The Effect of Different Levels of Shading in a Photovoltaic Greenhouse with a North–South Orientation

Abstract

:1. Introduction

2. Materials and Methods

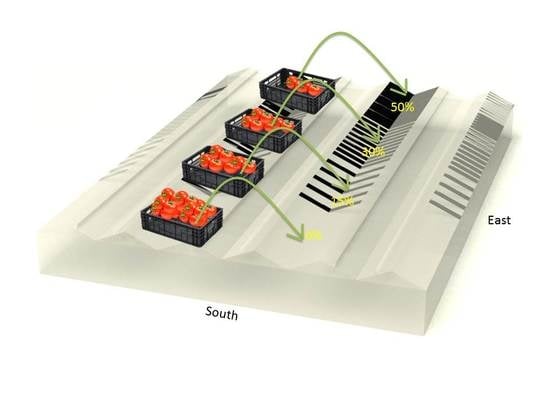

2.1. Experimental Design

2.2. Crop Conditions

2.3. Climatic Parameters Register

2.4. Agronomic Parameters Register

2.5. Data Analysis

3. Results

3.1. Effects of Shading Treatments over Temperature and PAR Radiation

3.2. Electric Conductivity and pH in the Substrate Solution.

3.3. Shading Effects on Crop Yields

3.4. Shading Effect on the Fruit Quality

4. Discussion

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Roslan, N.; Ya’acob, M.E.; Radzi, M.A.M.; Hashimoto, Y.; Jamaludin, D.; Chen, G. Dye Sensitized Solar Cell (DSSC) greenhouse shading: New insights for solar radiation manipulation. Renew. Sustain. Energy Rev. 2018, 92, 171–186. [Google Scholar] [CrossRef]

- Yano, A.; Cossu, M. Energy sustainable greenhouse crop cultivation using photovoltaic technologies. Renew. Sustain. Energy Rev. 2019, 109, 116–137. [Google Scholar] [CrossRef]

- Yano, A.; Tsuchiya, K.; Nishi, K.; Moriyama, T.; Ide, O. Development of a Greenhouse Side-ventilation Controller driven by Photovoltaic Energy. Biosyst. Eng. 2007, 96, 633–641. [Google Scholar] [CrossRef]

- Djevic, M.; Dimitrijevic, A. Energy consumption for different greenhouse constructions. Energy 2009, 34, 1325–1331. [Google Scholar] [CrossRef]

- Mohammadi, A.; Omid, M. Economical analysis and relation between energy inputs and yield of greenhouse cucumber production in Iran. Appl. Energy 2010, 87, 191–196. [Google Scholar] [CrossRef]

- Xu, J.; Li, Y.; Wang, R.Z.; Liu, W. Performance investigation of a solar heating system with underground seasonal energy storage for greenhouse application. Energy 2014, 67, 63–73. [Google Scholar] [CrossRef]

- Russo, G.; Anifantis, A.S.; Verdiani, G.; Mugnozza, G.S. Environmental analysis of geothermal heat pump and LPG greenhouse heating systems. Biosyst. Eng. 2014, 127, 11–23. [Google Scholar] [CrossRef]

- Carreño-Ortega, A.; Galdeano-Gómez, E.; Pérez-Mesa, J.C.; Galera-Quiles, M.D.C. Policy and Environmental Implications of Photovoltaic Systems in Farming in Southeast Spain: Can Greenhouses Reduce the Greenhouse Effect? Energies 2017, 10, 761. [Google Scholar] [CrossRef] [Green Version]

- Friman-Peretz, M.; Geoola, F.; Yehia, I.; Ozer, S.; Levi, A.; Magadley, E.; Brikman, R.; Rosenfeld, L.; Levy, A.; Kacira, M.; et al. Testing organic photovoltaic modules for application as greenhouse cover or shading element. Biosyst. Eng. 2019, 184, 24–36. [Google Scholar] [CrossRef]

- Moretti, S.; Marucci, A. A Photovoltaic Greenhouse with Variable Shading for the Optimization of Agricultural and Energy Production. Energies 2019, 12, 2589. [Google Scholar] [CrossRef] [Green Version]

- Vadiee, A.; Martin, V. Energy management in horticultural applications through the closed greenhouse concept, state of the art. Renew. Sustain. Energy Rev. 2012, 16, 5087–5100. [Google Scholar] [CrossRef]

- Hassanien, R.H.E.; Li, M.; Dong Lin, W. Advanced applications of solar energy in agricultural greenhouses. Renew. Sustain. Energy Rev. 2016, 54, 989–1001. [Google Scholar] [CrossRef]

- Cuce, E.; Harjunowibowo, D.; Cuce, P.M. Renewable and sustainable energy saving strategies for greenhouse systems: A comprehensive review. Renew. Sustain. Energy Rev. 2016, 64, 34–59. [Google Scholar] [CrossRef]

- Ntinas, G.K.; Neumair, M.; Tsadilas, C.D.; Meyer, J. Carbon footprint and cumulative energy demand of greenhouse and open-field tomato cultivation systems under Southern and Central European climatic conditions. J. Clean. Prod. 2017, 142, 3617–3626. [Google Scholar] [CrossRef]

- Al-Ibrahim, A.; Al-Abbadi, N.; Al-Helal, I. PV greenhouse system—System description, performance and lesson learned. Acta Hortic. 2006, 710, 251–264. [Google Scholar] [CrossRef]

- Chaurey, A.; Kandpal, T.C. Assessment and evaluation of PV based decentralized rural electrification: An overview. Renew. Sustain. Energy Rev. 2010, 14, 2266–2278. [Google Scholar] [CrossRef]

- Qoaider, L.; Steinbrecht, D. Photovoltaic systems: A cost competitive option to supply energy to off-grid agricultural communities in arid regions. Appl. Energy 2010, 87, 427–435. [Google Scholar] [CrossRef]

- Pérez-Alonso, J.; Pérez-García, M.; Pasamontes-Romera, M.; Callejón-Ferre, A.J. Performance analysis and neural modelling of a greenhouse integrated photovoltaic system. Renew. Sustain. Energy Rev. 2012, 16, 4675–4685. [Google Scholar] [CrossRef]

- Qian, T.; Dieleman J., A.; Elings, A.; van Kooten, O. Comparison of climate and production in closed, semi-closed and open greenhouses. Acta Hortic. 2011, 893, 807–814. [Google Scholar] [CrossRef] [Green Version]

- Rocamora, M.C.; Tripanagnostopoulos, Y. Aspects of PV/T solar system application for ventilation needs in greenhouses. Acta Hortic. 2006, 719, 239–246. [Google Scholar] [CrossRef]

- Marucci, A.; Monarca, D.; Cecchini, M.; Colantoni, A.; Manzo, A.; Cappuccini, A. The Semitransparent Photovoltaic Films for Mediterranean Greenhouse: A New Sustainable Technology. Math. Prob. Eng. 2012, 2012, 1–14. [Google Scholar] [CrossRef]

- Marucci, A.; Gusman, A.; Pagniello, B.; Cappuccini, A. Limits and prospects of photovoltaic covers in Mediterranean greenhouses. J. Agric. Eng. Res. 2013, 43, 1. [Google Scholar] [CrossRef]

- Bhat, I.K.; Prakash, R. LCA of renewable energy for electricity generation systems: A review. Renew. Renew. Sustain. Energy Rev. 2009, 13, 1067–1073. [Google Scholar] [CrossRef]

- Ureña-Sánchez, R.; Callejón-Ferre, Á.J.; Pérez-Alonso, J.; Carreño-Ortega, Á. Greenhouse tomato production with electricity generation by roof-mounted flexible solar panels. Sci. Agr. 2012, 69, 233–239. [Google Scholar] [CrossRef]

- Aroca-Delgado, R.; Pérez-Alonso, J.; Callejón-Ferre, Á.-J.; Díaz-Pérez, M. Morphology, yield and quality of greenhouse tomato cultivation with flexible photovoltaic rooftop panels (Almería-Spain). Sci. Hortic. 2019, 257, 108768. [Google Scholar] [CrossRef]

- Cossu, M.; Cossu, A.; Deligios, P.A.; Ledda, L.; Li, Z.; Fatnassi, H.; Poncet, C.; Yano, A. Assessment and comparison of the solar radiation distribution inside the main commercial photovoltaic greenhouse types in Europe. Renew. Sustain. Energy Rev. 2018, 94, 822–834. [Google Scholar] [CrossRef]

- Cockshull, K.E.; Graves, C.J.; Cave, C.R.J. The influence of shading on yield of glasshouse tomatoes. J. Hortic. Sci. 1992, 67, 11–24. [Google Scholar] [CrossRef]

- Challa, H.; Bakker, J. Potential Production within the Greenhouse Environment. Ecosystems of the World. The Greenhouse Ecosystem; Enoch, Z., Stanhill, G., Eds.; Elsevier: Amsterdan, The Netherlands, 1998; pp. 333–348. [Google Scholar]

- Lorenzo, P.; García, M.L.; Sánchez-Guerrero, M.C.; Medrano, E.; Caparros, I.; Giménez, M. Influence of mobile shading on yield, crop transpiration and water use efficiency. Acta Hortic. 2006, 719, 471–478. [Google Scholar] [CrossRef]

- Callejón-Ferre, A.J.; Manzano-Agugliaro, F.; Díaz-Pérez, M.; Carreño-Ortega, A.; Pérez-Alonso, J. Effect of shading with aluminised screens on fruit production and quality in tomato (Solanum lycopersicum L.) under greenhouse conditions. Span. J. Agric. Res. 2009, 7, 41–49. [Google Scholar] [CrossRef] [Green Version]

- Cossu, M.; Murgia, L.; Ledda, L.; Deligios, P.A.; Sirigu, A.; Chessa, F.; Pazzona, A. Solar radiation distribution inside a greenhouse with south-oriented photovoltaic roofs and effects on crop productivity. Appl. Energy 2014, 133, 89–100. [Google Scholar] [CrossRef]

- Aroca-Delgado, R.; Pérez-Alonso, J.; Callejón-Ferre, Á.; Velázquez-Martí, B. Compatibility between Crops and Solar Panels: An Overview from Shading Systems. Sustainability 2018, 10, 743. [Google Scholar] [CrossRef] [Green Version]

- Yano, A.; Kadowaki, M.; Furue, A.; Tamaki, N.; Tanaka, T.; Hiraki, E. Shading and electrical features of a photovoltaic array mounted inside the roof of an east-west oriented greenhouse. Biosyst. Eng. 2010, 106, 367–377. [Google Scholar] [CrossRef]

- Yano, A.; Furue, A.; Kadowaki, M.; Tanaka, T.; Hiraki, E.; Miyamoto, M.; Ishizu, F.; Noda, S. Electrical energy generated by photovoltaic modules mounted inside the roof of a north–south oriented greenhouse. Biosyst. Eng. 2009, 103, 228–238. [Google Scholar] [CrossRef]

- Bertin, N.; Fatnassi, H.; Vercambre, G.; Poncet, C. Simulation of tomato production under photovoltaic greenhouses. Acta Hortic. 2017, 1170, 425–432. [Google Scholar] [CrossRef]

- Ezzaeri, K.; Fatnassi, H.; Bouharroud, R.; Gourdo, L.; Bazgaou, A.; Wifaya, A.; Demrati, H.; Bekkaoui, A.; Aharoune, A.; Poncet, C.; et al. The effect of photovoltaic panels on the microclimate and on the tomato production under photovoltaic canarian greenhouses. Sol. Energy 2018, 173, 1126–1134. [Google Scholar] [CrossRef]

- López-Aragón, L.; López-Liria, R.; Callejón-Ferre, A.J.; Pérez-Alonso, J. Musculoskeletal disorders of agricultural workers in the greenhouses of Almería (Southeast Spain). Saf. Sci. 2018, 109, 219–235. [Google Scholar] [CrossRef]

- Arana, J. Textural Properties of Foods. In Phisical Properties of Foods, 1st ed.; CRC Press: Boca Raton, FL, USA, 2012; pp. 53–88. [Google Scholar] [CrossRef]

- McIntosh, M.S. Analysis of combined experiments. Agron. J. 1983, 75, 153–155. [Google Scholar] [CrossRef]

- Montgomery, D.C. Design and Analysis of Experiments; John Wiley and Sons Inc.: New York, NY, USA, 1991. [Google Scholar]

- Gómez, K.A.; Gómez, A.A. Statistical Procedures for Agricultural Research; Wiley: New York, NY, USA, 1984. [Google Scholar]

- Freund, R.J.; Wilson, W.J.; Mohr, D.L. Inferences for Two or More Means. In Statistical Methods, 3rd ed.; Elsevier: Burlington, VT, USA, 2010; pp. 245–320. [Google Scholar] [CrossRef]

- Armstrong, R.A. When to use the Bonferroni correction. Ophthal. Physl. Opt. 2014, 34, 502–508. [Google Scholar] [CrossRef]

- Bulgari, R.; Cola, G.; Ferrante, A.; Franzoni, G.; Mariani, L.; Martinetti, L. Micrometeorological environment in traditional and photovoltaic greenhouses and effects on growth and quality of tomato (Solanum lycopersicum L.). Ital. J. Agrometeorol. 2015, 20, 27–38. [Google Scholar]

- Kläring, H.P.; Krumbein, A. The Effect of Constraining the Intensity of Solar Radiation on the Photosynthesis, Growth, Yield and Product Quality of Tomato. J. Agron. Crop. Sci. 2013, 199, 351–359. [Google Scholar] [CrossRef]

- Gent, M.P.N. Effect of shade on quality of greenhouse tomato. Acta Hortic. 2007, 747, 107–112. [Google Scholar] [CrossRef]

- Bénard, C.; Bernillon, S.; Biais, B.; Osorio, S.; Maucourt, M.; Ballias, P.; Deborde, C.; Colombié, S.; Cabasson, C.; Jacob, D.; et al. Metabolomic profiling in tomato reveals diel compositional changes in fruit affected by source–sink relationships. J. Exp. Bot. 2015, 66, 3391–3404. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Dorais, M.; Ehret, D.L.; Papadopoulos, A.P. Tomato (Solanum lycopersicum) health components: From the seed to the consumer. Phytochem. Rev. 2008, 7, 231–250. [Google Scholar] [CrossRef]

- Winsor, G.W.; Adams, P. Changes in the composition and quality of tomato fruit throughout the season. Annu. Rep. Glasshouse Crops 1976, 1975, 134–142. [Google Scholar]

| % Shading | Days after Transplant | |||||||

|---|---|---|---|---|---|---|---|---|

| 113 | 131 | 141 | 161 | 181 | 209 | 222 | 239 | |

| 0% | 1.02a | 3.5a | 5.3a | 8.5a | 12.9a | 15.7a | 17.3a | 18.8ª |

| 15% | 0.60b | 2.1b | 3.2b | 5.5b | 9.4b | 11.9b | 14.1b | 16.9b |

| 30% | 0.19c | 1.4c | 2.3c | 4.1c | 7.4c | 9.1c | 10.5c | 13.4c |

| 50% | 0.01c | 0.7d | 1.5c | 3.3c | 6.3c | 7.8c | 9.0c | 11.5d |

| Significance | *** | *** | *** | *** | *** | *** | *** | *** |

| % Shade | AFW (g) | Croma | Firmness (N) | TSS (ºBrix) | pH |

|---|---|---|---|---|---|

| 0% | 101.6 | 30.15ª | 4.3c | 4.49a | 4.40 |

| 15% | 97.0 | 27.92b | 4.5bc | 4.60a | 4.38 |

| 30% | 95.6 | 27.43c | 4.7ab | 4.43b | 4.40 |

| 50% | 94.9 | 27.40c | 4.8a | 4.40b | 4.45 |

| Significance | n.s. | *** | *** | *** | n.s. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

López-Díaz, G.; Carreño-Ortega, A.; Fatnassi, H.; Poncet, C.; Díaz-Pérez, M. The Effect of Different Levels of Shading in a Photovoltaic Greenhouse with a North–South Orientation. Appl. Sci. 2020, 10, 882. https://doi.org/10.3390/app10030882

López-Díaz G, Carreño-Ortega A, Fatnassi H, Poncet C, Díaz-Pérez M. The Effect of Different Levels of Shading in a Photovoltaic Greenhouse with a North–South Orientation. Applied Sciences. 2020; 10(3):882. https://doi.org/10.3390/app10030882

Chicago/Turabian StyleLópez-Díaz, Guadalupe, Angel Carreño-Ortega, Hicham Fatnassi, Christine Poncet, and Manuel Díaz-Pérez. 2020. "The Effect of Different Levels of Shading in a Photovoltaic Greenhouse with a North–South Orientation" Applied Sciences 10, no. 3: 882. https://doi.org/10.3390/app10030882