Nanolayer Growth on 3-Dimensional Micro-Objects by Pulsed Laser Deposition

Abstract

:1. Introduction

2. Materials and Methods

2.1. Experimental Configurations

2.2. Cellulose Growth

2.3. Polymer/Y3Al5O12:Ce Growth

3. Results

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Zhao, H.; Lee, Y.; Han, M.; Sharma, B.K.; Chen, X.; Ahn, J.-H.; Rogers, J.A. Nanofabrication approaches for functional three-dimensional architectures. Nano Today 2020, 30, 100825. [Google Scholar] [CrossRef]

- Eason, R. Pulsed Laser Deposition of Thin Films: Applications-Led Growth of Functional Materials; John Wiley and Sons: Hoboken, NJ, USA, 2007. [Google Scholar]

- Lorusso, A.; Perrone, A.; Gontad, F. Overview on development of metallic and superconducting photocathodes by the PLD technique for linear accelerator source. Nucl. Instrum. Methods Phys. Res. Sect. A 2019, 942, 162429. [Google Scholar] [CrossRef]

- Anderson, A.A.; Eason, R.W.; Hickey, L.M.B.; Jelinek, M.; Grivas, C.; Gill, D.S.; Vainos, N.A. Ti:Sapphire planar waveguide laser grown by pulsed laser deposition. Opt. Lett. 1997, 22, 1556–1558. [Google Scholar] [CrossRef]

- Grant-Jacob, J.A.; Beecher, S.J.; Parsonage, T.L.; Hua, P.; Mackenzie, J.I.; Shepherd, D.P.; Eason, R.W. An 11.5 W Yb:YAG planar waveguide laser fabricated via pulsed laser deposition. Opt. Mater. Express 2016, 6, 91–96. [Google Scholar] [CrossRef]

- Grivas, C.; Gill, D.S.; Mailis, S.; Boutsikaris, L.; Vainos, N.A. Indium oxide thin-film holographic recorders grown via excimer laser reactive sputtering. Appl. Phys. A 1998, 66, 201–204. [Google Scholar] [CrossRef]

- Tsigara, A.; Velli, L.; Giannoudakos, A.; Varsamis, C.P.E.; Kompitsas, M.; Vainos, N.A.; Kamitsos, E.I. Pulsed laser deposited lead-germanate glass systems. Appl. Phys. A 2004, 79, 1319–1321. [Google Scholar] [CrossRef]

- Hänisch, J.; Iida, K.; Hühne, R.; Tarantini, C. Fe-based superconducting thin films preparation and tuning of superconducting properties. Supercond. Sci. Technol. 2019, 32, 093001. [Google Scholar] [CrossRef]

- De Bonis, A.; Teghil, R. Ultra-Short Pulsed Laser Deposition of Oxides, Borides and Carbides of Transition Elements. Coatings 2020, 10, 501. [Google Scholar] [CrossRef]

- Hansen, S.G.; Robitaille, T.E. Formation of polymer films by pulsed laser evaporation. Appl. Phys. Lett. 1988, 52, 81–83. [Google Scholar] [CrossRef]

- Chrisey, D.B.; Pique’, A.; McGill, R.A.; Horwitz, J.S.; Ringeisen, B.R.; Bubb, D.M.; Wu, P.K. Laser Deposition of Polymer and Biomaterial Films. Chem. Rev. 2003, 103, 553–576. [Google Scholar] [CrossRef]

- Gittard, S.D.; Miller, P.R.; Jin, C.; Martin, T.N.; Boehm, R.D.; Chisholm, B.J.; Stafslien, S.J.; Daniels, J.W.; Cilz, N.; Monteiro-Riviere, N.A.; et al. Deposition of antimicrobial coatings on microstereolithography-fabricated microneedles. JOM 2011, 63, 59–68. [Google Scholar] [CrossRef]

- Courtenay, J.C.; Johns, M.A.; Galembeck, F.; Deneke, C.; Lanzoni, E.M.; Costa, C.A.; Scott, J.L.; Sharma, R.I. Surface modified cellulose scaffolds for tissue engineering. Cellulose 2017, 24, 253–567. [Google Scholar] [CrossRef] [Green Version]

- Bonne, M.J.; Edler, K.J.; Buchanan, J.G.; Wolverson, D.; Psillakis, E.; Helton, M.; Thielemans, W.; Marken, F. Thin film modified electrodes with reconstituted cellulose-PDDAC films for the accumulation and detection of triclosan. J. Phys. Chem. C 2008, 112, 2660–2666. [Google Scholar] [CrossRef]

- He, P.J.W.; Katis, I.N.; Kumar, A.J.U.; Bryant, C.A.; Keevil, C.W.; Somani, B.K.; Mahobia, N.; Eason, R.W.; Sones, C.L. Laser-patterned paper-based sensors for rapid point-of-care detection and antibiotic-resistance testing of bacterial infections. Biosens. Bioelectron. 2020, 152, 112008. [Google Scholar] [CrossRef]

- Petritz, A.; Wolfberger, A.; Fian, A.; Irimia-Vladu, M.; Haase, A.; Gold, H.; Rothlander, T.; Griesser, T.; Stadlober, B. Cellulose as biodegradable high-k dielectric layer in organic complementary inverters. Appl. Phys. Lett. 2013, 103, 153303. [Google Scholar] [CrossRef]

- Karoutsos, V.; Raptis, P.; Bagiokis, E.; Lorusso, A.; Perrone, A.; Vainos, N.A. High optical quality cellulose thin films grown from raw natural cotton by pulsed laser deposition. Appl. Phys. A 2019, 125, 268. [Google Scholar] [CrossRef]

- Röder, J.; Faupel, J.; Krebs, H.-U. Growth of polymer–Metal nanocomposites by pulsed laser deposition. Appl. Phys. A 2008, 93, 863. [Google Scholar] [CrossRef] [Green Version]

- Karoutsos, V.; Koutselas, I.; Orfanou, P.; Mpatzaka, T.; Vasileiadis, M.; Vassilakopoulou, A.; Vainos, N.A.; Perrone, A. One-pot synthesis and transfer of PMMA/Ag photonic nanocomposites by pulsed laser deposition. Appl. Phys. A 2015, 120, 707–716. [Google Scholar] [CrossRef]

- Vainos, N.A. Remote-point photonic sensors (RPHOS): Concepts-materials-devices. Opt. Data Process. Storage 2018, 4, 30–37. [Google Scholar] [CrossRef] [Green Version]

- Xu, L.; Zhao, G.; Meng, S.; Fang, Y.; Hou, J.; Liu, Y.; Liao, M.; Zou, J.; Hu, L. Enhanced luminescent performance for remote LEDs of YAG:Ce phosphor in-glass film on regular textured glass substrate by using chemical wet etching. Ceram. Int. 2018, 44, 22283. [Google Scholar] [CrossRef]

- Chen, L.-C.; Lin, W.-W.; Chen, J.W. Fabrication of GaN-Based White Light-Emitting Diodes on Yttrium Aluminum Garnet-Polydimethylsiloxane Flexible Substrates. Adv. Mater. Sci. Eng. 2015, 2015, 537163. [Google Scholar] [CrossRef] [Green Version]

- Sreevalsa, S.; Ranjith, P.; Ahmad, S.; Sahoo, S.K.; Som, S.; Pandeye, M.K.; Das, S. Host sensitized photoluminescence in Sr2.9−3x/2LnxAlO4F: 0.1Eu3+ (Ln = Gd, Y) for innovative flexible lighting applications. Ceram. Int. 2020, 46, 21448–21460. [Google Scholar] [CrossRef]

- Parajuli, P.; Allison, S.W.; Sabri, F. Spincoat-fabricated multilayer PDMS phosphor composites for thermometry. Meas. Sci. Technol. 2017, 28, 065101. [Google Scholar] [CrossRef]

- Smet, P.F.; Parmentier, A.B.; Poelman, D. Selecting Conversion Phosphors for White Light-Emitting Diodes. J. Electrochem. Soc. 2011, 158, R37–R54. [Google Scholar] [CrossRef] [Green Version]

- Fang, Y.; Tian, X.; Liu, J.; Zhang, Y.; Liu, Y.; Zhao, G.; Zou, J.; Vainos, N.; Hou, J. Tri-chromatic Emission from a Single-phase Na5Y4(SiO4)4F: Eu2+, Tb3+, Eu3+ Phosphor for White-light-emitting Diodes. J. Lumin. 2019, 207, 34–40. [Google Scholar] [CrossRef]

- Ricci, P.C. Assessment of crystalline materials for solid state lighting applications: Beyond the rare earth elements. Crystals 2020, 10, 559. [Google Scholar] [CrossRef]

- Ruan, C.; Zhang, Y.; Lu, M.; Ji, C.; Sun, C.; Chen, X.; Chen, H.; Colvin, V.L.; Yu, W.W. White Light-Emitting Diodes Based on AgInS2/ZnS Quantum Dots with Improved Bandwidth in Visible Light Communication. Nanomaterials 2016, 6, 13. [Google Scholar] [CrossRef] [Green Version]

- Vainos, N.A.; Grivas, C.; Fotakis, C.; Eason, R.W.; Anderson, A.A.; Gill, D.S.; Shepherd, D.P.; Jelinek, M.; Lancock, J.; Sonsky, J. Planar Waveguides of Ti:Sapphire, Nd:GGG and Nd:YAG grown by pulsed laser deposition. Appl. Surf. Sci. 1998, 129, 514–519. [Google Scholar] [CrossRef]

- Choe, J.Y. Luminescence and compositional analysis of Y3Al5O12:Ce films fabricated by pulsed-laser deposition. Mat. Res. Innov. 2002, 6, 238–241. [Google Scholar] [CrossRef]

- Korir, P.C.; Dejene, F.B. Substrate temperature effect on the structural and photoluminescence properties of (Y-Gd)3Al5O12:Ce3+ thin films prepared by pulsed laser deposition. Mater. Res. Express 2019, 6, 096431. [Google Scholar] [CrossRef]

- Darwish, A.M.; Moore, S.; Mohammad, A.; Alexander, D.; Bastian, T.; Dorlus, W.; Sarkisov, S.; Patel, D.; Mele, P.; Koplitz, B.; et al. Polymer nano-composite films with inorganic upconversion phosphor and electro-optic additives made by concurrent triple-beam matrix assisted and direct pulsed laser deposition. Compos. Part. B 2017, 109, 82–90. [Google Scholar] [CrossRef] [Green Version]

- Tucureanu, V.; Matei, A.; Mihalache, I.; Danila, M.; Popescu, M.; Bita, B. Synthesis and characterization of YAG:Ce, Gd and YAG:Ce, Gd/PMMA nanocomposites for optoelectronic applications. J. Mater. Sci. 2015, 50, 1883–1890. [Google Scholar] [CrossRef]

- Tucureanu, V.; Matei, A.; Avram, A. The effect of the polymeric matrix on the emission properties of YAG based phosphors. J. Alloys Compd. 2020, 844, 156136. [Google Scholar] [CrossRef]

- Kasuya, R.; Kawano, A.; Isobe, T.; Kuma, H.; Katano, J. Characteristic optical properties of transparent color conversion film prepared from YAG:Ce3+ nanoparticles. Appl. Phys. Lett. 2007, 91, 111916. [Google Scholar] [CrossRef] [Green Version]

- Koizumi, H.; Watabe, J.; Sugiyama, S.; Hirabayashi, H.; Tokuno, Y.; Wada, H.; Homma, T. Properties of Ce3+-Doped Y3Al5O12 Phosphor Nanoparticles Formed by Laser Ablation in Liquid. ECS J. Solid State Sci. Technol. 2018, 7, R63–R69. [Google Scholar] [CrossRef]

| Experimental Condition/Parameter | Specification |

|---|---|

| Target | Natural raw cotton |

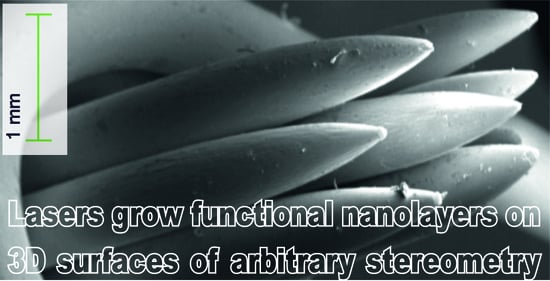

| Substrate | Ensemble of stainless-steel needles |

| Target—substrate distance | 12 mm |

| Deposition temperature | 20 °C |

| Background pressure | <1 × 10−4 Pa |

| Laser wavelength | 193 nm |

| Laser pulse duration | 5 ns |

| Laser spot size | 1 mm2 |

| Laser fluence | ~8 mJ cm−2 |

| Laser pulse repetition rate | 100 Hz |

| Number of pulses nominal per run | 360,000 |

| Experimental Condition/Parameter | Specification |

|---|---|

| Targets | PMMA/YAG:Ce and PDMS/YAG:Ce (10:1 w/w) |

| Substrates | Metal parts/Polymer fibers (dia. 100 µm/500 µm) |

| Target—substrate distance | 12 mm |

| Deposition temperature | 20 °C |

| Background pressure | <1 × 10−3 Pa |

| Laser wavelength | 193 nm |

| Laser pulse duration | 5 ns |

| Laser spot size | 0.9 mm2 |

| Laser fluence | PMMA: 50–200 mJ cm−2/PDMS: 25–100 mJ cm−2 |

| Laser pulse repetition rate | 100 Hz |

| Number of pulses nominal per run | 360,000 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Vainos, N.A.; Bagiokis, E.; Karoutsos, V.; Hou, J.; Liu, Y.; Zou, J.; Fang, Y.; Papachristopoulou, K.; Lorusso, A.; Caricato, A.P.; et al. Nanolayer Growth on 3-Dimensional Micro-Objects by Pulsed Laser Deposition. Nanomaterials 2021, 11, 35. https://doi.org/10.3390/nano11010035

Vainos NA, Bagiokis E, Karoutsos V, Hou J, Liu Y, Zou J, Fang Y, Papachristopoulou K, Lorusso A, Caricato AP, et al. Nanolayer Growth on 3-Dimensional Micro-Objects by Pulsed Laser Deposition. Nanomaterials. 2021; 11(1):35. https://doi.org/10.3390/nano11010035

Chicago/Turabian StyleVainos, Nikolaos A., Eleftherios Bagiokis, Vagelis Karoutsos, Jingshan Hou, Yufeng Liu, Jun Zou, Yongzheng Fang, Konstantina Papachristopoulou, Antonella Lorusso, Anna Paola Caricato, and et al. 2021. "Nanolayer Growth on 3-Dimensional Micro-Objects by Pulsed Laser Deposition" Nanomaterials 11, no. 1: 35. https://doi.org/10.3390/nano11010035