Eco-Friendly Poly(Vinyl Alcohol) Nanofiber-Based Air Filter for Effectively Capturing Particulate Matter

Abstract

:Featured Application

Abstract

1. Introduction

2. Materials and Methods

2.1. Preparation

2.2. Characterization

2.3. Testing

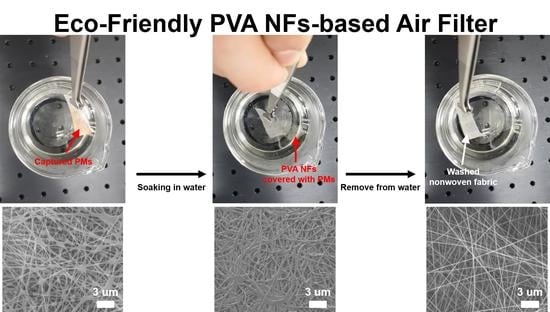

3. Results and Discussion

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Choi, S.; Jeon, H.; Jang, M.; Kim, H.; Shin, G.; Koo, J.M.; Lee, M.; Sung, H.K.; Eom, Y.; Yang, H.-S.; et al. Biodegradable, Efficient, and Breathable Multi-Use Face Mask Filter. Adv. Sci. 2021, 8, 2003155. [Google Scholar] [CrossRef] [PubMed]

- Jung, S.; Kim, J. Advanced Design of Fiber-Based Particulate Filters; Materials, Morphology, and Construction of Fibrous Assembly. Polymers 2020, 12, 1714. [Google Scholar] [CrossRef] [PubMed]

- Zhang, X.; Liu, J.; Zhang, H.; Hou, J.; Wang, Y.; Deng, C.; Huang, C.; Jin, A. Multi-Layered, Corona Charged Melt Blown Nonwovens as High Performance PM0.3 Air Filters. Polymers 2021, 13, 485. [Google Scholar] [CrossRef]

- Zhang, H.; Liu, N.; Zeng, Q.; Liu, J.; Zhang, X.; Ge, M.; Zhang, W.; Li, S.; Fu, Y.; Zhang, Y. Design of Polypropylene Electret Melt Blown Nonwovens with Superior Filtration Efficiency Stability through Thermally Stimulated Charging. Polymers 2020, 12, 2341. [Google Scholar] [CrossRef]

- Zhao, C.; Mark, L.H.; Chang, E.; Chu, R.K.M.; Lee, P.C.; Park, C.B. Highly Expanded, Highly Insulating Polypropylene/Polybutylene-Terephthalate Composite Foams Manufactured by Nano-Fibrillation Technology. Mater. Des. 2020, 188, 108450. [Google Scholar] [CrossRef]

- Zhao, M.; Liao, L.; Xiao, W.; Yu, X.; Wang, H.; Wang, Q.; Lin, Y.L.; Kilinc-Balci, F.S.; Price, A.; Chu, L.; et al. Household Materials Selection for Homemade Cloth Face Coverings and Their Filtration Efficiency Enhancement with Triboelectric Charging. Nano Lett. 2020, 20, 5544–5552. [Google Scholar] [CrossRef]

- Yeo, J.H.; Kim, M.; Lee, H.; Cho, J.; Park, J. Facile and Novel Eco-Friendly Poly(Vinyl Alcohol) Nanofibers Using the Photocatalytic Property of Titanium Dioxide. ACS Omega 2020, 5, 5026–5033. [Google Scholar] [CrossRef]

- Nkwachukwu, O.I.; Chima, C.H.; Ikenna, A.O.; Albert, L. Focus on Potential Environmental Issues on Plastic World Towards a Sustainable Plastic Recycling in Developing Countries. Int. J. Ind. Chem. 2013, 4, 1–13. [Google Scholar] [CrossRef] [Green Version]

- Jeong, S.; Cho, H.; Han, S.; Won, P.; Lee, H.; Hong, S.; Yeo, J.; Kwon, J.; Ko, S.H. High Efficiency, Transparent, Reusable, and Active PM2.5 Filters by Hierarchical Ag Nanowire Percolation Network. Nano Lett. 2017, 17, 4339–4346. [Google Scholar] [CrossRef] [Green Version]

- Lim, H.; Suh, B.L.; Kim, M.J.; Yun, H.; Kim, J.; Kim, B.J.; Jang, S.G. High-performance, Recyclable Ultrafiltration Membranes from P4VP-assisted Dispersion of Flame-resistive Boron Nitride Nanotubes. J. Membr. Sci. 2018, 551, 172–179. [Google Scholar] [CrossRef]

- Ullah, S.; Ullah, A.; Lee, J.; Jeong, Y.; Hashmi, M.; Zhu, C.; Joo, K.I.; Cha, H.J.; Kim, I.S. Reusability Comparison of Melt-Blown vs Nanofiber Face Mask Filters for Use in the Coronavirus Pandemic. ACS App. Nano Mater. 2020, 3, 7231–7241. [Google Scholar] [CrossRef]

- Zhang, Q.; Li, Q.; Young, T.M.; Harper, D.P.; Wang, S. A Novel Method for Fabricating an Electrospun Poly (Vinyl Alcohol)/Cellulose Nanocrystals Composite Nanofibrous Filter with Low Air Resistance for High-Efficiency Filtration of Particulate Matter. ACS Sustain. Chem. Eng. 2019, 7, 8706–8714. [Google Scholar] [CrossRef]

- Kim, H.-J.; Park, S.J.; Park, C.S.; Le, T.-H.; Lee, S.H.; Ha, T.H.; Kim, H.; Kim, J.; Lee, C.-S.; Yoon, H.; et al. Surface-modified Polymer Nanofiber Membrane for High-efficiency Microdust Capturing. Chem. Eng. J. 2018, 339, 204–213. [Google Scholar] [CrossRef]

- Li, Q.; Xu, Y.; Wei, H.; Wang, X. An Electrospun Polycarbonate Nanofibrous Membrane for High Efficiency Particulate Matter Filtration. RSC Adv. 2016, 6, 65275–65281. [Google Scholar] [CrossRef]

- Zhang, R.; Liu, C.; Hsu, P.-C.; Zhang, C.; Liu, N.; Zhang, J.; Lee, H.R.; Lu, Y.; Qiu, Y.; Chu, S.; et al. Nanofiber Air Filters with High-Temperature Stability for Efficient PM2.5 Removal from the Pollution Sources. Nano Lett. 2016, 16, 3642–3649. [Google Scholar] [CrossRef]

- Kim, H.-J.; Park, S.J.; Kim, D.-I.; Lee, S.; Kwon, O.S.; Kim, I.K. Moisture Effect on Particulate Matter Filtration Performance using Electro-Spun Nanofibers including Density Functional Theory Analysis. Sci. Rep. 2019, 9, 1–8. [Google Scholar] [CrossRef] [Green Version]

- Xu, J.; Liu, C.; Hsu, P.-C.; Liu, K.; Zhang, R.; Liu, Y.; Cui, Y. Liu Roll-to-Roll Transfer of Electrospun Nanofiber Film for High-Efficiency Transparent Air Filter. Nano Lett. 2016, 16, 1270–1275. [Google Scholar] [CrossRef]

- Cao, J.; Cheng, Z.; Kang, L.; Lin, M.; Han, L. Patterned Nanofiber Air Filters with High Optical Transparency, Robust Mechanical Strength, and Effective PM2.5 Capture Capability. RSC Adv. 2020, 10, 20155–20161. [Google Scholar] [CrossRef]

- Liu, C.; Hsu, P.-C.; Lee, H.-W.; Ye, M.; Zheng, G.; Liu, N.; Li, W.; Cui, Y. Transparent Air Filter for High-Efficiency PM2.5 capture. Nat. Commun. 2015, 6, 1–9. [Google Scholar] [CrossRef] [Green Version]

- Zhang, R.; Liu, B.; Yang, A.; Zhu, Y.; Liu, C.; Zhou, G.; Sun, J.; Hsu, P.-C.; Zhao, W.; Lin, D.; et al. In Situ Investigation on the Nanoscale Capture and Evolution of Aerosols on nanofibers. Nano Lett. 2018, 18, 1130–1138. [Google Scholar] [CrossRef]

- He, Z.; Rault, F.; Lewandowski, M.; Mohsenzadeh, E.; Salaün, F. Electrospun PVDF Nanofibers for Piezoelectric Applications: A Review of the Influence of Electrospinning Parameters on the β Phase and Crystallinity Enhancement. Polymers 2021, 13, 174. [Google Scholar] [CrossRef]

- Choi, D.Y.; Jung, S.-H.; Song, D.K.; An, E.J.; Park, D.; Kim, T.-O.; Jung, J.H.; Lee, H.M. Al-Coated Conductive Fibrous Filter with Low Pressure Drop for Efficient Electrostatic Capture of Ultrafine Particulate Pollutants. ACS Appl. Mater. Interfaces 2017, 9, 16495–16504. [Google Scholar] [CrossRef]

- Wu, H.; Kong, D.; Ruan, Z.; Hsu, P.-C.; Wang, S.; Yu, Z.; Carney, T.J.; Hu, L.; Fan, S.; Cui, Y. A Transparent Electrode Based on a Metal Nanotrough Network. Nat. Nanotechnol. 2013, 8, 421–425. [Google Scholar] [CrossRef] [PubMed]

| Sample | Mean Fiber Diameter [nm] | E [%] | ∆P [Pa] | |

|---|---|---|---|---|

| Nonwoven fabric substrate (without PVA NF) | ~20,000 | 42.10 | 63 | 0.008674 |

| PVA NF-based filter (Electrospinning time: 60 s) | ~150 | 50.41 | 79 | 0.008878 |

| PVA NF-based filter (Electrospinning time: 180 s) | 67.76 | 125 | 0.009056 | |

| PVA NF-based filter (Electrospinning time: 300 s) | 86.81 | 191 | 0.010606 | |

| PVA NF-based filter (Electrospinning time: 600 s) | 89.07 | 220 | 0.010062 | |

| Cabin air filter | ~22,000 | 40.27 | 49 | 0.010517 |

| Dust mask (KF80) | ~13,000 | 85.61 | 213 | 0.009102 |

| HEPA filter | ~16,000 | 94.55 | 189 | 0.015394 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kim, H.-J.; Choi, D.-I.; Sung, S.-K.; Lee, S.-H.; Kim, S.-J.; Kim, J.; Han, B.-S.; Kim, D.-I.; Kim, Y. Eco-Friendly Poly(Vinyl Alcohol) Nanofiber-Based Air Filter for Effectively Capturing Particulate Matter. Appl. Sci. 2021, 11, 3831. https://doi.org/10.3390/app11093831

Kim H-J, Choi D-I, Sung S-K, Lee S-H, Kim S-J, Kim J, Han B-S, Kim D-I, Kim Y. Eco-Friendly Poly(Vinyl Alcohol) Nanofiber-Based Air Filter for Effectively Capturing Particulate Matter. Applied Sciences. 2021; 11(9):3831. https://doi.org/10.3390/app11093831

Chicago/Turabian StyleKim, Han-Jung, Dong-In Choi, Sang-Keun Sung, Su-Han Lee, Sang-Jin Kim, Junhee Kim, Byong-Sam Han, Dong-Ik Kim, and Yoonkap Kim. 2021. "Eco-Friendly Poly(Vinyl Alcohol) Nanofiber-Based Air Filter for Effectively Capturing Particulate Matter" Applied Sciences 11, no. 9: 3831. https://doi.org/10.3390/app11093831