Modeling of Short-Pulse Laser Interactions with Monolithic and Porous Silicon Targets with an Atomistic–Continuum Approach

Abstract

:1. Introduction

2. Materials and Methods

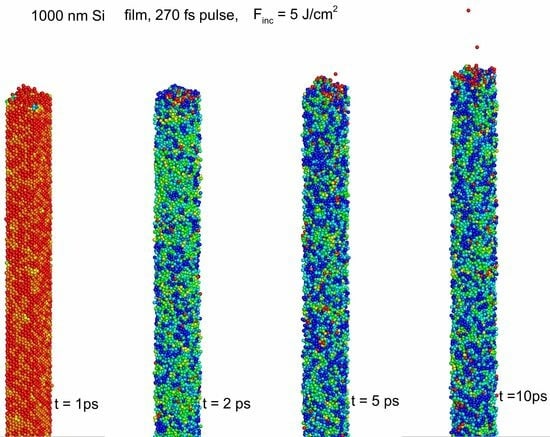

3. Results and Discussion

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Chichkov, B.N.; Momma, C.; Nolte, S.; von Alvensleben, F.; Tünnermann, A. Femtosecond, Picosecond and Nanosecond Laser Ablation of Solids. Appl. Phys. A 1996, 63, 109–115. [Google Scholar] [CrossRef]

- Gattass, R.R.; Mazur, E. Femtosecond Laser Micromachining in Transparent Materials. Nat. Photonics 2008, 2, 219–225. [Google Scholar] [CrossRef]

- Vorobyev, A.Y.; Guo, C. Direct femtosecond laser surface nano/microstructuring and its applications. Laser Photonics Rev. 2013, 7, 385–407. [Google Scholar] [CrossRef]

- Ablez, A.; Toyoda, K.; Miyamoto, K.; Omatsu, T. Microneedle structuring of Si(111) by irradiation with picosecond optical vortex pulses. Appl. Phys. Express 2020, 13, 062006. [Google Scholar]

- Kuchmizhak, A.A.; Pavlov, D.; Vitrik, O.; Kulchin, Y.N. Laser ablative fabrication of nanocrowns and nanojets on the Cu supported film surface using femtosecond laser pulses. Appl. Surf. Sci. 2015, 357, 2378–2384. [Google Scholar]

- Pedraza, A.J.; Fowlkes, J.D.; Lowndes, D.H. Silicon Microcolumn Arrays Grown by Nanosecond Pulsed-Excimer Laser Irradiation. Appl. Phys. Lett. 1999, 74, 2322–2324. [Google Scholar]

- Wu, C.; Crouch, C.H.; Zhao, L.; Mazur, E. Visible Luminescence from Silicon Surfaces Microstructured in Air. Appl. Phys. Lett. 2002, 81, 1999–2001. [Google Scholar]

- Bonse, J.; Hoehm, S.; Kirner, S.V.; Rosenfeld, A.; Krueger, J. Laser-Induced Periodic Surface Structures—A Scientific Evergreen. IEEE J. Sel. Top. Quantum Electron. 2017, 23, 9000615. [Google Scholar]

- Yamada, Y.; Orii, T.; Umezu, I.; Takeyama, S.; Yoshida, T. Optical Properties of Silicon Nanocrystallites Prepared by Excimer Laser Ablation in Inert Gas. Jpn. J. Appl. Phys. 1996, 35, 1361–1365. [Google Scholar] [CrossRef]

- Kabashin, A.V.; Charbonneau-Lefort, M.; Meunier, M.; Leonelli, R. Effects of Deposition and Post-Fabrication Conditions on Photoluminescent Properties of Nanostructured Si/SiOx Films Prepared by Laser Ablation. Appl. Surf. Sci. 2000, 168, 328–331. [Google Scholar]

- Marine, W.; Patrone, L.; Luk’yanchuk, B.; Sentis, M. Strategy of Nanocluster and Nanostructure Synthesis by Conventional Pulsed Laser Ablation. Appl. Surf. Sci. 2000, 154, 345–352. [Google Scholar] [CrossRef]

- Kabashin, A.V.; Delaporte, P.; Pereira, A.; Grojo, D.; Torres, R.; Sarnet, T.; Sentis, M. Nanofabrication with Pulsed Lasers. Nanoscale Res. Lett. 2010, 5, 454–463. [Google Scholar] [CrossRef] [PubMed]

- Zhang, D.S.; Goekce, B.; Barcikowski, S. Laser Synthesis and Processing of Colloids: Fundamentals and Applications. Chem. Rev. 2017, 117, 3990–4103. [Google Scholar]

- Busch, K.; von Freymann, G.; Linden, S.; Mingaleev, S.F.; Tkeshelashvili, L.; Wegener, M. Periodic nanostructures for photonics. Phys. Rep. 2007, 444, 101–202. [Google Scholar]

- Kabashin, A.V.; Singh, A.; Swihart, M.T.; Zavestovskaya, I.N.; Prasad, P.N. Laser Processed Nanosilicon: A Multifunctional Nanomaterial for Energy and Health Care. ACS Nano 2019, 13, 9841–9867. [Google Scholar] [CrossRef] [PubMed]

- Liu, E.; Lee, H.J.; Lu, X. Superhydrophobic Surfaces Enabled by Femtosecond Fiber Laser-Written Nanostructures. Appl. Sci. 2020, 10, 2678. [Google Scholar] [CrossRef]

- Zhang, D.S.; Li, X.Z.; Fu, Y.; Yao, Q.H.; Li, Z.G.; Sugioka, K. Liquid vortexes and flows induced by femtosecond laser ablation in liquid governing formation of circular and crisscross LIPSS. Opto-Electron. Adv. 2022, 5, 210066. [Google Scholar]

- Zhang, D.; Liu, R.; Li, Z. Irregular LIPSS produced on metals by single linearly polarized femtosecond laser. Int. J. Extrem. Manuf. 2022, 4, 015102. [Google Scholar]

- Omatsu, T.; Miyamoto, K.; Toyoda, K.; Morita, R.; Arita, Y.; Dholakia, K. A New Twist for Materials Science: The Formation of Chiral Structures Using the Angular Momentum of Light. Adv. Opt. Mater. 2019, 7, 1801672. [Google Scholar] [CrossRef]

- Syubaev, S.; Zhizhchenko, A.; Kuchmizhak, A.; Porfirev, A.; Pustovalov, E.; Vitrik, O.; Kulchin, Y.; Khonina, S.; Kudryashov, S. Direct laser printing of chiral plasmonic nanojets by vortex beams. Opt. Express 2017, 25, 10214–10223. [Google Scholar] [CrossRef]

- Kotov, N.A.; Liz-Marzán, L.M.; Weiss, P.S. Chiral Nanostructures: New Twists. ACS Nano 2021, 15, 12457–12460. [Google Scholar] [CrossRef]

- Jalil, S.A.; Akram, M.; Bhat, J.A.; Hayes, J.J.; Singh, S.C.; ElKabbash, M.; Guo, C. Creating superhydrophobic and antibacterial surfaces on gold by femtosecond laser pulses. Appl. Surf. Sci. 2020, 506, 144952. [Google Scholar] [CrossRef] [PubMed]

- He, Y.; Su, Y. Silicon Nano-Biotechnology; Springer: Berlin/Heidelberg, Germany, 2014; p. 109. [Google Scholar] [CrossRef]

- Santos, H.A. Porous Silicon for Biomedical Applications; Elsevier/Woodhead Publishing: Amsterdam, The Netherlands, 2014; p. 526. [Google Scholar] [CrossRef]

- Jaganathan, H.; Godin, B. Biocompatibility assessment of Si-based nano-and micro-particles. Adv. Drug Deliv. Rev. 2012, 64, 1800–1819. [Google Scholar]

- Hasany, M.; Taebnia, N.; Yaghmaei, S.; Shahbazi, M.-A.; Mehrali, M.; Dolatshahi-Pirouz, A.; Arpanaei, A. Silica nanoparticle surface chemistry: An important trait affecting cellular biocompatibility in two and three dimensional culture systems. Colloids Surf. B Biointerfaces 2019, 182, 110353. [Google Scholar]

- Canham, L.T. Silicon Quantum Wire Array Fabrication by Electrochemical and Chemical Dissolution of Wafers. Appl. Phys. Lett. 1990, 57, 1046–1048. [Google Scholar] [CrossRef]

- Takagi, H.; Ogawa, H.; Yamazaki, Y.; Ishizaki, A.; Nakagiri, T. Quantum Size Effects on Photoluminescence in Ultrafine Si Particles. Appl. Phys. Lett. 1990, 56, 2379–2380. [Google Scholar] [CrossRef]

- Erogbogbo, F.; Yong, K.-T.; Roy, I.; Xu, G.; Prasad, P.N.; Swihart, M.T. Biocompatible Luminescent Silicon Quantum Dots for Imaging of Cancer Cells. ACS Nano 2008, 2, 873–878. [Google Scholar]

- Gongalsky, M.B.; Osminkina, L.A.; Pereira, A.; Manankov, A.A.; Fedorenko, A.A.; Vasiliev, A.N.; Solovyev, V.V.; Kudryavtsev, A.A.; Sentis, M.; Kabashin, A.V.; et al. Laser-Synthesized Oxide-Passivated Bright Si Quantum Dots for Bioimaging. Sci. Rep. 2016, 6, 24732. [Google Scholar] [PubMed]

- Erogbogbo, F.; Chang, C.-W.; May, J.L.; Liu, L.; Kumar, R.; Law, W.-C.; Ding, H.; Yong, K.T.; Roy, I.; Sheshadri, M.; et al. Bioconjugation of Luminescent Silicon Quantum Dots to Gadolinium Ions for Bioimaging Applications. Nanoscale 2012, 4, 5483–5489. [Google Scholar]

- Tamarov, K.P.; Osminkina, L.A.; Zinovyev, S.V.; Maximova, K.A.; Kargina, J.V.; Gongalsky, M.B.; Ryabchikov, Y.; Al-Kattan, A.; Sviridov, A.P.; Sentis, M.; et al. Radio Frequency Radiation-Induced Hyperthermia Using Si Nanoparticle-Based Sensitizers for Mild Cancer Therapy. Sci. Rep. 2014, 4, 7034. [Google Scholar] [PubMed]

- Lee, C.; Kim, H.; Hong, C.; Kim, M.; Hong, S.; Lee, D.; Lee, W.I. Porous silicon as an agent for cancer thermotherapy based on near-infrared light irradiation. J. Mater. Chem. 2008, 18, 4790–4795. [Google Scholar]

- Park, J.-H.; Gu, L.; Von Maltzahn, G.; Ruoslahti, E.; Bhatia, S.N.; Sailor, M.J. Biodegradable luminescent porous silicon nanoparticles for in vivo applications. Nat. Mater. 2009, 8, 331–336. [Google Scholar]

- Kovalev, D.; Fujii, M. Silicon Nanocrystals: Photosensitizers for Oxygen Molecules. Adv. Mater. 2005, 17, 2531–2544. [Google Scholar]

- Timoshenko, V.Y.; Kudryavtsev, A.A.; Osminkina, L.A.; Vorontsov, A.S.; Ryabchikov, Y.V.; Belogorokhov, I.A.; Kovalev, D.; Kashkarov, P.K. Silicon Nanocrystals as Photosensitizers of Active Oxygen for Biomedical Applications. JETP Lett. 2006, 83, 423–426. [Google Scholar]

- Petriev, V.M.; Tischenko, V.K.; Mikhailovskaya, A.A.; Popov, A.A.; Tselikov, G.; Zelepukin, I.; Deyev, S.M.; Kaprin, A.D.; Ivanov, S.; Timoshenko, V.Y.; et al. Nuclear Nanomedicine Using Si Nanoparticles as Safe and Effective Carriers of 188Re Radionuclide for Cancer Therapy. Sci. Rep. 2019, 9, 2017. [Google Scholar] [CrossRef] [PubMed]

- Dolgaev, S.I.; Simakin, A.V.; Voronov, V.V.; Shafeev, G.A.; Bozon-Verduraz, F. Nanoparticles Produced by Laser Ablation of Solids in Liquid Environment. Appl. Surf. Sci. 2002, 186, 546–551. [Google Scholar]

- Kabashin, A.V.; Meunier, M. Synthesis of Colloidal Nanoparticles During Femtosecond Laser Ablation of Gold in Water. J. Appl. Phys. 2003, 94, 7941–7943. [Google Scholar]

- Mafuné, F.; Kohno, J.-Y.; Takeda, Y.; Kondow, T.; Sawabe, H. Formation of Gold Nanoparticles by Laser Ablation in Aqueous Solution of Surfactant. J. Phys. Chem. B 2001, 105, 5114–5120. [Google Scholar] [CrossRef]

- Li, Z.; Barnes, J.C.; Bosoy, A.; Stoddart, J.F.; Zink, J.I. Mesoporous silica nanoparticles in biomedical applications. Chem. Soc. Rev. 2012, 41, 2590–2605. [Google Scholar] [CrossRef]

- Salonen, J.; Kaukonen, A.M.; Hirvonen, J.; Lehto, V.-P. Mesoporous Silicon in Drug Delivery Applications. J. Pharm. Sci. 2008, 97, 632–653. [Google Scholar]

- Zabotnov, S.V.; Skobelkina, A.V.; Sergeeva, E.A.; Kurakina, D.A.; Khilov, A.V.; Kashaev, F.V.; Kaminskaya, T.P.; Presnov, D.E.; Agrba, P.D.; Shuleiko, D.V.; et al. Nanoparticles Produced via Laser Ablation of Porous Silicon and Silicon Nanowires for Optical Bioimaging. Sensors 2020, 20, 4874. [Google Scholar] [CrossRef]

- Skobelkina, A.V.; Kashaev, F.V.; Zabotnov, S.V.; Kolchin, A.V.; Kaminskaya, T.P.; Presnov, D.E.; Sergeeva, E.A.; Kirillin, M.Y.; Golovan, L.A.; Kashkarov, P.K. Structural and Photoluminescence Properties of Nanoparticles Formed by Laser Ablation of Porous Silicon in Ethanol and Liquid Nitrogen. In Proceedings of the 4th International Conference on Nanotechnologies and Biomedical Engineering, Chisinau, Moldova, 18–21 September 2019; pp. 101–104. [Google Scholar]

- Skobelkina, A.V.; Kashaev, F.V.; Kolchin, A.V.; Shuleiko, D.V.; Kaminskaya, T.P.; Presnov, D.E.; Golovan, L.V.; Kashkarov, P.K. Silicon Nanoparticles Formed via Pulsed Laser Ablation of Porous Silicon in Liquids. Tech. Phys. Lett. 2020, 46, 687–690. [Google Scholar] [CrossRef]

- Zabotnov, S.; Kurakina, D.; Kashaev, F.; Skobelkina, A.; Kolchin, A.; Kaminskaya, T.; Khilov, A.; Agrba, P.; Sergeeva, E.; Kashkarov, P.; et al. Structural and optical properties of nanoparticles formed by laser ablation of porous silicon in liquids: Perspectives in biophotonics. Quantum Electron. 2020, 50, 69–75. [Google Scholar] [CrossRef]

- Stillinger, F.H.; Weber, T.A. Computer simulation of local order in condensed phases of silicon. Phys. Rev. B 1985, 31, 5262–5271. [Google Scholar] [CrossRef]

- Tersoff, J. New empirical approach for the structure and energy of covalent systems. Phys. Rev. B 1988, 37, 6991–7000. [Google Scholar] [CrossRef]

- Shokeen, L.; Schelling, P.K. Thermodynamics and kinetics of silicon under conditions of strong electronic excitation. J. Appl. Phys. 2011, 109, 073503. [Google Scholar] [CrossRef]

- Lipp, V.P.; Ivanov, D.S.; Rethfeld, B.; Garcia, M.E. On the interatomic interaction potential that describes bond weakening in classical molecular-dynamic modelling. J. Opt. Technol. 2014, 81, 254–255. [Google Scholar] [CrossRef]

- EZijlstra, S.; Zier, T.; Bauerhenne, B.; Krylow, S.; Geiger, P.M.; Garcia, M.E. Femtosecond laser-induced bond breaking and structural modifications in silicon, TiO2, and defective graphene: An ab initio molecular dynamics study. Appl. Phys. A 2014, 114, 1–9. [Google Scholar]

- Kempkes, M.; Zier, T.; Singer, K.; Garcia, M.E. Ultrafast nonthermal NV center formation in diamond. Carbon 2021, 174, 524–530. [Google Scholar]

- Bauerhenne, B.; Lipp, V.P.; Zier, T.; Zijlstra, E.S.; Garcia, M.E. Self-Learning Method for Construction of Analytical Interatomic Potentials to Describe Laser-Excited Materials. Phys. Rev. Lett. 2020, 124, 085501. [Google Scholar] [CrossRef] [PubMed]

- Ivanov, D.S.; Zhigilei, L.V. Combined Atomistic-Continuum Modelling of Short-Pulse Laser Melting and Disintegration of Metal Films. Phys. Rev. B 2003, 68, 064114. [Google Scholar] [CrossRef]

- Anisimov, S.I.; Kapeliovich, B.L.; Perel’man, T.L. Electron Emission from Metal Surfaces Exposed to Ultrashort Laser Pulses. Zh. Eksp. Teor. Fiz. 1974, 66, 776. [Google Scholar]

- Lipp, V.P.; Rethfeld, B.; Garcia, M.E.; Ivanov, D.S. Atomistic-Continuum Modeling of Short Laser Pulse Melting of Si Targets. Phys. Rev. B 2014, 90, 245306. [Google Scholar] [CrossRef]

- van Driel, H.M. Kinetics of high-density plasmas generated in Si by 1.06- and 0.53-μm picosecond laser pulses. Phys. Rev. B 1987, 35, 8166–8176. [Google Scholar] [CrossRef]

- Shih, C.-Y.; Streubel, R.; Heberle, J.; Letzel, A.; Shugaev, M.V.; Wu, C.; Schmidt, M.; Gökce, B.; Barcikowski, S.; Zhigilei, L.V. Two mechanisms of nanoparticle generation in picosecond laser ablation in liquids: The origin of the bimodal size distribution. Nanoscale 2018, 10, 6900–6910. [Google Scholar] [CrossRef]

- Inogamov, N.A.; Khokhlov, V.A.; Petrov, Y.V.; Zhakhovsky, V.V. Hydrodynamic and molecular-dynamics modeling of laser ablation in liquid: From surface melting till bubble formation. Opt. Quantum Electron. 2020, 52, 63. [Google Scholar] [CrossRef]

- Rämer, A.; Osmani, O.; Rethfeld, B. Laser damage in silicon: Energy absorption, relaxation, and transport. J. Appl. Phys. 2014, 116, 053508. [Google Scholar] [CrossRef]

- Gaudiuso, C.; Terekhin, P.; Volpe, A.; Nolte, S.; Rethfeld, B.; Ancona, A. Experimental and theoretical study of the ablation of silicon with THz bursts of fs laser pulses. In Proceedings of the SPIE 119890H, Laser-Based Micro- and Nanoprocessing XVI, San Francisco, CA, USA, 22 January–28 February 2022; Volume 11989. [Google Scholar]

- Derrien, T.J.-Y.; Bulgakova, N.M. Modeling of silicon in femtosecond laser-induced modification regimes: Accounting for ambipolar diffusion. In Proceedings of the SPIE 102280E, Nonlinear Optics and Applications X, Prague, Czech Republic, 24–27 April 2017; Volume 102280. [Google Scholar]

- Marine, W.; Bulgakova, N.M.; Patrone, L.; Ozerov, I. Electronic mechanism of ion expulsion under UV nanosecond laser excitation of silicon: Experiment and modelling. Appl. Phys. A 2004, 79, 771–774. [Google Scholar] [CrossRef]

- Gan, Y.; Chen, J.K. A hybrid method for integrated atomistic-continuum simulation of ultrashort-pulse laser interaction with semiconductors. Comput. Phys. Commun. 2012, 183, 278–284. [Google Scholar] [CrossRef]

- Chen, J.K.; Tzou, D.Y.; Beraun, J.E. Numerical investigation of ultrashort laser damage in semiconductors. Int. J. Heat Mass Transf. 2005, 48, 501–509. [Google Scholar] [CrossRef]

- Kudryashov, S.I.; Danilov, P.A.; Bezhanov, S.G.; Rudenko, A.A.; Ionin, A.A.; Uryupin, S.A.; Umanskaya, S.F.; Smirnov, N.A. Plasmon-Enhanced Two-Photon Absorption of Infrared Femtosecond Laser Pulses in Thin Gold Films. JETP Lett. 2019, 109, 382–386. [Google Scholar] [CrossRef]

- Itina, T.E.; Shcheblanov, N.S. Effect of Laser field on Collision Frequencies and Absorption during Ultra-Short Laser Interactions with Dielectric Materials. In Fundamentals of Laser-Assisted Micro- and Nanotechnologies; Springer: Cham, Switzerland, 2014; Volume 906506. [Google Scholar]

- Venkat, P.; Otobe, T. Three-temperature modeling of laser-induced damage process in silicon. Appl. Phys. Express 2022, 15, 041008. [Google Scholar]

- Gnilitskyi, I.; Gruzdev, V.; Bulgakova, N.M.; Mocek, T.; Orazi, L. Mechanisms of high-regularity periodic structuring of silicon surface by sub-MHz repetition rate ultrashort laser pulses. Appl. Phys. Lett. 2016, 109, 143101. [Google Scholar]

- Lipp, V.; Rethfeld, B.; Garcia, M.; Ivanov, D. Solving a System of Differential Equations Containing a Diffusion Equation with Nonlinear Terms on the Example of Laser Heating in Silicon. Appl. Sci. 2020, 10, 1853. [Google Scholar]

- Wang, T.-Y.; Lee, Y.-M.; Chen, C.C.-P. 3D Thermal-ADI: An Efficient Chip-Level Transient Thermal Simulator. In Proceedings of the 2003 International Symposium on Physical Design, Monterey, CA, USA, 6–9 April 2003; pp. 10–17. [Google Scholar]

- Petrov, Y.V.; A Inogamov, N.; I Anisimov, S.; Migdal, K.P.; A Khokhlov, V.; Khishchenko, K.V. Thermal conductivity of condensed gold in states with the strongly excited electron subsystem. J. Phys. Conf. Ser. 2015, 653, 012087. [Google Scholar] [CrossRef]

- Petrov, Y.V.; A Inogamov, N.; A Khokhlov, V.; Migdal, K.P. Electron thermal conductivity of nickel and aluminum in solid and liquid phases in two-temperature states. J. Phys. Conf. Ser. 2021, 1787, 012025. [Google Scholar] [CrossRef]

- Zhigilei, L.V.; Lin, Z.; Ivanov, D.S. Atomistic Modeling of Short Pulse Laser Ablation of Metals: Connections between Melting, Spallation, and Phase Explosion. J. Phys. Chem. C 2009, 113, 11892–11906. [Google Scholar] [CrossRef]

- Ivanov, D.S.; Izgin, T.; Maiorov, A.N.; Veiko, V.P.; Rethfeld, B.; Dombrovska, Y.I.; Garcia, M.E.; Zavestovskaya, I.N.; Klimentov, S.M.; Kabashin, A.V. Numerical Investigation of Ultrashort Laser-Ablative Synthesis of Metal Nanoparticles in Liquids Using Atomistic-Continuum Model. Molecules 2019, 25, 67. [Google Scholar]

- Ivanov, D.S.; Klimentov, S.M.; Mayorov, A.N.; Timoshenko, V.Y.; Zavestovskaya, I.N.; Rethfeld, B.; Garcia, M.E.; Popov, A.; Shakhov, P.; Kabashin, A.V. Ultrafast laser ablation of gold in liquids: Effect of laser pulse overlap-induced surface porosity on size distribution of formed nanoparticles. Appl. Surf. Sci. 2023, 158662. [Google Scholar] [CrossRef]

- Timoshenko, V.Y.; Dittrich, T.; Sieber, I.; Rappich, J.; Kamenev, B.V.; Kashkarov, P.K. Laser-induced melting of porous silicon. Phys. Status Solidi A 2000, 182, 325–330. [Google Scholar] [CrossRef]

- Ivanov, K.A.; Gavrilin, I.M.; Nazarkina, Y.V.; Kargina, Y.V.; Bozhev, I.V.; Sukhanov, N.S.; Volkov, R.V.; Timoshenko, V.Y.; Gavrilov, S.A.; Savel’ev, A.B. Imitating the effect of amplified sponta neous emission pedestal at relativistically intense laser interaction with nanostructured solid targets. Laser Phys. Lett. 2020, 17, 045302. [Google Scholar] [CrossRef]

- Kharin, A.Y.; Grigoryeva, M.S.; Zavestovskaya, I.N.; Timoshenko, V.Y. Effect of Silicon Target Porosity on Laser Ablation Threshold: Molecular Dynamics Simulation. Laser Phys. Lett. 2021, 18, 076001. [Google Scholar]

- Bulgakova, N.M.; Stoian, R.; Rosenfeld, A.; Hertel, I.V.; Campbell, E.E.B. Fast Electronic Transport and Coulomb Explosion in Materials Irradiated with Ultrashort Laser Pulses. In Laser Ablation and Its Applications; Springer Series in Optical Sciences; Springer: Boston, MA, USA, 2007; Volume 129, pp. 17–36. [Google Scholar]

- Smirnov, N.; Kudryashov, S.; Rudenko, A.; Zayarny, D.; Ionin, A. Pulsewidth and ambient medium effects during ultrashort-pulse laser ablation of silicon in air and water. Appl. Surf. Sci. 2021, 562, 150243. [Google Scholar]

- Wang, J.; Fang, F.; An, H.; Wu, S.; Qi, H.; Cai, Y.; Guo, G. Laser machining fundamentals: Micro, nano, atomic and close-to-atomic scales. J. Extrem. Manuf. 2023, 5, 012005. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Grigoryeva, M.S.; Kutlubulatova, I.A.; Lukashenko, S.Y.; Fronya, A.A.; Ivanov, D.S.; Kanavin, A.P.; Timoshenko, V.Y.; Zavestovskaya, I.N. Modeling of Short-Pulse Laser Interactions with Monolithic and Porous Silicon Targets with an Atomistic–Continuum Approach. Nanomaterials 2023, 13, 2809. https://doi.org/10.3390/nano13202809

Grigoryeva MS, Kutlubulatova IA, Lukashenko SY, Fronya AA, Ivanov DS, Kanavin AP, Timoshenko VY, Zavestovskaya IN. Modeling of Short-Pulse Laser Interactions with Monolithic and Porous Silicon Targets with an Atomistic–Continuum Approach. Nanomaterials. 2023; 13(20):2809. https://doi.org/10.3390/nano13202809

Chicago/Turabian StyleGrigoryeva, Maria S., Irina A. Kutlubulatova, Stanislav Yu. Lukashenko, Anastasia A. Fronya, Dmitry S. Ivanov, Andrey P. Kanavin, Victor Yu. Timoshenko, and Irina N. Zavestovskaya. 2023. "Modeling of Short-Pulse Laser Interactions with Monolithic and Porous Silicon Targets with an Atomistic–Continuum Approach" Nanomaterials 13, no. 20: 2809. https://doi.org/10.3390/nano13202809