Fractal Cracking Patterns in Concretes Exposed to Sulfate Attack

Abstract

:1. Introduction

2. Experimental Methodology

2.1. Materials

2.2. Mixture Design and Sample Preparation

2.3. Method

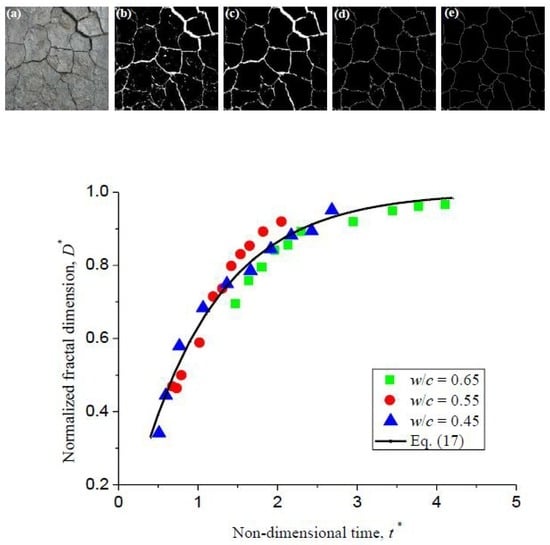

3. Fractal Characteristics of Surface Cracks

3.1. Image Processing of Surface Cracks

3.2. Fractal Dimension of Surface Cracks

3.3. Damage Degree Caused by Surface Cracks

3.4. Relationship between Damage Degree and Fractal Dimension

4. Theoretical Damage Model

5. Conclusions

- (1)

- Although the surface cracks are complex due to the arbitrary evolution of their lengths and directions, they can be described by a fractal dimension, which is an exponential function of non-dimensional time.

- (2)

- Fractal dimension exponentially increases with the corrosion time due to the chemical reaction speed.

- (3)

- The greater the values of water-to-cement ratios of concrete, the greater the damage degrees and fractal dimensions of the samples.

- (4)

- The chemo-mechanical method adopted in this paper can be applied to analyze the corrosion damage of concretes under sulfate attack, and it is also instructive to the evaluation of corrosion damage in other materials.

Author Contributions

Funding

Conflicts of Interest

References

- Da, B.; Yu, H.F.; Ma, H.Y.; Tan, Y.S.; Mi, R.J.; Dou, X.M. Chloride diffusion study of coral concrete in a marine environment. Constr. Build. Mater. 2016, 123, 47–58. [Google Scholar] [CrossRef]

- Yu, H.F.; Da, B.; Ma, H.Y.; Zhu, H.W.; Yu, Q.; Ye, H.M.; Jing, X.S. Durability of concrete structures in tropical atoll environment. Ocean Eng. 2017, 135, 1–10. [Google Scholar] [CrossRef]

- Liu, Q.F.; Yang, J.; Xia, J.; Easterbrook, D.; Li, L.Y.; Lu, X.Y. A numerical study on chloride migration in cracked concrete usingmulti-component ionic transport models. Comp. Mater. Sci. 2015, 99, 396–416. [Google Scholar] [CrossRef]

- Liu, Q.F.; Easterbrook, D.; Yang, J.; Li, L.Y. A three-phase multi-component ionic transport model for simulation of chloride penetration in concrete. Eng. Struct. 2015, 86, 122–133. [Google Scholar] [CrossRef]

- Hime, W.G.; Mather, B. “Sulfate attack” or is it? Cem. Concr. Res. 1999, 29, 789–791. [Google Scholar] [CrossRef]

- Santhanam, M.; Cohen, M.D.; Olek, J. Sulfate attack research—Wither now? Cem. Concr. Res. 2001, 31, 845–851. [Google Scholar] [CrossRef]

- Neville, A. The confused world of sulfate attack on concrete. Cem. Concr. Res. 2004, 34, 1275–1296. [Google Scholar] [CrossRef]

- Nie, Q.K.; Zhou, C.J.; Shu, X.; He, Q.; Huang, B.S. Chemical, mechanical, and durability properties of concrete with local mineral admixtures under sulfate environment in Northwest China. Materials 2014, 7, 3772–3785. [Google Scholar] [CrossRef]

- Xie, J.H.; Zhao, J.B.; Wang, J.J.; Wang, C.H.; Huang, P.Y.; Fang, C. Sulfate resistance of recycled aggregate concrete with GGBS and fly ash-based geopolymer. Materials 2019, 12, 1247. [Google Scholar] [CrossRef]

- Boyd, A.J.; Mindess, S. The use of tension testing to investigate the effect of W/C ratio and cement type on the resistance of concrete to sulfate attack. Cem. Concr. Res. 2004, 34, 373–377. [Google Scholar] [CrossRef]

- Shanahan, N.; Zayed, A. Cement composition and sulfate attack: Part I. Cem. Concr. Res. 2007, 37, 618–623. [Google Scholar] [CrossRef]

- Chen, J.K.; Qian, C.; Song, H. A new chemo-mechanical model of damage in concrete under sulfate attack. Constr. Build. Mater. 2016, 115, 536–543. [Google Scholar] [CrossRef] [Green Version]

- Müllauer, W.; Beddoe, R.E.; Heinz, D. Sulfate attack expansion mechanisms, Cem. Concr. Res. 2013, 52, 208–215. [Google Scholar] [CrossRef]

- Santhanam, M.; Cohen, M.D.; Olek, J. Mechanism of sulfate attack: A fresh look Part 1. Summary of experimental results. Cem. Concr. Res. 2002, 32, 915–921. [Google Scholar] [CrossRef]

- Santhanam, M.; Cohen, M.D.; Olek, J. Mechanism of sulfate attack: A fresh look Part 2. Proposed mechanisms. Cem. Concr. Res. 2003, 33, 341–346. [Google Scholar] [CrossRef]

- Yu, C.; Sun, W.; Scrivener, K. Mechanism of expansion of mortars immersed in sodium sulfate solutions. Cem. Concr. Res. 2013, 43, 105–111. [Google Scholar] [CrossRef]

- Ringot, F.; Bascoul, A. About the analysis of microcracking in concrete. Cem. Concr. Compos. 2001, 23, 261–266. [Google Scholar] [CrossRef]

- Mandelbrot, B.B. The Fractal Geometry of Nature; Freeman: New York, NY, USA, 1982. [Google Scholar]

- Jones, R.; Chen, F.; Pitt, S.; Paggi, M.; Carpinteri, A. From NASGRO to fractals: Representing crack growth in metals. Int. J. Fatigue 2016, 82, 540–549. [Google Scholar] [CrossRef]

- Lu, C.; Mai, Y.-W.; Xie, H. A sudden drop of fractal dimension: A likely precursor of catastrophic failure in disordered media. Philos. Mag. Lett. 2005, 85, 33–40. [Google Scholar] [CrossRef]

- Pramanik, B.; Tadepalli, T.; Mantena, P.R. Surface fractal analysis for estimating the fracture energy absorption of nanoparticle reinforced composites. Materials 2012, 5, 922–936. [Google Scholar] [CrossRef]

- Gao, H.H.; Qiang, T. Fracture surface morphology and impact strength of cellulose/PLA composites. Materials 2017, 10, 624. [Google Scholar] [CrossRef] [PubMed]

- Szeląg, M. The influence of metakaolinite on the development of thermal cracks in a cement matrix. Materials 2018, 11, 520. [Google Scholar] [CrossRef] [PubMed]

- Vogel, H.J.; Hoffmann, H.; Roth, K. Studies of crack dynamics in clay soil: I. Experimental methods, results, and morphological quantification. Geoderma 2005, 125, 213–223. [Google Scholar] [CrossRef]

- Zhao, P.F.; Zsaki, A.M.; Nokken, M.R. Using digital image correlation to evaluate plastic shrinkage cracking in cement-based materials. Constr. Build. Mater. 2018, 182, 108–117. [Google Scholar] [CrossRef]

- Abd El-Halim, A.A. Image processing technique to assess the use of sugarcane pith to mitigate clayey soil cracks: Laboratory experiment. Soil. Till. Res. 2017, 169, 138–145. [Google Scholar] [CrossRef]

- Maruyama, I.; Sasano, H.; Lin, M. Impact of aggregate properties on the development of shrinkage-induced cracking in concrete under restraint conditions. Cem. Concr. Res. 2016, 85, 82–101. [Google Scholar] [CrossRef]

- Yin, A.Y.; Yang, X.H.; Zeng, G.W.; Gao, H. Experimental and numerical investigation of fracture behavior of asphalt mixture under direct shear loading. Constr. Build. Mater. 2015, 86, 21–32. [Google Scholar] [CrossRef]

- Yin, A.Y.; Yang, X.H.; Zhang, C.C.; Zeng, G.W. Three-dimensional heterogeneous fracture simulation of asphalt mixture under uniaxial tension with cohesive crack model. Constr. Build. Mater. 2015, 76, 103–117. [Google Scholar] [CrossRef]

- Lu, C.; Vere-Jones, D.; Takayasu, H. Avalanche behavior and statistical properties in a microcrack coalescence process. Phys. Rev. Lett. 1999, 82, 347–350. [Google Scholar] [CrossRef]

- Lu, C.; Mai, Y.-W.; Bai, Y. Fractals and scaling in fracture induced by microcrack coalescence. Philos. Mag. Lett. 2005, 85, 67–75. [Google Scholar] [CrossRef] [Green Version]

- Chiaia, B.; Van Mier, J.G.M.; Vervuurt, A. Crack growth mechanisms in four different concretes: microscopic observations and fractal analysis. Cem. Concr. Compos. 1998, 28, 103–114. [Google Scholar] [CrossRef]

- Yan, A.; Wu, K.; Zhang, X. A quantitative study on the surface crack pattern of concrete with high content of steel fiber. Cem. Concr. Res. 2002, 32, 1371–1375. [Google Scholar] [CrossRef]

- Dougan, L.T.; Addison, P.S. Estimating the cut-off in the fractal scaling of fractured concrete. Cem. Concr. Res. 2001, 31, 1043–1048. [Google Scholar] [CrossRef]

- Wang, Y.T.; Diamond, S. A fractal study of the fracture surfaces of cement pastes and mortars using a stereoscopic SEM method. Cem. Concr. Res. 2001, 31, 1385–1392. [Google Scholar] [CrossRef]

- Mechtcherine, V. Fracture mechanical behavior of concrete and the condition of its fracture surface. Cem. Concr. Res. 2009, 39, 620–628. [Google Scholar] [CrossRef]

- Carpinteri, A.; Brighenti, R. Fracture behavior of plain and fiber-reinforced concrete with different water content under mixed mode loading. Mater. Design 2010, 31, 2032–2042. [Google Scholar] [CrossRef]

- Erdem, S.; Blankson, M.A. Fractal–fracture analysis and characterization of impact-fractured surfaces in different types of concrete using digital image analysis and 3D nanomaplaser profilometery. Constr. Build. Mater. 2013, 40, 70–76. [Google Scholar] [CrossRef]

- Szeląg, M. Influence of specimen’s shape and size on the thermal cracks’ geometry of cement paste. Constr. Build. Mater. 2018, 189, 1155–1172. [Google Scholar] [CrossRef]

- Szeląg, M. Evaluation of cracking patterns of cement paste containing polypropylene fibers. Compos. Struct. 2019, 220, 402–411. [Google Scholar] [CrossRef]

- Bilotta, A.; Ceroni, F.; Lignola, G.P.; Prota, A. Use of DIC technique for investigating the behaviour of FRCM materials for strengthening masonry elements. Compos. Part. B-Eng. 2017, 129, 251–270. [Google Scholar] [CrossRef]

- Tekieli, M.; De Santis, S.; de Felice, G.; Kwiecień, A.; Roscini, F. Application of Digital Image Correlation to composite reinforcements testing. Application of Digital Image Correlation to composite reinforcements testing. Compos. Struct. 2017, 160, 670–688. [Google Scholar]

- Ren, J.H.; Li, X.J.; Zhao, K. Quantitative analysis of relationships between crack characteristics and properties of soda-saline soils in Songnen Plain, China. Chin. Geogra. Sci. 2015, 25, 591–601. [Google Scholar] [CrossRef]

- Perfect, E. Fractal models for the fragmentation of rocks and soils: A review. Eng. Geol. 1997, 48, 185–198. [Google Scholar] [CrossRef]

- Xie, H.P. Fractals-An Introduction to Rock Mechanics; Science Press: Beijing, China, 1996; pp. 15–23. [Google Scholar]

- Tixier, R.; Mobasher, B. Modeling of damage in cement-based materials subjected to external sulfate attack. I: Formulation. J. Mater. Civ. Eng. 2003, 15, 305–313. [Google Scholar] [CrossRef]

- Ikumi, T.; Cavalaro, S.H.P.; Segura, I.; Aguado, A. Alternative methodology to consider damage and expansions in external sulfate attack modeling. Cem. Concr. Res. 2014, 63, 105–116. [Google Scholar] [CrossRef] [Green Version]

- Chen, J.K.; Jiang, M.Q. Long-term evolution of delayed ettringite and gypsum in Portland cement mortars under sulfate erosion. Constr. Build. Mater. 2009, 23, 812–816. [Google Scholar] [CrossRef] [Green Version]

| Al2O3 | CaO | Fe2O3 | K2O | MgO | Na2O | SO3 | SiO2 | TiO2 | Loss |

|---|---|---|---|---|---|---|---|---|---|

| 7.70 | 56.81 | 4.19 | 1.47 | 1.71 | 0.83 | 2.57 | 23.34 | 0.86 | 0.52 |

| C3S | C2S | C3A | C4AF | Gypsum | SiO2 | Calcite | Brushite |

|---|---|---|---|---|---|---|---|

| 35.7 | 5.7 | 3.2 | — | 1.8 | 10.5 | 22.8 | 20.3 |

| w/c | tu | E | F | R2 |

|---|---|---|---|---|

| 0.65 | 60.77 | 1.90 | 6.21 × 10−10 | 0.97 |

| 0.55 | 174.90 | 1.89 | 2.81 × 10−14 | 0.93 |

| 0.45 | 234.80 | 1.84 | 4.40 × 10−12 | 0.98 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yao, J.; Chen, J.; Lu, C. Fractal Cracking Patterns in Concretes Exposed to Sulfate Attack. Materials 2019, 12, 2338. https://doi.org/10.3390/ma12142338

Yao J, Chen J, Lu C. Fractal Cracking Patterns in Concretes Exposed to Sulfate Attack. Materials. 2019; 12(14):2338. https://doi.org/10.3390/ma12142338

Chicago/Turabian StyleYao, Jinwei, Jiankang Chen, and Chunsheng Lu. 2019. "Fractal Cracking Patterns in Concretes Exposed to Sulfate Attack" Materials 12, no. 14: 2338. https://doi.org/10.3390/ma12142338