Ultrasonic Pulse Velocity—Compressive Strength Relationship for Portland Cement Mortars Cured at Different Conditions

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Curing Conditions

- (i)

- kept under a saturated limewater solution for twenty-eight days at a temperature of 22 ± 1 °C to establish a reference condition,

- (ii)

- under lab conditions for twenty-eight days at 22 ± 2 °C and 50% RH, and

- (iii)

- some mortar samples were kept in a climatic chamber during twenty-eight days at 22 ± 1 °C and 95% RH.

2.3. Mechanical Testing

2.4. Non-Destructive Ultrasonic Pulse Velocity

- (i)

- Transmitting and receiving transducers were positioned at opposite ends of each mortar cement specimen (Figure 1). Then, this instrument generates low-frequency ultrasonic pulses.

- (ii)

- Measurements of the travelling time of the signal through the specimen of pulses between both transducers were done.

- (iii)

- The longitudinal ultrasonic velocities of the samples, V, were determined using Equation (2) from the distance between the two transducers (path length) and the measured transit time of the pulse.

3. Results and Discussion

3.1. Characterization of the Portland Mortar Samples

3.2. Ultrasonic Characterization

3.3. Effect of the Curing Conditions on the Average Ultrasonic Velocity

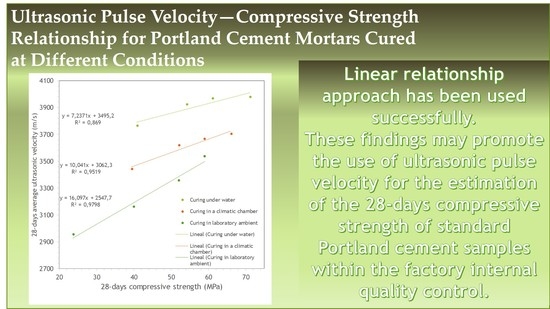

3.4. Correlation Between 28-Day compressive Strength and Average Ultrasonic Pulse Velocity

3.5. Modeling Assessment

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Mehta, P.K.; Monteiro, P.J.M. Concrete: Microstructure, Properties, and Materials, 4th ed.; McGraw-Hill Education: New York, NY, USA, 2014; pp. 1–704. [Google Scholar]

- Taylor, H.F.W. Cement Chemistry, 2nd ed.; Thomas Telford Ltd.: London, UK, 1997; pp. 1–480. [Google Scholar]

- Sanjuán, M.A.; Estévez, E.; Argiz, C.; del Barrio, D. Effect of curing time on granulated blast-furnace slag cement mortars. Cem. Concr. Compos. 2018, 90, 257–265. [Google Scholar] [CrossRef]

- Lafhaj, Z.; Goueygou, M.; Djerbi, A. Correlation between porosity, permeability and ultrasonic parameters of motar with variable water/cement ratio and water content. Cem. Concr. Res. 2006, 36, 625–633. [Google Scholar] [CrossRef]

- Tomsett, H.N. The practical use of ultrasonic pulse velocity measurements in the assessment of concrete quality. Mag. Concr. Res. 1980, 32, 7–16. [Google Scholar] [CrossRef]

- Punurai, W.; Jarzynski, J.; Qu, J.; Kim, J.-Y.; Jacobs, L.J.; Kurtis, K.E. Characterization of multi-scale porosity in cement paste by advanced ultrasonic techniques. Cem. Concr. Res. 2007, 37, 38–46. [Google Scholar] [CrossRef]

- Concu, G.; Trulli, N. Concrete Defects Sizing by Means of Ultrasonic Velocity Maps. Buildings 2018, 8, 176. [Google Scholar] [CrossRef] [Green Version]

- Hernández, M.G.; Anaya, J.J.; Sánchez, T.; Segura, I. Porosity estimation of aged mortar using a micromechanical model. Ultrasonics 2006, 44, e1007–e1011. [Google Scholar] [CrossRef]

- Akkaya, Y. Nondestructive measurement of concrete strength gain by an ultrasonic wave reflection method. Mater. Struct. 2003, 36, 507–514. [Google Scholar] [CrossRef]

- Jasiński, R.; Drobiec, Ł.; Mazur, W. Validation of Selected Non-Destructive Methods for Determining the Compressive Strength of Masonry Units Made of Autoclaved Aerated Concrete. Materials 2019, 12, 389. [Google Scholar] [CrossRef] [Green Version]

- Yoo, D.-Y.; Shin, H.-O.; Yoon, Y.-S. Ultrasonic Monitoring of Setting and Strength Development of Ultra-High-Performance Concrete. Materials 2016, 9, 294. [Google Scholar] [CrossRef]

- Del Río, L.M.; Jiménez, A.; López, F.; Rosa, F.J.; Rufo, M.M.; Paniagua, J.M. Characterization and hardening of concrete with ultrasonic testing. Ultrasonics 2004, 42, 527–530. [Google Scholar] [CrossRef]

- Reinhardt, H.; Grosse, C.; Herb, A. Ultrasonic monitoring of setting and hardening of cement mortar—a new device. Mater. Struct. 2000, 33, 581–583. [Google Scholar] [CrossRef]

- Drobiec, Ł.; Jasiński, R.; Mazur, W. Accuracy of Eddy-Current and Radar Methods Used in Reinforcement Detection. Materials 2019, 12, 1168. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Laureti, S.; Ricci, M.; Mohamed, M.N.I.B.; Senni, L.; Davis, L.A.J.; Hutchins, D.A. Detection of rebars in concrete using advanced ultrasonic pulse compression techniques. Ultrasonics 2018, 85, 31–38. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Ervin, B.; Kuchma, D. Monitoring corrosion of rebar embedded in mortar using high-frequency guided ultrasonic waves. J. Eng. Mech. 2009, 1635, 9–19. [Google Scholar] [CrossRef]

- Chung, H.W. Effects of embedded steel bars upon ultrasonic testing of concrete. Mag. Concr. Res. 1978, 30, 19–25. [Google Scholar] [CrossRef]

- Schabowicz, K.; Gorzelańczyk, T.; Szymków, M. Identification of the Degree of Degradation of Fibre-Cement Boards Exposed to Fire by Means of the Acoustic Emission Method and Artificial Neural Networks. Materials 2019, 12, 656. [Google Scholar] [CrossRef] [Green Version]

- Ranachowski, Z.; Ranachowski, P.; Dębowski, T.; Gorzelańczyk, T.; Schabowicz, K. Investigation of Structural Degradation of Fiber Cement Boards Due to Thermal Impact. Materials 2019, 12, 944. [Google Scholar] [CrossRef] [Green Version]

- Gorzelańczyk, T.; Schabowicz, K. Effect of Freeze–Thaw Cycling on the Failure of Fibre-Cement Boards, Assessed Using Acoustic Emission Method and Artificial Neural Network. Materials 2019, 12, 2181. [Google Scholar] [CrossRef] [Green Version]

- Ait Ouarabi, M.; Antonaci, P.; Boubenider, F.; Gliozzi, A.S.; Scalerandi, M. Ultrasonic Monitoring of the Interaction between Cement Matrix and Alkaline Silicate Solution in Self-Healing Systems. Materials 2017, 10, 46. [Google Scholar] [CrossRef] [Green Version]

- Lafhaj, Z.; Goueygou, M. Experimental study on sound and damaged mortar: Variation of ultrasonic parameters with porosity. Constr. Build. Mater. 2009, 23, 953–958. [Google Scholar] [CrossRef]

- Logoń, D. Identification of the Destruction Process in Quasi Brittle Concrete with Dispersed Fibers Based on Acoustic Emission and Sound Spectrum. Materials 2019, 12, 2266. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Stawiski, B.; Kania, T. Examining the Distribution of Strength across the Thickness of Reinforced Concrete Elements Subject to Sulphate Corrosion Using the Ultrasonic Method. Materials 2019, 12, 2519. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Aggelis, D.G.; Kordatos, E.Z.; Strantza, M.; Soulioti, D.V.; Matikas, T.E. NDT approach for characterization of subsurface cracks in concrete. Constr. Build. Mater. 2011, 25, 3089–3097. [Google Scholar] [CrossRef]

- Ham, S.; Song, H.; Oelze, M.L.; Popovics, J.S. A contactless ultrasonic surface wave approach to characterize distributed cracking damage in concrete. Ultrasonics 2017, 75, 46–57. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Carrión, A.; Genovés, V.; Gosálbez, J.; Miralles, R.; Payá, J. Ultrasonic signal modality: A novel approach for concrete damage evaluation. Cem. Concr. Res. 2017, 101, 25–32. [Google Scholar] [CrossRef] [Green Version]

- Ugur, I.; Sengun, N.; Demirdag, S.; Altindag, R. Analysis of the alterations in porosity features of some natural stones due to thermal effect. Ultrasonics 2014, 54, 1332–1336. [Google Scholar] [CrossRef]

- Trtnik, G.; Gams, M. Recent advances of ultrasonic testing of cement-based materials at early ages. Ultrasonics 2014, 54, 66–75. [Google Scholar] [CrossRef]

- Trtnik, G.; Valicˇ, M.I.; Kavčič, F.; Turk, G. Comparison between two ultrasonic methods in their ability to monitor the setting process of cement pastes. Cem. Concr. Res. 2009, 39, 876–882. [Google Scholar] [CrossRef] [Green Version]

- Mohammed, T.U.; Mahmood, A.H. Effects of maximum aggregate size on UPV of brick aggregate concrete. Ultrasonics 2016, 69, 129–136. [Google Scholar] [CrossRef]

- Ben-Zeitun, A.E. Use of pulse velocity to predict compressive strength of concrete. Int. J. Cem. Compos. Light. Concr. 1986, 8, 51–59. [Google Scholar] [CrossRef]

- Pacheco Torgal, F.; Castro-Gomes, J.P. Influence of physical and geometrical properties of granite and limestone aggregates on the durability of a C20/25 strength class concrete. Constr. Build. Mater. 2006, 20, 1079–1088. [Google Scholar] [CrossRef]

- Segura, I.; Molero, M.; Aparicio, S.; Anaya, J.J.; Moragues, A. Decalcification of cement mortars: Characterisation and modelling. Cem. Concr. Compos. 2013, 35, 136–150. [Google Scholar] [CrossRef] [Green Version]

- Trtnik, G.; Kavčič, F.; Turk, G. Prediction of concrete strength using ultrasonic pulse velocity and artificial neural networks. Ultrasonics 2009, 49, 53–60. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Lee, S.C. Prediction of concrete strength using artificial neural networks. Eng. Struct. 2003, 25, 849–857. [Google Scholar] [CrossRef]

- Yılmaz, T.; Ercikdi, B.; Karaman, K.; Külekçi, G. Assessment of strength properties of cemented paste backfill by ultrasonic pulse velocity test. Ultrasonics 2014, 54, 1386–1394. [Google Scholar] [CrossRef]

- Akçaözoğlu, S.; Akçaözoğlu, K.; Atiş, C.D. Thermal conductivity, compressive strength and ultrasonic wave velocity of cementitious composite containing waste PET lightweight aggregate (WPLA). Compos. Part B 2013, 45, 721–726. [Google Scholar]

- Colangelo, F.; Cioffi, R. Mechanical properties and durability of mortar containing fine fraction of demolition wastes produced by selective demolition in South Italy. Compos. Part B 2017, 115, 43–50. [Google Scholar] [CrossRef]

- EN 197-1:2011. Cement—Part 1: Composition, Specifications and Conformity Criteria for Common Cements; European Committee for Standardization (CEN) Standards: Brussels, Belgium, 2011. [Google Scholar]

- Sanjuán, M.A.; Argiz, C. The new European standard on common cements specifications EN 197-1:2011. Mater. Construcc. 2012, 62, 425–430. [Google Scholar] [CrossRef] [Green Version]

- EN 196-2:2013. Method of Testing Cement. Chemical Analysis of Cement; European Committee for Standardization (CEN) Standards: Brussels, Belgium, 2013. [Google Scholar]

- EN 196-1:2016. Methods of Testing of Cement: Part 1. Determination of Strength; European Committee for Standardization (CEN) Standards: Brussels, Belgium, 2016. [Google Scholar]

- EN 12504-4:2004. Determination of Ultrasonic Pulse Velocity; European Committee for Standardization (CEN) Standards: Brussels, Belgium, 2004. [Google Scholar]

- ASTM C597-16. Standard Test Method for Pulse Velocity through Concrete; Book of Standards, ASTM Standards. Vol. 04.02: West Conshohocken, PA, USA, 2016. [Google Scholar]

- Argiz, C.; Menéndez, E.; Sanjuán, M.A. Effect of mixes made of coal bottom ash and fly ash on the mechanical strength and porosity of Portland cement. Mater. Construcc. 2013, 63, 49–64. [Google Scholar]

- Sanjuán, M.A.; Argiz, C.; Gálvez, J.C.; Moragues, A. Effect of silica fume fineness on the improvement of Portland cement strength performance. Constr. Build. Mater. 2015, 96, 55–64. [Google Scholar] [CrossRef]

- Xu, W.; Li, Q.; Liu, B. Coupled effect of curing temperature and age on compressive behavior, microstructure and ultrasonic properties of cemented tailings backfill. Constr. Build. Mater. 2020, 237, 117738. [Google Scholar] [CrossRef]

- Jiang, H.; Yi, H.; Yilmaz, E.; Liu, S.; Qiu, J. Ultrasonic evaluation of strength properties of cemented paste backfill: Effects of mineral admixture and curing temperature. Ultrasonics 2020, 100, 105983. [Google Scholar] [CrossRef] [PubMed]

- Olteanu, A.; Teodoriu, C. Uncertainty in ultrasonic measurements of oil-based mud contaminated cement. Mater. Today Commun. 2020, 22, 100783. [Google Scholar] [CrossRef]

- Barluenga, G.; Puentes, J.; Palomar, I.; Guardia, C. Methodology for monitoring Cement Based Materials at Early Age combining NDT techniques. Constr. Build. Mater. 2018, 193, 373–383. [Google Scholar] [CrossRef]

- Singh, H.; Gupta, R. Cellulose fiber as bacteria-carrier in mortar: Self-healing quantification using UPV. J. Build. Eng. 2020, 28, 101090. [Google Scholar] [CrossRef]

| Cement Type | CaO | SiO2 | Fe2O3 | Al2O3 | MgO | SO3 | Na2O | K2O | Ti2O5 | P2O5 | LOI | IR1 | Cl− |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| CEM I 52.5 R | 62.7 | 20.9 | 3.5 | 4.3 | 1.9 | 3.4 | 0.30 | 0.90 | 0.25 | 0.10 | 3.7 | 1.04 | 0.02 |

| CEM I 42.5 R | 59.9 | 22.2 | 3.9 | 5.3 | 1.9 | 3.3 | 0.32 | 1.02 | 0.24 | 0.10 | 2.2 | 0.90 | 0.03 |

| CEM II/A-V 42.5 R | 51.8 | 24.9 | 4.6 | 7.8 | 1.8 | 2.8 | 0.35 | 1.27 | 0.20 | 0.08 | - | - | 0.03 |

| CEM II/B-V 32.5 R | 43.8 | 28.0 | 5.5 | 10.4 | 1.8 | 2.4 | 0.38 | 1.56 | 0.17 | 0.07 | - | - | 0.02 |

| Cement Type | 2 Days | 28 Days | ||||||

|---|---|---|---|---|---|---|---|---|

| FS | SD | CS | SD | FS | SD | CS | SD | |

| CEM I 52.5 R | 9.5 ± 0.3 | 0.3 | 49.1 ± 1.2 | 1.5 | 10.3 ± 0.6 | 0.5 | 67.5 ± 1.5 | 1.8 |

| CEM I 42.5 R | 6.9 ± 0.4 | 0.3 | 35.4 ± 0.8 | 0.9 | 9.9 ± 0.4 | 0.3 | 57.6 ± 1.1 | 1.3 |

| CEM II/A-V 42.5 R | 6.7 ± 0.6 | 0.5 | 32.1 ± 0.2 | 0.2 | 9.5 ± 0.8 | 0.7 | 55.4 ± 1.9 | 2.4 |

| CEM II/B-V 32.5 R | 4.1 ± 0.2 | 0.1 | 18.1 ± 0.3 | 0.4 | 8.4 ± 0.3 | 0.3 | 39.5 ± 0.6 | 0.8 |

| Cement Type | Average Ultrasonic Velocity (m/s) | ||||

|---|---|---|---|---|---|

| Under Water UPV (m/s) | 95% RH UPV (m/s) | Difference (95% RH- Water) % | 50% RH UPV (m/s) | Difference (50% RH- Water) % | |

| CEM I 52.5 R | 3977 ± 33 | 3704 ± 50 | −7 | 3535 ± 27 | −11 |

| CEM I 42.5 R | 3966 ± 15 | 3665 ± 30 | −8 | 3357 ± 13 | −15 |

| CEM II/A-V 42.5 R | 3922 ± 15 | 3618 ± 36 | −8 | 3160 ± 37 | −19 |

| CEM II/B-V 32.5 R | 3763 ± 48 | 3440 ± 61 | −9 | 2954 ± 13 | −22 |

| Mortar Quality | Excellent | Good | Poor | Very Poor |

|---|---|---|---|---|

| UPV (m/s) | >3800 | 3800–3500 | 3500–3200 | <3200 |

| Fitting Parameters | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Under Water | 95% RH | 50% RH | |||||||

| a | b | R2 | a | b | R 2 | a | b | R 2 | |

| 28-days average ultrasonic velocity (m/s) | −412.2 | 0.120 | 0.87 | −287.7 | 0.0948 | 0.95 | −154.2 | 0.0609 | 0.98 |

| 14-days average ultrasonic velocity (m/s) | −396.9 | 0.1161 | 0.85 | −262.6 | 0.0856 | 0.96 | −154.9 | 0.0586 | 0.96 |

| 7-days average ultrasonic velocity (m/s) | −365.1 | 0.1102 | 0.89 | −206.0 | 0.0719 | 0.98 | −154.2 | 0.0571 | 0.9873 |

| 2-days average ultrasonic velocity (m/s) | −230.1 | 0.0783 | 0.98 | −110.4 | 0.0463 | 0.93 | −167.2 | 0.0615 | 0.99 |

| 1-day average ultrasonic velocity (m/s) | −93.3 | 0.0448 | 0.93 | −62.2 | 0.0355 | 0.96 | −85.39 | 0.0405 | 0.98 |

| Fitting Parameters | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Under Water | 95% RH | 50% RH | |||||||

| a | b | R 2 | a | b | R 2 | a | b | R 2 | |

| 28-days average ultrasonic velocity (m/s) | 0.0076 | 0.0023 | 0.92 | 0.0609 | 0.0019 | 0.98 | 0.2671 | 0.0016 | 0.94 |

| 14-days average ultrasonic velocity (m/s) | 0.0100 | 0.0022 | 0.91 | 0.1079 | 0.0017 | 0.96 | 0.2142 | 0.0016 | 0.99 |

| 7-days average ultrasonic velocity (m/s) | 0.0192 | 0.0021 | 0.94 | 0.3286 | 0.0014 | 0.98 | 0.2292 | 0.0015 | 0.99 |

| 2-days average ultrasonic velocity (m/s) | 0.2676 | 0.0015 | 0.99 | 2.0241 | 0.0009 | 0.96 | 0.1651 | 0.0016 | 0.99 |

| 1-day average ultrasonic velocity (m/s) | 3.3263 | 0.0008 | 0.97 | 5.3544 | 0.0007 | 0.98 | 1.3707 | 0.0011 | 0.99 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Estévez, E.; Martín, D.A.; Argiz, C.; Sanjuán, M.Á. Ultrasonic Pulse Velocity—Compressive Strength Relationship for Portland Cement Mortars Cured at Different Conditions. Crystals 2020, 10, 133. https://doi.org/10.3390/cryst10020133

Estévez E, Martín DA, Argiz C, Sanjuán MÁ. Ultrasonic Pulse Velocity—Compressive Strength Relationship for Portland Cement Mortars Cured at Different Conditions. Crystals. 2020; 10(2):133. https://doi.org/10.3390/cryst10020133

Chicago/Turabian StyleEstévez, Esteban, Domingo Alfonso Martín, Cristina Argiz, and Miguel Ángel Sanjuán. 2020. "Ultrasonic Pulse Velocity—Compressive Strength Relationship for Portland Cement Mortars Cured at Different Conditions" Crystals 10, no. 2: 133. https://doi.org/10.3390/cryst10020133