1. Introduction

Traceability is usually defined as the ability to follow the movement of a product through specific phases of production, processing, and distribution tracking the history, the origin of materials and parts, the processing, the distribution, and the position of the product [

1]. Backward traceability (tracing) is defined as the process that allows to trace back a product and its transformations within crucial steps of the food chain, to identify a specific event or action [

2]. Nowadays, one of the main problems in the food industry is to define tools to identify the origin of raw materials of food products in order to guarantee their traceability and tracing [

3].

One of food products at the base of Mediterranean diet is extra virgin olive oil (EVOO); this foodstuff plays an important role in international food commerce. The Report of the Parliamentary Committee Inquiry on Counterfeiting signalized that authentic olive oil is under an increasing the risk of adulteration [

4]. A traceability system could be a direct system able to fight counterfeit EVOO. Methods supporting EVOO traceability are continuously evolving to optimize the supply chain, increase the prevention of mislabeling in relation with geographical origin and olive cultivar, and assuring the presence of correct and additional information for the consumers [

5]. Since the largest main traceability weakness is related to the certain attribution of the geographical origin, the European Commission, to safeguard the identification of extra virgin olive oil, applied two kinds of certification, namely Protected Designation of Origin (PDO) and Protected Geographical Indication (PGI) [

6]. Italy is the second biggest olive oil producer in the world, after Spain, with an average production of 555,574 tons from 1993 to 2014 [

7]. A total of 80% of Italian’s olive oil production is concentrated in the Southern regions. In Italy, according to Census data [

8], counterfeiting is a growing phenomenon on par with a similar EU trend. As reported by numerous surveys, the continuous counterfeiting linked to “made in Italy” is leading to some new phenomena such as the so-called “Italian Sounding” [

9], namely the imitative practice that causes damage to the image of an Italian product. Such a problem leads to increase safety requirements and consumer protection systems with regard to the oil quality and security from “field to fork”.

Generally, EVOO costs 4–5 times more than other vegetables oils. This is mainly imputable to the higher production costs as well as for its higher nutritional and organoleptic properties [

10], therefore, the higher cost should be justified by higher quality guarantees. The implementation of a traceability system for EVOO represents a significant running cost for producers and processing companies. The price paid does include the resources to set-up (scale on the base of the production needs) and run the system. Such a cost should be in an acceptable range that would incentivize companies to adopt traceability systems in order to receive reasonable benefits with positive repercussions concerning information reliability, effectiveness, and productivity depending upon the organization [

11]. In the competitive market, the increase of costs, as a result of traceability systems, can rebound in the consumer with little change in quantity demanded because of relatively lower food demand price elasticity compared to most industrial products [

12]. However, in recent years consumers’ willingness to pay for food traceability has been given increasing attention due to the worldwide concern about food safety [

12]. It is very important that companies, in balancing benefits and costs, understand consumers’ preferences about advantages, costs, and reliability of traceability systems. However, it is important that knowledge related to food quality, security, and certification is seen by consumers a crucial factor in terms of “willingness to pay” for a food product with implementation of traceability system [

12,

13]. Traceability will be increasingly integrated with smart sensing systems and consequently add data about product features, production methods, and ambient conditions (Internet of Food (IoF)) [

14].

A process to keep records reporting the trail of an input from suppliers to customers is defined as an infotracing system [

15]. At the end of the infotracing flow, consumers acquire information on the product by reading a physical label [

16] or a digital application. Currently, it is possible to obtain information about traceability along the food supply chain using smart tags such as Radio Frequency Identification (RFID), Near Field Communication (NFC), and the most diffused barcodes. This last example is commonly present in the food market as 1D barcodes or 2D codes (i.e., Quick Response (QR) code) [

17]. Other technologies use electronic tags. These tags store information in a digital format that can be read by a compatible scanner using small integrated circuits. The most used ones, with varying underlying communication technologies, are NFC/RFID. RFID tags report logistic advantages being automatable and readable within logistic platforms [

17]. Many studies demonstrate, for food traceability purposes, RFID systems produce more advantages when compared to the barcode ones [

18]. For example, Gandino et al. [

19] proposed the RFID adoption for fruit warehouse traceability, remarking many benefits for the supply chain management, commodity value addition, and brand management. There are also visible or electronic markers (2D codes, NFC) with environmental sensing functions (functional ink, sensors, indicators) combined with software intelligence (user information, location, etc.) in order to provide context aware services to end users. In the study by Mainetti et al. [

20] an NFC system was implemented to trace an IV range products supply chain in conjunction with a mobile app to allow the linking of plants and traceability information. These smart tags should increase the consumer trust towards food products (integrity, quality, safety, authenticity) and service providers (food value chains) [

21]. Today, consumers are familiar with QR codes and NFC, but they are not willing to read them regularly using their mobile phones; they feel that they do not get any additional value from it. It is essential that the consumers trust the service and service provider [

22,

23].

Currently, these modern technologies are proposed for food traceability systems. Tarjan et al. [

24], present a concept for fruit yogurts labeling based on QR codes, which enables traceability of products and provides additional information about the peculiarities of the product. Another example of smart technologies used for food traceability is NFC. In the work by Pigini et al. [

25], they proposed a solution based on NFC tags to obtain information in the pig supply chain in order to inform the consumer.

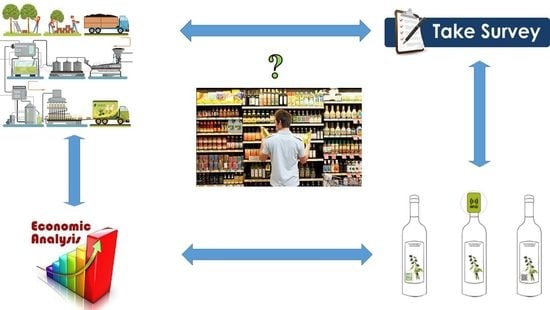

The aim of this work is to explore the willingness of the consumers to accept and adopt EVOO electronic traceability systems and explore the economic sustainability their introduction and use in a stable market such as the EVOO one. To pursue this aim, we proposed a questionnaire to a limited number of consumers, proposing three alternative technologies for traceability (NFC, tamper-proof device protected by RFID sticker, and QR code protected by a “scratch and win” system and associated with blockchains), and analyzed the economic feasibility of the introduction of these technologies at three different production levels, representative of Italian EVOO production panorama. This work is organized into a Materials and methods, which illustrate the innovative electronic labels proposed, the questionnaire disseminated to consumers and private companies, and the economic sustainability analysis. The results and discussion section is composed by a section regarding the consumer interviews, another related to the stakeholder interviews, and the results of the economic analysis.

4. Conclusions

This study contributes to the EVOO production panorama providing concrete tools for improving the internal logistics of the company on the one hand and promoting infotracing and safeguarding consumers on the other. Even if the technologies have been present on the market for some years, now they are almost new to the olive oil production food chain.

EVOO represents the one of the excellences of Italian products; it is a basic ingredient of the Mediterranean diet; for this reason, it must be protected from fraud and sophistication that could damage “made in Italy” and have repercussions both for producers and consumers. This study showed some interesting and surprising outcomes. Following the questionnaire results, the high level of the respondent education could mainly due to the media (a specialized online tool) adopted to spread the questionnaire. First of all, the unexpectedly high willingness to pay (+17.8%) by Italian consumers for the implementation of traceability information on EVOO mediated by smart technologies. This interesting result is not affected by the high level of education of the respondents (63% graduated) even if it may have influenced the considerable percentage (93.9%) of those interviewed. However, the education level and technological knowledge may not be properly on par. Furthermore, according with the survey results, the age composition revealed different spending behavior patterns. Respondents less than 35 years old (19.9% of the respondents) were less available to pay additional costs for the implementation of information regarding traceability. A future study could try to improve the effectiveness of the present work crossing data related to technological knowledge along with those already asked.

Although blockchains are not yet very widespread in EVOO traceability, their use may be an excellent solution to ensure reliability, transparency, and security, especially for those commodities susceptible to fraud such as EVOO. Among the three proposed technologies for traceability, consumers greatly prefer the QR-B system, despite the different advantages linkable to the other systems. The success of the QR-B could be ascribable to different aspects: the indubitable cutting-edge fashion trend of blockchain in the food sector, the use of incentives (financial rewards mechanism), the easy-to-use QR-code, and the gamification strategy. Another interesting result regards the economic analysis which reports a sustainable implementation of the three technologies proposed starting from a mid-production EVOO level. However, it must be said that further studies should investigate the deeper costs that farms/industries etc., would have to pay in relation to the business planning, prior the technological system adoption.

On the basis of the obtained results, it is possible to predict an evolution of the proposed traceability systems merging the benefits of each technology into a syncretic one, aiming to preserve the bottle content (DAB), the easy-to-use properties (NFC and QR-code) with the QR-B aforementioned qualities, and integrating other information, such as the preservation status from bottling to consumers adopting functional inks.