Processing and Characterization of Polymer-Based Far-Infrared Composite Materials

Abstract

:1. Introduction

2. Materials and Methods

2.1. The Characterization of Ceramic Powders

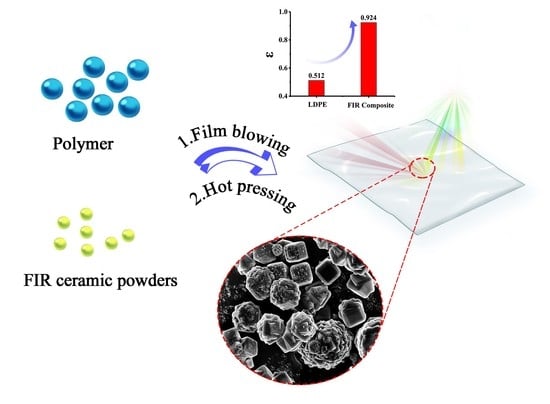

2.2. The Processing of Composite Films

2.3. Characterization of Composite Films

2.4. Statistical Analysis

3. Results and Discussion

3.1. Mineralogical Analysis of Ceramic Powders

3.2. Mechanical Properties of Composite Films

3.3. TG and DSC Properties of Composite Films

3.4. Contact Angle Properties of Composite Films

3.5. Far-Infrared Emissivity, Light Transmittance, Moisture Permeability Properties, and Photomicrographs

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Wang, J.L.; Lin, Y.C.; Young, T.H.; Chen, M.H. Far-infrared ray radiation promotes neurite outgrowth of neuron-like PC12cells through AKT1 signaling. J. Formos. Med. Assoc. 2019, 118, 600–610. [Google Scholar] [CrossRef] [PubMed]

- Sobajima, M.; Nozawa, T.; Ihori, H.; Shida, T.; Ohori, T.; Suzuki, T.; Matsuki, A.; Yasumura, S.; Inoue, H. Repeated sauna therapy improves myocardial perfusion in patients with chronically occluded coronary artery-related ischemia. Int. J. Cardiol. 2013, 167, 237–243. [Google Scholar] [CrossRef] [PubMed]

- Tao, Y.F.; Li, T.H.; Yang, C.X.; Wang, N.X.; Yan, F.; Li, L. The Influence of Fiber Cross-Section on Fabric Far-Infrared Properties. Polymers 2018, 10, 1147. [Google Scholar] [CrossRef] [PubMed]

- Hwang, S.; Lee, D.H.; Lee, I.K.; Park, Y.M.; Jo, I. Far-infrared radiation inhibits proliferation, migration, and angiogenesis of human umbilical vein endothelial cells by suppressing secretory clusterin levels. Cancer Lett. 2014, 346, 74–83. [Google Scholar] [CrossRef] [PubMed]

- Vatansever, F.; Hamblin, M.R. Far infrared radiation (FIR): Its biological effects and medical applications. Photonics Lasers Med. 2012, 4, 255–266. [Google Scholar] [CrossRef] [PubMed]

- Wang, F.; Liang, J.S.; Tang, Q.G.; Li, L.W.; Han, L.J. Preparation and Far Infrared Emission Properties of Natural Sepiolite Nanofibers. J. Nanosci. Nanotechnol. 2010, 10, 2017–2022. [Google Scholar] [CrossRef] [PubMed]

- Liang, J.S.; Zhu, D.B.; Meng, J.P.; Wang, L.J.; Li, F.P.; Liu, Z.G.; Ding, Y.; Liu, L.H.; Liang, G.C. Performance and application of far infrared rays emitted from rare earth mineral composite materials. J. Nanosci. Nanotechnol. 2008, 8, 1203–1210. [Google Scholar] [PubMed]

- Chen, G.W.; Luo, H.Y.; Wu, S.J.; Guan, J.; Luo, J.; Zhao, T.S. Flexural deformation and fracture behaviors of bamboo with gradient hierarchical fibrous structure and water content. Compos. Sci. Technol. 2018, 157, 126–133. [Google Scholar] [CrossRef]

- Huang, Z.H.; Wang, T.; Zhang, X.L.; Zheng, L.N.; Xue, G.; Liang, J.S. Preparation of tourmaline/graphene oxide and its application in thermal interface materials. J. Compos. Mater. 2016, 50, 3953–3960. [Google Scholar] [CrossRef]

- Nikolic, P.M.; Paraskevopoulos, K.M.; Zachariadis, G.; Valasiadis, O.; Zorba, T.T.; Vujatovic, S.S.; Nikolic, N.; Aleksic, O.S.; Ivetic, T.; Cvetkovic, O.; et al. Far infrared study of local impurity modes of Boron-doped PbTe. J. Mater. Sci. 2012, 47, 2384–2389. [Google Scholar] [CrossRef]

- Deng, Y.; Zhang, K.W.; Yang, Y.Y.; Shi, X.Y.; Yang, L.; Yang, W.Z.; Wang, Y.; Chen, Z.G. Ce/Mn dual-doped LaAlO3 ceramics with enhanced far-infrared emission capability synthesized via a facile microwave sintering method. J. Alloys Compd. 2019, 774, 434–442. [Google Scholar] [CrossRef]

- Deng, Y.; Zhang, K.W.; Shi, X.Y.; Dong, T.S.; Yang, L.; Yang, W.Z.; Hong, M.; Wang, Y.; Dargusch, M.; Chen, Z.G. Exploring the underlying mechanisms behind the increased far infrared radiation properties of perovskite-type Ce/Mn co-doped ceramics. Mater. Res. Bull. 2019, 109, 233–239. [Google Scholar] [CrossRef]

- Caminero, M.A.; Chacon, J.M.; Garcia-Plaza, E.; Nunez, P.J.; Reverte, J.M.; Becar, J.P. Additive Manufacturing of PLA-Based Composites Using Fused Filament Fabrication: Effect of Graphene Nanoplatelet Reinforcement on Mechanical Properties, Dimensional Accuracy and Texture. Polymers 2019, 11, 799. [Google Scholar] [CrossRef] [PubMed]

- Ferrel-Alvarez, A.C.; Dominguez-Crespo, M.A.; Torres-Huerta, A.M.; Cong, H.B.; Brachetti-Sibaja, S.B.; Lopez-Oyama, A.B. Intensification of Electrochemical Performance of AA7075 Aluminum Alloys Using Rare Earth Functionalized Water-Based Polymer Coatings. Polymers 2017, 9, 178. [Google Scholar] [CrossRef] [PubMed]

- Sebastian, M.T.; Jantunen, H. Polymer-Ceramic Composites of 0–3 Connectivity for Circuits in Electronics: A Review. Int. J. Appl. Ceram. Technol. 2010, 7, 415–434. [Google Scholar] [CrossRef]

- Leung, T.K.; Chen, C.H.; Lai, C.H.; Lee, C.M.; Chen, C.C.; Yang, J.C.; Chen, K.C.; Chao, J.S. Bone and Joint Protection Ability of Ceramic Material with Biological Effects. Chin. J. Physiol. 2012, 55, 47–54. [Google Scholar] [PubMed]

- Leung, T.K.; Lin, Y.S.; Lee, C.M.; Chen, Y.C.; Shang, H.F.; Hsiao, S.Y.; Chang, H.T.; Chao, J.S. Direct and Indirect Effects of Ceramic Far Infrared Radiation on the Hydrogen Peroxide-scavenging Capacity and on Murine Macrophages under Oxidative Stress. J. Med. Biol. Eng. 2011, 31, 345–351. [Google Scholar] [CrossRef]

- Jiang, M.M.; Zhang, B.; Tang, X.N.; Liu, Q.L.; Tian, S.L. Preparation and characterization of hybrid antimicrobial materials based on Zn-Lu composites. J. Mater. Sci. 2018, 53, 14922–14932. [Google Scholar] [CrossRef]

- Bhaskar, R.; Li, J.L.; Xu, L.J. A Comparative-Study of Particle-Size Dependency of Ir and Xrd Methods for Quartz Analysis. Am. Ind. Hyg. Assoc. J. 1994, 55, 605–609. [Google Scholar] [CrossRef]

- Heath, C.; Pejcic, B.; Delle Piane, C.; Esteban, L. Development of far-infrared attenuated total reflectance spectroscopy for the mineralogical analysis of shales. Fuel 2016, 182, 771–779. [Google Scholar] [CrossRef]

- Greffrath, F.; Gorewoda, J.; Schiemann, M.; Scherer, V. Influence of chemical composition and physical structure on normal radiant emittance characteristics of ash deposits. Fuel 2014, 134, 307–314. [Google Scholar] [CrossRef]

- Sabola, K.D.A.; Fechine, P.B.A.; Santos, M.R.P.; Freire, F.N.A.; Pereira, F.M.M.; Sombra, A.S.B. Composite screen-printed thick films for high dielectric constant devices: Bi4Ti3O12-CaCu3Ti4O12 films. Polym. Compos. 2007, 28, 771–777. [Google Scholar] [CrossRef]

- Xiong, Y.B.; Huang, S.Y.; Wang, W.Q.; Liu, X.H.; Li, H.B. Properties and Applications of High Emissivity Composite Films Based on Far-Infrared Ceramic Powder. Materials 2017, 10, 1370. [Google Scholar] [CrossRef] [PubMed]

- Kim, S.; Park, J.C. Environment-friendly Hwangtoh Composite Materials Using Water Soluble Resin for Indoor Air Quality and Human Health. J. Compos. Mater. 2010, 44, 905–913. [Google Scholar] [CrossRef]

- Defebvin, J.; Barrau, S.; Lyskawa, J.; Woisel, P.; Lefebvre, J.M. Influence of nitrodopamine-functionalized barium titanate content on the piezoelectric response of poly(vinylidene fluoride) based polymer-ceramic composites. Compos. Sci. Technol. 2017, 147, 16–21. [Google Scholar] [CrossRef]

- Ganfoud, R.; Puchot, L.; Fouquet, T.; Verge, P. H-bonding supramolecular interactions driving the dispersion of kaolin into benzoxazine: A tool for the reinforcement of polybenzoxazines thermal and thermo-mechanical properties. Compos. Sci. Technol. 2015, 110, 1–7. [Google Scholar] [CrossRef]

- Dayyoub, T.; Maksimkin, A.V.; Kaloshkin, S.; Kolesnikov, E.; Chukov, D.; Dyachkova, T.P.; Gutnik, I. The Structure and Mechanical Properties of the UHMWPE Films Modified by the Mixture of Graphene Nanoplates with Polyaniline. Polymers 2019, 11, 23. [Google Scholar] [CrossRef] [PubMed]

- Qin, C.R.; Lu, W.; He, Z.L.; Qi, G.S.; Li, J.L.; Hu, X.M. Effect of Silane Treatment on Mechanical Properties of Polyurethane/Mesoscopic Fly Ash Composites. Polymers 2019, 11, 741. [Google Scholar] [CrossRef] [PubMed]

- Soares, A.R.; Ponton, P.I.; Mancic, L.; d’Almeida, J.R.M.; Romao, C.P.; White, M.A.; Marinkovic, B.A. Al2Mo3O12/polyethylene composites with reduced coefficient of thermal expansion. J. Mater. Sci. 2014, 49, 7870–7882. [Google Scholar] [CrossRef]

- Ma, L.C.; Wu, G.S.; Zhao, M.; Li, X.R.; Han, P.; Song, G.J. Modification of carbon fibers surfaces with polyetheramines: The role of interphase microstructure on adhesion properties of CF/epoxy composites. Polym. Compos. 2018, 39, E2346–E2355. [Google Scholar] [CrossRef]

- Ayyoob, M.; Kim, Y.J. Effect of Chemical Composition Variant and Oxygen Plasma Treatments on the Wettability of PLGA Thin Films, Synthesized by Direct Copolycondensation. Polymers 2018, 10, 1132. [Google Scholar] [CrossRef] [PubMed]

- Hu, X.L.; Tian, M.W.; Qu, L.J.; Zhu, S.F.; Han, G.T. Multifunctional cotton fabrics with graphene/polyurethane coatings with far-infrared emission, electrical conductivity, and ultraviolet-blocking properties. Carbon 2015, 95, 625–633. [Google Scholar] [CrossRef]

| Elongation at Break (mm) | Young’s Modulus (MPa) | Tensile Stress (MPa) | Strength at Break (N/Tex) | Energy at Break (J) | |

|---|---|---|---|---|---|

| Mean ± SD | Mean ± SD | Mean ± SD | Mean ± SD | Mean ± SD | |

| x-Axis | |||||

| 1 | 331.93abc ± 14.99 | 32.74bcd ± 5.04 | 3.74a ± 0.43 | 56.20a ± 6.51 | 11.31c ± 1.49 |

| 2 | 301.12bc ± 14.58 | 33.01bcd ± 2.22 | 3.41ab ± 0.65 | 51.23ab ± 6.84 | 10.07c ± 1.25 |

| 3 | 264.53cd ± 11.94 | 36.40b ± 5.93 | 2.94ab ± 0.46 | 44.18bc ± 6.91 | 8.18c ± 1.58 |

| 4 | 201.08d ± 8.26 | 42.22a ± 3.73 | 2.44bc ± 0.94 | 36.74c ± 4.20 | 6.74c ± 0.77 |

| 5 | 338.46abc ± 12.29 | 2.52gh ± 0.64 | 1.34de ± 0.27 | 20.10d ± 4.07 | 3.25c ± 0.94 |

| 6 | 325.44bc ± 12.61 | 2.44gh ± 0.98 | 1.27de ± 0.21 | 19.17de ± 4.79 | 2.92c ± 1.02 |

| 7 | 305.33bc ± 10.43 | 1.60h ± 0.61 | 1.07de ± 0.22 | 16.08defg ± 3.34 | 2.22c ±0. 63 |

| 8 | 298.44bc ± 10.99 | 2.09gh ± 0.78 | 1.13de ± 0.31 | 17.09def ± 4.72 | 2.42c ±0. 80 |

| y-Axis | |||||

| 1 | 311.12bc ± 15.14 | 30.71cde ± 1.41 | 3.18ab ± 0.61 | 9.85defg ± 1.99 | 47.71a ± 3.17 |

| 2 | 215.44d ± 15.48 | 26.49e ± 2.45 | 1.82cd ± 0.25 | 5.56g ± 0.82 | 27.34b ± 1.32 |

| 3 | 320.34bc ± 12.62 | 29.04de ± 2.34 | 3.15ab ± 0.35 | 9.60defg ± 0.96 | 47.34a ± 4.17 |

| 4 | 323.88bc ± 13.22 | 35.57bc ± 2.54 | 3.78a ± 0.84 | 11.93defg ± 1.99 | 56.77a ± 4.65 |

| 5 | 405.83a ± 10.84 | 9.61f ± 1.61 | 0.89de ± 0.12 | 10.62defg ± 0.98 | 2.21c ± 0.26 |

| 6 | 302.26bc ± 10.76 | 6.69fg ± 0.92 | 0.42e ± 0.08 | 6.25fg ±0.33 | 1.50c ± 0.14 |

| 7 | 331.87abc ± 11.21 | 7.65f ± 0.61 | 0.67e ± 0.06 | 8.65efg ±0.61 | 1.98c ± 0.12 |

| 8 | 373.53ab ± 11.89 | 8.38f ± 0.91 | 0.72e ± 0.07 | 9.25defg ± 0.82 | 2.38c ± 0.22 |

| Composite Films | DSC | TG | |||||

|---|---|---|---|---|---|---|---|

| Glass Transition (°C) | Crystallinity (%) | Onset Temperature (°C) | Inflection Temperature (°C) | End Temperature (°C) | Mass Change (%) | Residual Mass (%) | |

| 1 | 111.43 | 25.68 | 465.5 | 488.8 | 493.1 | 98.77 | 0.9 |

| 2 | 102.96 | 20.32 | 461.0 | 482.7 | 492.8 | 98.59 | 0.91 |

| 3 | 102.85 | 19.73 | 462.5 | 479.3 | 490.2 | 98.68 | 1.11 |

| 4 | 102.45 | 16.79 | 462.1 | 482.3 | 492.1 | 97.91 | 1.37 |

| 5 | 112.31 | 26.09 | 461.9 | 474.7 | 492.0 | 99.13 | 0.37 |

| 6 | 101.99 | 22.85 | 461.5 | 476.0 | 492.4 | 98.8 | 0.79 |

| 7 | 101.57 | 21.01 | 464.3 | 481.6 | 491.6 | 98.4 | 1.34 |

| 8 | 101.56 | 19.13 | 464.0 | 480.8 | 491.9 | 97.98 | 1.24 |

| Composite Films | Far-Infrared Emissivity (ε) | Light Transmittance (%) | Moisture Permeability (g/m2·day) |

|---|---|---|---|

| 1 | 0.512 | 14.7 | 0.27 |

| 2 | 0.861 | 13.1 | 0.32 |

| 3 | 0.892 | 12.4 | 0.4 |

| 4 | 0.921 | 10.9 | 0.45 |

| 5 | 0.508 | 71.3 | 1.73 |

| 6 | 0.866 | 67.9 | 2.17 |

| 7 | 0.89 | 67.6 | 3.27 |

| 8 | 0.924 | 57.6 | 3.38 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xiong, Y.; Zou, Y.; Cai, S.; Liu, H.; Huang, S.; Li, H. Processing and Characterization of Polymer-Based Far-Infrared Composite Materials. Polymers 2019, 11, 1451. https://doi.org/10.3390/polym11091451

Xiong Y, Zou Y, Cai S, Liu H, Huang S, Li H. Processing and Characterization of Polymer-Based Far-Infrared Composite Materials. Polymers. 2019; 11(9):1451. https://doi.org/10.3390/polym11091451

Chicago/Turabian StyleXiong, Yabo, Yang Zou, Shaoyong Cai, Huihui Liu, Shaoyun Huang, and Houbin Li. 2019. "Processing and Characterization of Polymer-Based Far-Infrared Composite Materials" Polymers 11, no. 9: 1451. https://doi.org/10.3390/polym11091451