Digital Twins for Construction Assets Using BIM Standard Specifications

Abstract

:1. Introduction

2. Systematic Review Methodology

- Publication year: 2016 to 2021;

- Document type: articles and review articles;

- Source type: journals;

- Language: English;

- Others: subject areas limited to engineering, energy, and environmental sciences.

3. Digital Twins—State of the Art

3.1. Digital Twins: Origin and Concept

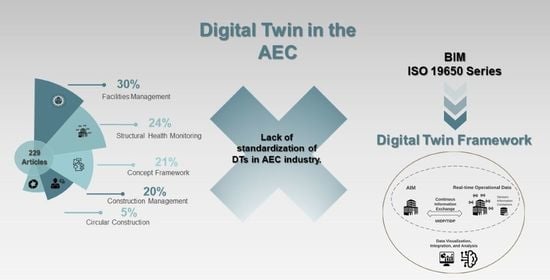

3.2. Digital Twins in the AEC Industry

3.2.1. Status of Digital Twins

3.2.2. Digital Twin Concept Evolution (BIM Dependency)

- The significant increase in BIM adoption and implementation in the AEC industry;

- The increase in BIM software packages currently on the market due to the pressing need to integrate BIM in the management of building information;

- Scope;

- Communication;

- Structure.

3.3. Clustering DT Studies

4. Framework Proposal

4.1. Standards in DTs

- Overview and general principles;

- Reference architecture;

- Digital representation of manufacturing elements;

- Information exchange.

4.2. Limitations of Current Research and Standards Pertaining to DTs

4.3. A Framework for DT Development for Construction Assets Using BIM ISO 19650 Standard Specifications

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Opoku, D.G.J.; Perera, S.; Osei-Kyei, R.; Rashidi, M. Digital Twin Application in the Construction Industry: A Literature Review. J. Build. Eng. 2021, 40, 102726. [Google Scholar] [CrossRef]

- Schweigkofler, A.; Braholli, O.; Akro, S.; Siegele, D.; Penna, P.; Marcher, C.; Tagliabue, L. Digital Twin as Energy Management Tool through IoT and BIM Data Integration. In Proceedings of the REHVA 14TH HVAC World Congress, Rotterdam, The Netherlands, 22–25 May 2022; pp. 1–8. [Google Scholar]

- Tchana, Y.; Ducellier, G.; Remy, S. Designing a Unique Digital Twin for Linear Infrastructures Lifecycle Management. Procedia CIRP 2019, 84, 545–549. [Google Scholar] [CrossRef]

- Zhang, Y.-Y.; Kang, K.; Lin, J.-R.; Zhang, J.-P.; Zhang, Y. Building Information Modeling–Based Cyber-Physical Platform for Building Performance Monitoring. Int. J. Distrib. Sens. Netw. 2020, 16, 1550147720908170. [Google Scholar] [CrossRef] [Green Version]

- EN ISO 19650-1; Organization and Digitization of Information about Buildings and Civil Engineering Works, Including Building Information Modelling (BIM)-Information Management Using Building Information Modelling-Part 1: Concepts and Principles. ISO: Geneva, Switzerland, 2018; ISBN 2831886376.

- Tang, S.; Shelden, D.R.; Eastman, C.M.; Pishdad-Bozorgi, P.; Gao, X. A Review of Building Information Modeling (BIM) and the Internet of Things (IoT) Devices Integration: Present Status and Future Trends. Autom. Constr. 2019, 101, 127–139. [Google Scholar] [CrossRef]

- UK BIM Alliance. BIM and Digital Twins [Positioning Statement]; UK BIM Alliance: London, UK, 2021. [Google Scholar]

- Tao, F.; Zhang, M.; Nee, A.Y.C. Background and Concept of Digital Twin. In Digital Twin Driven Smart Manufacturing; Academic Press: Cambridge, MA, USA, 2019; pp. 3–28. [Google Scholar]

- Singh, M.; Fuenmayor, E.; Hinchy, E.P.; Qiao, Y.; Murray, N.; Devine, D. Digital Twin: Origin to Future. Appl. Syst. Innov. 2021, 4, 36. [Google Scholar] [CrossRef]

- Digital Twin Market. Digital Twin Market by Enterprise, Application (Predictive Maintenance, Business Optimization), Industry (Aerospace, Automotive & Transportation, Healthcare, Infrastructure, Energy & Utilities) and Geography-Global Forecast to 2027. Available online: https://www.marketsandmarkets.com/Market-Reports/digital-twin-market-225269522.html?gclid=CjwKCAjwoMWBhAdEwAVJ2ndn2zsFCn00pvhe8FbqHp8V5avZkh3hmDbnCwMw8Z4bQY8cU3dvAAhoCQWUQAvDBwE (accessed on 15 July 2022).

- Halmetoja, E. The Role of Digital Twins and Their Application for the Built Environment. In Industry 4.0 for the Built Environment: Methodologies, Technologies and Skills; Bolpagni, M., Gavina, R., Ribeiro, D., Eds.; Springer International Publishing: Cham, Switzerland, 2022; pp. 415–442. ISBN 978-3-030-82430-3. [Google Scholar]

- Jones, D.; Snider, C.; Nassehi, A.; Yon, J.; Hicks, B. Characterising the Digital Twin: A Systematic Literature Review. CIRP J. Manuf. Sci. Technol. 2020, 29, 36–52. [Google Scholar] [CrossRef]

- Rasheed, A.; San, O.; Kvamsdal, T. Digital Twin: Values, Challenges and Enablers from a Modeling Perspective. IEEE Access 2020, 8, 21980–22012. [Google Scholar] [CrossRef]

- Fuller, A.; Fan, Z.; Day, C.; Barlow, C. Digital Twin: Enabling Technologies, Challenges and Open Research. IEEE Access 2020, 8, 108952–108971. [Google Scholar] [CrossRef]

- Khajavi, S.H.; Motlagh, N.H.; Jaribion, A.; Werner, L.C.; Holmstrom, J. Digital Twin: Vision, Benefits, Boundaries, and Creation for Buildings. IEEE Access 2019, 7, 147406–147419. [Google Scholar] [CrossRef]

- Rosen, R.; Von Wichert, G.; Lo, G.; Bettenhausen, K.D. About the Importance of Autonomy and Digital Twins for the Future of Manufacturing. IFAC-PapersOnLine 2015, 28, 567–572. [Google Scholar] [CrossRef]

- Grieves, M. Digital Twin: Manufacturing Excellence through Virtual Factory Replication; Digital Twin Institute: Boston, MA, USA, 2014. [Google Scholar]

- Grieves, M.; Vickers, J. Digital Twin: Mitigating Unpredictable, Undesirable Emergent Behavior in Complex Systems. In Transdisciplinary Perspectives on Complex Systems; Springer: Cham, Switzerland, 2016; pp. 85–113. [Google Scholar] [CrossRef]

- Shafto, M.; Conroy, M.; Doyle, R.; Glaessgen, E.; Kemp, C.; LeMoigne, J.; Wang, L. DRAFT Modeling, Simulation, Information Technology & Processing Roadmap-Technology Area 11; NASA: Washington, DC, USA, 2010.

- Shafto, M.; Conroy, M.; Doyle, R.; Glaessgen, E.; Kemp, C.; LeMoigne, J.; Wang, L. Modeling, Simulation, Information Technology & Processing Roadmap-Technology Area 11; NASA: Washington, DC, USA, 2012.

- Saddik, A. El Digital Twins: The Convergence of Multimedia Technologies. IEEE Multimed. 2018, 5, 87–92. [Google Scholar] [CrossRef]

- Negri, E.; Fumagalli, L.; Macchi, M. A Review of the Roles of Digital Twin in CPS-Based Production Systems. Procedia Manuf. 2017, 11, 939–948. [Google Scholar] [CrossRef]

- Tao, F.; Zhang, H.; Liu, A.; Nee, A.Y.C. Digital Twin in Industry: State-of-the-Art. IEEE Trans. Ind. Inform. 2019, 15, 2405–2415. [Google Scholar] [CrossRef]

- Pereira, P.F.; Ramos, N.M.M. Low-Cost Arduino-Based Temperature, Relative Humidity and CO2 Sensors-An Assessment of Their Suitability for Indoor Built Environments. J. Build. Eng. 2022, 60, 105151. [Google Scholar] [CrossRef]

- Zhou, L.; An, C.; Shi, J.; Lv, Z.; Liang, H. Design and Construction Integration Technology Based on Digital Twin. In Proceedings of the 2021 Power System and Green Energy Conference (PSGEC), Shanghai, China, 20–22 August 2021; pp. 7–11. [Google Scholar]

- Boje, C.; Guerriero, A.; Kubicki, S.; Rezgui, Y. Towards a Semantic Construction Digital Twin: Directions for Future Research. Autom. Constr. 2020, 114, 103179. [Google Scholar] [CrossRef]

- Coupry, C.; Noblecourt, S.; Richard, P.; Baudry, D.; Bigaud, D. BIM-Based Digital Twin and XR Devices to Improve Maintenance Procedures in Smart Buildings: A Literature Review. Appl. Sci. 2021, 11, 6810. [Google Scholar] [CrossRef]

- Liu, Z.; Zhang, A.; Wang, W. A Framework for an Indoor Safety Management System Based on Digital Twin. Sensors 2020, 20, 5771. [Google Scholar] [CrossRef] [PubMed]

- Dawkins, O.; Hudson-Smith, A.; Dennett, A.; Hudson-Smith, A. Living with a Digital Twin: Operational Management and Engagement Using IoT and Mixed Realities at UCL’s Here East Campus on the Queen Elizabeth Olympic Park; Centre for Advanced Spatial Analysis (CASA), University College London: London, UK, 2018. [Google Scholar]

- Halmetoja, E.; Forns-Samso, F. Evaluating Graphical User Interfaces for Buildings. J. Corp. Real Estate 2020, 22, 48–70. [Google Scholar] [CrossRef]

- Chen, F.; Jiao, H.; Han, L.; Shen, L.; Du, W.; Ye, Q.; Yu, G. Real-Time Monitoring of Construction Quality for Gravel Piles Based on Internet of Things. Autom. Constr. 2020, 116, 103228. [Google Scholar] [CrossRef]

- Chang, K.-M.; Dzeng, R.-J.; Wu, Y.-J. An Automated IoT Visualization BIM Platform for Decision Support in Facilities Management. Appl. Sci. 2018, 8, 1086. [Google Scholar] [CrossRef] [Green Version]

- Darko, A.; Chan, A.P.C.C.; Adabre, M.A.; Edwards, D.J.; Hosseini, M.R.; Ameyaw, E.E. Artificial Intelligence in the AEC Industry: Scientometric Analysis and Visualization of Research Activities. Autom. Constr. 2020, 112, 103081. [Google Scholar] [CrossRef]

- Gubbi, J.; Buyya, R.; Marusic, S.; Palaniswami, M. Internet of Things (IoT): A Vision, Architectural Elements, and Future Directions. Future Gener. Comput. Syst. 2013, 29, 1645–1660. [Google Scholar] [CrossRef] [Green Version]

- Lin, Y.-C.; Cheung, W.-F. Developing WSN/BIM-Based Environmental Monitoring Management System for Parking Garages in Smart Cities. J. Manag. Eng. 2020, 36, 04020012. [Google Scholar] [CrossRef]

- European Comission Destination Earth. Available online: https://digital-strategy.ec.europa.eu/library/destination-earth (accessed on 3 January 2022).

- Building Smart International Enabling an Ecosystem of Digital Twins [Positioning Paper]. Available online: https://www.buildingsmart.org/wp-content/uploads/2020/05/Enabling-Digital-Twins-Positioning-Paper-Final.pdf (accessed on 26 December 2021).

- Lu, Q.; Xie, X.; Heaton, J.; Parlikad, A.K.; Schooling, J. From BIM towards Digital Twin: Strategy and Future Development for Smart Asset Management. In Studies in Computational Intelligence; Springer International Publishing: Cham, Switzerland, 2020; Volume 853, pp. 392–404. ISBN 9783030274771. [Google Scholar]

- ALLPLAN BIM and the Digital Twin Model. Available online: https://blog.allplan.com/en/bim-and-the-digital-twin-model (accessed on 19 October 2020).

- Sepasgozar, S.M.E. Differentiating Digital Twin from Digital Shadow: Elucidating a Paradigm Shift to Expedite a Smart, Sustainable Built Environment. Buildings 2021, 11, 151. [Google Scholar] [CrossRef]

- Liu, Y.; van Nederveen, S.; Hertogh, M. Understanding Effects of BIM on Collaborative Design and ConstructionAn Empirical Study in China. Int. J. Proj. Manag. 2017, 35, 686–698. [Google Scholar] [CrossRef]

- Hu, Z.; Zhang, J. BIM- and 4D-Based Integrated Solution of Analysis and Management for Conflicts and Structural Safety Problems during Construction: 2. Development and Site Trials. Autom. Constr. 2011, 20, 167–180. [Google Scholar] [CrossRef]

- Marzouk, M.; Abubakr, A. Decision Support for Tower Crane Selection with Building Information Models and Genetic Algorithms. Autom. Constr. 2016, 61, 1–15. [Google Scholar] [CrossRef]

- Han, K.K.; Golparvar-Fard, M. Potential of Big Visual Data and Building Information Modeling for Construction Performance Analytics: An Exploratory Study. Autom. Constr. 2017, 73, 184–198. [Google Scholar] [CrossRef] [Green Version]

- Kropp, C.; Koch, C.; König, M. Interior Construction State Recognition with 4D BIM Registered Image Sequences. Autom. Constr. 2018, 86, 11–32. [Google Scholar] [CrossRef]

- Lu, Q.; Won, J.; Cheng, J.C.P. A Financial Decision Making Framework for Construction Projects Based on 5D Building Information Modeling (BIM). Int. J. Proj. Manag. 2016, 34, 3–21. [Google Scholar] [CrossRef]

- Marzouk, M.; Azab, S.; Metawie, M. BIM-Based Approach for Optimizing Life Cycle Costs of Sustainable Buildings. J. Clean. Prod. 2018, 188, 217–226. [Google Scholar] [CrossRef]

- Guerriero, A.; Kubicki, S.; Berroir, F.; Lemaire, C. BIM-Enhanced Collaborative Smart Technologies for LEAN Construction Processes. In Proceedings of the 2017 International Conference on Engineering, Technology and Innovation: Engineering, Technology and Innovation Management Beyond 2020: New Challenges, New Approaches, ICE/ITMC 2017-Proceedings, Madeira, Portugal, 27–29 June 2017; pp. 1023–1030. [Google Scholar]

- Singh, P.; Sadhu, A. System Identification-Enhanced Visualization Tool for Infrastructure Monitoring and Maintenance. Front. Built Environ. 2020, 6, 76. [Google Scholar] [CrossRef]

- Shim, C.-S.; Dang, N.-S.; Lon, S.; Jeon, C.-H. Development of a Bridge Maintenance System for Prestressed Concrete Bridges Using 3D Digital Twin Model. Struct. Infrastruct. Eng. 2019, 15, 1319–1332. [Google Scholar] [CrossRef]

- Angjeliu, G.; Coronelli, D.; Cardani, G. Development of the Simulation Model for Digital Twin Applications in Historical Masonry Buildings: The Integration between Numerical and Experimental Reality. Comput. Struct. 2020, 238, 106282. [Google Scholar] [CrossRef]

- Zhou, C.; Luo, H.; Fang, W.; Wei, R.; Ding, L. Cyber-Physical-System-Based Safety Monitoring for Blind Hoisting with the Internet of Things: A Case Study. Autom. Constr. 2019, 97, 138–150. [Google Scholar] [CrossRef]

- Rogage, K.; Clear, A.; Alwan, Z.; Lawrence, T.; Kelly, G. Assessing Building Performance in Residential Buildings Using BIM and Sensor Data. Int. J. Build. Pathol. Adapt. 2020, 38, 176–191. [Google Scholar] [CrossRef]

- Kaewunruen, S.; Lian, Q. Digital Twin Aided Sustainability-Based Lifecycle Management for Railway Turnout Systems. J. Clean. Prod. 2019, 228, 1537–1551. [Google Scholar] [CrossRef]

- Tagliabue, L.C.; Cecconi, F.R.; Maltese, S.; Rinaldi, S.; Ciribini, A.L.C.; Flammini, A. Leveraging Digital Twin for Sustainability Assessment of an Educational Building. Sustainability 2021, 13, 480. [Google Scholar] [CrossRef]

- Jiang, F.; Ma, L.; Broyd, T.; Chen, K. Digital Twin and Its Implementations in the Civil Engineering Sector. Autom. Constr. 2021, 130, 103838. [Google Scholar] [CrossRef]

- Moretti, N.; Blanco Cadena, J.D.; Mannino, A.; Poli, T.; Re Cecconi, F. Maintenance Service Optimization in Smart Buildings through Ultrasonic Sensors Network. Intell. Build. Int. 2020, 13, 4–16. [Google Scholar] [CrossRef]

- Ozturk, G.B. Digital Twin Research in the AECO-FM Industry. J. Build. Eng. 2021, 40, 102730. [Google Scholar] [CrossRef]

- Quinn, C.; Shabestari, A.Z.; Misic, T.; Gilani, S.; Litoiu, M.; McArthur, J.J. Building Automation System-BIM Integration Using a Linked Data Structure. Autom. Constr. 2020, 118, 103257. [Google Scholar] [CrossRef]

- Villa, V.; Naticchia, B.; Bruno, G.; Aliev, K.; Piantanida, P.; Antonelli, D. Iot Open-Source Architecture for the Maintenance of Building Facilities. Appl. Sci. 2021, 11, 5374. [Google Scholar] [CrossRef]

- Wong, J.K.W.; Ge, J.; He, S.X. Digitisation in Facilities Management: A Literature Review and Future Research Directions. Autom. Constr. 2018, 92, 312–326. [Google Scholar] [CrossRef]

- Agostinelli, S.; Cumo, F.; Guidi, G.; Tomazzoli, C. Cyber-Physical Systems Improving Building Energy Management: Digital Twin and Artificial Intelligence. Energies 2021, 14, 2338. [Google Scholar] [CrossRef]

- Mehmood, F.; Edwards, D.; Lai, J.; Parn, E.A.; Riaz, Z. Engineering-out Hazards: Digitising the Management Working Safety in Confined Spaces. Facilities 2019, 37, 196–215. [Google Scholar] [CrossRef]

- Valinejadshoubi, M.; Moselhi, O.; Bagchi, A.; Salem, A. Development of an IoT and BIM-Based Automated Alert System for Thermal Comfort Monitoring in Buildings. Sustain. Cities Soc. 2021, 66, 102602. [Google Scholar] [CrossRef]

- Lydon, G.P.; Caranovic, S.; Hischier, I.; Schlueter, A. Coupled Simulation of Thermally Active Building Systems to Support a Digital Twin. Energy Build. 2019, 202, 109298. [Google Scholar] [CrossRef]

- Pasini, D. Connecting BIM and IoT for Addressing User Awareness toward Energy Savings. J. Struct. Integr. Maint. 2018, 3, 243–253. [Google Scholar] [CrossRef]

- Petri, I.; Kubicki, S.; Rezgui, Y.; Guerriero, A.; Li, H. Optimizing Energy Efficiency in Operating Built Environment Assets through Building Information Modeling: A Case Study. Energies 2017, 10, 1167. [Google Scholar] [CrossRef] [Green Version]

- Kaewunruen, S.; Rungskunroch, P.; Welsh, J. A Digital-Twin Evaluation of Net Zero Energy Building for Existing Buildings. Sustainability 2019, 11, 159. [Google Scholar] [CrossRef] [Green Version]

- Kensek, K.M. Teaching Visual Scripting in Bim: A Case Study Using a Panel Controlled by Solar Angles. J. Green Build. 2018, 13, 115–137. [Google Scholar] [CrossRef]

- Francisco, A.; Truong, H.; Khosrowpour, A.; Taylor, J.E.; Mohammadi, N. Occupant Perceptions of Building Information Model-Based Energy Visualizations in Eco-Feedback Systems. Appl. Energy 2018, 221, 220–228. [Google Scholar] [CrossRef]

- Zhao, L.; Zhang, H.; Wang, Q.; Wang, H. Digital-Twin-Based Evaluation of Nearly Zero-Energy Building for Existing Buildings Based on Scan-to-BIM. Adv. Civ. Eng. 2021, 2021, 6638897. [Google Scholar] [CrossRef]

- Han, T.; Zhao, J.; Li, W. Smart-Guided Pedestrian Emergency Evacuation in Slender-Shape Infrastructure with Digital Twin Simulations. Sustainability 2020, 12, 9701. [Google Scholar] [CrossRef]

- Park, S.; Hong, C. Roles and Scope of System Interface in Integrated Control System for Multi Disaster Countermeasure. Int. J. Saf. Secur. Eng. 2017, 7, 361–366. [Google Scholar] [CrossRef] [Green Version]

- Wetzel, E.M.; Thabet, W.Y. Utilizing Six Sigma to Develop Standard Attributes for a Safety for Facilities Management (SFFM) Framework. Saf. Sci. 2016, 89, 355–368. [Google Scholar] [CrossRef]

- Alshammari, K.; Beach, T.; Rezgui, Y. Cybersecurity for Digital Twins in the Built Environment: Current Research and Future Directions. J. Inf. Technol. Constr. 2021, 26, 159–173. [Google Scholar] [CrossRef]

- Tran, H.; Nguyen, T.N.; Christopher, P.; Bui, D.K.; Khoshelham, K.; Ngo, T.D. A Digital Twin Approach for Geometric Quality Assessment of As-Built Prefabricated Façades. J. Build. Eng. 2021, 41, 102377. [Google Scholar] [CrossRef]

- Antonino, M.; Nicola, M.; Claudio, D.M.; Luciano, B.; Fulvio, R.C. Office Building Occupancy Monitoring through Image Recognition Sensors. Int. J. Saf. Secur. Eng. 2019, 9, 371–380. [Google Scholar] [CrossRef] [Green Version]

- Bonci, A.; Carbonari, A.; Cucchiarelli, A.; Messi, L.; Pirani, M.; Vaccarini, M. A Cyber-Physical System Approach for Building Efficiency Monitoring. Autom. Constr. 2019, 102, 68–85. [Google Scholar] [CrossRef]

- Cheng, J.C.P.; Chen, K.; Wong, P.K.-Y.; Chen, W.; Li, C.T. Graph-Based Network Generation and CCTV Processing Techniques for Fire Evacuation. Build. Res. Inf. 2021, 49, 179–196. [Google Scholar] [CrossRef]

- Edirisinghe, R.; Woo, J. BIM-Based Performance Monitoring for Smart Building Management. Facilities 2020, 39, 19–35. [Google Scholar] [CrossRef]

- Huynh, D.; Nguyen-Ky, S. Engaging Building Automation Data Visualisation Using Building Information Modelling and Progressive Web Application. Open Eng. 2020, 10, 434–442. [Google Scholar] [CrossRef]

- Lu, Q.; Xie, X.; Parlikad, A.K.; Schooling, J.M. Digital Twin-Enabled Anomaly Detection for Built Asset Monitoring in Operation and Maintenance. Autom. Constr. 2020, 118, 103277. [Google Scholar] [CrossRef]

- Altohami, A.B.A.; Haron, N.A.; Alias, A.H.; Law, T.H. Investigating Approaches of Integrating BIM, IoT, and Facility Management for Renovating Existing Buildings: A Review. Sustainability 2021, 13, 3930. [Google Scholar] [CrossRef]

- Edmondson, V.; Cerny, M.; Lim, M.; Gledson, B.; Lockley, S.; Woodward, J. A Smart Sewer Asset Information Model to Enable an ‘Internet of Things’ for Operational Wastewater Management. Autom. Constr. 2018, 91, 193–205. [Google Scholar] [CrossRef]

- Marzouk, M.; Othman, A. Modeling the Performance of Sustainable Sanitation Systems Using Building Information Modeling. J. Clean. Prod. 2017, 141, 1400–1410. [Google Scholar] [CrossRef]

- Levoni, P.; Angeli, D.; Cingi, P.; Barozzi, G.S.; Cipollone, M. An Integrated Approach for the Analysis and Modeling of Road Tunnel Ventilation. Part I: Continuous Measurement of the Longitudinal Airflow Profile. Transp. Eng. 2021, 3, 100039. [Google Scholar] [CrossRef]

- Park, S.; Park, S.H.; Park, L.W.; Park, S.; Lee, S.; Lee, T.; Lee, S.H.; Jang, H.; Kim, S.M.; Chang, H.; et al. Design and Implementation of a Smart IoT Based Building and Town Disaster Management System in Smart City Infrastructure. Appl. Sci. 2018, 8, 2239. [Google Scholar] [CrossRef] [Green Version]

- Nikolopoulos, D.; Moraitis, G.; Bouziotas, D.; Lykou, A.; Karavokiros, G.; Makropoulos, C. Cyber-Physical Stress-Testing Platform for Water Distribution Networks. J. Environ. Eng. 2020, 146, 4020061. [Google Scholar] [CrossRef]

- Pedersen, A.N.; Borup, M.; Brink-Kjær, A.; Christiansen, L.E.; Mikkelsen, P.S. Living and Prototyping Digital Twins for Urban Water Systems: Towards Multi-Purpose Value Creation Using Models and Sensors. Water 2021, 13, 592. [Google Scholar] [CrossRef]

- Shafiee, M.E.; Rasekh, A.; Sela, L.; Preis, A. Streaming Smart Meter Data Integration to Enable Dynamic Demand Assignment for Real-Time Hydraulic Simulation. J. Water Resour. Plan. Manag. 2020, 146, 06020008. [Google Scholar] [CrossRef]

- Sun, C.; Puig, V.; Cembrano, G. Real-Time Control of Urban Water Cycle under Cyber-Physical Systems Framework. Water 2020, 12, 406. [Google Scholar] [CrossRef] [Green Version]

- Yin, X.; Liu, H.; Chen, Y.; Wang, Y.; Al-Hussein, M. A BIM-Based Framework for Operation and Maintenance of Utility Tunnels. Tunn. Undergr. Space Technol. 2020, 97, 103252. [Google Scholar] [CrossRef]

- Yu, G.; Wang, Y.; Mao, Z.; Hu, M.; Sugumaran, V.; Wang, Y.K. A Digital Twin-Based Decision Analysis Framework for Operation and Maintenance of Tunnels. Tunn. Undergr. Space Technol. 2021, 116, 104125. [Google Scholar] [CrossRef]

- Piselli, C.; Guastaveglia, A.; Romanelli, J.; Cotana, F.; Pisello, A.L. Facility Energy Management Application of HBIM for Historical Low-Carbon Communities: Design, Modelling and Operation Control of Geothermal Energy Retrofit in a Real Italian Case Study. Energies 2020, 13, 6338. [Google Scholar] [CrossRef]

- Atef, A.; Bristow, D. Risk Assessment of Infrastructure Facilities Considering Spatial and Operational Interdependencies: Temporal Simulation Model. Struct. Infrastruct. Eng. 2021, 18, 1138–1151. [Google Scholar] [CrossRef]

- Evjen, T.Å.; Raviz, S.R.H.; Petersen, S.A.; Krogstie, J. Smart Facility Management: Future Healthcare Organization through Indoor Positioning Systems in the Light of Enterprise Bim. Smart Cities 2020, 3, 793–805. [Google Scholar] [CrossRef]

- Peng, Y.; Zhang, M.; Yu, F.; Xu, J.; Gao, S. Digital Twin Hospital Buildings: An Exemplary Case Study through Continuous Lifecycle Integration. Adv. Civ. Eng. 2020, 2020, 8846667. [Google Scholar] [CrossRef]

- Xie, Q.; Zhou, X.; Wang, J.; Gao, X.; Chen, X.; Chun, L. Matching Real-World Facilities to Building Information Modeling Data Using Natural Language Processing. IEEE Access 2019, 7, 119465–119475. [Google Scholar] [CrossRef]

- Yuan, S.; Hu, Z.Z.; Lin, J.R.; Zhang, Y.Y. A Framework for the Automatic Integration and Diagnosis of Building Energy Consumption Data. Sensors 2021, 21, 1395. [Google Scholar] [CrossRef]

- Desogus, G.; Quaquero, E.; Rubiu, G.; Gatto, G.; Perra, C. BIM and IoT Sensors Integration: A Framework for Consumption and Indoor Conditions Data Monitoring of Existing Buildings. Sustainability 2021, 13, 4496. [Google Scholar] [CrossRef]

- Ma, G.; Liu, Y.; Shang, S. A Building Information Model (BIM) and Artificial Neural Network (ANN) Based System for Personal Thermal Comfort Evaluation and Energy Efficient Design of Interior Space. Sustainability 2019, 11, 4972. [Google Scholar] [CrossRef] [Green Version]

- Francisco, A.; Mohammadi, N.; Taylor, J.E. Smart City Digital Twin–Enabled Energy Management: Toward Real-Time Urban Building Energy Benchmarking. J. Manag. Eng. 2020, 36, 4019045. [Google Scholar] [CrossRef]

- Xie, X.; Lu, Q.; Rodenas-Herraiz, D.; Parlikad, A.K.A.K.; Schooling, J.M.J.M. Visualised Inspection System for Monitoring Environmental Anomalies during Daily Operation and Maintenance. Eng. Constr. Archit. Manag. 2020, 27, 1835–1852. [Google Scholar] [CrossRef]

- Zaballos, A.; Briones, A.; Massa, A.; Centelles, P.; Caballero, V. A Smart Campus’ Digital Twin for Sustainable Comfort Monitoring. Sustainability 2020, 12, 9196. [Google Scholar] [CrossRef]

- Shalabi, F.; Turkan, Y. BIM–Energy Simulation Approach for Detecting Building Spaces with Faults and Problematic Behavior. J. Inf. Technol. Constr. 2020, 25, 342–360. [Google Scholar] [CrossRef]

- Clausen, A.; Arendt, K.; Johansen, A.; Sangogboye, F.C.; Kjærgaard, M.B.; Veje, C.T.; Jørgensen, B.N. A Digital Twin Framework for Improving Energy Efficiency and Occupant Comfort in Public and Commercial Buildings. Energy Inform. 2021, 4, 40. [Google Scholar] [CrossRef]

- Gao, X.; Pishdad-Bozorgi, P.; Shelden, D.R.; Tang, S. Internet of Things Enabled Data Acquisition Framework for Smart Building Applications. J. Constr. Eng. Manag. 2021, 147, 04020169. [Google Scholar] [CrossRef]

- Carreira, P.; Castelo, T.; Gomes, C.C.; Ferreira, A.; Ribeiro, C.; Costa, A.A. Virtual Reality as Integration Environments for Facilities Management: Application and Users Perception. Eng. Constr. Archit. Manag. 2018, 25, 90–112. [Google Scholar] [CrossRef]

- Martínez, I.; Zalba, B.; Trillo-Lado, R.; Blanco, T.; Cambra, D.; Casas, R. Internet of Things (Iot) as Sustainable Development Goals (Sdg) Enabling Technology towards Smart Readiness Indicators (Sri) for University Buildings. Sustainability 2021, 13, 7647. [Google Scholar] [CrossRef]

- Kazado, D.; Kavgic, M.; Eskicioglu, R. Integrating Building Information Modeling (BIM) and Sensor Technology for Facility Management. J. Inf. Technol. Constr. 2019, 24, 440–458. [Google Scholar] [CrossRef]

- Pavón, R.M.; Alberti, M.G.; Álvarez, A.A.A.; Del Rosario Chiyón Carrasco, I. Use of Bim-Fm to Transform Large Conventional Public Buildings into Efficient and Smart Sustainable Buildings. Energies 2021, 14, 3127. [Google Scholar] [CrossRef]

- Yoo, W.; Kim, H.; Shin, M. Stations-Oriented Indoor Localization (SOIL): A BIM-Based Occupancy Schedule Modeling System. Build. Environ. 2020, 168, 106520. [Google Scholar] [CrossRef]

- Lu, Q.; Parlikad, A.K.; Woodall, P.; Don Ranasinghe, G.; Xie, X.; Liang, Z.; Konstantinou, E.; Heaton, J.; Schooling, J. Developing a Digital Twin at Building and City Levels: Case Study of West Cambridge Campus. J. Manag. Eng. 2020, 36, 05020004. [Google Scholar] [CrossRef]

- Seghezzi, E.; Locatelli, M.; Pellegrini, L.; Pattini, G.; Di Giuda, G.M.G.M.; Tagliabue, L.C.L.C.; Boella, G. Towards an Occupancy-Oriented Digital Twin for Facility Management: Test Campaign and Sensors Assessment. Appl. Sci. 2021, 11, 3108. [Google Scholar] [CrossRef]

- Yang, L.H.; Xu, L.; Wang, W.C.; Wang, S.H. Building Information Model and Optimization Algorithms for Supporting Campus Facility Maintenance Management: A Case Study of Maintaining Water Dispensers. KSCE J. Civ. Eng. 2021, 25, 12–27. [Google Scholar] [CrossRef]

- McGlinn, K.; Yuce, B.; Wicaksono, H.; Howell, S.; Rezgui, Y. Usability Evaluation of a Web-Based Tool for Supporting Holistic Building Energy Management. Autom. Constr. 2017, 84, 154–165. [Google Scholar] [CrossRef]

- Shahinmoghadam, M.; Natephra, W.; Motamedi, A. BIM- and IoT-Based Virtual Reality Tool for Real-Time Thermal Comfort Assessment in Building Enclosures. Build. Environ. 2021, 199, 107905. [Google Scholar] [CrossRef]

- Su, G.; Kensek, K. Fault-Detection through Integrating Real-Time Sensor Data into BIM [Detección de Fallas En Tiempo Real Por Medio de La Integración de Sensores de Información En BIM]. Inf. Constr. 2021, 73, e416. [Google Scholar] [CrossRef]

- De Oliveira, A.C.F.; do Carmo, C.S.T.; Cruz, A.S.; Faisca, R.G. A Case Study to Explore the Synergy between HBIM and BEM for Maintenance of Historical Buildings. Int. J. Build. Pathol. Adapt. 2021. [Google Scholar] [CrossRef]

- Cheng, J.C.P.; Chen, W.; Chen, K.; Wang, Q. Data-Driven Predictive Maintenance Planning Framework for MEP Components Based on BIM and IoT Using Machine Learning Algorithms. Autom. Constr. 2020, 112, 103087. [Google Scholar] [CrossRef]

- Moretti, N.; Ellul, C.; Re Cecconi, F.; Papapesios, N.; Dejaco, M.C. GeoBIM for Built Environment Condition Assessment Supporting Asset Management Decision Making. Autom. Constr. 2021, 130, 103859. [Google Scholar] [CrossRef]

- Bigoni, C.; Hesthaven, J.S. Simulation-Based Anomaly Detection and Damage Localization: An Application to Structural Health Monitoring; Elsevier Science SA: Lausanne, Switzerland, 2020; Volume 363. [Google Scholar]

- Cao, Y.; Miraba, S.; Rafiei, S.; Ghabussi, A.; Bokaei, F.; Baharom, S.; Haramipour, P.; Assilzadeh, H. Economic Application of Structural Health Monitoring and Internet of Things in Efficiency of Building Information Modeling. Smart Struct. Syst. 2020, 26, 559–573. [Google Scholar] [CrossRef]

- Theiler, M.; Smarsly, K. IFC Monitor—An IFC Schema Extension for Modeling Structural Health Monitoring Systems. Adv. Eng. Inform. 2018, 37, 54–65. [Google Scholar] [CrossRef]

- Xia, Y. Research on Dynamic Data Monitoring of Steel Structure Building Information Using BIM. J. Eng. Des. Technol. 2020, 18, 1165–1173. [Google Scholar] [CrossRef]

- Tibaut, A.; Zazula, D. Sustainable Management of Construction Site Big Visual Data. Sustain. Sci. 2018, 13, 1311–1322. [Google Scholar] [CrossRef]

- Liu, T.; Yang, B.; Zhang, Q. Health Monitoring System Developed for Tianjin 117 High-Rise Building. J. Aerosp. Eng. 2017, 30, B4016004. [Google Scholar] [CrossRef]

- Malekloo, A.; Ozer, E.; AlHamaydeh, M.; Girolami, M. Machine Learning and Structural Health Monitoring Overview with Emerging Technology and High-Dimensional Data Source Highlights. Struct. Health Monit. 2021. [Google Scholar] [CrossRef]

- Panah, R.S.; Kioumarsi, M. Application of Building Information Modelling (BIM) in the Health Monitoring and Maintenance Process: A Systematic Review. Sensors 2021, 21, 837. [Google Scholar] [CrossRef] [PubMed]

- Ribeiro, D.; Santos, R.; Shibasaki, A.; Montenegro, P.; Carvalho, H.; Calçada, R. Remote Inspection of RC Structures Using Unmanned Aerial Vehicles and Heuristic Image Processing. Eng. Fail. Anal. 2020, 117, 104813. [Google Scholar] [CrossRef]

- Rosafalco, L.; Manzoni, A.; Mariani, S.; Corigliano, A. Fully Convolutional Networks for Structural Health Monitoring through Multivariate Time Series Classification. Adv. Model. Simul. Eng. Sci. 2020, 7, 38. [Google Scholar] [CrossRef]

- Tahmasebinia, F.; Fogerty, D.; Wu, L.O.O.; Li, Z.; Sepasgozar, S.M.E.M.E.; Zhang, K.; Sepasgozar, S.M.E.M.E.; Marroquin, F.A.A. Numerical Analysis of the Creep and Shrinkage Experienced in the Sydney Opera House and the Rise of Digital Twin as Future Monitoring Technology. Buildings 2019, 9, 137. [Google Scholar] [CrossRef] [Green Version]

- Taraben, J.; Morgenthal, G. Methods for the Automated Assignment and Comparison of Building Damage Geometries. Adv. Eng. Inform. 2021, 47, 101186. [Google Scholar] [CrossRef]

- Theiler, M.; Ibáñez, S.; Legatiuk, D.; Smarsly, K. Metaization Concepts for Monitoring-Related Information. Adv. Eng. Inform. 2020, 46, 101158. [Google Scholar] [CrossRef]

- Di Re, P.; Lofrano, E.; Ciambella, J.; Romeo, F. Structural Analysis and Health Monitoring of Twentieth-Century Cultural Heritage: The Flaminio Stadium in Rome. Smart Struct. Syst. 2021, 27, 285–303. [Google Scholar] [CrossRef]

- Kita, A.; Cavalagli, N.; Venanzi, I.; Ubertini, F. A New Method for Earthquake-Induced Damage Identification in Historic Masonry Towers Combining OMA and IDA. Bull. Earthq. Eng. 2021, 19, 5307–5337. [Google Scholar] [CrossRef]

- O’Shea, M.; Murphy, J. Design of a BIM Integrated Structural Health Monitoring System for a Historic Offshore Lighthouse. Buildings 2020, 10, 131. [Google Scholar] [CrossRef]

- Youn, H.C.; Yoon, J.S.; Ryoo, S.L. HBIM for the Characteristics of Korean Traditional Wooden Architecture: Bracket Set Modelling Based on 3D Scanning. Buildings 2021, 11, 506. [Google Scholar] [CrossRef]

- Funari, M.F.; Hajjat, A.E.; Masciotta, M.G.; Oliveira, D.V.; Lourenço, P.B. A Parametric Scan-to-FEM Framework for the Digital Twin Generation of Historic Masonry Structures. Sustainability 2021, 13, 1088. [Google Scholar] [CrossRef]

- Augustyn, D.; Ulriksen, M.D.; Sørensen, J.D. Reliability Updating of Offshore Wind Substructures by Use of Digital Twin Information. Energies 2021, 14, 5859. [Google Scholar] [CrossRef]

- Baldassarre, A.; Ceruti, A.; Valyou, D.N.; Marzocca, P. Towards a Digital Twin Realization of the Blade System Design Study Wind Turbine Blade. Wind Struct. Int. J. 2019, 28, 271–284. [Google Scholar] [CrossRef]

- Chen, X.; Eder, M.A.; Shihavuddin, A.S.M.; Zheng, D. A Human-cyber-physical System toward Intelligent Wind Turbine Operation and Maintenance. Sustainability 2021, 13, 561. [Google Scholar] [CrossRef]

- Kim, H.C.; Kim, M.H.; Choe, D.E. Structural Health Monitoring of Towers and Blades for Floating Offshore Wind Turbines Using Operational Modal Analysis and Modal Properties with Numerical-Sensor Signals. Ocean Eng. 2019, 188, 106226. [Google Scholar] [CrossRef]

- Lin, J.J.; Ibrahim, A.; Sarwade, S.; Golparvar-Fard, M. Bridge Inspection with Aerial Robots: Automating the Entire Pipeline of Visual Data Capture, 3D Mapping, Defect Detection, Analysis, and Reporting. J. Comput. Civ. Eng. 2021, 35, 4020064. [Google Scholar] [CrossRef]

- Lin, K.; Xu, Y.L.; Lu, X.; Guan, Z.; Li, J. Digital Twin-Based Collapse Fragility Assessment of a Long-Span Cable-Stayed Bridge under Strong Earthquakes. Autom. Constr. 2021, 123, 103547. [Google Scholar] [CrossRef]

- Liu, H.B.; Zhang, Q.; Zhang, B.H. Structural Health Monitoring of a Newly Built High-Piled Wharf in a Harbor with Fiber Bragg Grating Sensor Technology: Design and Deployment. Smart Struct. Syst. 2017, 20, 163–173. [Google Scholar] [CrossRef]

- Meixedo, A.; Santos, J.; Ribeiro, D.; Calçada, R.; Todd, M. Damage Detection in Railway Bridges Using Traffic-Induced Dynamic Responses. Eng. Struct. 2021, 238, 112189. [Google Scholar] [CrossRef]

- Morgenthal, G.; Hallermann, N.; Kersten, J.; Taraben, J.; Debus, P.; Helmrich, M.; Rodehorst, V. Framework for Automated UAS-Based Structural Condition Assessment of Bridges. Autom. Constr. 2019, 97, 77–95. [Google Scholar] [CrossRef]

- Nguyen, D.-C.; Nguyen, T.-Q.; Jin, R.; Jeon, C.-H.; Shim, C.-S. BIM-Based Mixed-Reality Application for Bridge Inspection and Maintenance. Constr. Innov. 2021, 22, 487–503. [Google Scholar] [CrossRef]

- Omer, M.; Margetts, L.; Hadi Mosleh, M.; Hewitt, S.; Parwaiz, M. Use of Gaming Technology to Bring Bridge Inspection to the Office. Struct. Infrastruct. Eng. 2019, 15, 1292–1307. [Google Scholar] [CrossRef] [Green Version]

- Qiu, S.; Mias, C.; Guo, W.; Geng, X. HS2 Railway Embankment Monitoring: Effect of Soil Condition on Underground Signals. SN Appl. Sci. 2019, 1, 537. [Google Scholar] [CrossRef] [Green Version]

- Shao, S.; Zhou, Z.; Deng, G.; Du, P.; Jian, C.; Yu, Z. Experiment of Structural Geometric Morphology Monitoring for Bridges Using Holographic Visual Sensor. Sensors 2020, 20, 1187. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Steyn, W.J.v.d.M.; Broekman, A. Development of a Digital Twin of a Local Road Network: A Case Study. J. Test. Eval. 2021, 51. [Google Scholar] [CrossRef]

- Baisthakur, S.; Chakraborty, A. Experimental Verification for Load Rating of Steel Truss Bridge Using an Improved Hamiltonian Monte Carlo-Based Bayesian Model Updating. J. Civ. Struct. Health Monit. 2021, 11, 1093–1112. [Google Scholar] [CrossRef]

- Steyn, W.J. van der M. Selected Implications of a Hyper-Connected World on Pavement Engineering. Int. J. Pavement Res. Technol. 2020, 13, 673–678. [Google Scholar] [CrossRef]

- Ye, C.; Kuok, S.C.; Butler, L.J.; Middleton, C.R. Implementing Bridge Model Updating for Operation and Maintenance Purposes: Examination Based on UK Practitioners’ Views. Struct. Infrastruct. Eng. 2021, 18, 1638–1657. [Google Scholar] [CrossRef]

- Ye, S.; Lai, X.; Bartoli, I.; Aktan, A.E. Technology for Condition and Performance Evaluation of Highway Bridges. J. Civ. Struct. Health Monit. 2020, 10, 573–594. [Google Scholar] [CrossRef]

- Yu, G.; Zhang, S.; Hu, M.; Ken Wang, Y. Prediction of Highway Tunnel Pavement Performance Based on Digital Twin and Multiple Time Series Stacking. Adv. Civ. Eng. 2020, 2020, 8824135. [Google Scholar] [CrossRef]

- Zhu, X.; Bao, T.; Yeoh, J.K.W.; Jia, N.; Li, H. Enhancing Dam Safety Evaluation Using Dam Digital Twins. Struct. Infrastruct. Eng. 2021. [Google Scholar] [CrossRef]

- Kampczyk, A.; Dybeł, K. The Fundamental Approach of the Digital Twin Application in Railway Turnouts with Innovative Monitoring of Weather Conditions. Sensors 2021, 21, 5757. [Google Scholar] [CrossRef] [PubMed]

- Justo, A.; Soilán, M.; Sánchez-Rodríguez, A.; Riveiro, B. Scan-to-BIM for the Infrastructure Domain: Generation of IFC-Complaint Models of Road Infrastructure Assets and Semantics Using 3D Point Cloud Data. Autom. Constr. 2021, 127, 103703. [Google Scholar] [CrossRef]

- Getuli, V.; Capone, P.; Bruttini, A.; Pour Rahimian, F. On-Demand Generation of as-Built Infrastructure Information Models for Mechanised Tunnelling from TBM Data: A Computational Design Approach. Autom. Constr. 2021, 121, 103434. [Google Scholar] [CrossRef]

- Bazán, Á.M.; Alberti, M.G.; Álvarez, A.A.; Trigueros, J.A. New Perspectives for Bim Usage in Transportation Infrastructure Projects. Appl. Sci. 2020, 10, 7072. [Google Scholar] [CrossRef]

- Boddupalli, C.; Sadhu, A.; Rezazadeh Azar, E.; Pattyson, S. Improved Visualization of Infrastructure Monitoring Data Using Building Information Modeling. Struct. Infrastruct. Eng. 2019, 15, 1247–1263. [Google Scholar] [CrossRef]

- Cha, G.; Park, S.; Oh, T. A Terrestrial LiDAR-Based Detection of Shape Deformation for Maintenance of Bridge Structures. J. Constr. Eng. Manag. 2019, 145, 4019075. [Google Scholar] [CrossRef]

- Davila Delgado, J.M.; Butler, L.J.; Brilakis, I.; Elshafie, M.Z.E.B.; Middleton, C.R. Structural Performance Monitoring Using a Dynamic Data-Driven BIM Environment. J. Comput. Civ. Eng. 2018, 32, 04018009. [Google Scholar] [CrossRef] [Green Version]

- Jeong, S.; Hou, R.; Lynch, J.P.; Sohn, H.; Law, K.H. An Information Modeling Framework for Bridge Monitoring. Adv. Eng. Softw. 2017, 114, 11–31. [Google Scholar] [CrossRef]

- Jiang, F.; Ding, Y.; Song, Y.; Geng, F.; Wang, Z. An Architecture of Lifecycle Fatigue Management of Steel Bridges Driven by Digital Twin. Struct. Monit. Maint. 2021, 8, 187–201. [Google Scholar] [CrossRef]

- Kaewunruen, S.; Sresakoolchai, J.; Ma, W.; Phil-Ebosie, O. Digital Twin Aided Vulnerability Assessment and Risk-Based Maintenance Planning of Bridge Infrastructures Exposed to Extreme Conditions. Sustainability 2021, 13, 2051. [Google Scholar] [CrossRef]

- Kang, J.S.; Chung, K.; Hong, E.J. Multimedia Knowledge-based Bridge Health Monitoring Using Digital Twin. Multimed. Tools Appl. 2021, 80, 34609–34624. [Google Scholar] [CrossRef]

- Liu, Z.; Shi, G.; Zhang, A.; Huang, C. Intelligent Tensioning Method for Prestressed Cables Based on Digital Twins and Artificial Intelligence. Sensors 2020, 20, 7006. [Google Scholar] [CrossRef] [PubMed]

- Liu, Z.; Jiang, A.; Zhang, A.; Xing, Z.; Du, X. Intelligent Prediction Method for Operation and Maintenance Safety of Prestressed Steel Structure Based on Digital Twin Technology. Adv. Civ. Eng. 2021, 2021, 6640198. [Google Scholar] [CrossRef]

- Murali Krishna, B.; Tezeswi, T.P.; Rathish Kumar, P.; Gopikrishna, K.; Sivakumar, M.V.N.; Shashi, M. QR Code as Speckle Pattern for Reinforced Concrete Beams Using Digital Image Correlation. Struct. Monit. Maint. 2019, 6, 67–84. [Google Scholar] [CrossRef]

- Lee, D.; Lee, S. Digital Twin for Supply Chain Coordination in Modular Construction. Appl. Sci. 2021, 11, 5909. [Google Scholar] [CrossRef]

- Zhou, Y.; Wei, X.; Peng, Y. The Modelling of Digital Twins Technology in the Construction Process of Prefabricated Buildings. Adv. Civ. Eng. 2021, 2021, 2801557. [Google Scholar] [CrossRef]

- Jang, J.; Ahn, S.; Cha, S.H.; Cho, K.; Koo, C.; Kim, T.W. Toward Productivity in Future Construction: Mapping Knowledge and Finding Insights for Achieving Successful Offsite Construction Projects. J. Comput. Des. Eng. 2021, 8, 1–14. [Google Scholar] [CrossRef]

- Kunic, A.; Naboni, R.; Kramberger, A.; Schlette, C. Design and Assembly Automation of the Robotic Reversible Timber Beam. Autom. Constr. 2021, 123, 103531. [Google Scholar] [CrossRef]

- Wang, X.; Liang, C.-J.; Menassa, C.C.; Kamat, V.R. Interactive and Immersive Process-Level Digital Twin for Collaborative Human–Robot Construction Work. J. Comput. Civ. Eng. 2021, 35, 04021023. [Google Scholar] [CrossRef]

- Zhang, Y.; Meina, A.; Lin, X.; Zhang, K.; Xu, Z. Digital Twin in Computational Design and Robotic Construction of Wooden Architecture. Adv. Civ. Eng. 2021, 2021, 8898997. [Google Scholar] [CrossRef]

- Hasan, S.M.; Lee, K.; Moon, D.; Kwon, S.; Jinwoo, S.; Lee, S. Augmented Reality and Digital Twin System for Interaction with Construction Machinery. J. ASIAN Archit. Build. Eng. 2020, 21, 564–574. [Google Scholar] [CrossRef]

- Agnusdei, G.P.; Elia, V.; Gnoni, M.G. Is Digital Twin Technology Supporting Safety Management? A Bibliometric and Systematic Review. Appl. Sci. 2021, 11, 2767. [Google Scholar] [CrossRef]

- Liu, Z.; Meng, X.; Xing, Z.; Jiang, A. Digital Twin-Based Safety Risk Coupling of Prefabricated Building Hoisting. Sensors 2021, 21, 3583. [Google Scholar] [CrossRef] [PubMed]

- Okpala, I.; Nnaji, C.; Awolusi, I.; Akanmu, A. Developing a Success Model for Assessing the Impact of Wearable Sensing Devices in the Construction Industry. J. Constr. Eng. Manag. 2021, 147, 4021060. [Google Scholar] [CrossRef]

- Torrecilla-García, J.A.; Pardo-Ferreira, M.C.; Rubio-Romero, J.C. Overall Introduction to the Framework of BIM-Based Digital Twinning in Decision-Making in Safety Management in Building Construction Industry. Dir. Organ. 2021, 74, 31–38. [Google Scholar] [CrossRef]

- Wu, Z.; Ren, C.; Wu, X.; Wang, L.; Zhu, L.; Lv, Z. Research on Digital Twin Construction and Safety Management Application of Inland Waterway Based on 3D Video Fusion. IEEE Access 2021, 9, 109144–109156. [Google Scholar] [CrossRef]

- Yap, J.B.H.; Lee, K.P.H.; Wang, C. Safety Enablers Using Emerging Technologies in Construction Projects: Empirical Study in Malaysia. J. Eng. Des. Technol. 2021. [Google Scholar] [CrossRef]

- Zhang, S.; Shang, C.; Fang, X.; He, S.; Yu, L.; Wang, C.; Yan, L. Wireless Monitoring\&\#x2013;Based Real-Time Analysis and Early-Warning Safety System for Deep and Large Underground Caverns. J. Perform. Constr. Facil. 2021, 35, 4020147. [Google Scholar] [CrossRef]

- Zhang, S.; Shang, C.; Wang, C.; Song, R.; Wang, X. Real-Time Safety Risk Identification Model during Metro Construction Adjacent to Buildings. J. Constr. Eng. Manag. 2019, 145, 4019034. [Google Scholar] [CrossRef]

- Akanmu, A.A.; Anumba, C.J.; Ogunseiju, O.O. Towards next Generation Cyber-Physical Systems and Digital Twins for Construction. J. Inf. Technol. Constr. 2021, 26, 505–525. [Google Scholar] [CrossRef]

- Asadzadeh, A.; Arashpour, M.; Li, H.; Ngo, T.; Bab-Hadiashar, A.; Rashidi, A. Sensor-Based Safety Management. Autom. Constr. 2020, 113, 103128. [Google Scholar] [CrossRef]

- Cho, C.; Kim, K.; Park, J.; Cho, Y.K. Data-Driven Monitoring System for Preventing the Collapse of Scaffolding Structures. J. Constr. Eng. Manag. 2018, 144, 4018077. [Google Scholar] [CrossRef]

- Deng, L.; Zhong, M.; Liao, L.; Peng, L.; Lai, S. Research on Safety Management Application of Dangerous Sources in Engineering Construction Based on Bim Technology. Adv. Civ. Eng. 2019, 2019, 7450426. [Google Scholar] [CrossRef] [Green Version]

- Getuli, V.; Capone, P.; Bruttini, A.; Sorbi, T. A Smart Objects Library for BIM-Based Construction Site and Emergency Management to Support Mobile VR Safety Training Experiences. Constr. Innov. 2021, 22, 504–530. [Google Scholar] [CrossRef]

- Hou, L.; Wu, S.; Zhang, G.K.; Tan, Y.; Wang, X. Literature Review of Digital Twins Applications in Constructionworkforce Safety. Appl. Sci. 2021, 11, 339. [Google Scholar] [CrossRef]

- Kim, H.; Lee, H.S.; Park, M.; Chung, B.Y.; Hwang, S. Automated Hazardous Area Identification Using Laborers’ Actual and Optimal Routes. Autom. Constr. 2016, 65, 21–32. [Google Scholar] [CrossRef]

- Li, M.; Lu, Q.; Bai, S.; Zhang, M.; Tian, H.; Qin, L. Digital Twin-Driven Virtual Sensor Approach for Safe Construction Operations of Trailing Suction Hopper Dredger. Autom. Constr. 2021, 132, 103961. [Google Scholar] [CrossRef]

- Bhargava, M.G.; Vidyullatha, P.; Venkateswara Rao, P.; Sucharita, V. A Study on Potential of Big Visual Data Analytics in Construction Arena. Int. J. Eng. Technol. 2018, 7, 652–656. [Google Scholar] [CrossRef]

- Braun, A.; Tuttas, S.; Borrmann, A.; Stilla, U. Improving Progress Monitoring by Fusing Point Clouds, Semantic Data and Computer Vision. Autom. Constr. 2020, 116, 103210. [Google Scholar] [CrossRef]

- Deng, H.; Hong, H.; Luo, D.; Deng, Y.; Su, C. Automatic Indoor Construction Process Monitoring for Tiles Based on BIM and Computer Vision. J. Constr. Eng. Manag. 2020, 146, 4019095. [Google Scholar] [CrossRef]

- Hamledari, H.; Sajedi, S.; McCabe, B.; Fischer, M. Automation of Inspection Mission Planning Using 4D BIMs and in Support of Unmanned Aerial Vehicle–Based Data Collection. J. Constr. Eng. Manag. 2021, 147, 04020179. [Google Scholar] [CrossRef]

- Ibrahim, F.S.; Esa, M.; Rahman, R.A. The Adoption of Iot in the Malaysian Construction Industry: Towards Construction 4.0. Int. J. Sustain. Constr. Eng. Technol. 2021, 12, 56–67. [Google Scholar] [CrossRef]

- Kang, L.S.; Kim, H.S.; Moon, H.S.; Kim, S.K. Managing Construction Schedule by Telepresence: Integration of Site Video Feed with an Active ND CAD Simulation. Autom. Constr. 2016, 68, 32–43. [Google Scholar] [CrossRef]

- Kim, J.W.; Golabchi, A.; Han, S.U.; Lee, D.E. Manual Operation Simulation Using Motion-Time Analysis toward Labor Productivity Estimation: A Case Study of Concrete Pouring Operations. Autom. Constr. 2021, 126, 103669. [Google Scholar] [CrossRef]

- Kim, W.G.; Ham, N.; Kim, J.J. Enhanced Subcontractors Allocation for Apartment Construction Project Applying Conceptual 4d Digital Twin Framework. Sustainability 2021, 13, 11784. [Google Scholar] [CrossRef]

- Kopsida, M.; Brilakis, I. Real-Time Volume-to-Plane Comparison for Mixed Reality–Based Progress Monitoring. J. Comput. Civ. Eng. 2020, 34, 4020016. [Google Scholar] [CrossRef]

- Lin, J.R.; Wu, D.P. An Approach to Twinning and Mining Collaborative Network of Construction Projects. Autom. Constr. 2021, 125, 103643. [Google Scholar] [CrossRef]

- Omar, H.; Mahdjoubi, L.; Kheder, G. Towards an Automated Photogrammetry-Based Approach for Monitoring and Controlling Construction Site Activities. Comput. Ind. 2018, 98, 172–182. [Google Scholar] [CrossRef]

- Pan, Y.; Zhang, L. A BIM-Data Mining Integrated Digital Twin Framework for Advanced Project Management. Autom. Constr. 2021, 124, 103564. [Google Scholar] [CrossRef]

- Ren, R.; Zhang, J. Semantic Rule-Based Construction Procedural Information Extraction to Guide Jobsite Sensing and Monitoring. J. Comput. Civ. Eng. 2021, 35, 04021026. [Google Scholar] [CrossRef]

- Sezer, A.A.; Bröchner, J. Site Managers’ ICT Tools for Monitoring Resources in Refurbishment. Eng. Constr. Archit. Manag. 2019, 27, 109–127. [Google Scholar] [CrossRef]

- Subedi, S.; Pradhananga, N.; Ergun, H. Monitoring Physiological Reactions of Construction Workers in Virtual Environment: Feasibility Study Using Noninvasive Affective Sensors. J. Leg. Aff. Disput. Resolut. Eng. Constr. 2021, 13, 4521016. [Google Scholar] [CrossRef]

- Wu, X. Wireless Management System of Prefabricated Construction Materials Based on BIM Technology. EURASIP J. Wirel. Commun. Netw. 2021, 2021, 116. [Google Scholar] [CrossRef]

- Alaloul, W.S.; Alzubi, K.M.; Malkawi, A.B.; Al Salaheen, M.; Musarat, M.A. Productivity Monitoring in Building Construction Projects: A Systematic Review. Eng. Constr. Archit. Manag. 2021, 29, 2760–2785. [Google Scholar] [CrossRef]

- Salehi, S.A.; Yitmen, İ.; Alizadeh Salehi, S.; Yitmen, İ. Modeling and Analysis of the Impact of BIM-Based Field Data Capturing Technologies on Automated Construction Progress Monitoring. Int. J. Civ. Eng. 2018, 16, 1669–1685. [Google Scholar] [CrossRef]

- Alizadehsalehi, S.; Yitmen, I. Digital Twin-Based Progress Monitoring Management Model through Reality Capture to Extended Reality Technologies (DRX). Smart Sustain. Built Environ. 2021. [Google Scholar] [CrossRef]

- Bapat, H.; Sarkar, D.; Gujar, R. Application of Integrated Fuzzy FCM-BIM-IoT for Sustainable Material Selection and Energy Management of Metro Rail Station Box Project in Western India. Innov. Infrastruct. Solut. 2021, 6, 73. [Google Scholar] [CrossRef]

- Kaewunruen, S.; Peng, S.; Phil-Ebosie, O. Digital Twin Aided Sustainability and Vulnerability Audit for Subway Stations. Sustainability 2020, 12, 7873. [Google Scholar] [CrossRef]

- Kaewunruen, S.; Sresakoolchai, J.; Zhou, Z. Sustainability-Based Lifecycle Management for Bridge Infrastructure Using 6D BIM. Sustainability 2020, 12, 2436. [Google Scholar] [CrossRef] [Green Version]

- Meža, S.; Mauko Pranjić, A.; Vezočnik, R.; Osmokrović, I.; Lenart, S. Digital Twins and Road Construction Using Secondary Raw Materials. J. Adv. Transp. 2021, 2021, 8833058. [Google Scholar] [CrossRef]

- Broo, D.G.; Schooling, J. A Framework for Using Data as an Engineering Tool for Sustainable Cyber-Physical Systems. IEEE Access 2021, 9, 22876–22882. [Google Scholar] [CrossRef]

- Bartie, N.J.; Cobos-Becerra, Y.L.; Fröhling, M.; Schlatmann, R.; Reuter, M.A. The Resources, Exergetic and Environmental Footprint of the Silicon Photovoltaic Circular Economy: Assessment and Opportunities. Resour. Conserv. Recycl. 2021, 169, 105516. [Google Scholar] [CrossRef]

- Chen, C.; Zhao, Z.; Xiao, J.; Tiong, R. A Conceptual Framework for Estimating Building Embodied Carbon Based on Digital Twin Technology and Life Cycle Assessment. Sustainability 2021, 13, 13875. [Google Scholar] [CrossRef]

- Lamptey, T.; Owusu-Manu, D.G.; Acheampong, A.; Adesi, M.; Ghansah, F.A. A Framework for the Adoption of Green Business Models in the Ghanaian Construction Industry. Smart Sustain. Built Environ. 2020, 10, 536–553. [Google Scholar] [CrossRef]

- Orozco-Messana, J.; Iborra-Lucas, M.; Calabuig-Moreno, R. Neighbourhood Modelling for Urban Sustainability Assessment. Sustainability 2021, 13, 4654. [Google Scholar] [CrossRef]

- Züst, S.; Züst, R.; Züst, V.; West, S.; Stoll, O.; Minonne, C. A Graph Based Monte Carlo Simulation Supporting a Digital Twin for the Curatorial Management of Excavation and Demolition Material Flows. J. Clean. Prod. 2021, 310, 127453. [Google Scholar] [CrossRef]

- O’grady, T.M.; Brajkovich, N.; Minunno, R.; Chong, H.-Y.; Morrison, G.M. Circular Economy and Virtual Reality in Advanced BIM-based Prefabricated Construction. Energies 2021, 14, 4065. [Google Scholar] [CrossRef]

- Chen, L.; Xie, X.; Lu, Q.; Parlikad, A.K.; Pitt, M.; Yang, J. Gemini Principles-Based Digital Twin Maturity Model for Asset Management. Sustainability 2021, 13, 8224. [Google Scholar] [CrossRef]

- Deng, M.; Menassa, C.C.C.C.; Kamat, V.R.V.R.R. From BIM to Digital Twins: A Systematic Review of the Evolution of Intelligent Building Representations in the AEC-FM Industry. J. Inf. Technol. Constr. 2021, 26, 58–83. [Google Scholar] [CrossRef]

- Godager, B.; Onstein, E.; Huang, L. The Concept of Enterprise BIM: Current Research Practice and Future Trends. IEEE Access 2021, 9, 42265–42290. [Google Scholar] [CrossRef]

- Mêda, P.; Calvetti, D.; Hjelseth, E.; Sousa, H. Incremental Digital Twin Conceptualisations Targeting Data-Driven Circular Construction. Buildings 2021, 11, 554. [Google Scholar] [CrossRef]

- Turner, C.J.; Oyekan, J.; Stergioulas, L.; Griffin, D. Utilizing Industry 4.0 on the Construction Site: Challenges and Opportunities. IEEE Trans. Ind. Inform. 2021, 17, 746–756. [Google Scholar] [CrossRef]

- Zhang, H.; Zhou, Y.; Zhu, H.; Sumarac, D.; Cao, M. Digital Twin-Driven Intelligent Construction: Features and Trends. SDHM Struct. Durab. Health Monit. 2021, 15, 183–206. [Google Scholar] [CrossRef]

- Zhang, J.S.; Zhao, L.H.; Ren, G.Q.; Li, H.J.; Li, X.F. Digital Twin Technology in the Architectural, Engineering and Construction (AEC) Industry. Adv. Civ. Eng. 2020, 2020, 8842113. [Google Scholar] [CrossRef]

- Al-Sehrawy, R.; Kumar, B.; Watson, R. A Digital Twin Uses Classification System for Urban Planning & City Infrastructure Management. J. Inf. Technol. Constr. 2021, 26, 832–862. [Google Scholar] [CrossRef]

- Broo, D.G.; Schooling, J. Digital Twins in Infrastructure: Definitions, Current Practices, Challenges and Strategies. Int. J. Constr. Manag. 2021. [Google Scholar] [CrossRef]

- Brucherseifer, E.; Winter, H.; Mentges, A.; Mühlhäuser, M.; Hellmann, M. Digital Twin Conceptual Framework for Improving Critical Infrastructure Resilience. At-Autom. 2021, 69, 1062–1080. [Google Scholar] [CrossRef]

- Callcut, M.; Cerceau Agliozzo, J.-P.J.P.; Varga, L.; McMillan, L. Digital Twins in Civil Infrastructure Systems. Sustainability 2021, 13, 11549. [Google Scholar] [CrossRef]

- Camposano, J.C.; Smolander, K.; Ruippo, T. Seven Metaphors to Understand Digital Twins of Built Assets. IEEE Access 2021, 9, 27167–27181. [Google Scholar] [CrossRef]

- Cera, V.; Campi, M. Segmentation Protocols in the Digital Twins of Monumental Heritage: A Methodological Development. Disegnarecon 2021, 14, 141–1410. [Google Scholar] [CrossRef]

- Mannino, A.; Dejaco, M.C.; Re Cecconi, F. Building Information Modelling and Internet of Things Integration for Facility Management-Literature Review and Future Needs. Appl. Sci. 2021, 11, 3062. [Google Scholar] [CrossRef]

- Sepasgozar, S.M.E.; Hui, F.K.P.; Shirowzhan, S.; Foroozanfar, M.; Yang, L.; Aye, L. Lean Practices Using Building Information Modeling (Bim) and Digital Twinning for Sustainable Construction. Sustainability 2021, 13, 10161. [Google Scholar] [CrossRef]

- Tezel, A.; Aziz, Z. From Conventional to It Based Visual Management: A Conceptual Discussion for Lean Construction. J. Inf. Technol. Constr. 2017, 22, 220–246. [Google Scholar]

- Banerjee, A.; Nayaka, R.R. A Comprehensive Overview on BIM-Integrated Cyber Physical System Architectures and Practices in the Architecture, Engineering and Construction Industry. Constr. Innov. 2021, 22, 727–748. [Google Scholar] [CrossRef]

- Bosch-Sijtsema, P.; Claeson-Jonsson, C.; Johansson, M.; Roupe, M. The Hype Factor of Digital Technologies in AEC. Constr. Innov. 2021, 21, 899–916. [Google Scholar] [CrossRef]

- Bruno, S.; De Fino, M.; Fatiguso, F. Historic Building Information Modelling: Performance Assessment for Diagnosis-Aided Information Modelling and Management. Autom. Constr. 2018, 86, 256–276. [Google Scholar] [CrossRef]

- Ham, Y.; Han, K.K.; Lin, J.J.; Golparvar-Fard, M. Visual Monitoring of Civil Infrastructure Systems via Camera-Equipped Unmanned Aerial Vehicles (UAVs): A Review of Related Works. Vis. Eng. 2016, 4, 1. [Google Scholar] [CrossRef] [Green Version]

- Huang, M.Q.; Ninić, J.; Zhang, Q.B. BIM, Machine Learning and Computer Vision Techniques in Underground Construction: Current Status and Future Perspectives. Tunn. Undergr. Space Technol. 2021, 108, 103677. [Google Scholar] [CrossRef]

- Khan, A.; Sepasgozar, S.; Liu, T.; Yu, R. Integration of Bim and Immersive Technologies for Aec: A Scientometric-swot Analysis and Critical Content Review. Buildings 2021, 11, 126. [Google Scholar] [CrossRef]

- Malagnino, A.; Montanaro, T.; Lazoi, M.; Sergi, I.; Corallo, A.; Patrono, L. Building Information Modeling and Internet of Things Integration for Smart and Sustainable Environments: A Review. J. Clean. Prod. 2021, 312, 127716. [Google Scholar] [CrossRef]

- Badenko, V.L.; Bolshakov, N.S.; Tishchenko, E.B.; Fedotov, A.A.; Celani, A.C.; Yadykin, V.K. Integration of Digital Twin and BIM Technologies within Factories of the Future. Mag. Civ. Eng. 2021, 101, 127716. [Google Scholar] [CrossRef]

- Dave, B.; Buda, A.; Nurminen, A.; Främling, K. A Framework for Integrating BIM and IoT through Open Standards. Autom. Constr. 2018, 95, 35–45. [Google Scholar] [CrossRef]

- Howard, D.A.; Ma, Z.; Veje, C.; Clausen, A.; Aaslyng, J.M.; Jørgensen, B.N. Greenhouse Industry 4.0—Digital Twin Technology for Commercial Greenhouses. Energy Inform. 2021, 4, 103677. [Google Scholar] [CrossRef]

- Jang, K.; Kim, J.-W.J.W.; Ju, K.-B.K.B.; An, Y.K.Y.-K. Infrastructure BIM Platform for Lifecycle Management. Appl. Sci. 2021, 11, 310. [Google Scholar] [CrossRef]

- Lu, Q.; Chen, L.; Li, S.; Pitt, M. Semi-Automatic Geometric Digital Twinning for Existing Buildings Based on Images and CAD Drawings. Autom. Constr. 2020, 115, 103183. [Google Scholar] [CrossRef]

- Moretti, N.; Xie, X.; Merino, J.; Brazauskas, J.; Parlikad, A.K. An Openbim Approach to Iot Integration with Incomplete As-Built Data. Appl. Sci. 2020, 10, 8287. [Google Scholar] [CrossRef]

- Rafsanjani, H.N.; Nabizadeh, A.H. Towards Digital Architecture, Engineering, and Construction (AEC) Industry through Virtual Design and Construction (VDC) and Digital Twin. Energy Built Environ. 2021; in press. [Google Scholar] [CrossRef]

- Rashid, K.M.; Louis, J.; Fiawoyife, K.K. Wireless Electric Appliance Control for Smart Buildings Using Indoor Location Tracking and BIM-Based Virtual Environments. Autom. Constr. 2019, 101, 48–58. [Google Scholar] [CrossRef]

- Wu, Y.; Shang, J.; Xue, F. Regard: Symmetry-Based Coarse Registration of Smartphone’s Colorful Point Clouds with Cad Drawings for Low-Cost Digital Twin Buildings. Remote Sens. 2021, 13, 1882. [Google Scholar] [CrossRef]

- You, Z.; Feng, L. Integration of Industry 4.0 Related Technologies in Construction Industry: A Framework of Cyber-Physical System. IEEE Access 2020, 8, 122908–122922. [Google Scholar] [CrossRef]

- Chen, L.; Whyte, J. Understanding Design Change Propagation in Complex Engineering Systems Using a Digital Twin and Design Structure Matrix. Eng. Constr. Archit. Manag. 2021, 29, 2950–2975. [Google Scholar] [CrossRef]

- Farghaly, K.; Abanda, F.H.; Vidalakis, C.; Wood, G. Taxonomy for BIM and Asset Management Semantic Interoperability. J. Manag. Eng. 2018, 34, 04018012. [Google Scholar] [CrossRef] [Green Version]

- Edirisinghe, R. Digital Skin of the Construction Site: Smart Sensor Technologies towards the Future Smart Construction Site. Eng. Constr. Archit. Manag. 2019, 26, 184–223. [Google Scholar] [CrossRef] [Green Version]

- Ding, L.; Li, K.; Zhou, Y.; Love, P.E.D.D. An IFC-Inspection Process Model for Infrastructure Projects: Enabling Real-Time Quality Monitoring and Control. Autom. Constr. 2017, 84, 96–110. [Google Scholar] [CrossRef]

- Greif, T.; Stein, N.; Flath, C.M. Peeking into the Void: Digital Twins for Construction Site Logistics. Comput. Ind. 2020, 121, 103264. [Google Scholar] [CrossRef]

- Jouan, P.; Hallot, P. Digital Twin: Research Framework to Support Preventive Conservation Policies. ISPRS Int. J. Geo-Inf. 2020, 9, 228. [Google Scholar] [CrossRef] [Green Version]

- Khalil, A.; Stravoravdis, S.; Backes, D. Categorisation of Building Data in the Digital Documentation of Heritage Buildings. Appl. Geomat. 2021, 13, 29–54. [Google Scholar] [CrossRef]

- Oti, A.H.; Kurul, E.; Cheung, F.; Tah, J.H.M. A Framework for the Utilization of Building Management System Data in Building Information Models for Building Design and Operation. Autom. Constr. 2016, 72, 195–210. [Google Scholar] [CrossRef] [Green Version]

- Zhao, J.; Feng, H.; Chen, Q.; Garcia de Soto, B. Developing a Conceptual Framework for the Application of Digital Twin Technologies to Revamp Building Operation and Maintenance Processes. J. Build. Eng. 2022, 49, 104028. [Google Scholar] [CrossRef]

- Wyckoff, A.; PILAT, D. Key Issues for Digital Transformation in the G20; OECD: Berlin, Germany, 2017. [Google Scholar]

- ISO 23247-1; Automation Systems and Integration—Digital Twin Framework for Manufacturing—Part 1: Overview and General Principles. ISO: Geneva, Switzerland, 2021.

- Ajayi, S.O.; Oyebiyi, F.; Alaka, H.A. Facilitating Compliance with BIM ISO 19650 Naming Convention through Automation. J. Eng. Des. Technol. 2021. [Google Scholar] [CrossRef]

- PD 19650-0; BSI Standards Publication-Transition Guidance to BS EN ISO 19650. BSI Standards Limited: London, UK, 2019.

- BSI. Collaborative Production of Architectural, Engineering and Construction Information–Code of Practice; BSI: London, UK, 2016; Volume 77, ISBN 9780580928178. [Google Scholar]

- Lu, Q.; Xie, X.; Parlikad, A.K.; Schooling, J.M.; Konstantinou, E. Moving from Building Information Models to Digital Twins for Operation and Maintenance. Proc. Inst. Civ. Eng.-Smart Infrastruct. Constr. 2020, 174, 46–59. [Google Scholar] [CrossRef] [Green Version]

- EN ISO 19650-2; Organization and Digitization of Information about Buildings and Civil Engineering Works, Including Building Information Modelling (BIM)-Information Management Using Building Information Modelling—Part 2: Delivery Phase of the Assets. ISO: Geveva, Switzerland, 2018; ISBN 9968687001202.

- EN ISO 19650-3; Organization and Digitization of Information about Buildings and Civil Engineering Works, Including Building Information Modelling (BIM)-Information Management Using Building Information Modelling—Part 3: Operational Phase of the Assets. European Committee for Standardization: Brussels, Belgium, 2020.

- EN ISO 19650-5; Organization and Digitization of Information about Buildings and Civil Engineering Works, Including Building Information Modelling (BIM)-Information Management Using Building Information Modelling—Part 5: Security-Minded Approach to Information Manage. European Committee for Standardization: Brussels, Belgium, 2020.

- Kor, M.; Yitmen, I.; Alizadehsalehi, S. An Investigation for Integration of Deep Learning and Digital Twins towards Construction 4.0. Smart Sustain. Built Environ. 2022. [Google Scholar] [CrossRef]

- Xu, Y.; Zhou, Y.; Sekula, P.; Ding, L. Machine Learning in Construction: From Shallow to Deep Learning. Dev. Built Environ. 2021, 6, 100045. [Google Scholar] [CrossRef]

| Group 1 | Group 2 | Group 3 | Group 4 | Group X1 | Group X2 | Group X3 |

|---|---|---|---|---|---|---|

| “Digital Twin” | BIM | AEC | Monitoring | “Safety Monitoring” | Construction | “BIM Standards” |

| “Digital replica” | “Building information modelling” | “Architecture engineering and construction” | Sensors | “Heritage” | “Operation and Maintenance” | “ISO 19650” |

| “Digital counterpart” | “Construction industry” | Simulation | “Renewable Energy” | Circularity | “PAS 1192” | |

| “Virtual Twin” | Utilities | Dynamo | “Energy Efficiency” | Demolition | IFC | |

| “Building services” | IoT | “Indoor Environmental Quality” | Design | “ISO 16739” | ||

| Infrastructures | “Internet of things” | IEQ | ||||

| “Asset management” | “Real-time data” | “Structural Health Monitoring” | ||||

| “Facility” | SHM | |||||

| “Performance Monitoring” | ||||||

| Productivity | ||||||

| “Sustainable Management” |

| Combinations * |

|---|

| G1 AND G2 |

| G1 AND G3 |

| G2 AND G3 AND G4 |

| G1 AND GX1 |

| G1 AND GX2 |

| G1 AND GX3 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nour El-Din, M.; Pereira, P.F.; Poças Martins, J.; Ramos, N.M.M. Digital Twins for Construction Assets Using BIM Standard Specifications. Buildings 2022, 12, 2155. https://doi.org/10.3390/buildings12122155

Nour El-Din M, Pereira PF, Poças Martins J, Ramos NMM. Digital Twins for Construction Assets Using BIM Standard Specifications. Buildings. 2022; 12(12):2155. https://doi.org/10.3390/buildings12122155

Chicago/Turabian StyleNour El-Din, Mohamed, Pedro F. Pereira, João Poças Martins, and Nuno M. M. Ramos. 2022. "Digital Twins for Construction Assets Using BIM Standard Specifications" Buildings 12, no. 12: 2155. https://doi.org/10.3390/buildings12122155