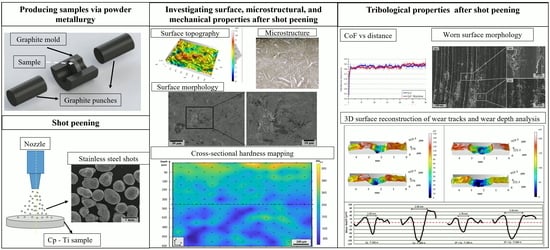

Surface and Tribological Properties of Powder Metallurgical Cp-Ti Titanium Alloy Modified by Shot Peening

Abstract

:1. Introduction

2. Materials and Methods

2.1. Processing Cp-Ti Samples

2.2. Shot Peening

2.3. Characterisation of Surface Properties

2.4. Characterisation of Mechanical Properties

2.5. Characterisation of Tribological Properties

3. Results

3.1. Surfaces Properties of Shot-Peened Cp-Ti Alloy

3.2. Tribological Properties

3.2.1. Variation of Coefficient of Friction

3.2.2. Variation of Wear Rate

3.2.3. Variation of Wear Track Topography

3.2.4. Worn Surface Morphology

4. Discussion

5. Conclusions

- The application of shot peening led to notable plastic deformation of the Cp-Ti alloy, resulting in the formation of craters, peaks, and valleys; and increased surface roughness that may affect tribological behavior. In addition, shot peening modified the microstructural features near the surface, resulting in the formation of a thin ultrafine-grained layer beneath the surface. However, it was not possible to clearly visualize and determine the average grain size of this layer due to the insufficient resolution of the microscopy techniques used. Therefore, the authors suggest that future research should focus solely on implementing advanced electron microscopy techniques (i.e., high-resolution SEM and electron backscatter diffraction) to reveal the nano-gradient and ultrafine-grained microstructural features after shot peening.

- Cross-sectional hardness mapping of shot-peening samples was used for the first time to reveal the formation of a work-hardened surface layer with shot peening, where a sharp increase in hardness was observed within the near surface, indicating that shot peening significantly modifies the near-surface microstructure.

- The coefficient of friction was similar for both shot-peened and unpeened samples, and changes in the sliding distance did not have a substantial effect.

- High-resolution 3D surface topographies of worn unpeened and shot-peened surfaces revealed micro-scratches and inhomogeneities along wear tracks, which were indicative of three-body abrasion mechanisms during contact.

- Ploughing was the primary mechanism of material removal in the shot-peened samples with no evidence of micro-cutting. EDS revealed the formation of oxide islands, suggesting denser tribolayer.

- Shot peening successfully reduced the wear rate of Cp-Ti samples due to the formation of a work-hardened layer and the modification of the microstructural features, although it is essential to further investigate the relationship between the modified microstructural features, mechanical properties and wear resistance of shot-peened materials.

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Jeje, S.O.; Shongwe, M.B.; Maledi, N.; Ogunmuyiwa, E.N.; Tshabalala, L.C.; Babalola, B.J.; Olubambi, P.A. Sintering behavior and alloying elements effects on the properties of CP-Titanium sintered using pulsed electric current. Mater. Chem. Phys. 2020, 256, 123707. [Google Scholar] [CrossRef]

- Keddam, M.; Makuch, N.; Boumaali, B.; Piasecki, A.; Miklaszewski, A.; Kulka, M. Liquid Boriding of Cp-Ti and Ti6Al4V Alloy: Characterization of Boride Layers and Tribological Properties. Surf. Eng. Appl. Electrochem. 2020, 56, 348–357. [Google Scholar] [CrossRef]

- Aniolek, K.; Barylski, A.; Kupka, M. Friction and Wear of Oxide Scale Obtained on Pure Titanium after High-Temperature Oxidation. Materials 2021, 14, 3764. [Google Scholar] [CrossRef] [PubMed]

- Jin, J.; Zhou, S.; Zhao, Y.; Zhang, Q.; Wang, X.; Li, W.; Chen, D.; Zhang, L.-C. Refined microstructure and enhanced wear resistance of titanium matrix composites produced by selective laser melting. Opt. Laser Technol. 2021, 134, 106644. [Google Scholar] [CrossRef]

- Baldin, E.K.; Santos, P.B.; de Castro, V.V.; Aguzzoli, C.; Maurmann, N.; Girón, J.; Pranke, P.; Malfatti, C.D.F. Plasma Electrolytic Oxidation (PEO) Coated CP-Ti: Wear Performance on Reciprocating Mode and Chondrogenic–Osteogenic Differentiation. J. Bio- Tribo-Corros. 2021, 8, 29. [Google Scholar] [CrossRef]

- Rajabi, M.; Miresmaeili, R.; Aliofkhazraei, M. Hardness and wear behavior of surface mechanical attrition treated titanium. Mater. Res. Express 2019, 6, 065003. [Google Scholar] [CrossRef]

- Celtik, C.; Yurekturk, Y.; Gecu, R.; Kaboglu, C.; Muhaffel, F. Surface characteristics of plasma electrolytic oxidation coatings on Cp-Ti and hot-dip aluminised Cp-Ti. Trans. IMF 2022, 100, 159–165. [Google Scholar] [CrossRef]

- Najim, A.N.; Mohammed, M.T.; Albozahid, M.A. Morphology, Topography and Wettability of CP-Ti after Anodization Process for Biomedical Applications. J. Phys. Conf. Ser. 2021, 1973, 012006. [Google Scholar] [CrossRef]

- Kumar, P.; Joshi, R.S.; Singla, R.K. Sliding wear behaviour of CP titanium laminates produced by large strain extrusion machining. Wear 2021, 477, 203774. [Google Scholar] [CrossRef]

- Yıldıran Avcu, Y.; Yetik, O.; Guney, M.; Sınmazçelik, T.; Avcu, E. Tailoring Surface Morphology and Topography of Shot-Peened Ti6Al4V via Grit Blasting. Mater. Tehnol. 2021, 55, 625–628. [Google Scholar] [CrossRef]

- Gurusami, K.; Sundaram, K.S.; Azhagarasan, N.S.; Gopal, G.H. Experimental Investigation on Microstructure and Mechanical Properties of Nd:YAG Laser Treated CP-Ti and & Ni-Cr Alloys for Dental Applications. Procedia Eng. 2013, 64, 1173–1182. [Google Scholar] [CrossRef] [Green Version]

- Alikhani Chamgordani, S.; Miresmaeili, R.; Aliofkhazraei, M. Improvement in tribological behavior of commercial pure titanium (CP-Ti) by surface mechanical attrition treatment (SMAT). Tribol. Int. 2018, 119, 744–752. [Google Scholar] [CrossRef]

- Bailey, R.; Sun, Y. Unlubricated sliding friction and wear characteristics of thermally oxidized commercially pure titanium. Wear 2013, 308, 61–70. [Google Scholar] [CrossRef]

- Yildiran Avcu, Y.; Yetik, O.; Guney, M.; Iakovakis, E.; Sinmazcelik, T.; Avcu, E. Surface, Subsurface and Tribological Properties of Ti6Al4V Alloy Shot Peened under Different Parameters. Materials 2020, 13, 4363. [Google Scholar] [CrossRef] [PubMed]

- Yıldıran Avcu, Y.; Yetik, O.; Koçoğlu, H.; Avcu, E.; Sınmazçelik, T. Dry Sliding Wear Behaviour of Shot Peened TI6AL4V Alloys at Different Peening Times. Acta Phys. Pol. A 2018, 134, 349–353. [Google Scholar] [CrossRef]

- Chen, C.; Zhang, H. Characteristics of friction and wear of Al-Zn-Mg-Cu alloy after application of ultrasonic shot peening technology. Surf. Coat. Technol. 2021, 423, 127615. [Google Scholar] [CrossRef]

- DiCecco, L.-A.; Mehdi, M.; Edrisy, A. Dry-Sliding Wear Mechanisms of Shot-Peened Additive Manufactured Alpha Titanium Featuring TiB Particles. Tribol. Lett. 2021, 69, 90. [Google Scholar] [CrossRef]

- Efe, Y.; Karademir, I.; Husem, F.; Maleki, E.; Unal, O. Surface Severe Plastically Deformed Nanostructured AA7075 Alloy: Assessment on Tribological and Axial Fatigue Behaviors. J. Mater. Eng. Perform. 2020, 29, 3774–3783. [Google Scholar] [CrossRef]

- Haghighi, O.; Amini, K.; Gharavi, F. Effect of Shot Peening Operation on the Microstructure and Wear Behavior of AZ31 Magnesium Alloy. Prot. Met. Phys. Chem. Surf. 2020, 56, 164–168. [Google Scholar] [CrossRef]

- Han, X.; Zhang, Z.; Hou, J.; Barber, G.C.; Qiu, F. Tribological behavior of shot peened/austempered AISI 5160 steel. Tribol. Int. 2020, 145, 106197. [Google Scholar] [CrossRef]

- Han, X.; Zhang, Z.; Pang, B.; Barber, G.C.; Zhao, J.; Qiu, F. The Effect of Shot-Peening Time on Tribological Behavior of AISI5160 Steel. Tribol. Trans. 2022, 65, 801–812. [Google Scholar] [CrossRef]

- Jia, S.; Qu, S.; Hu, X.; Lai, F.; Duan, C.; Li, X. Effect of Shot Peening on Microstructures and High-Temperature Tribological Properties of 4Cr9Si2 Valve Steel. Steel Steel Steel Res. Int. 2021, 92, 2100250. [Google Scholar] [CrossRef]

- Silva, K.H.S.; Carneiro, J.R.; Coelho, R.S.; Pinto, H.; Brito, P. Influence of shot peening on residual stresses and tribological behavior of cast and austempered ductile iron. Wear 2019, 440–441, 203009. [Google Scholar] [CrossRef]

- Trung, P.Q.; Khun, N.W.; Butler, D.L. Effects of shot peening pressure, media type and double shot peening on the microstructure, mechanical and tribological properties of low-alloy steel. Surf. Topogr. Metrol. Prop. 2016, 4, 045001. [Google Scholar] [CrossRef]

- Walczak, M.; Szala, M. Effect of shot peening on the surface properties, corrosion and wear performance of 17-4PH steel produced by DMLS additive manufacturing. Arch. Civ. Mech. Eng. 2021, 21, 157. [Google Scholar] [CrossRef]

- Yang, Q.; Zhou, W.; Zhong, Y.; Zhang, X.; Fu, X.; Chen, G.; Li, Z. Effect of shot-peening on the fretting wear and crack initiation behavior of Ti-6Al-4V dovetail joint specimens. Int. J. Fatigue 2018, 107, 83–95. [Google Scholar] [CrossRef]

- Zaleski, K. The effect of vibratory and rotational shot peening and wear on fatigue life of steel. Eksploat. I Niezawodn. -Maint. Reliab. 2016, 19, 102–107. [Google Scholar] [CrossRef]

- Zhan, K.; Zhang, Y.; Zhao, S.; Yang, Z.; Zhao, B.; Ji, V. Tribological Behavior and Corrosion Resistance of S30432 Steel after Different Shot Peening Processes. J. Mater. Eng. Perform. 2021, 31, 1250–1258. [Google Scholar] [CrossRef]

- Zhang, H.; Qiu, X.; Zhao, X.; Xu, D. Effect of surface self-nanocrystallization on friction and wear behavior of Al7075-T6511 alloy. Mater. Res. Express 2019, 6, 115031. [Google Scholar] [CrossRef]

- Zhang, Y.; Lai, F.; Qu, S.; Ji, V.; Liu, H.; Li, X. Effect of shot peening on residual stress distribution and tribological behaviors of 17Cr2Ni2MoVNb steel. Surf. Coat. Technol. 2020, 386, 125497. [Google Scholar] [CrossRef]

- Avcu, Y.Y.; Gonul, B.; Yetik, O.; Sonmez, F.; Cengiz, A.; Guney, M.; Avcu, E. Modification of Surface and Subsurface Properties of AA1050 Alloy by Shot Peening. Materials 2021, 14, 6575. [Google Scholar] [CrossRef] [PubMed]

- Żebrowski, R.; Walczak, M. Effect of The Shot Peening on Surface Properties and Tribological Performance of Ti-6Al-4V Alloy Produced by Means of DMLS Technology. Arch. Metall. Mater. 2019, 64, 377–386. [Google Scholar] [CrossRef]

- Rominiyi, A.L.; Shongwe, M.B.; Ogunmuyiwa, E.N.; Babalola, B.J.; Lepele, P.F.; Olubambi, P.A. Effect of nickel addition on densification, microstructure and wear behaviour of spark plasma sintered CP-titanium. Mater. Chem. Phys. 2020, 240, 122130. [Google Scholar] [CrossRef]

- Iakovakis, E.; Avcu, E.; Roy, M.J.; Gee, M.; Matthews, A. Wear resistance of an additively manufactured high-carbon martensitic stainless steel. Sci. Rep. 2022, 12, 12554. [Google Scholar] [CrossRef]

- Brayshaw, W.J.; Roy, M.J.; Sun, T.; Akrivos, V.; Sherry, A.H. Iterative mesh-based hardness mapping. Sci. Technol. Weld. Join. 2016, 22, 404–411. [Google Scholar] [CrossRef] [Green Version]

- Gobber, F.S.; Fracchia, E.; Spotorno, R.; Fais, A.; Manfredi, D. Wear and Corrosion Resistance of AlSi10Mg-CP-Ti Metal-Metal Composite Materials Produced by Electro-Sinter-Forging. Materials 2021, 14, 6761. [Google Scholar] [CrossRef]

- Suh, N.P.; Sin, H.C. The genesis of friction. Wear 1981, 69, 91–114. [Google Scholar] [CrossRef]

- Wang, S.; Ma, Z.; Liao, Z.; Song, J.; Yang, K.; Liu, W. Study on improved tribological properties by alloying copper to CP-Ti and Ti-6Al-4V alloy. Mater. Sci. Eng. C Mater. Biol. Appl. 2015, 57, 123–132. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Avcu, Y.Y.; Iakovakis, E.; Guney, M.; Çalım, E.; Özkılınç, A.; Abakay, E.; Sönmez, F.; Koç, F.G.; Yamanoğlu, R.; Cengiz, A.; et al. Surface and Tribological Properties of Powder Metallurgical Cp-Ti Titanium Alloy Modified by Shot Peening. Coatings 2023, 13, 89. https://doi.org/10.3390/coatings13010089

Avcu YY, Iakovakis E, Guney M, Çalım E, Özkılınç A, Abakay E, Sönmez F, Koç FG, Yamanoğlu R, Cengiz A, et al. Surface and Tribological Properties of Powder Metallurgical Cp-Ti Titanium Alloy Modified by Shot Peening. Coatings. 2023; 13(1):89. https://doi.org/10.3390/coatings13010089

Chicago/Turabian StyleAvcu, Yasemin Yıldıran, Eleftherios Iakovakis, Mert Guney, Emirhan Çalım, Ayşe Özkılınç, Eray Abakay, Fikret Sönmez, Funda Gül Koç, Rıdvan Yamanoğlu, Abdulkadir Cengiz, and et al. 2023. "Surface and Tribological Properties of Powder Metallurgical Cp-Ti Titanium Alloy Modified by Shot Peening" Coatings 13, no. 1: 89. https://doi.org/10.3390/coatings13010089