Starch-Based Super Water Absorbent: A Promising and Sustainable Way to Increase Survival Rate of Trees Planted in Arid Areas

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

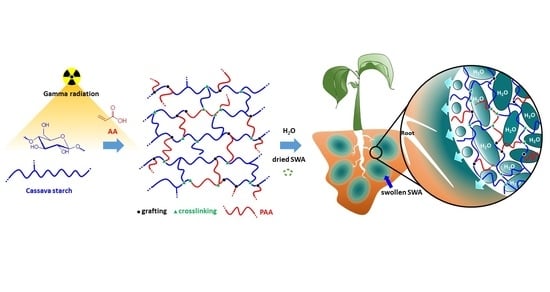

2.2. Up-Scaling Production of Starch-g-PAA (SWA)

2.3. Available Water Capacity (AWC)

2.4. Characterization of SWA

2.5. Field Tests with Young Rubber Trees Planted in Arid Area

2.6. Statistical Analysis

3. Results

3.1. Degree of Grafting and Swelling Ratio

3.2. Available Water Capacity (AWC)

3.3. Characterization of SWA

3.4. Field Tests with Young Rubber Trees Planted in Arid Area

4. Discussion

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Chang, C.; Duan, B.; Cai, J.; Zhang, L. Superabsorbent hydrogels based on cellulose for smart swelling and controllable delivery. Eur. Polym. J. 2010, 46, 92–100. [Google Scholar] [CrossRef]

- Głowińska, A.; Trochimczuk, A.W.; Jakubiak-Marcinkowska, A. Novel acrylate/organophosphorus-based hydrogels for agricultural applications. New outlook and innovative concept for the use of 2-(methacryloyloxy)ethyl phosphate as a multi-purpose monomer. Eur. Polym. J. 2019, 110, 202–210. [Google Scholar] [CrossRef]

- Narayanan, A.; Kartik, R.; Sangeetha, E.; Dhamodharan, R. Super water absorbing polymeric gel from chitosan, citric acid and urea: Synthesis and mechanism of water absorption. Carbohydr. Polym. 2018, 191, 152–160. [Google Scholar] [CrossRef] [PubMed]

- Pourjavadi, A.; Jahromi, P.E.; Seidi, F.; Salimi, H. Synthesis and swelling behavior of acrylatedstarch-g-poly (acrylic acid) and acrylatedstarch-g-poly (acrylamide) hydrogels. Carbohydr. Polym. 2010, 79, 933–940. [Google Scholar] [CrossRef]

- Raju, M.P.; Raju, K.M. Design and synthesis of superabsorbent polymers. J. Appl. Polym. Sci. 2001, 80, 2635–2639. [Google Scholar] [CrossRef]

- Raju, K.M.; Raju, M.P.; Mohan, Y.M. Synthesis and water absorbency of crosslinked superabsorbent polymers. J. Appl. Polym. Sci. 2002, 85, 1795–1801. [Google Scholar] [CrossRef]

- Sannino, A.; Demitri, C.; Madaghiele, M. Biodegradable Cellulose-based Hydrogels: Design and Applications. Materials 2009, 2, 353–373. [Google Scholar] [CrossRef]

- Sawut, A.; Yimit, M.; Sun, W.; Nurulla, I. Photopolymerisation and characterization of maleylatedcellulose-g-poly(acrylic acid) superabsorbent polymer. Carbohydr. Polym. 2014, 101, 231–239. [Google Scholar] [CrossRef] [PubMed]

- Vundavalli, R.; Vundavalli, S.; Nakka, M.; Rao, D.S. Biodegradable Nano-Hydrogels in Agricultural Farming - Alternative Source For Water Resources. Procedia Mater. Sci. 2015, 10, 548–554. [Google Scholar] [CrossRef] [Green Version]

- Wu, L.; Liu, M.; Liang, R. Preparation and properties of a double-coated slow-release NPK compound fertilizer with superabsorbent and water-retention. Bioresour. Technol. 2008, 99, 547–554. [Google Scholar] [CrossRef]

- Gharekhani, H.; Olad, A.; Mirmohseni, A.; Bybordi, A. Superabsorbent hydrogel made of NaAlg-g-poly(AA-co-AAm) and rice husk ash: Synthesis, characterization, and swelling kinetic studies. Carbohydr. Polym. 2017, 168, 1–13. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Nakason, C.; Wohmang, T.; Kaesaman, A.; Kiatkamjornwong, S. Preparation of cassava starch-graft-polyacrylamide superabsorbents and associated composites by reactive blending. Carbohydr. Polym. 2010, 81, 348–357. [Google Scholar] [CrossRef]

- Witono, J.; Noordergraaf, I.; Heeres, H.; Janssen, L. Graft copolymerization of acrylic acid to cassava starch—Evaluation of the influences of process parameters by an experimental design method. Carbohydr. Polym. 2012, 90, 1522–1529. [Google Scholar] [CrossRef]

- Alla, S.G.A.; Sen, M.; El-Naggar, A.W.M. Swelling and mechanical properties of superabsorbent hydrogels based on Tara gum/acrylic acid synthesized by gamma radiation. Carbohydr. Polym. 2012, 89, 478–485. [Google Scholar] [CrossRef] [PubMed]

- El-Rehim, H.A.A.; Hegazy, E.-S.A.; El-Mohdy, H.L.A. Radiation synthesis of hydrogels to enhance sandy soils water retention and increase plant performance. J. Appl. Polym. Sci. 2004, 93, 1360–1371. [Google Scholar] [CrossRef]

- Chen, P.; Zhang, W.; Luo, W.; Fang, Y. Synthesis of superabsorbent polymers by irradiation and their applications in agriculture. J. Appl. Polym. Sci. 2004, 93, 1748–1755. [Google Scholar] [CrossRef]

- Elbarbary, A.M.; El-Rehim, H.A.A.; El-Sawy, N.M.; Hegazy, E.-S.A.; Soliman, E.-S.A. Radiation induced crosslinking of polyacrylamide incorporated low molecular weights natural polymers for possible use in the agricultural applications. Carbohydr. Polym. 2017, 176, 19–28. [Google Scholar] [CrossRef]

- Fekete, T.; Borsa, J.; Takács, E.; Wojnárovits, L. Synthesis of cellulose-based superabsorbent hydrogels by high-energy irradiation in the presence of crosslinking agent. Radiat. Phys. Chem. 2016, 118, 114–119. [Google Scholar] [CrossRef]

- Fekete, T.; Borsa, J.; Takács, E.; Wojnárovits, L. Synthesis of carboxymethylcellulose/acrylic acid hydrogels with superabsorbent properties by radiation-initiated crosslinking. Radiat. Phys. Chem. 2016, 124, 135–139. [Google Scholar] [CrossRef]

- Francis, S.; Kumar, M.; Varshney, L. Radiation synthesis of superabsorbent poly(acrylic acid)–carrageenan hydrogels. Radiat. Phys. Chem. 2004, 69, 481–486. [Google Scholar] [CrossRef]

- Kiatkamjornwong, S.; Chomsaksakul, W.; Sonsuk, M. Radiation modification of water absorption of cassava starch by acrylic acid/acrylamide. Radiat. Phys. Chem. 2000, 59, 413–427. [Google Scholar] [CrossRef]

- Kiatkamjornwong, S.; Mongkolsawat, K.; Sonsuk, M. Synthesis and property characterization of cassava starch grafted poly[acrylamide-co-(maleic acid)] superabsorbent via γ-irradiation. Polymer 2002, 43, 3915–3924. [Google Scholar] [CrossRef]

- Raafat, A.I.; Eid, M.; El-Arnaouty, M.B. Radiation synthesis of superabsorbent CMC based hydrogels for agriculture applications. Nucl. Instrum. Methods Phys. Res. Sect. B Beam Interac. Mater. At. 2012, 283, 71–76. [Google Scholar] [CrossRef]

- Şen, M.; Hayrabolulu, H. Radiation synthesis and characterisation of the network structure of natural/synthetic double-network superabsorbent polymers. Radiat. Phys. Chem. 2012, 81, 1378–1382. [Google Scholar] [CrossRef]

- Sen, M.; Hayrabolulu, H. Radiation synthesis and characterization of natural polymer based superabsorbents. In The Radiation Chemistry of Polysaccharides; Al-Assaf, S., Coqueret, X., Zaman, K., Sen, M., Ulanski, P., Eds.; International Atomic Energy Agency: Vienna, Austria, 2016; pp. 331–348. [Google Scholar]

- Yang, L.; Ma, X.; Guo, N. Synthesis and properties of sodium alginate/Na+rectorite grafted acrylic acid composite superabsorbent via 60Coγ irradiation. Carbohydr. Polym. 2011, 85, 413–418. [Google Scholar] [CrossRef]

- Zhang, S.; Wang, W.; Wang, H.; Qi, W.; Yue, L.; Ye, Q. Synthesis and characterisation of starch grafted superabsorbent via 10MeV electron-beam irradiation. Carbohydr. Polym. 2014, 101, 798–803. [Google Scholar] [CrossRef] [PubMed]

- Bhattacharya, A. Radiation and industrial polymers. Prog. Polym. Sci. 2000, 25, 371–401. [Google Scholar] [CrossRef]

- IAEA–TECDOC–1420. Advances in Radiation Chemistry of Polymers; International Atomic Energy Agency: Vienna, Austria, 2004. [Google Scholar]

- IAEA–TECDOC–1422. Radiation Processing of Polysaccharides; International Atomic Energy Agency: Vienna, Austria, 2004. [Google Scholar]

- Chmielewski, A.G.; Haji-Saeid, M.; Ahmed, S. Progress in radiation processing of polymers. Nucl. Instrum. Methods. Phys. Res. B 2005, 236, 44–54. [Google Scholar] [CrossRef]

- Haji-Saeid, M.; Sáfrány, Ágnes; Sampa, M.H.D.O.; Ramamoorthy, N. Radiation processing of natural polymers: The IAEA contribution. Radiat. Phys. Chem. 2010, 79, 255–260. [Google Scholar] [CrossRef]

- Ashfaq, A.; Clochard, M.-C.; Coqueret, X.; Dispenza, C.; Driscoll, M.S.; Ulański, P.; Al-Sheikhly, M. Polymerization Reactions and Modifications of Polymers by Ionizing Radiation. Polymers 2020, 12, 2877. [Google Scholar] [CrossRef] [PubMed]

- Fekete, T.; Borsa, J.; Takács, E.; Wojnárovits, L. Synthesis and characterization of superabsorbent hydrogels based on hydroxyethylcellulose and acrylic acid. Carbohydr. Polym. 2017, 166, 300–308. [Google Scholar] [CrossRef] [PubMed]

- Gao, J.; Yang, Q.; Ran, F.; Ma, G.; Lei, Z. Preparation and properties of novel eco-friendly superabsorbent composites based on raw wheat bran and clays. Appl. Clay Sci. 2016, 132–133, 739–747. [Google Scholar] [CrossRef]

- Guilherme, M.R.; Aouada, F.A.; Fajardo, A.R.; Martins, A.F.; Paulino, A.T.; Davi, M.F.; Rubira, A.F.; Muniz, E.C. Superabsorbent hydrogels based on polysaccharides for application in agriculture as soil conditioner and nutrient carrier: A review. Eur. Polym. J. 2015, 72, 365–385. [Google Scholar] [CrossRef] [Green Version]

- Ismail, H.; Irani, M.; Ahmad, Z. Starch-Based Hydrogels: Present Status and Applications. Int. J. Polym. Mater. 2013, 62, 411–420. [Google Scholar] [CrossRef]

- Lanthong, P.; Nuisin, R.; Kiatkamjornwong, S. Graft copolymerization, characterization, and degradation of cassava starch-g-acrylamide/itaconic acid superabsorbents. Carbohydr. Polym. 2006, 66, 229–245. [Google Scholar] [CrossRef]

- Li, A.; Zhang, J.; Wang, A. Utilization of starch and clay for the preparation of superabsorbent composite. Bioresour. Technol. 2007, 98, 327–332. [Google Scholar] [CrossRef] [PubMed]

- Peng, N.; Wang, Y.; Ye, Q.; Liang, L.; An, Y.; Li, Q.; Chang, C. Biocompatible cellulose-based superabsorbent hydrogels with antimicrobial activity. Carbohydr. Polym. 2016, 137, 59–64. [Google Scholar] [CrossRef]

- Senna, A.M.; Carmo, J.B.D.; da Silva, J.M.S.; Botaro, V.R. Synthesis, characterization and application of hydrogel derived from cellulose acetate as a substrate for slow-release NPK fertilizer and water retention in soil. J. Environ. Chem. Eng. 2015, 3, 996–1002. [Google Scholar] [CrossRef]

- Sharma, S.; Dua, A.; Malik, A. Polyaspartic acid based superabsorbent polymers. Eur. Polym. J. 2014, 59, 363–376. [Google Scholar] [CrossRef]

- Teli, M.; Waghmare, N.G. Synthesis of superabsorbents from Amaranthus starch. Carbohydr. Polym. 2010, 81, 695–699. [Google Scholar] [CrossRef]

- Thombare, N.; Mishra, S.; Siddiqui, M.; Jha, U.; Singh, D.; Mahajan, G.R. Design and development of guar gum based novel, superabsorbent and moisture retaining hydrogels for agricultural applications. Carbohydr. Polym. 2018, 185, 169–178. [Google Scholar] [CrossRef] [PubMed]

- Witono, J.; Noordergraaf, I.; Heeres, H.; Janssen, L. Water absorption, retention and the swelling characteristics of cassava starch grafted with polyacrylic acid. Carbohydr. Polym. 2014, 103, 325–332. [Google Scholar] [CrossRef] [Green Version]

- Xiao, X.; Yu, L.; Xie, F.; Bao, X.; Liu, H.; Ji, Z.; Chen, L. One-step method to prepare starch-based superabsorbent polymer for slow release of fertilizer. Chem. Eng. J. 2017, 309, 607–616. [Google Scholar] [CrossRef] [Green Version]

- Ye, Z.; Tang, M.; Hong, X.; Hui, K. Sustainable composite super absorbents made from polysaccharides. Mater. Lett. 2016, 183, 394–396. [Google Scholar] [CrossRef] [Green Version]

- Zhang, H.; Luan, Q.; Huang, Q.; Tang, H.; Huang, F.; Li, W.; Wan, C.; Liu, C.; Xu, J.; Guo, P.; et al. A facile and efficient strategy for the fabrication of porous linseed gum/cellulose superabsorbent hydrogels for water conservation. Carbohydr. Polym. 2017, 157, 1830–1836. [Google Scholar] [CrossRef] [PubMed]

- Zhong, K.; Lin, Z.-T.; Zheng, X.-L.; Jiang, G.-B.; Fang, Y.-S.; Mao, X.-Y.; Liao, Z.-W. Starch derivative-based superabsorbent with integration of water-retaining and controlled-release fertilizers. Carbohydr. Polym. 2013, 92, 1367–1376. [Google Scholar] [CrossRef] [PubMed]

- Suwanmala, P.; Tangthong, T.; Hemvichian, K. Superabsorbent Prepared by Radiation Induced Graft Copolymerization of Acrylic Acid onto Cassava Starch. In Radiation Processed Materials in Products from Polymers for Agricultural Applications; IAEA–TECDOC–1745; International Atomic Energy Agency: Vienna, Austria, 2017; pp. 163–168. [Google Scholar]

- El-Rehim, H.A.A. Characterization and possible agricultural application of polyacrylamide/sodium alginate crosslinked hydrogels prepared by ionizing radiation. J. Appl. Polym. Sci. 2006, 101, 3572–3580. [Google Scholar] [CrossRef]

- Cannazza, G.; Cataldo, A.; De Benedetto, E.; Demitri, C.; Madaghiele, M.; Sannino, A. Experimental Assessment of the Use of a Novel Superabsorbent polymer (SAP) for the Optimization ofWater Consumption in Agricultural Irrigation Process. Water 2014, 6, 2056–2069. [Google Scholar] [CrossRef] [Green Version]

- Demitri, C.; Scalera, F.; Madaghiele, M.; Sannino, A.; Maffezzoli, A. Potential of Cellulose-Based Superabsorbent Hydrogels as Water Reservoir in Agriculture. Int. J. Polym. Sci. 2013, 2013, 1–6. [Google Scholar] [CrossRef]

- Fernando, T.; Ariadurai, S.; Disanayaka, C.; Kulathunge, S.; Aruggoda, A. Development of Radiation Grafted Super Absorbent Polymers for Agricultural Applications. Energy Procedia 2017, 127, 163–177. [Google Scholar] [CrossRef]

- Satriani, A.; Catalano, M.; Scalcione, E. The role of superabsorbent hydrogel in bean crop cultivation under deficit irrigation conditions: A case-study in Southern Italy. Agric. Water Manag. 2018, 195, 114–119. [Google Scholar] [CrossRef]

- Cao, Y.; Wang, B.; Guo, H.; Xiao, H.; Wei, T. The effect of super absorbent polymers on soil and water conservation on the terraces of the loess plateau. Ecol. Eng. 2017, 102, 270–279. [Google Scholar] [CrossRef]

- Montesano, F.F.; Parente, A.; Santamaria, P.; Sannino, A.; Serio, F. Biodegradable Superabsorbent Hydrogel IncreasesWater Retention Properties of Growing Media and Plant Growth. Agric. Agric. Sci. Procedia 2015, 4, 451–458. [Google Scholar] [CrossRef] [Green Version]

- Nnadi, F.; Brave, C. Environmentally friendly superabsorbent polmers for water conservation in agricultural lands. J. Soil Sci. Environ. Manag. 2011, 2, 206–211. [Google Scholar]

- Yang, L.; Yang, Y.; Chen, Z.; Guo, C.; Li, S. Influence of super absorbent polymer on soil water retention, seed germination and plant survivals for rocky slopes eco-engineering. Ecol. Eng. 2014, 62, 27–32. [Google Scholar] [CrossRef]

- Abdallah, A.M. The effect of hydrogel particle size on water retention properties and availability under water stress. Int. Soil Water Conserv. Res. 2019, 7, 275–285. [Google Scholar] [CrossRef]

- Mbah, C.N. Determining the field capacity, wilting point and available water capacity of some southeast Nigerian soil using soil saturation from capillary rise. Nig. J. Biotech. 2012, 24, 41–47. [Google Scholar]

- Da Costa, A.; Albuquerque, J.A.; Da Costa, A.; Pértile, P.; Da Silva, F.R. Water retention and availability in soils of the State of Santa Catarina-Brazil: Effect of textural classes, soil classes and lithology. Rev. Bras. Ciênc. Solo 2013, 37, 1535–1548. [Google Scholar] [CrossRef] [Green Version]

- Lampert, J.B.; Shurvell, H.F.; Lightner, D.A.; Graham Cooks, R. Group Frequencies: Infrared and Raman. In Organic Structural Spectroscopy; Prentice Hall: Upper Saddle River, NJ, USA, 1998; pp. 175–200. [Google Scholar]

- Hemvichian, K.; Suwanmala, P.; Kangsumrith, W.; Sudcha, P.; Inchoto, K.; Pongprayoon, T.; Güven, O. Enhancing compatibility between poly(lactic acid) and thermoplastic starch using admicellar polymerization. J. Appl. Polym. Sci. 2016, 133, 43755. [Google Scholar] [CrossRef]

- Thai Meteorological Department, Statistics, Chachoengsao. Average Temperature and Rainfall during 30-Year Period (1961–1990). Available online: https://www.tmd.go.th/en/province_weather_stat.php?StationNumber=48458 (accessed on 28 January 2021).

| Preparation Method | Dg (%) | Swelling Ratio (g/g) |

|---|---|---|

| Lab-scale synthesis | 260.48 | 543.93 |

| Up-scaling production | 594.68 | 218.27 |

| SWA Samples | Available Water Capacity (AWC) (%) |

|---|---|

| Cassava starch-based | 5511 |

| Cellulose-based | 1278 |

| Commercial | 2987 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lertsarawut, P.; Rattanawongwiboon, T.; Tangthong, T.; Laksee, S.; Kwamman, T.; Phuttharak, B.; Romruensukharom, P.; Suwanmala, P.; Hemvichian, K. Starch-Based Super Water Absorbent: A Promising and Sustainable Way to Increase Survival Rate of Trees Planted in Arid Areas. Polymers 2021, 13, 1314. https://doi.org/10.3390/polym13081314

Lertsarawut P, Rattanawongwiboon T, Tangthong T, Laksee S, Kwamman T, Phuttharak B, Romruensukharom P, Suwanmala P, Hemvichian K. Starch-Based Super Water Absorbent: A Promising and Sustainable Way to Increase Survival Rate of Trees Planted in Arid Areas. Polymers. 2021; 13(8):1314. https://doi.org/10.3390/polym13081314

Chicago/Turabian StyleLertsarawut, Pattra, Thitirat Rattanawongwiboon, Theeranan Tangthong, Sakchai Laksee, Tanagorn Kwamman, Butri Phuttharak, Phayao Romruensukharom, Phiriyatorn Suwanmala, and Kasinee Hemvichian. 2021. "Starch-Based Super Water Absorbent: A Promising and Sustainable Way to Increase Survival Rate of Trees Planted in Arid Areas" Polymers 13, no. 8: 1314. https://doi.org/10.3390/polym13081314