The effects of HA, pure PP beads concentration, and pH were investigated in the hybrid water treatment process of seven-channel alumina MF (HC10) membrane and pure PP beads with periodic water backwashing and UV irradiation. Membrane resistance, boundary layer, and membrane fouling (

Rm,

Rb, and

Rf) were calculated from permeate flux (

J) data using the resistance-in-series filtration equation (

J = Δ

P/(

Rm +

Rb +

Rf)) which was the same method as the previous study [

24], where Δ

P is the transmembrane pressure. For a new membrane, the equation was simplified to

J = Δ

P/

Rm because there were no boundary layer resistances, and membrane fouling and

Rm could be determined using

J data for a new membrane. For the synthetic water of HA and kaolin, the equation was modified to

J = Δ

P/(

Rm +

Rb) at initial time, and

Rb could be determined using

J0 and

Rm data. Irreversible and reversible membrane fouling resistances (

Rif,

Rrf) could be found from

J data after physical washing using a brush inside the membrane.

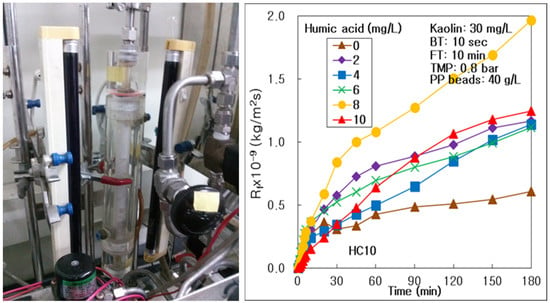

3.1. Effect of HA Concentration on Membrane Fouling and Treatment Efficiency

The membrane fouling resistance (

Rf) was significantly influenced by humic acid (HA), which was one of the major natural organic matters (NOM) in lakes or rivers, and

Rf was the minimum at HA 0 g/L, and almost constant at 2 to 6 mg/L of HA; however, it increased dramatically with an increase in the concentration of HA from 6 mg/L to 8 mg/L, and then, decreased suddenly in a concentration of HA from 8 mg/L to 10 mg/L , as shown in

Figure 2a. This means that DOM, similar to HA, could drive membrane fouling more severely on the surface and inside the alumina membrane, with an increase of HA concentration from 6 mg/L to 8 mg/L in water. However, the membrane fouling decreased from 8 mg/L to 10 mg/L of HA, because the thick fouling cake on the membrane could be removed by water backwashing at 10 mg/L of HA. As summarized in

Table 2, the membrane resistance (

Rm) was controlled at a constant value by combustion in a furnace and washing with an acid and alkali solution. The final

Rf (

Rf,180) value after operating for 180 min at HA 8 mg/L was 1.963 × 10

9 kg/m

2s, which was 3.24 times higher than 0.606 × 10

9 kg/m

2s of the

Rf,180 value at HA 0 mg/L.

In the previous study [

22] for the hybrid water treatment process of the same tubular carbon fiber UF and the same pure PP beads,

Rf increased dramatically with an increase in the concentration of HA from 2 mg/L to 10 mg/L. The increasing rate of

Rf was very high, when HA increased from 6 mg/L to 10 mg/L, in particular. This means that DOM, similar to HA, could drive membrane fouling more severely on the surface and inside the carbon fiber membrane, with an increase of HA concentration in water, and specifically at a high HA concentration. There was a little different trend as compared with the study of HC10, depending on the membrane type and material. The

Rf,180 value after operating for 180 min at HA 10 mg/L was 6.998 × 10

9 kg/m

2s, which was 3.94 times higher than 1.775 × 10

9 kg/m

2s of the

Rf,180 value at HA 2 mg/L. The

Rf,180 value was much higher than those of this result of HC10 in this study, meaning that membrane fouling could be much less developed in the seven-channel HC10 membrane as compared with the tubular C005 membrane.

As shown in

Figure 2b, the dimensionless permeate flux (

J/

J0), where

J0 was the initial permeate flux predicted using the initial two data by an extrapolation method, was plotted according to HA concentration. The

J/

J0 overlapped in the range of HA 2 to 6 mg/L, and it showed the highest values at HA 0 mg/L and the lowest at HA 8 mg/L during 180 min; however, it was much higher at HA 10 mg/L. This means that the permeate flux could be maintained low at HA 8 mg/L and increased at HA 10 mg/L, because the membrane fouling was developed severely by DOM, and the cake layer could be removed at HA 10 mg/L by water backwashing.

As arranged in

Table 2, the final

J/

J0 after operating for 180 min (

J180/

J0) was 0.578 at HA 0 mg/L, which was 1.88 times higher than 0.307 at HA 8 mg/L. In the previous work [

22] of the C005,

J/

J0 tended to decrease with an increase in the HA concentration from 2 to 10 mg/L, specifically from 6 to 8 mg/L, because of the membrane fouling development by the more DOM. The

J180/

J0 was 0.241 at HA 2 mg/L, which was 2.84 times higher than 0.085 at HA 10 mg/L. This means that the permeate flux decline rate was affected more severely by HA concentration in the hybrid process of C005 than HC10, because the membrane fouling increased dramatically with an increase in HA concentration.

In addition, the permeate volume (

VT) of 14.18 L at HA 0 mg/L was 1.57 times higher than 9.05 L of

VT at HA 8 mg/L, as shown in

Table 2, because high flux was maintained at HA 4 mg/L during 180 min as compared in

Figure 2b. In [

22], the result of the tubular carbon fiber C005,

VT at HA 2 mg/L was 4.98 L, which was 2.59 times higher than 1.92 L of

VT at HA 10 mg/L. The difference rate of

VT was higher in the hybrid process of C005 than HC10. This means that DOM affected membrane fouling more at tubular UF C005 membrane than multichannel MF HC10.

As listed in

Table 3, the treatment efficiency of turbidity showed an increasing trend, with an increase of HA concentration. Furthermore, in the result by [

22] with C005, the treatment efficiency of turbidity was almost constant. This means that the DOM could affect the treatment of suspended particles, such as kaolin, in the hybrid process of the multichannel alumina MF and the pure PP beads, because the thick membrane fouling layer rejected kaolin particles at a high HA concentration. However, DOM could not affect the process of tubular carbon fiber UF membrane, because of the tubular membrane type.

As shown in

Table 4, the treatment efficiency of UV

254 absorbance, which means the concentration of DOM, increased with an increase in HA concentration, and finally showed the maximum 49.7% at HA 10 mg/L. This means that DOM could be treated more effectively at a high DOM condition in the hybrid water treatment process of seven-channel alumina MF and pure PP beads. The maximum treatment efficiency of DOM was 69.3% at HA 6 mg/L, in the previous work [

22] for the hybrid process of the tubular carbon fiber MF membrane and the same PP beads. From 2 mg/L to 6 mg/L of HA, most of DOM could be adsorbed on fouling materials inside the membrane or retained by cake layer on the membrane, and the remained things passed through the membrane adsorbed or oxidized by the PP beads and UV. It happened that the treated water quality of HA increased less slowly than the feed water quality. However, above 6 mg/L of HA, most of DOM passed through the membrane and could not be treated by adsorption or photooxidation by the PP beads and UV. And the treated water quality of HA increased more rapidly than the feed water quality.

3.2. Effect of Pure PP Beads on Membrane Fouling and Treatment Efficiency

In this study, the pure PP beads were induced for adsorption of DOM and turbid matters. The effect of pure PP beads concentration was investigated at the most severe HA 10 mg/L condition, at kaolin 30 mg/L, and pH 7. The membrane fouling resistances (

Rf) showed the highest at 50 g/L and the lowest at 5 g/L during the 180 min operation, as shown in

Figure 3a. This means that the optimal PP beads concentration could be 5 g/L to control the membrane fouling and high permeate flux in this hybrid process of 7-channel alumina MF HC10 and PP beads.

In the previous work by [

23] for the hybrid process of the tubular carbon fiber UF C005 and the same PP beads, the

Rf showed the highest at 50 g/L during the 180 min operation, and the lowest at 5 g/L until 120 min, and at 0 g/L of PP beads after 120 min. This result almost agreeds with the trend of PP beads effect in this study and showed that the effect of PP beads concentration on membrane fouling could not depend on the membrane type and materials in this hybrid water treatment process of ceramic membrane and pure PP beads.

In the hybrid process of ceramic membrane and PP beads, the boundary layer resistance (

Rb), which was produced by concentration polarization on the membrane surface, was the lowest at 50 g/L of PP beads independent of membrane type and materials, as shown in

Table 5. This means that the frequent colliding of more PP beads on the membrane surface could reduce the concentration polarization for both HC10 and C005. The

Rf,180 after 180 min was the highest, i.e., 12.94 × 10

9 kg/m

2s, at 50 g/L, which was 3.06 times higher than 4.23 × 10

9 kg/m

2s for the

Rf,180 at 0 g/L of PP beads. The

Rrf showed an increasing trend, with an increasing PP beads concentration from 0 g/L to 50 g/L; however, the minimum

Rif was at 40 g/L and the maximum was at 0 g/L of PP beads. This means that the reversible membrane fouling could be inhibited at 50 g/L of PP beads, because the optimal amount of PP beads captured the turbid or organic materials by adsorption.

In the previous result by [

23] for the hybrid process of the C005 and the pure PP beads, the

Rf,180 after 180 min was the highest of 4.892 × 10

9 kg/m

2s at 50 g/L, which was 1.48 times higher than 3.306 × 10

9 kg/m

2s of the

Rf,180 at 0 g/L of PP beads. These

Rf,180 were much higher than those of HC10 in this study; however, the trends depending on PP beads concentration was exactly the same in this hybrid process. Additionally, the

Rrf increased with an increasing PP beads concentration from 0 g/L to 50 g/L of PP beads; however, the

Rif was the minimum at 50 g/L and the maximum at 10 g/L of PP beads. This result was also almost in agreement with that of this study using HC10.

The

J/

J0 was compared to investigate the effect of PP beads on the relative decline of permeate flux, as shown in

Figure 3b. The

J/

J0 maintained higher until 90 min at PP beads 5 g/L than those at other PP beads concentration, and showed the lowest at PP beads 50 g/L after 60 min. As arranged in

Table 5, the

J0 and

J180 decreased to 40 g/L and to 50 g/L, respectively, with an increase in PP beads concentration, because the

Rb and

Rf increased to 40 g/L and to 50 g/L of PP beads, correspondingly. Finally, the

J180/

J0 after 180 min of operation at 0 g/L of the PP beads was the maximum 0.230, which was 2.13 times higher than 0.108 at 50 g/L. However, the

VT was the highest, 11.75 L at 5 g/L of PP beads, because

J maintained higher all through the operation than those of other PP beads conditions.

In the previous work by [

23] for the hybrid process of the C005 and the pure PP beads, the

J/

J0 showed higher during the 5 to 90 min at 5 g/L than those at other PP beads concentration. The

J0 decreased and

J180 increased as increasing PP beads concentration, because the

Rb was the minimum at 50 g/L of PP beads. In addition, the

J180/

J0 after 180 min of operation at 0 g/L of the PP beads was the maximum 0.126, which was 1.62 times higher than 0.078 at 50 g/L. The increasing rate, 1.62 of

J180/

J0 for C005, was much lower than 2.13 for HC10, because PP beads controlled more effectively the membrane fouling in the hybrid process of HC10 than C005. Also, the

VT was the highest 4.99 L at 5 g/L of PP beads for the C005 process, which was the exact same trend of HC10 in this study.

As arranged in

Table 6, the treatment efficiencies of turbidity were almost constant in the range of 97.5% and 98.9% in the hybrid process of HC10 MF, independent of the pure PP beads concentration. This means that the tubid matters could be treated effectively, independent of PP beads concentration in this hybrid process. In the previous result by [

23] for the hybrid process of the C005 and the pure PP beads, the treatment efficiencies of turbidity were the highest, i.e., 99.3% at 30 g/L. This means that the optimal PP beads concentration could be 30 g/L to treat the turbid matter in the hybrid process of C005 UF membrane.

As shown in

Table 7, the treatment efficiency of DOM (UV

254 absorbance) did not show a trend; however, that was the maximal of 51.3% at 5 g/L of PP beads. This proves that the optimal PP beads concentration was 5 g/L to remove DOM in this hybrid process of HC10 MF and pure PP beads. In the previous work by [

23] for the hybrid process of the C005 and the pure PP beads, the treatment efficiency of DOM showed a trend to increase dramatically from 75.9% to 84.1%, with an increase in the PP beads concentration. It was much higher than those for the hybrid HC10 MF process in this study, because the secondary gel layer could be formed denser on the UF membrane surface of smaller pore size than MF. Finally, the more PP beads could adsorb the more efficiently DOM on the surface of PP beads in the hybrid C005 UF process.

3.3. Effect of pH on Membrane Fouling and Treatment Efficiency

To investigate the pH effect on membrane fouling and treatment efficiency, the pH of synthetic feed water was controlled by nitric acid (HNO

3) and sodium hydroxide (NaOH). As shown in

Figure 4a, the

Rf maintained the highest values at pH 9, and the lowest at pH 5 during 180 min. There was a dramatic trend to increase as the pH increased from 5 to 9 in the hybrid process of HC10 MF. As arranged in

Table 8, the

Rf,180 and R

rf were the minimum at pH 5; however, the

Rb was the lowest at pH 6. Conclusively, the

Rf,180 increased dramatically with an increase in pH, and was the highest, 20.20 × 10

9 kg/m

2s, at pH 9, which was 4.58 times higher than 4.41 × 10

9 kg/m

2s at pH 6. The

Rrf and

Rif were the maximum at pH 9 and pH 8, respectively. This means that the reversible and irreversible membrane fouling, and concentration polarization could be inhibited at acid condition, because both the membrane and humic materials had a negative surface charge at acid conditions below a pH of 7, as reported that the surface charge of ZrO

2 membrane was changed depending on the pH [

25]. The surface charge of seven-channel alumina HC10 membrane, used in this study, could be changed depending on the pH, because those were the similar ceramic membranes as ZrO

2 membrane.

In the previous result by [

23] for the hybrid process of the C005 and the pure PP beads, the

Rf showed the highest at a pH of 9 after 90 min and the lowest at a pH of 5 after 150 min, and finally have a trend to increase, with an increase in pH from 5 to 9. This result agreeds exactly with that in the hybrid process of HC10 in this study. The

Rb and

Rif were the minimum at a pH of 5; however, the

Rf,180 and

Rrf were the lowest at a pH of 6. However, this trend did not match the result for HC10 in this study. Conclusively, the

Rf,180 was the highest, 5.51 × 10

9 kg/m

2s, at a pH of 9, which was 1.32 times higher than 4.16 × 10

9 kg/m

2s at a pH of 6. The

Rrf and

Rif were the maximum at pH 9. The increasing rate, i.e., 1.32 of

Rf,180 for C005 was much lower than 4.58 for HC10, because pH controlled more effectively the membrane fouling in the hybrid process of HC10 than C005.

As compared in

Figure 4b to investigate the pH effect on relative permeate flux, the

J/

J0 showed a trend to decrease dramatically, with an increase in the pH from 5 to 9. The

J180/

J0 after 180 min of operation at pH 5 was 0.306, which was 2.94 times higher than 0.104 at pH 9, as shown in

Table 8. And the

J180 was the maximum 327 L/m

2h at pH 6, and the minimum 270 L/m

2h at pH 9. This means that the high permeate flux could be acquired at pH 5, because the membrane fouling was inhibited by repulsion force between the carbon fiber membrane and humic materials, which had the same negative surface charge, as reported that the surface charge of ZrO

2 membrane was changed depending on the pH [

25]. Finally, the

VT was the highest of 8.12 L at pH 5, because the

J could maintain highly during a 180 min operation.

In the previous work by [

23] for the hybrid process of the C005 and the pure PP beads, the

J180/

J0 after 180 min of operation at a pH of 6 was 0.099, which was 1.46 times higher than 0.068 at a pH of 9. The increasing rate, 1.42 of

J180/

J0 for C005, was much lower than 2.94 for HC10, because the pH maintained higher the permeate flux in the hybrid process of HC10 than C005. Additionally, J

180 was the maximum 138 L/m

2h at a pH of 6, and the minimum, 107 L/m

2h, at a pH of 9. Finally, the

VT was the highest of 3.85 L at pH 8, because the permeate flux could maintain highly during operation. These trends did not match exactly with the result for HC10 in this study, because of the different membrane type and material.

As arranged in

Table 9, the treatment efficiency of turbidity decreased slightly from 98.6% to 98.0%, with an increase in pH from 5 to 9. This means that the turbid matter, such as kaolin, could be removed more effectively at acidic pH conditions in the hybrid process of the alumina HC10 MF membrane with periodic water backwashing. Y. Zhao et al. [

26] reported that zeta-potential of alumina membrane decreased with an increase in pH. This phenomenon could be explained that the treatment efficiency of turbidity decreased slightly, because the decrease of zeta potential of HC10 membrane resulted in a decrease of the electroviscous effect. However, in the previous result [

23] for the hybrid process of the C005 and the pure PP beads, the treatment efficiency of turbidity was almost constantly above 98.7%, independent of the pH. This means that the pH could not affect treating the turbid matter for carbon fiber UF process with water backwashing.

As shown in

Table 10, the treatment efficiency of DOM showed the highest value at a pH of 9. This means that DOM could be removed effectively at alkalic condition, because of the secondary layer on the membrane surface accumulated by the most severe membrane fouling. However, in the previous result [

23] for the hybrid process of the C005 and the pure PP beads, the treatment efficiency of DOM was the highest at a pH of 5. This means that DOM could be removed effectively at acid condition, because of repulsion force between the carbon fiber membrane and humic materials.