E-Skin Development and Prototyping via Soft Tooling and Composites with Silicone Rubber and Carbon Nanotubes

Abstract

:1. Introduction

2. Materials and Methods

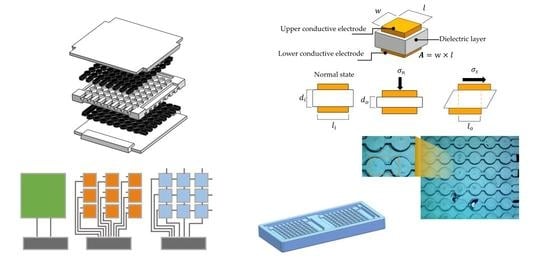

2.1. Artificial Skin Design

2.2. Different Formultions with Vaying Materials for Nanocomposites

2.3. Nanocomposite and Substrate Fabrication

2.4. Microelectrode Fabrication and Assessment

2.5. Soft Tooling Manufacturing Using Stereolithography-Based Additive Manufacturing

2.6. Mechanical Characterization

2.7. Hyperelastic Model Based on Mullins Effect

3. Results and Discussion

3.1. Nanocomposite and Substrate Fabrication

3.1.1. Challenges Associated with the Processing of SWCNT Nanocomposites

3.1.2. Defect Inspection of Nanocomposite Micropatterned Layers

3.1.3. Surface Resistance Measurements Results

3.2. Uniaxial stress-strain Behavior and Mullin’s Effect

3.3. Design Guidelines for AM-Based Soft Tooling

- Definition of requirements and limitations. Define the overall dimensions of the multilayer structure of the artificial skin, the thicknesses of the layers independently, the quantities of layers to be assembled, the required quality standards (e.g., surface roughness), the number of cavities and cores, the volume of production, material selection, critical specifications, and geometric tolerances [48].

- Design of the topology of the replicated structure. Define the size and depth of the conductive microchannels, the shape of the geometry engraved in the mold, the spatial orientation, distance to the cavity edges, draft angles, and rounding in intricate corners.

- Design of the alignment system. Define the type of alignment (geometric, magnetic, mechanical, etc.), pin dowel material, locking units, and complete restriction of the six D.O.F.

- Design of machine structure. Define the rigid mold carrier, mold support frame, ejector pins, and rigidity on the support surface; consider the effects of external forces (e.g., gravity), and available operating space.

- Cavity design. Define cavity orientation, wall thicknesses, cavity spacing or interconnection, cavity tightness and sealing, projected surface, and cross-section design.

- Runner-system design. Define the feeding ducts, the amount of material required per cycle, the injection or casting speed, runners, sprue, gates, cavity-nesting, reservoirs, reverberators, and computational simulations.

- Sequential process design. Define the release agent and the surfaces with release angles; define the production cycle times, design the Process Flow Diagram (P.F.D.), SMED changes, process parameter variation, and tolerance stack-up analysis.

- Thermodynamic process design. This includes the percentage of contraction or expansion, in-mold rheology, surface coatings, and hot zones required for special thermoregulation, melt temperature, and mold temperature [49].

- Design considering the manufacturing process. Especially for additive manufacturing, the definition of mold impression orientation, placement of support and filler material and its interference with critical zones, the machine’s capacity where the mold will be manufactured, the cross-section of internal ducts [50].

- Accessories and various designs. Define spare parts and useful life, a preventive and corrective maintenance plan, mounting or transportation accessories, soft tooling release documentation, safety equipment for operability, and external environment factors [51].

4. Conclusions and Future Work

- Fabricating multilayer materials such as artificial electronic skin via printed soft tooling by additive manufacturing is feasible for materials with properties similar to RTV-2 and SWCNT-based nanocomposites.

- Using RTV-2 material casting into the mold cavities, we showcased the application of soft tooling in the development and prototyping stages with very promising scalability and a low production cost approach.

- An Ogden–Roxburgh model was successfully implemented to analyze the energy dissipation of flexible materials with values greater than R2 > 0.86.

- We developed a set of guidelines for the AM-based soft tooling of e-skin.

- We verified the electrical path of the SWCNTs’ micropattern geometries with advantages that included low volumetric and surface resistivity.

- Future work will focus on testing the assembly of the micropatterned layers and the ability to generate capacitive phenomena to detect the deformation of the electrodes. Furthermore, the application of the design guidelines and the effect on the performance of the device remains to be developed in the future.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Bauer, S.; Bauer-Gogonea, S.; Graz, I.; Kaltenbrunner, M.; Keplinger, C.; Schwödiauer, R.; Bauer, S.; Bauer-Gogonea, S.; Graz, I.; Kaltenbrunner, M.; et al. 25th Anniversary Article: A Soft Future: From Robots and Sensor Skin to Energy Harvesters. Adv. Mater. 2014, 26, 149–162. [Google Scholar] [CrossRef] [Green Version]

- Nag, A.; Mukhopadhyay, S.C.; Kosel, J. Wearable Flexible Sensors: A Review. IEEE Sens. J. 2017, 17, 3949–3960. [Google Scholar] [CrossRef] [Green Version]

- Hait, A.; Powers, S.E. The value of reusable feminine hygiene products evaluated by comparative environmental life cycle assessment. Resour. Conserv. Recycl. 2019, 150, 104422. [Google Scholar] [CrossRef]

- Tien, N.T.; Jeon, S.; Kim, D.I.; Trung, T.Q.; Jang, M.; Hwang, B.U.; Byun, K.E.; Bae, J.; Lee, E.; Tok, J.B.H.; et al. A Flexible Bimodal Sensor Array for Simultaneous Sensing of Pressure and Temperature. Adv. Mater. 2014, 26, 796–804. [Google Scholar] [CrossRef]

- Lipomi, D.J.; Vosgueritchian, M.; Tee, B.C.K.; Hellstrom, S.L.; Lee, J.A.; Fox, C.H.; Bao, Z. Skin-like pressure and strain sensors based on transparent elastic films of carbon nanotubes. Nat. Nanotechnol. 2011, 6, 788–792. [Google Scholar] [CrossRef] [PubMed]

- Sadri, B.; Goswami, D.; Martinez, R.V. Rapid Fabrication of Epidermal Paper-Based Electronic Devices Using Razor Printing. Micromachines 2018, 9, 420. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Khan, Y.; Ostfeld, A.E.; Lochner, C.M.; Pierre, A.; Arias, A.C. Monitoring of Vital Signs with Flexible and Wearable Medical Devices. Adv. Mater. 2016, 28, 4373–4395. [Google Scholar] [CrossRef]

- Wolf, M.P.; Salieb-Beugelaar, G.B.; Hunziker, P. PDMS with designer functionalities—Properties, modifications strategies, and applications. Prog. Polym. Sci. 2018, 83, 97–134. [Google Scholar] [CrossRef]

- Sánchez-González, C.M.; Soriano-Peña, J.F.; Rubio-Avalos, J.C.; Pacheco-Ibarra, J.J. Fabrication of flexible piezoresistive sensors based on RTV-silicone and milled carbon fibers and the temperature’s effect on their electric resistance. Sens. Actuators A Phys. 2020, 302, 111811. [Google Scholar] [CrossRef]

- Cochrane, C.; Koncar, V.; Lewandowski, M.; Dufour, C. Design and Development of a Flexible Strain Sensor for Textile Structures Based on a Conductive Polymer Composite. Sensors 2007, 7, 473–492. [Google Scholar] [CrossRef] [Green Version]

- Maiti, S.; Shrivastava, N.K.; Suin, S.; Khatua, B.B. Polystyrene/MWCNT/Graphite Nanoplate Nanocomposites: Efficient Electromagnetic Interference Shielding Material through Graphite Nanoplate–MWCNT–Graphite Nanoplate Networking. ACS Appl. Mater. Interfaces 2013, 5, 4712–4724. [Google Scholar] [CrossRef]

- Su, Y.; Zhang, W.; Chen, S.; Yao, D.; Zhang, X.; Chen, H.; Xu, H. Piezoresistive Electronic-Skin Sensors Produced with Self-Channeling Laser Microstructured Silicon Molds. IEEE Trans. Electron Devices 2021, 68, 786–792. [Google Scholar] [CrossRef]

- Reitelshöfer, S.; Göttler, M.; Schmidt, P.; Treffer, P.; Landgraf, M.; Franke, J. Aerosol-Jet-Printing silicone layers and electrodes for stacked dielectric elastomer actuators in one processing device. Proc. Electroact. Polym. Actuat. Dev. (EAPAD) 2016, 9798, 350–358. [Google Scholar] [CrossRef]

- Yang, H.; Gong, L.H.; Zheng, Z.; Yao, X.F. Highly stretchable and sensitive conductive rubber composites with tunable piezoresistivity for motion detection and flexible electrodes. Carbon 2020, 158, 893–903. [Google Scholar] [CrossRef]

- Herzberger, J.; Sirrine, J.M.; Williams, C.B.; Long, T.E. Polymer Design for 3D Printing Elastomers: Recent Advances in Structure, Properties, and Printing. Prog. Polym. Sci. 2019, 97, 101144. [Google Scholar] [CrossRef]

- Colpani, A.; Fiorentino, A.; Ceretti, E. Feasibility analysis and characterization of an extrusion-based AM process for a two-component and biocompatible silicone. J. Manuf. Process. 2020, 49, 116–125. [Google Scholar] [CrossRef]

- Khosravani, M.R.; Reinicke, T. 3D-printed sensors: Current progress and future challenges. Sens. Actuators A Phys. 2020, 305, 111916. [Google Scholar] [CrossRef]

- Martínez-López, J.I.; Betancourt Cervantes, H.A.; Cuevas Iturbe, L.D.; Vázquez, E.; Naula, E.A.; Martínez López, A.; Siller, H.R.; Mendoza-Buenrostro, C.; Rodríguez, C.A. Characterization of Soft Tooling Photopolymers and Processes for Micromixing Devices with Variable Cross-Section. Micromachines 2020, 11, 970. [Google Scholar] [CrossRef] [PubMed]

- Liu, H.; Su, J.; Li, X. Process Analysis for Rapid Tooling Technology Based on Rapid Prototyping. Adv. Mater. Res. 2011, 216, 798–803. [Google Scholar] [CrossRef]

- Dempsey, D.; Mcdonald, S.; Masato, D.; Barry, C. Characterization of Stereolithography Printed Soft Tooling for Micro Injection Molding. Micromachines 2020, 11, 819. [Google Scholar] [CrossRef]

- Rajaraman, S.; Bragg, J.A.; Ross, J.D.; Allen, M.G. Micromachined three-dimensional electrode arrays for transcutaneous nerve tracking. J. Micromech. Microeng. 2011, 21, 085014. [Google Scholar] [CrossRef] [Green Version]

- Barata, D.; Dias, P.; Wieringa, P.; Van Blitterswijk, C.; Habibovic, P. Cell-instructive high-resolution micropatterned polylactic acid surfaces. Biofabrication 2017, 9, 035004. [Google Scholar] [CrossRef]

- Lv, S.; Nie, J.; Gao, Q.; Xie, C.; Zhou, L.; Qiu, J.; Fu, J.; Zhao, X.; He, Y. Micro/nanofabrication of brittle hydrogels using 3D printed soft ultrafine fiber molds for damage-free demolding. Biofabrication 2020, 12, 025015. [Google Scholar] [CrossRef]

- Manapat, J.Z.; Chen, Q.; Ye, P.; Advincula, R.C. 3D Printing of Polymer Nanocomposites via Stereolithography. Macromol. Mater. Eng. 2017, 302, 1–14. [Google Scholar] [CrossRef]

- Linares-Alvelais, J.A.R.; Obedt Figueroa-Cavazos, J.; Chuck-Hernandez, C.; Siller, H.R.; Rodríguez, C.A.; Martínez-López, J.I. Hydrostatic high-pressure post-processing of specimens fabricated by DLP, SLA, and FDM: An alternative for the sterilization of polymer-based biomedical devices. Materials 2018, 11, 2540. [Google Scholar] [CrossRef] [Green Version]

- Ali, A.; Muhammad, N.; Hussain, S.; Jamil, M.I.; Uddin, A.; Aziz, T.; Tufail, M.K.; Guo, Y.; Wei, T.; Rasool, G.; et al. Kinetic and thermal study of ethylene and propylene homo polymerization catalyzed by ansa-zirconocene activated with alkylaluminum/borate: Effects of alkylaluminum on polymerization kinetics and polymer structure. Polymers 2021, 13, 268. [Google Scholar] [CrossRef]

- Kumar, V.; Kumar, A.; Han, S.S.; Park, S.S. RTV silicone rubber composites reinforced with carbon nanotubes, titanium-di-oxide and their hybrid: Mechanical and piezoelectric actuation performance. Nano Mater. Sci. 2021, 3, 233–240. [Google Scholar] [CrossRef]

- Behera, K.; Veluri, S.; Chang, Y.H.; Yadav, M.; Chiu, F.C. Nanofillers-induced modifications in microstructure and properties of PBAT/PP blend: Enhanced rigidity, heat resistance, and electrical conductivity. Polymer 2020, 203, 122758. [Google Scholar] [CrossRef]

- Nurazzi, N.M.; Sabaruddin, F.A.; Harussani, M.M.; Kamarudin, S.H.; Rayung, M.; Asyraf, M.R.M.; Aisyah, H.A.; Norrrahim, M.N.F.; Ilyas, R.A.; Abdullah, N.; et al. Mechanical Performance and Applications of CNTs Reinforced Polymer Composites—A Review. Nanomater 2021, 11, 2186. [Google Scholar] [CrossRef] [PubMed]

- Kumar, V.; Alam, M.N.; Manikkavel, A.; Song, M.; Lee, D.J.; Park, S.S. Silicone Rubber Composites Reinforced by Carbon Nanofillers and Their Hybrids for Various Applications: A Review. Polymers 2021, 13, 2322. [Google Scholar] [CrossRef] [PubMed]

- Mazzeo, A.D.; Hardt, D.E. Centrifugal casting of microfluidic components with PDMS. J. Micro Nano-Manuf. 2013, 1, 021001. [Google Scholar] [CrossRef]

- Kuo, C.C.; Wu, M.H.; Lai, M.Y. Development of a Low-Cost Automatic Vacuum Degassing System for Rapid Tooling. Appl. Mech. Mater. 2014, 459, 349–355. [Google Scholar] [CrossRef]

- Vakili-Nezhaad, G.; Dorany, A. Effect of Single-Walled Carbon Nanotube on the Viscosity of Lubricants. Energy Procedia 2012, 14, 512–517. [Google Scholar] [CrossRef] [Green Version]

- Kundalwal, S.I.; Rathi, A. Improved mechanical and viscoelastic properties of CNT-composites fabricated using an innovative ultrasonic dual mixing technique. J. Mech. Behav. Mater. 2020, 29, 77–85. [Google Scholar] [CrossRef]

- Cheng, M.; Zhu, G.; Zhang, F.; Tang, W.-L.; Shi, J.; Yang, J.-Q.; Zhu, L.-Y. A review of flexible force sensors for human health monitoring. J. Adv. Res. 2020, 26, 53–68. [Google Scholar] [CrossRef] [PubMed]

- ASTM D412-06. Standard Test Methods for Vulcanized Rubber and Thermoplastic Elastomers—Tension; ASTM International: West Conshohocken, PA, USA, 2017; Available online: http://www.astm.org/cgi-bin/resolver.cgi?D0412-06 (accessed on 4 July 2021).

- Luo, R.K. Mullins damage effect on rubber products with residual strain. Int. J. Damage Mech. 2014, 24, 153–167. [Google Scholar] [CrossRef]

- Bergström, J. Mechanics of Solid Polymers: Theory and Computational Modeling; Elsevier: Amsterdam, The Netherlands, 2015; ISBN 9780323322966. [Google Scholar]

- Lagarias, J.C.; Reeds, J.A.; Wright, M.H.; Wright, P.E. Convergence Properties of the Nelder–Mead Simplex Method in Low Dimensions. SIAM J. Optim. 2006, 9, 112–147. [Google Scholar] [CrossRef] [Green Version]

- ASTM D257-14(2021)e1. Standard Test Methods for DC Resistance or Conductance of Insulating Materials; ASTM International: West Conshohocken, PA, USA, 2021; Available online: http://www.astm.org/cgi-bin/resolver.cgi?D257 (accessed on 4 July 2021).

- Ogden, R.W.; Roxburgh, D.G. A pseudoelastic model for the Mullins effect in filled rubber. Proc. R. Soc. Lond. Ser. A Math. Phys. Eng. Sci. 1999, 455, 2861–2877. [Google Scholar] [CrossRef]

- Xu, W.; Zhang, M.; Liu, Y.; Zhang, H.; Chen, M.; Jiang, H.; Wang, Y. Stress-Softening in Particle-Filled Polyurethanes under Cyclic Compressive Loading. Polymers 2020, 12, 1588. [Google Scholar] [CrossRef]

- De Tommasi, D.; Ferri, D.; Marano, G.C.; Puglisi, G. Material parameters identification and experimental validation of damage models for rubberlike materials. Eur. Polym. J. 2016, 78, 302–313. [Google Scholar] [CrossRef]

- MCalibration® by PolymerFEM. Available online: https://polymerfem.com/mcalibration (accessed on 25 October 2021).

- Ètschke, P.P.; Fornes, T.D.; Paul, D.R. Rheological behavior of multiwalled carbon nanotube/polycarbonate composites. Polymer 2002, 43, 3247–3255. [Google Scholar] [CrossRef]

- Rudyak, V.Y.; Minakov, A.V.; Pryazhnikov, M.I. Preparation, characterization, and viscosity studding the single-walled carbon nanotube nanofluids. J. Mol. Liq. 2021, 329, 115517. [Google Scholar] [CrossRef]

- Barrett, J.D. Taguchi’s Quality Engineering Handbook. Technometrics 2012, 49, 224–225. [Google Scholar] [CrossRef]

- Polytechnica, P.; Eng, S.M. Influence of Mold Properties on the Quality of Injection Molded Parts. Period. Polytech. Mech. Eng. 2005, 49, 115–122. [Google Scholar]

- Zink, B.; Kovács, N.K.; Kovács, J.G. Thermal analysis based method development for novel rapid tooling applications. Int. Commun. Heat Mass Transf. 2019, 108, 104297. [Google Scholar] [CrossRef]

- Dizon, J.R.C.; Valino, A.D.; Souza, L.R.; Espera, A.H.; Chen, Q.; Advincula, R.C. Three-dimensional-printed molds and materials for injection molding and rapid tooling applications. MRS Commun. 2019, 9, 1267–1283. [Google Scholar] [CrossRef]

- Hanumaiah, N.; Ravi, B.; Mukherjee, N.P. Rapid hard tooling process selection using QFD-AHP methodology. J. Manuf. Technol. Manag. 2006, 17, 332–350. [Google Scholar] [CrossRef]

| Property | ELASTOSIL® 7600 | ELASTOSIL® 7683 |

|---|---|---|

| Density | 0.99 g/cm3 (A) | 0.99 g/cm3 (A) |

| 1.05 g/cm3 (B) | 1.05 g/cm3 (B) | |

| Viscosity | 4000 mPa·s (A) | 1400 mPa·s (A) |

| 2000 mPa·s (B) | 4000 mPa·s (B) | |

| Pot life | 27 min | 40 min |

| Color | Translucent | Translucent |

| Hardness (Shore 00) | 26 | 25 |

| Elongation at break | 600% | 500% |

| Component | Sample I Weight, g (3 wt.%) | Sample II Weight, g (4 wt.%) | Sample III Weight, g (5 wt.%) |

|---|---|---|---|

| SWCNTs Tuball™ Matrix 601 | 3.6 | 4.8 | 5.0 |

| RTV-2 part A | 58.2 | 57.6 | 57.0 |

| RTV-2 part B | 58.2 | 57.6 | 57.0 |

| Group | N | Median | Mean Rank | Z-Value | |

| 3 wt.% | 12 | 8.0 | 6.3 | −4.8 | |

| 4 wt.% | 12 | 11.5 | 19.1 | 0.23 | |

| 5 wt.% | 12 | 14.5 | 29.8 | 4.56 | |

| Total N | 36 | - | 18.5 | - | |

| Method | DF | K-Value | p-Value | ||

| Not adjusted for ties | 2 | 29.27 | 0.00000044 | ||

| Adjusted for ties | 2 | 29.65 | 0.00000036 | ||

| Samples | Test Statistic K | Std. Error | Std. Test Statistic | p-Value | p-Value * |

|---|---|---|---|---|---|

| 3 wt.%–4 wt.% | −12.500 | 4.274 | −2.925 | 0.003 | 0.010 |

| 3 wt.%–5 wt.% | −23.250 | 4.274 | −5.440 | <0.001 | 0.000 |

| 4 wt.%–5 wt.% | −10.750 | 4.274 | −2.515 | 0.012 | 0.036 |

| Property | ELASTOSIL® 7600 | ELASTOSIL® 7683 | ||

|---|---|---|---|---|

| [MPa] | −0.023 | 0.024 | 1.65 × 10−4 | 0.068 |

| [MPa] | −0.010 | 0.049 | 0.013 | 0.021 |

| [MPa] | 0.079 | 0.061 | 3.74 × 10−4 | 0.017 |

| [–] | 1.396 | 0.226 | 1.733 | 0.271 |

| [–] | 1.322 | 0.266 | 0.571 | 0.345 |

| [–] | −2.641 | 0.267 | −2.051 | 0.372 |

| [MPa] | 1.589 | 1.581 | 1.374 | 1.383 |

| [MPa] | 0.120 | 0.119 | 0.124 | 0.120 |

| [MPa] | 3.36 × 10−11 | 2.27 × 10−4 | 8.74 × 10−5 | 1.67 × 10−4 |

| N | ELASTOSIL® 7600 | ELASTOSIL® 7683 | ||

|---|---|---|---|---|

| 3 | 0.865 | 0.871 | 0.921 | 0.918 |

| 4 | 0.883 | 0.889 | 0.922 | 0.912 |

| 5 | 0.894 | 0.897 | 0.916 | 0.921 |

| 6 | 0.865 | 0.871 | 0.921 | 0.918 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

García-Ávila, J.; Rodríguez, C.A.; Vargas-Martínez, A.; Ramírez-Cedillo, E.; Martínez-López, J.I. E-Skin Development and Prototyping via Soft Tooling and Composites with Silicone Rubber and Carbon Nanotubes. Materials 2022, 15, 256. https://doi.org/10.3390/ma15010256

García-Ávila J, Rodríguez CA, Vargas-Martínez A, Ramírez-Cedillo E, Martínez-López JI. E-Skin Development and Prototyping via Soft Tooling and Composites with Silicone Rubber and Carbon Nanotubes. Materials. 2022; 15(1):256. https://doi.org/10.3390/ma15010256

Chicago/Turabian StyleGarcía-Ávila, Josué, Ciro A. Rodríguez, Adriana Vargas-Martínez, Erick Ramírez-Cedillo, and J. Israel Martínez-López. 2022. "E-Skin Development and Prototyping via Soft Tooling and Composites with Silicone Rubber and Carbon Nanotubes" Materials 15, no. 1: 256. https://doi.org/10.3390/ma15010256