Formulation of Chlorine-Dioxide-Releasing Nanofibers for Disinfection in Humid and CO2-Rich Environment

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

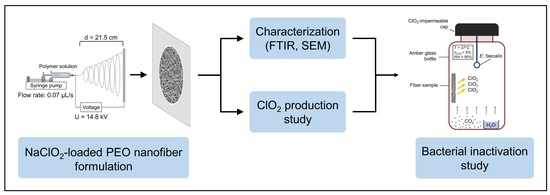

2.2. Precursor Polymer Solutions and Electrospinning

2.3. Fourier-Transform Infrared (FTIR) Spectroscopy

2.4. Scanning Electron Microscopy

2.5. Chlorine Dioxide Production of the Fibrous Samples

2.5.1. Experimental Setup

2.5.2. Measurements and Data Analysis

- To measure the total amount of ClO2 generated in 24 h by fibers of various weights, we used 1, 5, 10, 15, 20 and 30 mg samples. Using these data, we calculated the ClO2-generating ability per weight and the ClO2 yield of the samples compared to the theoretical values. In this experiment, the CO2 concentration was set to 5%.

- We examined the effect of different CO2 concentrations (5, 10, 15%) on the ClO2 production of 5 mg samples in a 24 h measurement.

- The effect of residence time of fibers in the medium was evaluated by measuring the ClO2 production of 5 mg samples after 24, 48 and 72 h.

2.6. Bacterial Inactivation Study

3. Results

3.1. Morphological Characterization

3.2. FTIR Analysis

3.3. Chlorine Dioxide Production

3.4. Bacterial Inactivation Study

4. Discussion

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Messler, S.; Klare, I.; Wappler, F.; Werner, G.; Ligges, U.; Sakka, S.G.; Mattner, F. Reduction of nosocomial bloodstream infections and nosocomial vancomycin-resistant Enterococcus faecium on an intensive care unit after introduction of antiseptic octenidine-based bathing. J. Hosp. Infect. 2019, 101, 264–271. [Google Scholar] [CrossRef] [PubMed]

- McDonnell, G.; Russell, A.D. Antiseptics and disinfectants: Activity, action, and resistance. Clin. Microbiol. Rev. 1999, 12, 147–179. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Hardy, K.; Sunnucks, K.; Gil, H.; Shabir, S.; Trampari, E.; Hawkey, P.; Webber, M. Increased Usage of Antiseptics Is Associated with Reduced Susceptibility in Clinical Isolates of Staphylococcus aureus. mBio 2018, 9, Issue 3. e00894–e00918. [Google Scholar] [CrossRef] [Green Version]

- Nicolae Dopcea, G.; Dopcea, I.; Nanu, A.E.; Diguta, C.F.; Matei, F. Resistance and cross-resistance in Staphylococcus spp. strains following prolonged exposure to different antiseptics. J. Glob. Antimicrob. Resist. 2020, 21, 399–404. [Google Scholar] [CrossRef] [PubMed]

- Kampf, G. Antibiotic Resistance Can Be Enhanced in Gram-Positive Species by Some Biocidal Agents Used for Disinfection. Antibiotics 2019, 8, 15. [Google Scholar] [CrossRef] [Green Version]

- Zhang, Y.Z.; Zhao, Y.J.; Xu, C.Q.; Zhang, X.C.; Li, J.H.; Dong, G.F.; Cao, J.M.; Zhou, T.L. Chlorhexidine exposure of clinical Klebsiella pneumoniae strains leads to acquired resistance to this disinfectant and to colistin. Int. J. Antimicrob. Agents 2019, 53, 864–867. [Google Scholar] [CrossRef]

- Liu, W.J.; Fu, L.; Huang, M.; Zhang, J.P.; Wu, Y.; Zhou, Y.S.; Zeng, J.; Wang, G.X. Frequency of antiseptic resistance genes and reduced susceptibility to biocides in carbapenem-resistant Acinetobacter baumannii. J. Med. Microbiol. 2017, 66, 13–17. [Google Scholar] [CrossRef]

- Herczegh, A.; Gyurkovics, M.; Agababyan, H.; Ghidán, Á.; Lohinai, Z. Comparing the efficacy of hyper-pure chlorine-dioxide with other oral antiseptics on oral pathogen microorganisms and biofilm in vitro. Acta Microbiol. Immunol. Hung. 2013, 60, 359–373. [Google Scholar] [CrossRef]

- Wen, G.; Xu, X.; Huang, T.; Zhu, H.; Ma, J. Inactivation of three genera of dominant fungal spores in groundwater using chlorine dioxide: Effectiveness, influencing factors, and mechanisms. Water Res. 2017, 125, 132–140. [Google Scholar] [CrossRef]

- Venkatnarayanan, S.; Sriyutha Murthy, P.; Kirubagaran, R.; Venugopalan, V.P. Chlorine dioxide as an alternative antifouling biocide for cooling water systems: Toxicity to larval barnacle Amphibalanus reticulatus (Utinomi). Mar. Pollut. Bull. 2017, 124, 803–810. [Google Scholar] [CrossRef]

- Ofori, I.; Maddila, S.; Lin, J.; Jonnalagadda, S.B. Chlorine dioxide inactivation of Pseudomonas aeruginosa and Staphylococcus aureus in water: The kinetics and mechanism. J. Water Process. Eng. 2018, 26, 46–54. [Google Scholar] [CrossRef]

- Stratilo, C.W.; Crichton, M.K.; Sawyer, T.W. Decontamination Efficacy and Skin Toxicity of Two Decontaminants against Bacillus anthracis. PLoS ONE 2015, 10, e0138491. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Wei, R.; Wang, X.; Cao, Y.; Gong, L.; Liu, X.; Zhang, G.; Guo, C. Chlorine Dioxide Inhibits African Swine Fever Virus by Blocking Viral Attachment and Destroying Viral Nucleic Acids and Proteins. Front. Vet. Sci. 2022, 9, 844058. [Google Scholar] [CrossRef] [PubMed]

- Noszticzius, Z.; Wittmann, M.; Kály-Kullai, K.; Beregvári, Z.; Kiss, I.; Rosivall, L.; Szegedi, J. Chlorine dioxide is a size-selective antimicrobial agent. PLoS ONE 2013, 8, e79157. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Akamatsu, A.; Lee, C.; Morino, H.; Miura, T.; Ogata, N.; Shibata, T. Six-month low level chlorine dioxide gas inhalation toxicity study with two-week recovery period in rats. J. Occup. Med. Toxicol. 2012, 7, 8. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Ma, J.W.; Huang, B.S.; Hsu, C.W.; Peng, C.W.; Cheng, M.L.; Kao, J.Y.; Way, T.D.; Yin, H.C.; Wang, S.S. Efficacy and Safety Evaluation of a Chlorine Dioxide Solution. Int. J. Environ. Res. Public. Health 2017, 14, 329. [Google Scholar] [CrossRef] [Green Version]

- Vincenti, S.; de Waure, C.; Raponi, M.; Teleman, A.A.; Boninti, F.; Bruno, S.; Boccia, S.; Damiani, G.; Laurenti, P. Environmental surveillance of Legionella spp. colonization in the water system of a large academic hospital: Analysis of the four-year results on the effectiveness of the chlorine dioxide disinfection method. Sci. Total Environ. 2019, 657, 248–253. [Google Scholar] [CrossRef]

- Trinh, V.M.; Yuan, M.-H.; Chen, Y.-H.; Wu, C.-Y.; Kang, S.-C.; Chiang, P.-C.; Hsiao, T.-C.; Huang, H.-P.; Zhao, Y.-L.; Lin, J.-F.; et al. Chlorine dioxide gas generation using rotating packed bed for air disinfection in a hospital. J. Clean. Prod. 2021, 320, 128885. [Google Scholar] [CrossRef]

- Lowe, J.J.; Gibbs, S.G.; Iwen, P.C.; Smith, P.W.; Hewlett, A.L. Impact of Chlorine Dioxide Gas Sterilization on Nosocomial Organism Viability in a Hospital Room. Int. J. Environ. Res. Public. Health 2013, 10, 2596–2605. [Google Scholar] [CrossRef] [Green Version]

- Lowe, J.J.; Hewlett, A.L.; Iwen, P.C.; Smith, P.W.; Gibbs, S.G. Evaluation of ambulance decontamination using gaseous chlorine dioxide. Prehosp. Emerg. Care 2013, 17, 401–408. [Google Scholar] [CrossRef]

- Saini, R. Efficacy of preprocedural mouth rinse containing chlorine dioxide in reduction of viable bacterial count in dental aerosols during ultrasonic scaling: A double-blind, placebo-controlled clinical trial. Dent. Hypotheses 2015, 6, 65–71. [Google Scholar] [CrossRef]

- Yeturu, S.K.; Acharya, S.; Urala, A.S.; Pentapati, K.C. Effect of Aloe vera, chlorine dioxide, and chlorhexidine mouth rinses on plaque and gingivitis: A randomized controlled trial. J. Oral Biol. Craniofac. Res. 2016, 6, 54–58. [Google Scholar] [CrossRef] [Green Version]

- Palcso, B.; Moldovan, Z.; Suvegh, K.; Herczegh, A.; Zelko, R. Chlorine dioxide-loaded poly(acrylic acid) gels for prolonged antimicrobial effect. Mater. Sci. Eng. C Mater. Biol. Appl. 2019, 98, 782–788. [Google Scholar] [CrossRef] [PubMed]

- Zhou, S.; Hu, C.; Zhao, G.; Jin, T.; Sheen, S.; Han, L.; Liu, L.; Yam, K.L. Novel generation systems of gaseous chlorine dioxide for Salmonella inactivation on fresh tomato. Food Control 2018, 92, 479–487. [Google Scholar] [CrossRef]

- Son, W.K.; Youk, J.H.; Lee, T.S.; Park, W.H. The effects of solution properties and polyelectrolyte on electrospinning of ultrafine poly(ethylene oxide) fibers. Polymer 2004, 45, 2959–2966. [Google Scholar] [CrossRef]

- Chuang, Y.-H.; Wu, K.-L.; Lin, W.-C.; Shi, H.-J. Photolysis of Chlorine Dioxide under UVA Irradiation: Radical Formation, Application in Treating Micropollutants, Formation of Disinfection Byproducts, and Toxicity under Scenarios Relevant to Potable Reuse and Drinking Water. Environ. Sci. Technol. 2022, 56, 2593–2604. [Google Scholar] [CrossRef]

- Kály-Kullai, K.; Wittmann, M.; Noszticzius, Z.; Rosivall, L. Can chlorine dioxide prevent the spreading of coronavirus or other viral infections? Medical hypotheses. Physiol. Int. 2020, 107, 1–11. [Google Scholar] [CrossRef] [Green Version]

- Fiore, E.; Van Tyne, D.; Gilmore, M.S. Pathogenicity of Enterococci. Microbiol. Spectr. 2019, 7, 189–221. [Google Scholar] [CrossRef]

- Shetty, S.S.; Jayarama, A.; Karunasagar, I.; Pinto, R. A review on chemi-resistive human exhaled breath biosensors for early diagnosis of disease. Mater. Today: Proc. 2022, 55, 122–126. [Google Scholar] [CrossRef]

- Saravanan, L.; Subramanian, S. Surface Chemical Studies on Silicon Carbide Suspensions in the Presence of Poly (Ethylene Glycol) and Chitosan. Colloid Surf. Sci. 2017, 2, 6–20. [Google Scholar] [CrossRef]

- Kieffer, R.G.; Gordon, G. Disproportionation of chlorous acid. II. Kinetics. Inorg. Chem. 1968, 7, 239–244. [Google Scholar] [CrossRef]

- Cramariuc, B.; Cramariuc, R.; Scarlet, R.; Manea, L.R.; Lupu, I.G.; Cramariuc, O. Fiber diameter in electrospinning process. J. Electrost. 2013, 71, 189–198. [Google Scholar] [CrossRef]

- Edikresnha, D.; Suciati, T.; Khairurrijal, K. Preliminary study of composite fibers polyvinylpyrrolidone/cellulose acetate loaded by garlic extract by means of electrospinning method. Mater. Today: Proc. 2021, 44, A1–A4. [Google Scholar] [CrossRef]

- Nartetamrongsutt, K.; Chase, G.G. The influence of salt and solvent concentrations on electrospun polyvinylpyrrolidone fiber diameters and bead formation. Polymer 2013, 54, 2166–2173. [Google Scholar] [CrossRef]

- Yalcinkaya, F.; Yalcinkaya, B.; Jirsak, O. Influence of Salts on Electrospinning of Aqueous and Nonaqueous Polymer Solutions. J. Nanomater. 2015, 2015, 134251. [Google Scholar] [CrossRef]

- Fan, L.; Xu, Y.; Zhou, X.; Chen, F.; Fu, Q. Effect of salt concentration in spinning solution on fiber diameter and mechanical property of electrospun styrene-butadiene-styrene tri-block copolymer membrane. Polymer 2018, 153, 61–69. [Google Scholar] [CrossRef]

- Chen, C.-K.; Liao, M.-G.; Wu, Y.-L.; Fang, Z.-Y.; Chen, J.-A. Preparation of Highly Swelling/Antibacterial Cross-Linked N-Maleoyl-Functional Chitosan/Polyethylene Oxide Nanofiber Meshes for Controlled Antibiotic Release. Mol. Pharm. 2020, 17, 3461–3476. [Google Scholar] [CrossRef]

- Angel, N.; Li, S.; Yan, F.; Kong, L. Recent advances in electrospinning of nanofibers from bio-based carbohydrate polymers and their applications. Trends Food Sci. Technol. 2022, 120, 308–324. [Google Scholar] [CrossRef]

| msample (mg) | nNaClO2 (mmol) | c(ClO2)g (ppm) | c(ClO2)g Theoretical (ppm) 1 | Yield (%) |

|---|---|---|---|---|

| 1 | 0.217 | 65.79 | 73.57 | 89.43 |

| 5 | 1.084 | 115.54 | 367.85 | 31.41 |

| 10 | 2.168 | 134.93 | 735.69 | 18.34 |

| 15 | 3.252 | 135.91 | 1103.54 | 12.32 |

| 20 | 4.336 | 141.16 | 1471.38 | 9.59 |

| 30 | 6.504 | 145.23 | 2207.07 | 6.58 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Palcsó, B.; Kazsoki, A.; Herczegh, A.; Ghidán, Á.; Pinke, B.; Mészáros, L.; Zelkó, R. Formulation of Chlorine-Dioxide-Releasing Nanofibers for Disinfection in Humid and CO2-Rich Environment. Nanomaterials 2022, 12, 1481. https://doi.org/10.3390/nano12091481

Palcsó B, Kazsoki A, Herczegh A, Ghidán Á, Pinke B, Mészáros L, Zelkó R. Formulation of Chlorine-Dioxide-Releasing Nanofibers for Disinfection in Humid and CO2-Rich Environment. Nanomaterials. 2022; 12(9):1481. https://doi.org/10.3390/nano12091481

Chicago/Turabian StylePalcsó, Barnabás, Adrienn Kazsoki, Anna Herczegh, Ágoston Ghidán, Balázs Pinke, László Mészáros, and Romána Zelkó. 2022. "Formulation of Chlorine-Dioxide-Releasing Nanofibers for Disinfection in Humid and CO2-Rich Environment" Nanomaterials 12, no. 9: 1481. https://doi.org/10.3390/nano12091481