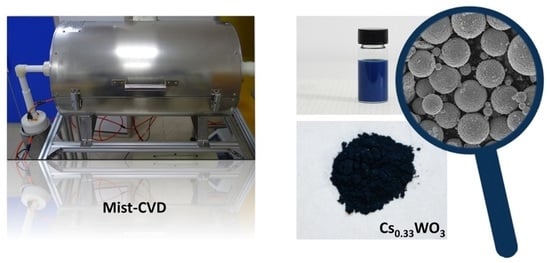

Preparation of Monodispersed Cs0.33WO3 Nanocrystals by Mist Chemical Vapor Deposition for Near-Infrared Shielding Application

Abstract

:1. Introduction

2. Materials and Methods

2.1. Chemicals

2.2. Preparation of Cs0.33WO Nanoparticles and Ink

2.3. Preparation of Cs0.33WO3/Polymer Nanocomposites Coatings

2.4. Material Characterization and Device Testing

3. Results and Discussions

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Chao, L.; Bao, L.; Wei, W.; Tegus, O. A review of recent advances in synthesis, characterization and NIR shielding property of nanocrystalline rare-earth hexaborides and tungsten bronzes. Sol. Energy 2019, 190, 10–27. [Google Scholar] [CrossRef]

- Hano, N.; Takafuji, M.; Noguchi, H.; Ihara, H. Monodisperse Surface-Charge-Controlled Black Nanoparticles for Near-Infrared Shielding. ACS Appl. Mater. Interfaces 2019, 2, 3597–3605. [Google Scholar] [CrossRef]

- Qi, S.; Xiao, X.; Lu, Y.; Huan, C.; Xu, G. A Facile method to Synthesize Small Size and Superior Crystalline Cs0.33WO3 Nanoparticles for Transparent NIR Shielding Coatings. Crystengcomm 2019, 21, 3264–3272. [Google Scholar] [CrossRef]

- Liu, J.; Fan, C.; Shi, F.; Yu, L.; Huang, X.; Hu, S.; Chen, B.; Ran, S.; Liu, S. Fabrication of Cs0. 32WO3/SiO2 aerogel multilayer composite coating for thermal insulation applications. Mater. Lett. 2016, 181, 140–143. [Google Scholar] [CrossRef]

- Chen, C.; Chen, D. Preparation and near-infrared photothermal conversion property of cesium tungsten oxide nanoparticles. Nanoscale Res. Lett. 2013, 8, 57. [Google Scholar] [CrossRef] [Green Version]

- Okada, M.; Ono, K.; Yoshio, S.; Fukuyama, H.; Adachi, K. Oxygen vacancies and pseudo Jahn-Teller destabilization in cesium-doped hexagonal tungsten bronzes. J. Am. Ceram. Soc. 2019, 102, 5386–5400. [Google Scholar] [CrossRef]

- Xu, Q.; Xiao, L.; Ran, J.; Tursun, R.; Zhou, G.; Deng, L.; Tang, D.; Shu, Q.; Qin, J.; Lu, G. Cs0.33WO3 as a high-performance transparent solar radiation shielding material for windows. J. Appl. Phys. 2018, 124, 193102. [Google Scholar] [CrossRef]

- Liu, J.; Luo, J.; Shi, F.; Liu, S.; Fan, C. Synthesis and characterization of F-doped Cs0.33WO3−xFx particles with improved near infrared shielding ability. J. Solid State Chem. 2015, 221, 255–262. [Google Scholar] [CrossRef]

- Sato, Y.; Terauchi, M.; Adachi, K. High energy-resolution electron energy-loss spectroscopy study on the near-infrared scattering mechanism of Cs0.33WO3 crystals and nanoparticles. J. Appl. Phys. 2012, 112, 074308. [Google Scholar] [CrossRef]

- Long, C.S.; Lu, H.H.; Lii, D.F.; Huang, J.L. Effects of annealing on near-infrared shielding properties of Cs-doped tungsten oxide thin films deposited by electron beam evaporation. Surf. Coat. Tech. 2015, 284, 75–79. [Google Scholar] [CrossRef]

- Shi, F.; Liu, J.; Dong, X.; Xu, Q.; Luo, J.; Ma, H. Hydrothermal synthesis of CsxWO3 and the effects of N2 annealing on its microstructure and heat shielding properties. J. Mater. Sci. Technol. 2014, 30, 342–346. [Google Scholar] [CrossRef]

- Adachi, K.; Ota, Y.; Tanaka, H.; Okada, M.; Oshimura, N.; Tofuku, A. Chromatic instabilities in cesium-doped tungsten bronze nanoparticles. J. Appl. Phys. 2013, 114, 194301–194304. [Google Scholar] [CrossRef]

- Yao, Y.; Zhang, L.; Chen, Z.; Cao, C.; Gao, Y.; Luo, H. Synthesis of CsxWO3 nanoparticles and their NIR shielding properties. Ceram. Int. 2018, 44, 13469–13475. [Google Scholar] [CrossRef]

- Liu, G.; Wang, S.; Nie, Y. Electrostatic-induced synthesis of tungsten bronze nanostructures with excellent photo-to-thermal conversion behavior. J. Mater. Chem. A 2013, 1, 10120–10129. [Google Scholar] [CrossRef]

- Liu, J.; Shi, F.; Dong, X.; Liu, S.; Fan, C.; Yin, S.; Sato, T. Morphology and phase controlled synthesis of CsxWO3 powders by solvothermal method and their optical properties. Powder Technol. 2015, 270, 329–336. [Google Scholar] [CrossRef]

- Takeda, H.; Adachi, K. Near Infrared Absorption of Tungsten Oxide Nanoparticle Dispersions. J. Am. Ceram. Soc. 2007, 90, 4059–4061. [Google Scholar] [CrossRef]

- Machida, K.; Adachi, K. Ensemble Inhomogeneity of Dielectric Functions in Cs-Doped Tungsten Oxide Nanoparticles. J. Phys. Chem. C 2016, 120, 16919–16930. [Google Scholar] [CrossRef]

- Liu, J.; Xu, Q.; Shi, F.; Liu, S.; Luo, J.; Bao, L.; Feng, X. Dispersion of Cs0.33WO3 particles for preparing its coatings with higher near infrared shielding properties. Appl. Surf. Sci. 2014, 309, 175–180. [Google Scholar] [CrossRef]

- Xu, X.; Zhang, W.; Hu, Y.; Wang, Y.; Lu, L.; Wang, S. Preparation and overall energy performance assessment of wide waveband two-component transparent NIR shielding coatings. Sol. Energy Mat. Sol. Cells 2017, 168, 119–129. [Google Scholar] [CrossRef]

- Zhu, Y.; Wang, B.; Zhang, Q.; Wang, H.; Zhu, J.; Liu, Y.; Zhang, Y.; Sun, X.; Zhang, X.; Yun, S. Paraffin wax–Cs0.33WO3 composite windows with excellent near infrared shielding and thermal energy storage abilities. Chem. Pap. 2019, 73, 1677–1684. [Google Scholar] [CrossRef]

- Cheng, J.; Hu, R.; Wang, K.; Meng, X.; Li, Y.; Yang, X.; Liao, X.; Li, L.; Chong, K.B. Air-Stable Solar Cells with 0.7 V Open-Circuit Voltage Using Selenized Antimony Sulfide Absorbers Prepared by Hydrazine-Free Solution Method. Sol. RRL 2019, 3, 1800346. [Google Scholar] [CrossRef]

- Cheng, J.; Hu, R.; Meng, X.; Li, Y.; Yan, X.; Yang, X.; Liao, X.; Li, L.; Pei, Q.; Chong, K.B. Realization of Large-Scale Polymer Solar Cells Using Ultrasonic Spray Technique Via Solvent Engineering. Sol. RRL 2018, 2, 1800064. [Google Scholar] [CrossRef]

- Dimitrov, V.; Komatsu, T.; Sato, R. Polarizability, Optical Basicity and O 1s Binding Energy of Simple Oxides. J. Ceram. Soc. Jpn. 1999, 107, 21–26. [Google Scholar] [CrossRef] [Green Version]

- Ishikawa, F.; Higashi, K.; Fuyuno, S.; Morifuji, M.; Kondow, M.; Trampert, A. Annealing induced atomic rearrangements on (Ga, In) (N, As) probed by hard X-ray photoelectron spectroscopy and X-ray absorption fine structure. Sci. Rep. 2018, 8, 5962. [Google Scholar] [CrossRef] [PubMed]

- Mattox, T.M.; Bergerud, A.; Agrawal, A.; Milliron, D.J. Influence of shape on the surface plasmon resonance of tungsten bronze nanocrystals. Chem. Mater. 2014, 26, 1779–1784. [Google Scholar] [CrossRef]

- Kang, L.; Xu, W.; Wang, K.; Liang, W.; Liu, X.; Gao, F.; Lan, A.; Yang, Y.; Gao, Y. Transparent (NH4) xWO3 colloidal dispersion and solar control foils: Low temperature synthesis, oxygen deficiency regulation and NIR shielding ability. Sol. Energy Mat. Sol. Cells 2014, 128, 184–189. [Google Scholar] [CrossRef]

- Vasilopoulou, M.; Soultati, A.; Georgiadou, D.G.; Stergiopoulos, T.; Palilis, L.C.; Kennou, S.; Stathopoulos, N.A.; Davazoglou, D.; Argitis, P. Hydrogenated under-stoichiometric tungsten oxide anode interlayers for efficient and stable organic photovoltaics. J. Mater. Chem. A 2014, 2, 1738–1749. [Google Scholar] [CrossRef]

- Romanov, R.I.; Kozodaev, M.G.; Lebedinskii, Y.Y.; Perevalov, T.V.; Slavich, A.S.; Hwang, C.S.; Markeev, A.M. Radical-Enhanced Atomic Layer Deposition of a Tungsten Oxide Film with the Tunable Oxygen Vacancy Concentration. J. Phys. Chem. C 2020, 124, 18156–18164. [Google Scholar] [CrossRef]

- Wang, Q.; Li, C.; Xu, W.; Zhao, X.; Zhu, J.; Jiang, H.; Kang, L.; Zhao, Z. Effects of Mo-doping on microstructure and near-infrared shielding performance of hydrothermally prepared tungsten bronzes. Appl. Surf. Sci. 2017, 399, 41–47. [Google Scholar] [CrossRef]

- Yoshio, S.; Adachi, K.; Kubo, M. Cesium desorption mechanism in Cs0.33WO3 by first-principles molecular dynamics calculations. J. Appl. Phys. 2019, 126, 073101. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Huang, L.; Tang, H.; Bai, Y.; Pu, Y.; Li, L.; Cheng, J. Preparation of Monodispersed Cs0.33WO3 Nanocrystals by Mist Chemical Vapor Deposition for Near-Infrared Shielding Application. Nanomaterials 2020, 10, 2295. https://doi.org/10.3390/nano10112295

Huang L, Tang H, Bai Y, Pu Y, Li L, Cheng J. Preparation of Monodispersed Cs0.33WO3 Nanocrystals by Mist Chemical Vapor Deposition for Near-Infrared Shielding Application. Nanomaterials. 2020; 10(11):2295. https://doi.org/10.3390/nano10112295

Chicago/Turabian StyleHuang, Lei, Hua Tang, Youjun Bai, Yong Pu, Lu Li, and Jiang Cheng. 2020. "Preparation of Monodispersed Cs0.33WO3 Nanocrystals by Mist Chemical Vapor Deposition for Near-Infrared Shielding Application" Nanomaterials 10, no. 11: 2295. https://doi.org/10.3390/nano10112295