Electrical Conductivity Performance of Predicted Modified Fibre Contact Model for Multi-Filler Polymer Composite

Abstract

:1. Introduction

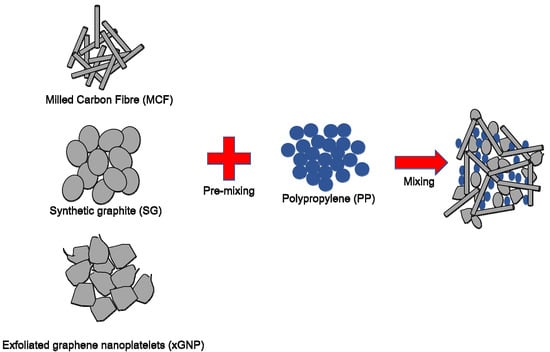

2. Methodology

3. Prediction of Electrical Conductivity by Mathematical Model

4. Results and Discussion

4.1. Physical Characterisation of PP/MCF/xGNP/SG Composite

4.2. Electrical Conductivity Behaviour

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Alaswad, A.; Baroutaji, A.; Achour, H.; Carton, J.; Al Makky, A.; Olabi, A.G. Developments in fuel cell technologies in the transport sector. Int. J. Hydrogen Energy 2015, 41, 16499–16508. [Google Scholar] [CrossRef]

- Chandan, A.; Hattenberger, M.; El-kharouf, A.; Du, S.; Dhir, A.; Self, V.; Pollet, B.G.; Ingram, A.; Bujalski, W. High temperature (HT) polymer electrolyte membrane fuel cells (PEMFC) – A review. J. Power Sources 2013, 231, 264–278. [Google Scholar] [CrossRef]

- Van Biert, L.; Godjevac, M.; Visser, K.; Aravind, P.V. A review of fuel cell systems for maritime applications. J. Power Sources 2016, 327, 345–364. [Google Scholar] [CrossRef] [Green Version]

- Hamimah, A.R.; Muhamad, N.; Abdullah, H.A.M. La1-xSrx Co1-y Fey O3-d(LSCF) Composite as Durable Cathode Materials for Intermediate-Low Temperature Solid Oxide Fuel Cell: Research Review. J. Kejuruter. 2010, 22, 1–10. [Google Scholar]

- Wang, Y.; Leung, D.Y.C.; Xuan, J.; Wang, H. A review on unitized regenerative fuel cell technologies, part-A: Unitized regenerative proton exchange membrane fuel cells. Renew. Sustain. Energy Rev. 2016, 65, 961–977. [Google Scholar] [CrossRef]

- Subasinghe, A.; Somashekar, A.A.; Bhattacharyya, D. Effects of wool fibre and other additives on the flammability and mechanical performance of polypropylene/kenaf composites. Compos. Part B Eng. 2018, 136, 168–176. [Google Scholar] [CrossRef]

- Ismail, M.H.; Muhamad, N.; Omar, M.A. Characterization of Metal Injection Molding (MIM) Feedstock Based on Water Soluble Binder System. J. Kejuruter. 2008, 20, 11–18. [Google Scholar]

- Nabilah, A.; Bakar, A.; Husaini, T.; Herianto, E.; Irwan, M.; Firdaus, M. Fabrication of multi- filler MCF/MWCNT/SG-based bipolar plates. Ceram. Int. 2019, 1–6. [Google Scholar] [CrossRef]

- González-Gutiérrez, A.G.; Pech-Canul, M.A.; Chan-Rosado, G.; Sebastian, P.J. Studies on the physical and electrochemical properties of Ni-P coating on commercial aluminum as bipolar plate in PEMFC. Fuel 2019, 235, 1361–1367. [Google Scholar] [CrossRef]

- Antunes, R.A.; De Oliveira, M.C.L.; Ett, G.; Ett, V. Carbon materials in composite bipolar plates for polymer electrolyte membrane fuel cells: A review of the main challenges to improve electrical performance. J. Power Sources 2011, 196, 2945–2961. [Google Scholar] [CrossRef] [Green Version]

- Zakaria, M.Y.; Sulong, A.B.; Sahari, J.; Suherman, H. Effect of the addition of milled carbon fiber as a secondary filler on the electrical conductivity of graphite/epoxy composites for electrical conductive material. Compos. Part B Eng. 2015, 83, 75–80. [Google Scholar] [CrossRef]

- Suherman, H.; Sulong, A.B.; Sahari, J. Effect of the compression molding parameters on the in-plane and through-plane conductivity of carbon nanotubes/graphite/epoxy nanocomposites as bipolar plate material for a polymer electrolyte membrane fuel cell. Ceram. Int. 2013, 39, 1277–1284. [Google Scholar] [CrossRef]

- Planes, E.; Gloaguen, F.; Flandin, L. Optimizing formulations of polymer composite with high filler content: Application to bipolar plate. Compos. Sci. Technol. 2015, 110, 17–25. [Google Scholar] [CrossRef]

- Taherian, R.; Hadianfard, M.J.; Golikand, A.N. Manufacture of a polymer-based carbon nanocomposite as bipolar plate of proton exchange membrane fuel cells. Mater. Des. 2013, 49, 242–251. [Google Scholar] [CrossRef]

- Taipalus, R.; Harmia, T.; Zhang, M.Q.; Friedrich, K. The electrical conductivity of carbon-fibre-reinforced polypropylene/polyaniline complex-blends: Experimental characterisation and modelling. Compos. Sci. Technol. 2001, 61, 801–814. [Google Scholar] [CrossRef]

- Taherian, R. Experimental and analytical model for the electrical conductivity of polymer-based nanocomposites. Compos. Sci. Technol. 2016, 123, 17–31. [Google Scholar] [CrossRef]

- Mohd Radzuan, N.A.; Sulong, A.B.; Sahari, J. A review of electrical conductivity models for conductive polymer composite. Int. J. Hydrogen Energy 2017, 42, 9262–9273. [Google Scholar] [CrossRef]

- Taherian, R.; Hadianfard, M.J.; Golikand, A.N. A new equation for predicting electrical conductivity of carbon-filled polymer composites used for bipolar plates of fuel cells. J. Appl. Polym. Sci. 2013, 128, 1497–1509. [Google Scholar] [CrossRef]

- Huynh, M.T.T.; Cho, H.B.; Suzuki, T.; Suematsu, H.; Nguyen, S.T.; Niihara, K.; Nakayama, T. Electrical property enhancement by controlled percolation structure of carbon black in polymer-based nanocomposites via nanosecond pulsed electric field. Compos. Sci. Technol. 2018, 154, 165–174. [Google Scholar] [CrossRef]

- Münstedt, H.; Starý, Z. Is electrical percolation in carbon-filled polymers reflected by rheological properties? Polymer. 2016, 98, 51–60. [Google Scholar] [CrossRef]

- Suherman, H.; Sahari, J.; Sulong, A.B. Effect of small-sized conductive filler on the properties of an epoxy composite for a bipolar plate in a PEMFC. Ceram. Int. 2013, 39, 7159–7166. [Google Scholar] [CrossRef]

- Afiqah, N.; Radzuan, M.; Sulong, A.B.; Irwan, M.; Firdaus, M.; Husaini, T.; Majlan, E.H. Fabrication of multi-filler MCF/MWCNT/SG-based bipolar plates. Ceram. Int. 2019, 45, 7413–7418. [Google Scholar]

- Soleimani, M.; Hasan, A.; Ahmad, K.; Golikand, N.; Shariati, S. Synthesis and characterization of epoxy/graphite/nano - copper nanocomposite for the fabrication of bipolar plate for PEMFCs. J. Nanostructure Chem. 2019, 9, 11–18. [Google Scholar] [CrossRef]

- Taherian, R.; Ghorbani, M.M. Investigation of the Electrical Properties of Polymer/Carbon Composites Exposed to Joule Heating and Heat Treatment. ECS J. Solid State Sci. Technol. 2017, 6, M3019–M3027. [Google Scholar] [CrossRef]

- Radzuan, N.A.M.N.A.M.; Sulong, A.B.A.B.; Somalu, M.R.M.R.; Majlan, E.H.; Husaini, T.; Rosli, M.I. Effects of Die Configuration on the Electrical Conductivity of Polypropylene Reinforced Milled Carbon Fibers: An Application on a Bipolar Plate. Polymers 2018, 10, 558. [Google Scholar] [CrossRef] [PubMed]

- Zare, Y.; Rhee, K.Y. Simplification and development of McLachlan model for electrical conductivity of polymer carbon nanotubes nanocomposites assuming the networking of interphase regions. Compos. Part B 2019, 156, 64–71. [Google Scholar] [CrossRef]

- Radzuan, N.A.M.; Sulong, A.B.; Rao Somalu, M. Electrical properties of extruded milled carbon fibre and polypropylene. J. Compos. Mater. 2017, 51, 3187–3195. [Google Scholar] [CrossRef]

- Taufiq, M.J.; Mansor, M.R.; Mustafa, Z. Characterisation of wood plastic composite manufactured from kenaf fibre reinforced recycled-unused plastic blend. Compos. Struct. 2018, 189, 510–515. [Google Scholar] [CrossRef]

- Wang, J.; Geng, C.; Luo, F.; Liu, Y.; Wang, K.; Fu, Q.; He, B. Shear induced fiber orientation, fiber breakage and matrix molecular orientation in long glass fiber reinforced polypropylene composites. Mater. Sci. Eng. A 2011, 528, 3169–3176. [Google Scholar] [CrossRef]

- Mishra, S.; Katti, P.; Kumar, S.; Bose, S. Macroporous epoxy-carbon fiber structures with a sacrificial 3D printed polymeric mesh suppresses electromagnetic radiation. Chem. Eng. J. 2018, 357, 384–394. [Google Scholar] [CrossRef]

- Iwashita, N. X-ray Powder Diffraction; Tsinghua University Press Limited: Beijing, China, 2016; ISBN 9780128052563. [Google Scholar]

- Inagaki, M.; Kang, F.; Toyoda, M.; Konn, H. Chapter 5—Stress Graphitization. In Advanced Materials Science and Engineering of Carbon; Elsevier: Amsterdam, The Netherlands, 2014; Volume 5, pp. 87–110. [Google Scholar]

- Yi, P.; Zhang, D.; Peng, L.; Lai, X. Impact of Film Thickness on Defects and the Graphitization of Nanothin Carbon Coatings Used for Metallic Bipolar Plates in Proton Exchange Membrane Fuel Cells. ACS Appl. Mater. Interfaces 2018, 10, 34561–34572. [Google Scholar] [CrossRef] [PubMed]

- Ting, Z.; Lehua, Q.; Shaolin, L.; Wenlong, T.; Jiming, Z. Evaluation of the effect of PyC coating thickness on the mechanical properties of T700 carbon fiber tows. Appl. Surf. Sci. 2018. [Google Scholar] [CrossRef]

- Hao, A.; Zhao, H.; Chen, J.Y. Kenaf/polypropylene nonwoven composites: The influence of manufacturing conditions on mechanical, thermal, and acoustical performance. Compos. Part B Eng. 2013, 54, 44–51. [Google Scholar] [CrossRef]

- Murr, L.E.; Martinez, E.; Gaytan, S.M.; Ramirez, D.A.; MacHado, B.I.; Shindo, P.W.; Martinez, J.L.; Medina, F.; Wooten, J.; Ciscel, D.; et al. Microstructural architecture, microstructures, and mechanical properties for a nickel-base superalloy fabricated by electron beam melting. Metall. Mater. Trans. A Phys. Metall. Mater. Sci. 2011, 42, 3491–3508. [Google Scholar] [CrossRef]

- Qu, M.; Schubert, D.W. Conductivity of melt spun PMMA composites with aligned carbon fibers. Compos. Sci. Technol. 2016, 136, 111–118. [Google Scholar] [CrossRef]

- Hietala, M.; Oksman, K. Pelletized cellulose fibres used in twin-screw extrusion for biocomposite manufacturing: Fibre breakage and dispersion. Compos. Part A Appl. Sci. Manuf. 2018, 109, 538–545. [Google Scholar] [CrossRef]

- Di Giuseppe, E.; Castellani, R.; Budtova, T.; Vergnes, B. Lignocellulosic fiber breakage in a molten polymer. Part 2. Quantitative analysis of the breakage mechanisms during compounding. Compos. Part A Appl. Sci. Manuf. 2017, 95, 31–39. [Google Scholar] [CrossRef]

- Adebayo, A.R. Journal of Petroleum Science and Engineering Measurements of capillary pressure and relative permeability curves for foam transport in porous media-A capillary bundle approach. J. Pet. Sci. Eng. 2019, 172, 1048–1056. [Google Scholar] [CrossRef]

- Huang, Z.; Gao, M.; Yan, Z.; Pan, T.; Ahmed, S.; Zhang, Y.; Zhang, H.; Lin, Y. Sensors and Actuators A: Physical Pyramid microstructure with single walled carbon nanotubes for flexible and transparent micro-pressure sensor with ultra-high sensitivity. Sensors Actuators A Phys. 2017, 266, 345–351. [Google Scholar] [CrossRef]

- Heo, S.I.; Yun, J.C.; Oh, K.S.; Han, K.S. Influence of particle size and shape on electrical and mechanical properties of graphite reinforced conductive polymer composites for the bipolar plate of PEM fuel cells. Adv. Compos. Mater. Off. J. Japan Soc. Compos. Mater. 2006, 15, 115–126. [Google Scholar] [CrossRef]

- Akhtar, M.N.; Sulong, A.B.; Umer, A.; Yousaf, A.B.; Khan, M.A. Multi-component MWCNT/NG/EP-based bipolar plates with enhanced mechanical and electrical characteristics fabricated by compression moulding. Ceram. Int. 2018, 44, 14457–14464. [Google Scholar] [CrossRef]

- Zhao, X.; Yang, X.; Li, Q.; He, J.; Hu, J. Synergistic effect of ZnO microspherical varistors and carbon fibers on nonlinear conductivity and mechanical properties of the silicone rubber-based material. Compos. Sci. Technol. 2017, 150, 187–193. [Google Scholar] [CrossRef]

- Chung, D.D.L.; Eddib, A.A. Effect of fiber lay-up configuration on the electromagnetic interference shielding effectiveness of continuous carbon fiber polymer-matrix composite. Carbon N. Y. 2018, 141, 685–691. [Google Scholar] [CrossRef]

- Froning, D.; Yu, J.; Reimer, U.; Lehnert, W. Stochastic Analysis of the Gas Flow at the Gas Diffusion Layer/Electrode Interface of a High-Temperature Polymer Electrolyte Fuel Cell. Transp. Porous Media 2018, 123, 403–420. [Google Scholar] [CrossRef]

- Hu, N.; Masuda, Z.; Yamamoto, G.; Fukunaga, H.; Hashida, T.; Qiu, J. Effect of fabrication process on electrical properties of polymer/multi-wall carbon nanotube nanocomposites. Compos. Part A Appl. Sci. Manuf. 2008, 39, 893–903. [Google Scholar] [CrossRef]

- Alavudeen, a.; Rajini, N.; Karthikeyan, S.; Thiruchitrambalam, M.; Venkateshwaren, N. Mechanical properties of banana/kenaf fiber-reinforced hybrid polyester composites: Effect of woven fabric and random orientation. Mater. Des. 2015, 66, 246–257. [Google Scholar] [CrossRef]

- Ma, P.; Liu, M.; Zhang, H.; Wang, S.; Wang, R.; Wang, K.; Wong, Y.; Tang, B.; Hong, S.; Paik, K.; et al. Enhanced Electrical Conductivity of Nanocomposites Containing Hybrid Fillers of Carbon Nanotubes and Carbon Black. ACS Appl. Mater. Interfaces 2009, 1, 1090–1096. [Google Scholar] [CrossRef] [PubMed]

- Qu, M.; Nilsson, F.; Qin, Y.; Yang, G.; Pan, Y.; Liu, X.; Hernandez Rodriguez, G.; Chen, J.; Zhang, C.; Schubert, D.W. Electrical conductivity and mechanical properties of melt-spun ternary composites comprising PMMA, carbon fibers and carbon black. Compos. Sci. Technol. 2017, 150, 24–31. [Google Scholar] [CrossRef]

- Lux, F. Models proposed to explain the electrical conductivity of mixtures made of conductive and insulating materials. J. Mater. Sci. 1993, 28, 285–301. [Google Scholar] [CrossRef]

| Sample | Preheat time (minutes) | Compress time (minutes) | Pressure (MPa) |

|---|---|---|---|

| S1 | 0 | 10 | 3 |

| S2 | 0 | 15 | 5 |

| S3 | 0 | 20 | 7 |

| S4 | 5 | 10 | 5 |

| S5 | 5 | 15 | 7 |

| S6 | 5 | 20 | 3 |

| S7 | 10 | 10 | 7 |

| S8 | 10 | 15 | 3 |

| S9 | 10 | 20 | 5 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mohd Radzuan, N.A.; Sulong, A.B.; Hui, D.; Verma, A. Electrical Conductivity Performance of Predicted Modified Fibre Contact Model for Multi-Filler Polymer Composite. Polymers 2019, 11, 1425. https://doi.org/10.3390/polym11091425

Mohd Radzuan NA, Sulong AB, Hui D, Verma A. Electrical Conductivity Performance of Predicted Modified Fibre Contact Model for Multi-Filler Polymer Composite. Polymers. 2019; 11(9):1425. https://doi.org/10.3390/polym11091425

Chicago/Turabian StyleMohd Radzuan, Nabilah Afiqah, Abu Bakar Sulong, David Hui, and Anil Verma. 2019. "Electrical Conductivity Performance of Predicted Modified Fibre Contact Model for Multi-Filler Polymer Composite" Polymers 11, no. 9: 1425. https://doi.org/10.3390/polym11091425