1. Introduction

Nowadays, there is great demand in the manufacturing industry for technologies that can deal with dynamic environments and customized products. Industry 4.0 and the notion of challenging trade by globalization have pushed companies to be more competitive in both large and small batches. This progress also shows a new way for computer numerical control (CNC) manufacturing industries to profit from large productions [

1]. During the last few decades, there has been significant progress in improving the efficacy of CNC machining to meet world challenges. These breakthroughs come from the implementation of automation approaches, such as adaptive control and active control. They allow companies to achieve higher operation performances [

1]. Manufacturing processes, such as computer-aided process planning (CAPP), expert processes planning systems (PP), computer-aided design (CAD) and computer-aided manufacturing (CAM) are now based on intelligent machining [

2,

3], which allow for the simulation and evaluation of variable environments. Complex cutting models can now predict fundamental variables related to machining operations performed in the industry [

4]. These approaches mainly aim to obtain suitable cutting parameters and control them within certain working conditions. Thus, this increases the efficiency during the machining process and reduces the implementation time.

Cutting parameters for machining processes have a high impact on performance and they are usually the variables that need to be tuned for optimizing models. Generally, cutting parameters refer to cutting velocity, feed rate, depth of cut, cutting forces, torque, spindle speed, etc. On the other hand, the parameters for evaluating the machining results normally include surface roughness, power consumption, machining time, production cost, tool life, production rate, etc. [

5,

6,

7]. For machining processes, accurate performance can be defined only within a working optimal range. This optimal range is evaluated by models, which generally relate the working conditions to cutting parameters and tool features. These models can be numeric, analytic, empiric, hybrid or AI-based models [

4]. Nowadays, the trend is to use AI-based models, which clearly show adaptability and high performance in machining operations. Furthermore, the advances in computer science have allowed for the wide application of these models in the manufacturing industry [

8,

9,

10].

In general, the implementation stage for machining processes takes a considerable amount of time and sometimes requires previous machining tests to reach admissible results. Because of this, some approaches seek to embed knowledge and technical data in machining processes. This results in the development of expert systems that are capable of optimally dealing with the changing conditions in shorter setting times. Many such expert systems use information from CAD models, databases, statement rules, tool preferences, suppliers, etc. [

2,

3,

4,

11,

12]. Zarkti et al. [

3] presented an automatic-optimized tool selector model based on CAD information to infer milling process stages. This approach uses a database from a tool supplier to build an expert system, which is capable of choosing suitable tools and suggesting optimal milling operation planning. Benkedjouh et al. [

13] developed a model, which was based on a support vector machine, to predict the life of a cutting tool. This approach uses experimental testing to obtain a nonlinear regression model to estimate and predict the level of wear in a cutting tool. Several sensors, which are installed around the machine, gather information during the machining process and create a database to infer the model. Some significant remarks were taken from Özel et al. [

14]. In this present study, the effects of cutting edge geometry on surface hardness are detailed. Moreover, this paper presents the relation between the cutting conditions and the surface roughness for turning processes. In addition, Arrazola et al. [

4] detailed several models for chip formation, which can be used to predict cutting forces, temperatures, stress and strain. These models are based on insert geometries and cutting parameters. The approach [

12] proposes a system software to optimize cutting parameters based on genetic algorithms. This model defines an objective function, which is based on theoretical models that relate fundamental variables in the machining operation. Ganesh et al. [

5] showed an optimization of cutting parameters for the turning process. This research defines the surface roughness as an objective function for turning machining of EN 8 steel. A genetic algorithm is also applied in this approach. This model can be considered to be a hybrid model. Although the study by Li et al. [

9] predicts annual power load consumption, the approach also shows an interesting hybrid model based on regression neural networks and the fruit fly optimization algorithm. This research presents a significant improvement in accuracy compared with previous approaches without neural network algorithms. Other models also show important achievements after applying training-based models that use the neural network algorithm. For instance, Xiong et al. [

15] used the weld bead geometry prediction; Babu et al. [

16] predicted the tensile behavior of tailor weld blanks; and Özel and Karpat [

17] presented a model for surface roughness and tool wear for turning operations. Additionally, Malinov et al. [

18] created an artificial neural network to predict the mechanical properties of titanium alloys as a function of the alloy composition. The research by Kuo et al. [

19] poses a singular model for intelligent stock trading decision support systems. This model captures the stock expert’s knowledge by a genetic-algorithm-based fuzzy neural network model.

Other important achievements for the optimization of cutting parameters have been proposed using only genetic algorithms. Although these approaches show dependency on the working conditions and the workpiece and tools, they can acquire models that can reach the optimal result with high efficiency. In the paper by Quiza Sardinas et al. [

20], a multi-objective optimization of cutting parameters in turning operations is presented. This approach entails the use of an objective function based on power consumption, cutting forces and surface roughness. It also presents a qualification of chromosome population, which is inherent to genetic algorithms, based on feasible individuals. Cus and Balic [

21] presents an approach for cutting parameters in turning operations. This paper also shows an experimental test for validating the model. Suresh et al. [

22] proposes a model to predict surface roughness. This model uses the response surface methodology and a genetic algorithm to converge to an optimal solution. Yang and Tarng [

23] showed an approach for optimization of cutting parameters using the Taguchi method and the analysis of variance (ANOVA) for a database obtained by testing surveys. Thamizhmanii et al. [

24] presents a similar approach using the Taguchi method and the ANOVA analysis but for optimizing surface roughness.

Unlike other research approaches, our research considers the insert information from a tool supplier to obtain neural network models of insert before determining the optimal cutting parameters. This approach allows the selection of a tool-insert and the inference of the corresponding cutting parameters by simultaneously considering tool specifications and working conditions. To do so, the research is based on a considerable amount of information defined by the tool supplier. The proposed model is an integrated optimization system, which selects a suitable tool-insert and suggests optimal cutting parameters based on certain working conditions and a fitness function optimization, respectively. This approach models the relationships between the geometrical and mechanical features of a tool-insert and the working conditions, thus introducing a novel approach to the modeling of cutting parameters for a turning tool. The output of the proposed approach is a set of recommended cutting parameters for an optimally selected cutting tool. This approach considers the entire information defined by the tool supplier and its intrinsic relationship with the working material in a turning operation. Thus, this makes more assertive recommendations for the cutting parameters.

The objective of this research is to obtain a model for cutting insert selections and cutting parameter optimization. This model must be constrained by working conditions and evaluated by an objective function. The objective function of this approach is defined as a combination of the lowest power consumption, the shortest machining time and surface roughness within a certain range. However, this function must be customizable under external conditions. Furthermore, the cutting insert selection must be based on commercially available tools. Since this research proposes a model for cutting insert selections based on commercially available tools, it requires a database from a tool supplier. The chosen tool supplier was Sandvik Coromant and the selected tool-insert model for building the datasets was CoroTurn® 107. The information about the recommended cutting parameters and the insert feature description was referenced from the official Sandvik Coromant website [

25]. The models used on this approach are two artificial neural networks. The first neural network model defines the cutting parameter feed rate as a function of macro-geometrical features and recommended cutting depths. The second model defines the cutting speed as a function of material cutting specifications, working conditions and the feed rate cutting parameter. To find optimal cutting parameters and a suitable cutting insert, a genetic algorithm optimization is proposed based on working conditions. This algorithm is defined by a heuristic search of insert features and cutting parameters, which are evaluated by the neural network models. This heuristic search is set up under a defined objective function, which is a combination of the lowest power consumption, the shortest machining time and an acceptable surface roughness. Due to the heuristic search of the genetic algorithm, the result might be a non-existent tool-insert. Thus, the last stage of this approach is to evaluate a Euclidean distance to find the closest existent tool-insert in the commercial database based on a predefined threshold.

The structure of this paper is as follows.

Section 2 aims to introduce the main features that define a tool-insert and the relations of the cutting parameters with geometrical features and the working conditions. This section also defines the database based on commercial data from a tool supplier. The section ends with the proposed dataset for this research.

Section 3 explains the procedure used to obtain neural network models for this research. Furthermore, this section introduces data preparation and error validation.

Section 4 details the mechanism behind the genetic algorithm implementation. Some concepts, such as individual chromosomes, encoding and decoding procedures and fitness function, are introduced in this section.

Section 5 aims to explain how to use this model for practical applications in more detail. Examples of applications shown in this section include light roughing machining, heavy roughing machining and finishing operations.

Section 6 summarizes this paper.

2. Datasets Description and Preparation

Turning is a process to remove material, which is mainly oriented to metal machining. Within this field, several criteria are used to establish the conditions for an acceptable turning process, including surface roughness, measurement tolerance, power consumption, machining time, forces, loads, etc. These measurement criteria are highly related to the selected cutting insert, cutting parameters, working material and working conditions [

25]. A cutting insert varies according to its geometry, shape and material composition. Thus, it is possible to apply a specific group of cutting inserts to a specific turning application, working material and working conditions. In general, a tool-insert can be defined by its geometrical features and material composition, which are hereinafter referred as tool-insert features. The most notable tool-insert features are the inscribed circle (ICmm), clearance angle (AN), cutting length (LEmm), corner radius (REmm), thickness (Smm) and shape angle (SC), as shown in

Figure 1.

The ICmm is a tool-insert feature that is highly related to the insert size. A large insert size increases the stability performance but oversizing can lead to high production costs. This feature must be linked with the depth of the cut, the entering angle and the cutting length to be used. The AN is the angle between the front face of the insert and the vertical axis of the workpiece [

25]. This feature also defines the negative or positive quality of an insert [

25]. On the other hand, the REmm feature is also related to the chip-breaking and cutting forces but it is mainly linked to finished surfaces. For a set feed rate cutting parameter, the machining yields a certain surface roughness. Furthermore, the radial forces that push away the insert in the turning machining become the axial forces as the depth of the cut increases with respect to the radius nose. As a suggestion from the supplier, the depth of cut should be greater or equal to 2/3 of the nose radius of the tool-insert [

25]. The insert-shape feature is the most tangible feature, which is mainly selected by accessibility requirements. This feature defines a tool-holder and the depth of cut range in the process. The SC feature is defined by the nose angle of the tool-insert, which is related to strength and reliability issues. Large nose angles are stronger but require more machining power. They also increase the vibration tendency of the machine. On the contrary, small nose angles are weaker and have small cutting edges but are linked to better surface roughness [

25].

The CTPT feature, which describes the cutting operation, is defined by three possible configurations: Finishing, Medium and Roughing operations. The WEP feature is a logical feature, which defines if the tool insert has a wiper radius. The GRADE feature describes the material composition of a tool-insert. Three features are linked to different grade features. These features describe the distribution of each grade in the range of area applications for ISO group materials. The introduced features are MC_L (machine condition low), MC_H (machine condition high) and MC_Suitability (machine condition suitability). The MC_L and MC_H features represent the low and high borders of each grade in the range of area application. The MC_Suitability feature is defined as a percentage of range for each grade that belongs to wear resistance region, which is in the upper region of the total field of application. For instance, the grade 4325 is defined as MC_L = 40, MC_H = 10 and MC_Suitability = 50%; the grade 5015 is defined as MC_L = 0, MC_H = 20 and MC_Suitability = 100%; and the grade GC30 is defined as MC_L = 35, MC_H = 45 and MC_Suitability = 0% [

25].

Figure 2 graphically shows the relation between the working material (hardness feature), cutting parameters (feed rate) and cutting velocity. It is important to note that the relation varies as a function of the insert grade feature.

There are two proposed datasets for this study. The first one is a dataset for insert features with cutting parameters. The second one is for working conditions with cutting parameters. The first dataset will be used to train a neural network model that infers the feed rate while the second one will be used to model the cutting velocity. The description for each dataset is shown in

Table 1 and

Table 2. The main reason for using two neural network models is the nature of the dataset. The dataset for this study is based on two main sources, which are namely the data description for the tool-insert and the working conditions for a certain working material. The data description for a tool-insert relates the insert features of a tool-insert (i.e., the nose angle, thickness, cutting length and so on) and the suggested cutting parameters (depth of the cut and feed rate). The dataset, which ensues from working conditions, does not relate the insert features to the cutting parameter. It is defined by different working material specifications and their impact on the cutting parameters.

3. Artificial Neural Network Models

An artificial neural network model is a powerful method to deal with nonlinear functions or to model systems with unknown input–output relations [

26,

27,

28]. In fact, the purpose of the algorithm in this research is to find two models that relate the tool-insert features and working conditions to the cutting parameters. Some important issues in the implementation of a neural network model come from the nature of a neural network model. Since a neural network model considers nonlinear combinations and often uses a gradient descent algorithm to update its parameters, the main issues revolve around the need to reach a global solution instead of a local one. Furthermore, given the fact that a neural network model is built on an available dataset, any irrelevant, non-numerical and poor representations of input features can adversely affect the final model [

29]. As a machine learning algorithm, neural network models mainly focus on the validation stage. For this reason, the error validation represents proof that the embedded information in the database is well represented by the resulting model. There are some concepts regarding neural network models, which need to be understood. These include overfitting, homogeneous representation and accuracy [

30].

For a neural network model, the dataset plays a crucial role. In fact, an effective preparation of the data can lead to an increase in accuracy, reduction in computing time and prevention of overfitting in the model [

31]. For the research’s dataset, two scaling methods were considered to prepare the data for the training stage. The independent variables, which define the model inputs, have a scaling method called the z-score. The dependent variables, which describe the output for the neural network model, have a scaling method based on its minimum and maximum values, which has a range from 0 to 1 [

31]. Equations (1) and (2) show the z-score and range scaling for inputs and outputs, respectively. It is also important to note that the output for a neural network model is highly dependent on the activation function, which is defined in the last layer (output layer). Generally, the activation function for the last layer is a hyperbolic tangent, softmax or a sigmoid function, which has an output range of 0 to 1. Other activation functions are widely used for neural network models although this research uses a linear function because it can be easily implemented with less computational burden.

The architecture and error validation of a neural network model are closely linked with each other. In fact, the performance of a neural network model is defined by its architecture, but this last one is selected by error validation. The architecture refers to the set of parameters that govern the complexity of the model, including the number of neurons, layers, updating and regularization algorithms among others. The error validation refers to an evaluation procedure for a certain architecture to find a balance between accuracy and error distribution without causing overfitting [

32]. In practical applications, the training and testing datasets are used to achieve an architecture model that represents almost all information in the dataset. The training data are used to teach the model on the input–output relations. The testing data validate the model so it represents most of the total spectrum of possibilities in the dataset. For the present research, the databases for the feed rate and cutting velocity model, which are described in

Table 1 and

Table 2, are divided into a ratio of 0.5 for training and testing validation. The algorithm for converging the weights in a neural network model also plays an important role in the architecture. For this implementation, a globally convergent training scheme, based on the resilient propagation, is used. A crucial advantage of this algorithm compared to the traditional back-propagation or normal resilient propagation is the computing time. This approach shows better accuracy performance with similar datasets to be used for this research (datasets that are compounded by factors and numerical mapped values [

29]).

The most important part in error validation is the definition of a good performance, which qualifies the architecture of a neural network model. For this approach, the traditional root mean square error comparison was not the only one considered to validate the models [

32]. Instead, the error validation for this research is defined by the comparison of error density functions for training and testing evaluations. Error density functions are continuous functions that represent the attained errors for training and testing evaluations by a known function. The Gaussian function is used to represent these density functions. In this way, the training and testing evaluations can be represented by a Gaussian error density function. It is important to note that a Gaussian function is defined by two parameters: mean or expectation and standard deviation. For this approach, the expectation value is zero and the entire range of errors in the validation is defined by +/− 3 standard deviations by its definition. Under this premise, a certain trained model will present a certain Gaussian density function. For such an attained model, a good performance should be defined by a testing Gaussian density function that is similar to the reached model in the training stage. For instance,

Figure 3 shows two models (model A and model B) that evaluate different architectures for the feed rate model as an example. Model A shows a testing evaluation with a particular density function, which is different to the one reached in the training evaluation. In contrast, model B shows a testing error density performance that is quite similar to the one reached in the training evaluations.

Table 3 numerically shows the same concept shown in

Figure 3.

Table 3 also shows additional error comparisons, including the root mean square error (RMSE), median absolute deviation (MAD), maximum and minimum error values, etc. It is important to note that the large differences between RMSE and MAD are indicative of the error density function [

30].

To achieve the best model for feed rate and cutting velocity, the following strategy was implemented to validate any possible architecture:

Consider random architectures with one and two hidden layers with different neurons per layer.

For each architecture, the training and testing error density functions are obtained. Hereinafter, these Gaussian functions are referred as

For each architecture, a Euclidean distance is evaluated between the functions of

and

. This Euclidean distance is calculated with the properties described in

Table 3. Equation (3) shows the implementation of this Euclidean distance:

For each architecture, the maximum distance between the mean error values is considered to be zero. Equation (4) shows the implementation of this distance as the maximum absolute value of the mean property in testing and training error functions:

A maximum range of error functions must be calculated. This range is defined by the maximum and minimum properties for each error function (

,

).

To consider the skew property for

and

, the distance between RMSE to MAD is calculated. Equation (6) shows the implementation of this distance as the maximum absolute value for the difference between RMSE and MAD for both

and

:

After this, the performance of a suggested model is given by Equation (7), which evaluates the Euclidean distance, mean distance to zero, the total error range and skew distance as a function of

and

. The constant

k allows the function to be adjusted to a certain range of values, which is shown as follows:

To validate several random architectures, a heuristic optimization search was implemented by using a genetic algorithm for the feed rate and cutting velocity models. The architectures differ from each other in layer and neuron numbers. Furthermore, this genetic algorithm is defined by Equation (7) as the fitness function.

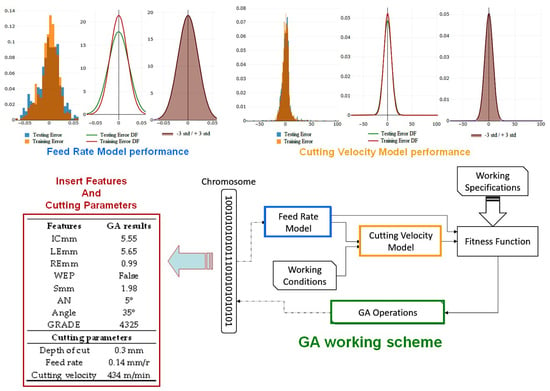

Table 4 shows the reached architectures for the feed rate and cutting velocity models. For the feed rate, a neural network model was established with two hidden layers. Furthermore, this model has 15 and 4 neurons per layer. The cutting velocity model was also established with two hidden layers, which has 25 and 7 neurons per layer. The graphical performance for both models is shown in

Figure 4 and

Figure 5 (feed rate and cutting velocity, respectively). In these figures, it is possible to appreciate the error density function in training and testing evaluations. These figures also show the reached genetic algorithm performance used to converge both models. It is important to note that the optimization by the genetic algorithm allows the achievement of good performance for both models in fewer iterations.

6. Conclusions

Neural network models for the selection of cutting inserts and cutting parameters were designed. These models were applied to roughing and finishing operations. This research uses the information from a tool supplier to embed knowledge for the tool-insert selection and optimization system developed in this research. The proposed system is based on artificial neural networks (ANNs) and a genetic algorithm (GA). These represent the modeling and optimization part of this research, respectively. For the modeling, two ANNs were implemented. These ANNs are able to infer the feed rate and cutting velocity parameters. The feed rate model is defined as a function of insert features and a set depth of the cut. The insert features represent the macro-geometries of a tool-insert, which include the cutting length, thickness, nose angle, nose radius, size and grade among others. For the cutting velocity model, the inputs are the material specifications and a set feed rate. The material specifications are defined as inherent features of a working material for turning processes. They include hardness, specific cutting force and ISO material group.

For the neural network validation, an error comparison based on density functions was implemented. This approach proposed an alternative solution for the error validation of regression models based on the recommended data by a supplier. To evaluate some architectures of the ANN models, a heuristic search based on GA was used. This approach evaluated the possible architectures and evolved them toward the most feasible one. For the proposed research, a heuristic searching method for a feasible tool-insert based on its characteristics in a certain environment was also introduced. The algorithm used for this search was a GA. The introduced GA optimization searches for an optimal tool-insert, which adapts to a working specification and evaluates an acceptable performance given by a customized objective function. This objective function evaluates the performance under certain working conditions, such as the lowest power consumption, the shortest machining time and an acceptable surface roughness. In this present study, different goal functions referring to different force models or tool life models can be used when designing the fitness function in order to obtain the optimal tool-insert with specific considerations. This research presents a model to simulate knowledge and expertise, which embeds the information from a tool supplier. It returns the most suitable insert-tool as a result, given certain working conditions. This research did not use a lookup table approach in the database as it instead modeled the mechanical relations between the geometrical features of an insert-tool and its recommended cutting parameters. This tool-insert selection and optimization system can embed the data from other models, different tool suppliers, previous machining works and expertise from machine-shop workers. However, because of the inherent discrepancy among different datasets, additional factors, such as input variation and data types, must be considered when using the developed system and approaches. Furthermore, because the developed system successfully represents the complex relationship between the working condition and the cutting parameters, the developed system can be a plug-in for CAD/CAM software or can be integrated with the controller of a CNC machine tool to be an auxiliary function for the automatic selection of the cutting parameters based on the preset working conditions presented in the part program. For this research, a fully connected ANN model was used due to the representation of a multi-dimensional space using the training data obtained from a database. Other networks with diverse characteristics, such as the convolutional networks, could also be used in future researches. Moreover, methods, such as the support vector machine and probabilistic regression, could be used for regression modeling. This research has used a GA for optimization. However, methods, such as the particle swarm optimization and gradient descent technique, can also be used to carry out optimization.