CrossRef]

- Connor, M.; Toll, S.; Månson, J.A.E.; Gibson, A.G. A Model for the consolidation of aligned thermoplastic powder impregnated composites. J. Thermoplast. Compos. Mater. 1995, 8, 138–162. [Google Scholar] [CrossRef]

- Chanteli, A.; Bandaru, A.K.; Peeters, D.; O’Higgins, R.M.; Weaver, P.M. Influence of repass treatment on carbon fibre-reinforced PEEK composites manufactured using laser-assisted automatic tape placement. Compos. Struct. 2020, 248, 112539. [Google Scholar] [CrossRef]

- Shadmehri, F.; Hoa, S.V.; Fortin-Simpson, J.; Ghayoor, H. Effect of in situ treatment on the quality of flat thermoplastic composite plates made by automated fiber placement (AFP). Adv. Manuf. Polym. Compos. Sci. 2018, 4, 41–47. [Google Scholar] [CrossRef] [Green Version]

- Ozawa, T. Kinetics of non-isothermal crystallization. Polymer 1971, 12, 150–158. [Google Scholar] [CrossRef]

- Joshi, S.C.; Lam, Y.C. Integrated approach for modelling cure and crystallization kinetics of different polymers in 3D pultrusion simulation. J. Mater. Process. Technol. 2006, 174, 178–182. [Google Scholar] [CrossRef]

- Choe, C.R.; Lee, K.H. Nonisothermal crystallization kinetics of poly(etheretherketone) (PEEK). Polym. Eng. Sci. 1989, 29, 801–805. [Google Scholar] [CrossRef]

- Tobin, M.C. Theory of phase transition kinetics with growth site impingement. I. Homogeneous nucleation. J. Polym. Sci. Polym. Phys. Ed. 1974, 12, 399–406. [Google Scholar] [CrossRef]

- Tobin, M.C. The theory of phase transition kinetics with growth site impingement. II. Heterogeneous nucleation. J. Polym. Sci. Polym. Phys. Ed. 1976, 14, 2253–2257. [Google Scholar] [CrossRef]

- Tobin, M.C. Theory of phase transition kinetics with growth site impingement. III. Mixed heterogeneous-homogeneous nucleation and nonintegral exponents of the time. J. Polym. Sci. Polym. Phys. Ed. 1977, 15, 2269–2270. [Google Scholar] [CrossRef]

- Maffezzoli, A.M.; Kenny, J.M.; Nicolais, L. Welding of PEEK/carbon fiber composite laminates. SAMPE J. 1989, 25, 35–39. [Google Scholar]

- Gordnian, K. Crystallization and Thermo-Viscoelastic Modelling of Polymer Composites. Ph.D. Thesis, The University of British Columbia, Vancouver, BC, Canada, 2017. [Google Scholar]

- Schlottermuller, M.; Lu, H.; Roth, Y.; Himmel, N.; Schledjewski, R.; Mitschang, P. Thermal residual stress simulation in thermoplastic filament winding process. J. Thermoplast. Compos. Mater. 2003, 16, 497–519. [Google Scholar] [CrossRef]

- Dedieu, C.; Barasinski, A.; Chinesta, F.; Dupillier, J.-M. About the origins of residual stresses in in situ consolidated thermoplastic composite rings. Int. J. Mater. Form. 2017, 10, 779–792. [Google Scholar] [CrossRef]

- Nam, J.-D.; Seferis, J.C. Generalized composite degradation kinetics for polymeric systems under isothermal and nonisothermal conditions. J. Polym. Sci. Part B Polym. Phys. 1992, 30, 455–463. [Google Scholar] [CrossRef]

- Sonmez, F.O.; Hahn, H.T. Analysis of the on-line consolidation process in thermoplastic composite tape placement. J. Thermoplast. Compos. Mater. 1997, 10, 543–572. [Google Scholar] [CrossRef]

- Doan, H.G.M.; Mertiny, P. Creep testing of thermoplastic fiber-reinforced polymer composite tubular coupons. Materials 2020, 13, 4637. [Google Scholar] [CrossRef] [PubMed]

- Samak, S.; Risteska, S.; Dukovski, V.; Trajkoski, S. Some experimental investigation of products from thermoplastic composite materials manufactured with robot and LAFP. Int. J. Eng. Res. Technol. 2020, 9, 1082–1088. [Google Scholar]

- Zhao, P.; Shirinzadeh, B.; Shi, Y.; Cheuk, S.; Clark, L. Multi-Pass layup process for thermoplastic composites using robotic fiber placement. Robot. Comput. Integr. Manuf. 2018, 49, 277–284. [Google Scholar] [CrossRef]

- Dobrzanski, L.A.; Domagala, J.; Silva, J.F. Application of Taguchi method in the optimisation of filament winding of thermoplastic composites. Arch. Mater. Sci. Eng. 2007, 28, 133–140. [Google Scholar]

- Clancy, G.; Peeters, D.; Oliveri, V.; Jones, D.; O’Higgins, R.M.; Weaver, P.M. A study of the influence of processing parameters on steering of carbon Fibre/PEEK tapes using laser-assisted tape placement. Compos. Part B Eng. 2019, 163, 243–251. [Google Scholar] [CrossRef]

- Zenker, T.; Gnaedinger, M. Consolidation behavior of fiber steered thermoplastic automated fiber placement preforms. In Proceedings of the 5th International Conference and Exhibition on Thermoplastic Composites ITHEC, Bremen, Germany, 13–14 October 2020. [Google Scholar]

- Tannous, M.; Barasinski, A.; Binetruy, C.; Courtemanche, B. Contribution of thermo-mechanical parameters and friction to the bonding of thermoplastic tapes in the tape winding process. J. Mater. Process. Technol. 2016, 229, 587–595. [Google Scholar] [CrossRef]

- Kollmannsberger, A. Heating Characteristics of Fixed Focus Laser Assisted Thermoplastic-Automated Fiber Placement of 2D and 3D Parts. Ph.D. Thesis, Technische Universitat Munchen, Munich, Germany, 2019. [Google Scholar]

- Gennaro, R.; Montagna, F.; Maffezzoli, A.; Fracasso, F.; Fracasso, S. On-Line consolidation of commingled polypropylene/glass roving during filament winding. J. Thermoplast. Compos. Mater. 2011, 24, 789–804. [Google Scholar] [CrossRef]

- Engelhardt, R.; Ehard, S.; Wolf, T.; Oelhafen, J.; Kollmannsberger, A.; Drechsler, K. In situ joining of unidirectional tapes on long fiber reinforced thermoplastic structures by thermoplastic automated fiber placement for scientific sounding rocket applications. Procedia CIRP 2019, 85, 189–194. [Google Scholar] [CrossRef]

- Frketic, J.; Dickens, T.; Ramakrishnan, S. Automated manufacturing and processing of fiber-reinforced polymer (FRP) composites: An additive review of contemporary and modern techniques for advanced materials manufacturing. Addit. Manuf. 2017, 14, 69–86. [Google Scholar] [CrossRef] [Green Version]

- Boon, Y.D.; Joshi, S.C.; Bhudolia, S.K.; Gohel, G. Recent advances on the design automation for performance-optimized fiber reinforced polymer composite components. J. Compos. Sci. 2020, 4, 61. [Google Scholar] [CrossRef]

- Sun, S.; Han, Z.; Zhang, J.; Jin, H.; Wang, Y. Multiscale collaborative process optimization method for automated fiber placement. Compos. Struct. 2021, 259, 113215. [Google Scholar] [CrossRef]

- Bhudolia, S.K.; Kam, K.K.C.; Perrotey, P.; Joshi, S.C. Effect of fixation stitches on out-of-plane response of textile non-crimp fabric composites. J. Ind. Text. 2018, 48, 1151–1166. [Google Scholar] [CrossRef]

- Bhudolia, S.K.; Joshi, S.C.; Bert, A.; Gohel, G.R.; Raama, M. Energy characteristics and failure mechanisms for textile spread tow thin ply thermoplastic composites under low-velocity impact. Fibers Polym. 2019, 20, 1716–1725. [Google Scholar] [CrossRef]

- Cugnoni, J.; Amacher, R.; Kohler, S.; Brunner, J.; Kramer, E.; Dransfeld, C.; Smith, W.; Scobbie, K.; Sorensen, L.; Botsis, J. Towards aerospace grade thin-ply composites: Effect of ply thickness, fibre, matrix and interlayer toughening on strength and damage tolerance. Compos. Sci. Technol. 2018, 168, 467–477. [Google Scholar] [CrossRef]

- Bhudolia, S.K.; Gohel, G.; Leong, K.F.; Joshi, S.C. Damping, impact and flexural performance of novel carbon/Elium® thermoplastic tubular composites. Compos. Part B Eng. 2020, 203, 108480. [Google Scholar] [CrossRef]

- Bhudolia, S.; Joshi, S.; Bert, A.; Boon, Y.D.; Makam, R.; Gohel, G. Flexural characteristics of novel carbon methylmethacrylate composites. Compos. Commun. 2019, 13. [Google Scholar] [CrossRef]

- Bhudolia, S.K.; Joshi, S.C. Low-Velocity impact response of carbon fibre composites with novel liquid Methylmethacrylate thermoplastic matrix. Compos. Struct. 2018, 203, 696–708. [Google Scholar] [CrossRef]

- Bhudolia, S.K.; Perrotey, P.; Joshi, S.C. Mode I fracture toughness and fractographic investigation of carbon fibre composites with liquid Methylmethacrylate thermoplastic matrix. Compos. Part B Eng. 2018, 134, 246–253. [Google Scholar] [CrossRef]

- Bhudolia, S.K.; Gohel, G.; Joshi, S.C.; Leong, K.F. Quasi-Static indentation response of core-shell particle reinforced novel NCCF/Elium® composites at different feed rates. Compos. Commun. 2020, 21, 100383. [Google Scholar] [CrossRef]

- Ricard, T. Automated preform manufacture at an affordable price. Reinf. Plast. 2017, 61, 149–152. [Google Scholar] [CrossRef]

- Casanovas, J.; Costa, J.; Mayugo, J.A.; Llongueras, A. Fabrication of hybrid thin ply tapes. IOP Conf. Ser. Mater. Sci. Eng. 2018, 406, 012067. [Google Scholar] [CrossRef]

- Galos, J. Thin-Ply composite laminates: A review. Compos. Struct. 2020, 236, 111920. [Google Scholar] [CrossRef]

- Yamashita, S.; Hirano, Y.; Sonehara, T.; Takahashi, J.; Kawabe, K.; Murakami, T. Residual mechanical properties of carbon fibre reinforced thermoplastics with thin-ply prepreg after simulated lightning strike. Compos. Part A Appl. Sci. Manuf. 2017, 101, 185–194. [Google Scholar] [CrossRef]

- Kazemi, M.E.; Shanmugam, L.; Li, Z.; Ma, R.; Yang, L.; Yang, J. Low-Velocity impact behaviors of a fully thermoplastic composite laminate fabricated with an innovative acrylic resin. Compos. Struct. 2020, 250, 112604. [Google Scholar] [CrossRef]

- Bhudolia, S.K.; Gohel, G.; Kah Fai, L.; Barsotti, R.J. Fatigue response of ultrasonically welded carbon/Elium® thermoplastic composites. Mater. Lett. 2020, 264, 127362. [Google Scholar] [CrossRef]

- Arkema. Elium Resin: A Disruptive Innovation in the World of Composites? Available online: https://www.arkema.com/global/en/webzine/post/elium-resin-a-disruptive-innovation-in-the-world-of-composites/ (accessed on 6 June 2021).

| Year | Matrix | Material form | Process | Heat Source | Nip Point Temperature (°C) | Line Speed (mm/s) | Compaction Force/Pressure | Other Processing Parameters | Physical and Mechanical Properties Studied | Ref. |

|---|---|---|---|---|---|---|---|---|---|---|

| 2017 | PA6 | Aramid/PA6 commingled yarns | FW | Hot gas torch | 320 | 10 | 190 N | Preheating of yarns to 330 °C | Void content, SBS strength, flexural modulus | [36] |

| 2019 | PA6 | Carbon/PA6 prepreg tapes | AFP | NIR diode laser | 260 | 100 | 130 N | Wedge peel strength | [53] | |

| 2019 | PA6 | Carbon/PA6 prepreg tapes | FW | Laser | 280 (hoop layer), 300 (axial layer) | 105 (hoop layer), 50 (axial layer) | 0.3 MPa | Void content, compression modulus, implosion strength (for composite tube) | [6] | |

| 1993 | PA12 | Glass/PA12 powder impregnated fibers | FW | Hot gas torch | 360 | 25 | 157 N | IR preheating of fibers at power 9.6 kW, mandrel temperature 100 °C | Interlaminar shear, fracture toughness (from DCB tests) | [47] |

| 2016 | PP | E-glass/PP commingled yarns | FW | Ultrasonic welding | 223 | 52.5 | 85 N (applied at sonotrode) | Compaction roller located 45 mm from the sonotrode | Void content, shear modulus | [35] |

| 2017 | PP | E-glass/PP prepreg tapes | AFP | Ultrasonic welding | 260 | 1 | 0.15 MPa (applied at compaction roller) | Ultrasonic amplitude 3 µm, frequency 40 kHz | SBS strength, fracture toughness (from DCB tests), impact toughness | [56] |

| 2011 | PP | Glass/PP commingled fibers | FW | Hot gas torch | 125 | 42 | 54 N | Preheating of fibers to 195 °C | Flexural modulus and strength, Charpy impact toughness | [116] |

| 2013 | PPS | Carbon/PPS prepreg tapes | AFP | Laser | 480 | 125 | 450 N | Laser power 1700 W | Fracture toughness (using mandrel peel test) | [41] |

| 1995 | PEI | Carbon/PEI powder impregnated fibers | FW | IR spot heater | 960 | 80 | Nil | Fiber tension 5 N per 1000 filaments, mandrel temperature 150 °C | Void content | [49] |

| 1996 | PEEK | AS4 carbon/PEEK prepreg tapes | FW | CO2 laser | 475 | 15 | 13.8 MPa | Laser power 50 W | SBS strength, fracture toughness (from DCB tests), wedge peel force | [42] |

| 2015 | PEEK | AS4 carbon/PEEK prepreg tapes | AFP | NIR diode laser | 500 | 100 | 500 N | Laser power 920 W | SBS strength | [52] |

| 2019 | PEEK | Carbon/PEEK prepreg tapes | AFP | NIR diode laser | 485 | 100 | 0.34 MPa (for 1st ply), 0.46 MPa (for plies 2–7) | Laser power up to 4 kW | Lap shear strength | [117] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Boon, Y.D.; Joshi, S.C.; Bhudolia, S.K. Review: Filament Winding and Automated Fiber Placement with In Situ Consolidation for Fiber Reinforced Thermoplastic Polymer Composites. Polymers 2021, 13, 1951. https://doi.org/10.3390/polym13121951

Boon YD, Joshi SC, Bhudolia SK. Review: Filament Winding and Automated Fiber Placement with In Situ Consolidation for Fiber Reinforced Thermoplastic Polymer Composites. Polymers. 2021; 13(12):1951. https://doi.org/10.3390/polym13121951

Chicago/Turabian StyleBoon, Yi Di, Sunil Chandrakant Joshi, and Somen Kumar Bhudolia. 2021. "Review: Filament Winding and Automated Fiber Placement with In Situ Consolidation for Fiber Reinforced Thermoplastic Polymer Composites" Polymers 13, no. 12: 1951. https://doi.org/10.3390/polym13121951