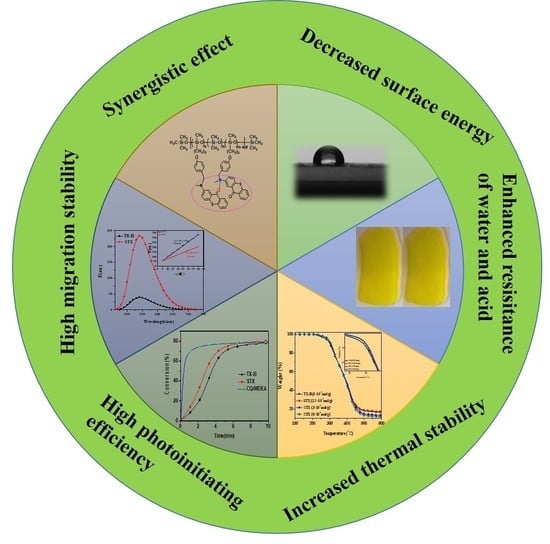

Silicone-Thioxanthone: A Multifunctionalized Visible Light Photoinitiator with an Ability to Modify the Cured Polymers

Abstract

:1. Introduction

2. Experimental

2.1. Materials

2.2. Instrumentation

2.3. Synthesis

2.3.1. Synthesis of γ-Chloropropylmethylpolysiloxane-co-dimethylpolysiloxane (PSO-Cl)

2.3.2. Synthesis of Silicone-Thioxanthone (STX)

2.4. Visible Light Photolysis Experiments

2.5. Photopolymerization Experiments

2.6. Migration/Extractability Study of STX in Polymer Films

2.7. Preparation of Polyurethane Films Initiated by TX-B and STX

2.8. Water and Acid Resistance of Cured PUA Films

3. Results and Discussion

3.1. Synthesis and Characterization of STX

3.2. Visible Light Photolysis

3.3. Photopolymerization

3.4. Migration/Extractability of STX in Polymer Films

3.5. Impacts of STX to Properties of Cured PUA Films

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Dietliker, K.; Jung, T.; Benkhoff, J.; Kura, H.; Matsumoto, A.; Oka, H.; Hristova, D.; Gescheidt, G.; Rist, G. New developments in photoinitiators. Macromol. Symp. 2004, 217, 77–98. [Google Scholar] [CrossRef]

- Yagci, Y.; Jockusch, S.; Turro, N.J. Photoinitiated polymerization: Advances, challenges, and opportunities. Macromolecules 2010, 43, 6245–6260. [Google Scholar] [CrossRef]

- Fouassier, J.P. Photoinitiators for Polymer Synthesis: Scope, Reactivity, and Efficiency; John Wiley & Sons: Hoboken, NJ, USA, 2012. [Google Scholar]

- Luo, A.; Jiang, X.; Yin, J. Thioxanthone-containing renewable vegetable oil as photoinitiators. Polymer 2012, 53, 2183–2189. [Google Scholar] [CrossRef]

- Burrows, R.; Davidson, R.S.; Illsley, D.R. Multifunctional photoinitiators (MFPIs): A new concept Photoinitiateurs multifunctions (MFPIs): A new concept Multifunktionelle Fotoinitiatoren (MFPIs): A new concept. Surf. Coat. Int. Part B Coat. Trans. 2004, 87, 127–135. [Google Scholar] [CrossRef]

- Liska, R. Photoinitiators with functional groups. V. New water-soluble photoinitiators containing carbohydrate residues and copolymerizable derivatives thereof. J. Polym. Sci. Part A Polym. Chem. 2002, 40, 1504–1518. [Google Scholar] [CrossRef]

- Klos, R.; Gruber, H.; Greber, G. Photoinitiators with Functional Groups. Part I. Polymer Photoinitiators. J. Macromol. Sci. Chem. 1991, 28, 925–947. [Google Scholar] [CrossRef]

- Nayak, B.R.; Mathias, L.J. A novel photoinimer for the polymerization of acrylates and methacrylates. J. Polym. Sci. Part A Polym. Chem. 2005, 43, 5661–5670. [Google Scholar] [CrossRef]

- Yang, J.; Liao, W.; Xiong, Y.; Tang, H. A multifunctionalized macromolecular silicone-naphthalimide visible photoinitiator for free radical polymerization. Prog. Org. Coat. 2018, 115, 151–158. [Google Scholar] [CrossRef]

- Yang, J.; Xiong, Y.; Wang, X.; Li, Z.; Tang, H. Naphthalimide-and Methacrylate-Functionalized Polysiloxanes: Visible-Light Photoinitiators, Modifiers for Polyurethane Acrylate and Photocurable Coatings. ChemPhotoChem 2018, 2, 818–824. [Google Scholar] [CrossRef]

- Xiao, P.; Shi, S.; Nie, J. Synthesis and characterization of copolymerizable one-component type II photoinitiator. Polym. Adv. Technol. 2008, 19, 1305–1310. [Google Scholar] [CrossRef]

- Xiao, P.; Zhang, H.; Dai, M.; Nie, J. Synthesis and characterization of 4, 4′-diacryloyloxybenzophenone. Prog. Org. Coat. 2009, 64, 510–514. [Google Scholar] [CrossRef]

- Yang, J.; Liao, W.; Xiong, Y.; Tang, H. Naphthalimide dyes: Polymerizable one-component visible light initiators. Dyes Pigments 2018, 148, 16–24. [Google Scholar] [CrossRef]

- Strzelczyk, R.; Podsiadły, R. Naphthoylenebenzimidazolone dyes as one-component photoinitiators. Color. Technol. 2017, 133, 178–183. [Google Scholar] [CrossRef]

- Wang, K.; Lu, Y.; Chen, P.; Shi, J.; Wang, H.; Yu, Q. Novel one-component polymeric benzophenone photoinitiator containing poly (ethylene glycol) as hydrogen donor. Mater. Chem. Phys. 2014, 143, 1391–1395. [Google Scholar] [CrossRef]

- Xiao, P.; Dumur, F.; Frigoli, M.; Tehfe, M.A.; Graff, B.; Fouassier, J.P.; Gigmes, D.; Lalevée, J. Naphthalimide based methacrylated photoinitiators in radical and cationic photopolymerization under visible light. Polym. Chem. 2013, 4, 5440–5448. [Google Scholar] [CrossRef]

- Wang, K.; Yang, K.; Yu, Q. Novel polymeric photoinitiators with side-chain benzophenone: Facile synthesis and photopolymerization properties without coinitiator. Prog. Org. Coat. 2014, 77, 1929–1934. [Google Scholar] [CrossRef]

- Wu, J.; Zhang, R.; Ma, G.; Hou, C.; Zhang, H. Preparation and properties of fluorinated oligomer with tertiary amine structure in the UV curable coatings. J. Appl. Polym. Sci. 2016, 133, 44387. [Google Scholar] [CrossRef]

- Wang, J.; Siqueira, G.; Müller, G.; Rentsch, D.; Huch, A.; Tingaut, P.; Levalois-Grützmacher, J.; Grützmacher, H. Synthesis of new bis (acyl) phosphane oxide photoinitiators for the surface functionalization of cellulose nanocrystals. Chem. Commun. 2016, 52, 2823–2826. [Google Scholar] [CrossRef]

- Bartlett, I.; Marshall, J.; Maud, J. Characterization and application of carbazole modified polysiloxanes to electrochromic displays. J. Non-Cryst. Solids 1996, 198, 665–668. [Google Scholar] [CrossRef]

- Bauer, F.; Gläsel, H.J.; Decker, U.; Ernst, H.; Freyer, A.; Hartmann, E.; Sauerland, V.; Mehnert, R. Trialkoxysilane grafting onto nanoparticles for the preparation of clear coat polyacrylate systems with excellent scratch performance. Prog. Org. Coat. 2003, 47, 147–153. [Google Scholar] [CrossRef]

- Matějec, V.; Rose, K.; Hayer, M.; Pospíšllová, M.; Chomát, M. Development of organically modified polysiloxanes for coating optical fibers and their sensitivity to gases and solvents. Sens. Actuators B Chem. 1997, 39, 438–442. [Google Scholar] [CrossRef]

- Sung, P.H.; Lin, C.-Y. Polysiloxane modified epoxy polymer network—II. Dynamic mechanical behavior of multicomponent graft-IPNs (epoxy/polysiloxane/polypropylene glycol). Eur. Polym. J. 1997, 33, 231–233. [Google Scholar] [CrossRef]

- Tsai, M.F.; Lee, Y.D.; Long, Y.C. Synthesis of a polydimethylsiloxane-block-hydroxyl grafted acrylate prepolymer copolymer to improve the adhesion between silicone rubber and polyurethane by induced surface reconstruction. J. Polym. Res. 2000, 7, 73–79. [Google Scholar] [CrossRef]

- Song, Y.; Yu, J.; Yu, L.; Alam, F.E.; Dai, W.; Li, C.; Jiang, N. Enhancing the thermal, electrical, and mechanical properties of silicone rubber by addition of graphene nanoplatelets. Mater. Des. 2015, 88, 950–957. [Google Scholar] [CrossRef]

- Imiela, M.; Anyszka, R.; Bielinski, D.M.; Pedzich, Z.; Zarzecka-Napierala, M.; Szumera, M. Effect of carbon fibers on thermal properties and mechanical strength of ceramizable composites based on silicone rubber. J. Therm. Anal. Calorim. 2016, 124, 197–203. [Google Scholar] [CrossRef]

- Ma, W.; Li, J.; Zhao, X. Improving the thermal and mechanical properties of silicone polymer by incorporating functionalized graphene oxide. J. Mater. Sci. 2013, 48, 5287–5294. [Google Scholar] [CrossRef]

- Lei, H.; He, D.; Guo, Y.; Tang, Y.; Huang, H. Synthesis and characterization of UV-absorbing fluorine-silicone acrylic resin polymer. Appl. Surf. Sci. 2018, 442, 71–77. [Google Scholar] [CrossRef]

- Necasova, B.; Liska, P.; Simackova, M.; Slanhof, J. Test of Adhesion and Cohesion of Silicone Sealants on Facade Cladding Materials within Extreme Weather Conditions. Adv. Mater. Res. 2014, 1041, 23–26. [Google Scholar] [CrossRef]

- Zhang, G.; Cao, Y.; Yu, J.; Sun, F.; Adhes, J. Photoinitiability of a water-borne polysiloxane-modified benzophenone macromolecular photoinitiator. J. Adhes. Sci. Technol. 2016, 30, 2289–2300. [Google Scholar] [CrossRef]

- Hou, H.; Gan, Y.; Yin, J.; Jiang, X. Multifunctional POSS-Based Nano-Photo-Initiator for Overcoming the Oxygen Inhibition of Photo-Polymerization and for Creating Self-Wrinkled Patterns. ACS Adv. Mater. Interfaces 2014, 1, 1400385–1400390. [Google Scholar] [CrossRef]

- Dadashi-Silab, S.; Aydogan, C.; Yagci, Y. Shining a light on an adaptable photoinitiator: Advances in photopolymerizations initiated by thioxanthones. Polym. Chem. 2015, 6, 6595–6615. [Google Scholar] [CrossRef]

- Dadashi-Silab, S.; Doran, S.; Yagci, Y. Photoinduced electron transfer reactions for macromolecular syntheses. Chem. Rev. 2016, 116, 10212–10275. [Google Scholar] [CrossRef] [PubMed]

- Xiao, P.; Zhang, J.; Dumur, F.; Tehfe, M.A.; Morlet-Savary, F.; Graff, B.; Gigmes, D.; Fouassier, J.P.; Lalevée, J. Visible light sensitive photoinitiating systems: Recent progress in cationic and radical photopolymerization reactions under soft conditions. Prog. Polym. Sci. 2015, 41, 32–66. [Google Scholar] [CrossRef]

- Karaca, N.; Balta, D.K.; Ocal, N.; Arsu, N. Thioxanthonation of fluorenone: Visible photoinitiator for radical polymerization. J. Polym. Sci. Part A Polym. Chem. 2016, 54, 1012–1019. [Google Scholar] [CrossRef]

- Balta, D.K.; Temel, G.; Goksu, G.; Ocal, N.; Arsu, N. Thioxanthone–diphenyl anthracene: Visible light photoinitiator. Macromolecules 2011, 45, 119–125. [Google Scholar] [CrossRef]

- Wu, Q.; Xiong, Y.; Liang, Q.; Tang, H. Developing thioxanthone based visible photoinitiators for radical polymerization. RSC Adv. 2014, 4, 52324–52331. [Google Scholar] [CrossRef]

- Wu, Q.; Xiong, Y.; Yang, J.; Tang, H.; Chen, S. Thioxanthone-Based Hydrophilic Visible Photoinitiators for Radical Polymerization. Macromol. Chem. Phys. 2016, 217, 1569–1578. [Google Scholar] [CrossRef]

- Wu, Q.; Wang, X.; Xiong, Y.; Yang, J.; Tang, H. Thioxanthone based one-component polymerizable visible light photoinitiator for free radical polymerization. RSC Adv. 2016, 6, 66098–66107. [Google Scholar] [CrossRef]

- Wu, Q.; Tang, K.; Xiong, Y.; Wang, X.; Yang, J.; Tang, H. High-Performance and Low Migration One-Component Thioxanthone Visible Light Photoinitiators. Macromol. Chem. Phys. 2017, 218, 1600484. [Google Scholar] [CrossRef]

- Podsiadły, R.; Strzelczyk, R. N-substituted quinoxalinobenzothiazine/iodonium salt systems as visible photoinitiators for hybrid polymerization. Dyes Pigments 2013, 97, 462–468. [Google Scholar] [CrossRef]

- Ligon, S.C.; Husar, B.; Wutzel, H.; Holman, R.; Liska, R. Strategies to reduce oxygen inhibition in photoinduced polymerization. Chem. Rev. 2013, 114, 557–589. [Google Scholar] [CrossRef] [PubMed]

- Bartholomew, R.F.; Davidson, R.S. The photosensitised oxidation of amines. Part I. The use of benzophenone as a sensitizer. J. Chem. Soc. C Org. 1971, 2342–2346. [Google Scholar] [CrossRef]

- Pouliquen, L.; Coqueret, X.; Morlet-Savary, F.; Fouassier, J.P. Functionalized polysiloxanes with thioxanthone side groups: A study of their reactivity as radical polymerization macroinitiators. Macromolecules 1995, 28, 8028–8034. [Google Scholar] [CrossRef]

- Albrecht, W.N.; Stephenson, R.L. Health hazards of tertiary amine catalysts. Scand. J. Work Environ. Health 1988, 14, 209–219. [Google Scholar] [CrossRef] [PubMed]

- Gireesh, K.; Jena, K.K.; Allauddin, S.; Radhika, K.; Narayan, R.; Raju, K. Structure and thermo-mechanical properties study of polyurethane-urea/glycidoxypropyltrimethoxysilane hybrid coatings. Prog. Org. Coat. 2010, 68, 165–172. [Google Scholar] [CrossRef]

- Zhao, G.; Wang, T.; Wang, Q. Studies on wettability, mechanical and tribological properties of the polyurethane composites filled with talc. Appl. Surf. Sci. 2012, 258, 3557–3564. [Google Scholar] [CrossRef]

- Yang, X.; Huang, W.; Yu, Y. Synthesis, characterization, and properties of silicone–epoxy resins. J. Appl. Polym. Sci. 2011, 120, 1216–1224. [Google Scholar] [CrossRef]

- Cheng, X.; Shi, W. Synthesis and thermal properties of silicon-containing epoxy resin used for UV-curable flame-retardant coatings. J. Therm. Anal. Calorim. 2011, 103, 303–310. [Google Scholar] [CrossRef]

- Wang, L.; Cui, S.; Ni, H.; Wu, M.; Wang, L. New washing-free printing binder based on organosilicon-modified polyacrylate for polyester fabric printing of disperse dyes. Prog. Org. Coat. 2018, 123, 75–81. [Google Scholar] [CrossRef]

- Zhang, Z.; Han, X.; Du, W.; Li, Z.; Li, L. Comparison and evaluation of in vitro degradation behaviors of organosilicone-modified gelatin hybrids. J. Sol-Gel Sci. Technol. 2019, 89, 370–379. [Google Scholar] [CrossRef]

- Xu, S.; Xie, L.; Yu, X.; Xiong, Y.; Tang, H. Synthesis and characterization of phenyl polysiloxane modified polyurea/polyurethanes. J. Polym. Sci. Part A Polym. Chem. 2015, 53, 1794–1805. [Google Scholar] [CrossRef]

| PI | WCA (°) | Water Absorbance (wt%) d | Acid Absorbance (wt%) e | T5(°C) f | T50(°C) g | Tg(°C) h |

|---|---|---|---|---|---|---|

| TX-B (1.0 wt%) | 81.8 | 2.17 | 1.12 | 279 | 393 | 48 |

| STX (1.5 wt% a, 0.6 wt% b, 0.9 wt% c) | 93.5 | 2.07 | 0.53 | 291 | 396 | - |

| STX (3.0 wt%, 1.2 wt%, 1.8 wt% c) | 96.8 | 0.40 | 0.29 | 291 | 396 | 43 |

| STX (6.0 wt%, 2.4wt%, 3.6 wt% c) | 102.3 | 0.36 | 0.12 | 290 | 392 | - |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wu, Q.; Liao, W.; Xiong, Y.; Yang, J.; Li, Z.; Tang, H. Silicone-Thioxanthone: A Multifunctionalized Visible Light Photoinitiator with an Ability to Modify the Cured Polymers. Polymers 2019, 11, 695. https://doi.org/10.3390/polym11040695

Wu Q, Liao W, Xiong Y, Yang J, Li Z, Tang H. Silicone-Thioxanthone: A Multifunctionalized Visible Light Photoinitiator with an Ability to Modify the Cured Polymers. Polymers. 2019; 11(4):695. https://doi.org/10.3390/polym11040695

Chicago/Turabian StyleWu, Qingqing, Wen Liao, Ying Xiong, Jianjing Yang, Zhen Li, and Hongding Tang. 2019. "Silicone-Thioxanthone: A Multifunctionalized Visible Light Photoinitiator with an Ability to Modify the Cured Polymers" Polymers 11, no. 4: 695. https://doi.org/10.3390/polym11040695