Discrimination of Aroma Characteristics for Cubeb Berries by Sensomics Approach with Chemometrics

Abstract

:1. Introduction

2. Results and Discussion

2.1. Optimization of SPME

2.2. Identification of Aroma Compounds

2.3. Aroma-Active Compounds by GC-MS-O

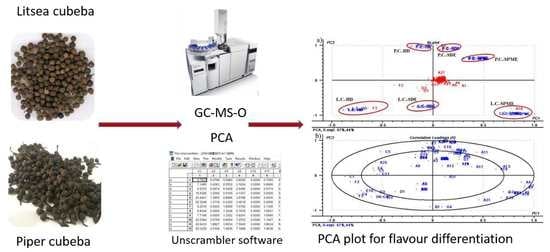

2.4. Principal Component Analysis (PCA)

3. Materials and Methods

3.1. Materials and Chemicals

3.2. Hydro-Distillation (HD)

3.3. Simultaneous Distillation Extraction (SDE)

3.4. Optimization of SPME Conditions

3.5. Analysis of Volatiles by GC-MS

3.6. GC-MS-Olfactometry

3.7. Statistical Data Analysis

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Li, Y.J.; Kong, W.J.; Li, M.H.; Liu, H.M.; Zhao, X.; Yang, S.H.; Yang, M.H. Litsea cubeba essential oil as the potential natural fumigant: Inhibition of aspergillus flavus and afb1 production in licorice. Ind. Crops Prod. 2016, 80, 186–193. [Google Scholar] [CrossRef]

- Liao, P.C.; Yang, T.S.; Chou, J.C.; Chen, J.; Lee, S.H.; Kuo, Y.H.; Ho, C.L.; Chao, L.K.P. Anti-inflammatory activity of neral and geranial isolated from fruits of Litsea cubeba Lour. J. Funct. Foods 2015, 19, 248–258. [Google Scholar] [CrossRef]

- Costa, R.; Salvo, A.; Rotondo, A.; Bartolomeo, G.; Pellizzeri, V.; Saija, Z. Combination of separation and spectroscopic analytical techniques: Application to compositional analysis of a minor citrus species. Nat. Prod. Res. 2018, 1–7. [Google Scholar] [CrossRef] [PubMed]

- Salvo, A.; Bruno, M.; La Torre, G.L.; Vadala, R.; Mottese, A. Interdonato lemon from Nizza di Sicilia (Italy): Chemical composition of hexane extract of lemon peel and histochemical investigation. Nat. Prod. Res. 2016, 30, 1517–1525. [Google Scholar] [CrossRef] [PubMed]

- Niwa, A.M.; Marcarini, J.C.; Sartori, D.; Maistro, E.; Mantorani, M.S. Effects of (−)-cubebin (Piper cubeba) on cytotoxicity, mutagenicity and expression of p38 MAP kinase and GSTa2 in a hepatoma cell line. J. Food Compos. Anal. 2013, 30, 1–5. [Google Scholar] [CrossRef]

- Perazzo, F.F.; Rodrigues, I.V.; Maistro, E.L.; Souza, S.M.; Nanaykkara, N.P.D.; Bastos, J.K.; Carvalho, J.C.T.; De Souza, G.H.B. Anti-inflammatory and analgesic evaluation of hydroalcoholic extract and fractions from seeds of Piper cubeba L. (Piperaceae). Pharmacogn. J. 2013, 5, 13–16. [Google Scholar] [CrossRef]

- Kim, H.J.; Baek, W.S.; Jang, Y.P. Identification of ambiguous cubeb fruit by DART-MS-based fingerprinting combined with principal component analysis. Food Chem. 2011, 129, 1305–1310. [Google Scholar] [CrossRef] [PubMed]

- D’Acampora Zellner, B.; Dugo, P.; Dugo, G. Gas chromatography–olfactometry in food flavour analysis. J. Chromatogr. A 2008, 1186, 123–143. [Google Scholar] [CrossRef] [PubMed]

- Jerkovic, I.; Mastelic, J.; Marijanovic, Z.; Mondello, L. Comparison of hydrodistillation and ultrasonic solvent extraction for the isolation of volatile compounds from two unifloral honeys of Robinia pseudoacacia L. and Castanea sativa L. Ultrason. Sonochem. 2007, 14, 750–756. [Google Scholar] [CrossRef] [PubMed]

- Cheng, H.; Chen, J.; Li, X.; Pan, J.; Xue, S.J.; Liu, D.; Ye, X. Differentiation of the volatile profiles of Chinese bayberry cultivars during storage by HS-SPME–GC/MS combined with principal component analysis. Postharvest Biol. Technol. 2015, 100, 59–72. [Google Scholar] [CrossRef]

- Majcher, M.; Jeleń, H.H. Comparison of suitability of SPME, SAFE and SDE methods for isolation of flavor compounds from extruded potato snacks. J. Food Compos. Anal. 2009, 22, 606–612. [Google Scholar] [CrossRef]

- Ning, L.; Fu-Ping, Z.; Hai-Tao, C.; Si, Y.L.; Chen, G.; Zhen, Y.S.; Bao, G.S. Identification of volatile components in Chinese Sinkiang fermented camel milk using SAFE, SDE, and HS-SPME-GC/MS. Food Chem. 2011, 129, 1242–1252. [Google Scholar] [CrossRef] [PubMed]

- Du, L.; Li, J.; Li, W.; Li, Y.; Li, T. Characterization of volatile compounds of pu-erh tea using solid-phase microextraction and simultaneous distillation–extraction coupled with gas chromatography–mass spectrometry. Food Res. Int. 2014, 57, 61–70. [Google Scholar] [CrossRef]

- Watkins, P.J.; Rose, G.; Warner, R.D.; Dunshea, F.R.; Pethick, D.W. A comparison of solid-phase microextraction (SPME) with simultaneous distillation–extraction (SDE) for the analysis of volatile compounds in heated beef and sheep fats. Meat Sci. 2012, 91, 99–107. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Selli, S.; Kelebek, H.; Ayseli, M.T.; Tokbas, H. Characterization of the most aroma-active compounds in cherry tomato by application of the aroma extract dilution analysis. Food Chem. 2014, 165, 540–546. [Google Scholar] [CrossRef] [PubMed]

- Pino, J.A. Odour-active compounds in papaya fruit cv. Red Maradol. Food Chem. 2014, 146, 120–126. [Google Scholar] [CrossRef] [PubMed]

- Kang, W.; Li, Y.; Xu, Y.; Jiang, W.; Tao, Y. Characterization of aroma compounds in Chinese bayberry (Myrica rubra Sieb. et Zucc.) by Gas Chromatography Mass Spectrometry (GC-MS) and Olfactometry (GC-O). J. Food Sci. 2012, 77, C1030–C1035. [Google Scholar] [CrossRef] [PubMed]

- Pang, X.; Guo, X.; Qin, Z.; Yao, Y.; Hu, X.; Wu, J. Identification of Aroma-Active compounds in Jiashi Muskmelon Juice by GC-O-MS and OAV Calculation. J. Agric. Food Chem. 2012, 60, 4179–4185. [Google Scholar] [CrossRef] [PubMed]

- Cheng, H.; Chen, J.; Chen, S.; Wu, D.; Liu, D.; Ye, X. Characterization of aroma-active volatiles in three Chinese bayberry (Myrica rubra) cultivars using GC–MS–olfactometry and an electronic nose combined with principal component analysis. Food Res. Int. 2015, 72, 8–15. [Google Scholar] [CrossRef]

- Wang, H.; Liu, Y. Chemical Composition and antibacterial activity of essential oils from different parts of Litsea cubeba. Chem. Biodivers. 2010, 7, 229–235. [Google Scholar] [CrossRef] [PubMed]

- Wang, F.; Chang, Z.; Duan, P.; Xu, Y.; Zhang, L.; Miao, J.; Fan, Y. Hydrothermal liquefaction of Litsea cubeba seed to produce bio-oils. Bioresour. Technol. 2013, 149, 509–515. [Google Scholar] [CrossRef] [PubMed]

- Díaz-Maroto, M.C.; Pérez-Coello, M.S.; Cabezudo, M.D. Effect of drying method on the volatiles in bay leaf (Laurus nobilis L.). J. Agric. Food Chem. 2002, 50, 4520–4524. [Google Scholar] [CrossRef] [PubMed]

- Barra, A.; Baldovini, N.; Loiseau, A.M.; Albino, L.; Lesecq, C.; Cuvelier, L.L. Chemical analysis of French beans (Phaseolus vulgaris L.) by headspace solid phase microextraction (HS-SPME) and simultaneous distillation/extraction (SDE). Food Chem. 2007, 101, 1279–1284. [Google Scholar] [CrossRef]

- Boschfuste, J.; Riuaumatell, M.; Guadayol, J.; Caixach, J.; López-Tamames, E.; Buxaderas, S. Volatile profiles of sparkling wines obtained by three extraction methods and gas chromatography–mass spectrometry (GC–MS) analysis. Food Chem. 2007, 105, 428–435. [Google Scholar] [CrossRef]

- Yi, Z.; Feng, T.; Zhuang, H.; Ye, R.; Li, M.; Liu, T. Comparison of different extraction methods in the analysis of volatile compounds in pomegranate juice. Food Anal. Methods 2016, 9, 2364–2373. [Google Scholar] [CrossRef]

- Kraujalytė, V.; Leitner, E.; Venskutonis, P.R. Characterization ofAronia melanocarpa Volatiles by Headspace-Solid-Phase Microextraction (HS-SPME), Simultaneous Distillation/Extraction (SDE), and Gas Chromatography-Olfactometry (GC-O) Methods. J. Agric. Food Chem. 2013, 61, 4728–4736. [Google Scholar] [CrossRef] [PubMed]

- Du, X.; Finn, C.E.; Qian, M.C. Volatile composition and odour-activity value of thornless ‘Black Diamond’ and ‘Marion’ blackberries. Food Chem. 2010, 119, 1127–1134. [Google Scholar] [CrossRef]

- Du, X.; Plotto, A.; Baldwin, E. Evaluation of volatiles from two subtropical strawberry cultivars using GC–Olfactometry, GC-MS Odor activity values, and sensory analysis. J. Agric. Food Chem. 2011, 59, 12569–12577. [Google Scholar] [CrossRef] [PubMed]

- Plotto, A.; Margaría, C.A.; Goodner, K.L.; Baldwin, E.A. Odour and flavour thresholds for key aroma components in an orange juice matrix: Esters and miscellaneous compounds. Flavour Fragr. J. 2008, 23, 398–406. [Google Scholar] [CrossRef]

- Hempfling, K.; Fastowski, O.; Kopp, M.; Pour Nikfardjam, M.; Engel, K.H. Analysis and sensory evaluation of gooseberry (Ribes uva crispa L.) volatiles. J. Agric. Food Chem. 2013, 61, 6240–6249. [Google Scholar] [CrossRef] [PubMed]

- Lee, S.; Ahn, B. Comparison of volatile components in fermented soybean pastes using simultaneous distillation and extraction (SDE) with sensory characterisation. Food Chem. 2009, 114, 600–609. [Google Scholar] [CrossRef]

- Zhang, Z.; Zeng, D.; Li, G. Study of the volatile profile characteristics of longan during storage by a combination sampling method coupled with GC/MS. J. Sci. Food Agric. 2008, 88, 1035–1042. [Google Scholar] [CrossRef]

- Ceva-Antunes, P.M.N.; Bizzo, H.R.; Alves, S.M.; Alves, S.M.; Antunes, O.A.C. Analysis of volatile Compounds of Taperebá (Spondias mombin L.) and Cajá (Spondias mombin L.) by Simultaneous Distillation and Extraction (SDE) and Solid Phase Microextraction (SPME). J. Agric. Food Chem. 2003, 51, 1387–1392. [Google Scholar] [CrossRef] [PubMed]

- Molyneux, R.J.; Schieberle, P. Compound Identification: A journal of agricultural and food chemistry perspective. J. Agric. Food Chem. 2007, 55, 4625–4629. [Google Scholar] [CrossRef] [PubMed]

- Cheng, H.; Chen, J.; Chen, S.; Xia, Q.; Liu, D.; Ye, X. Sensory evaluation, physicochemical properties and aroma-active profiles in a diverse collection of Chinese bayberry (Myrica rubra) cultivars. Food Chem. 2016, 212, 374–385. [Google Scholar] [CrossRef] [PubMed]

Sample Availability: Samples of the compounds are not available from the authors. |

| Codes | RI 1 | Volatile Compounds | Chemical Formula | Concentration for Litsea cubeba (%) 2 | Concentration for Piper cubeba (%) | ||||

|---|---|---|---|---|---|---|---|---|---|

| HD 3 | SDE 3 | SPME 3 | HD 3 | SDE 3 | SPME 3 | ||||

| Terpenes | |||||||||

| A1 | 925 | α-Pinene | C10H16 | nd 4 | 1.44 ± 0.01 | 10.81 ± 0.36 | 0.09 ± 0.01 | 1.06 ± 0.02 | 5.74 ± 0.11 |

| A2 | 944 | Camphene | C10H16 | nd | 0.52 ± 0 | 3.37 ± 0.16 | 0.07 ± 0 | 0.47 ± 0.01 | 2.09 ± 0.03 |

| A3 | 971 | β-Phellandrene | C10H16 | nd | 0.3 ± 0 | nd | 0.11 ± 0 | 0.93 ± 0.02 | nd |

| A4 | 973 | β-Pinene | C10H16 | nd | 1.22 ± 0.01 | 7.33 ± 0.13 | 0.21 ± 0.01 | 1.02 ± 0.01 | 6.22 ± 0.11 |

| A5 | 991 | β-Myrcene | C10H16 | nd | 1.45 ± 0.02 | 6.99 ± 0.42 | 0.16 ± 0.03 | 0.45 ± 0.01 | 1.97 ± 0.04 |

| A6 | 1002 | α-Phellandrene | C10H16 | nd | nd | 0.13 ± 0.07 | 0.46 ± 0.01 | 1.75 ± 0.02 | 4.55 ± 0.07 |

| A7 | 1008 | 3-Carene | C10H16 | nd | 0.23 ± 0 | nd | nd | 0.08 ± 0 | nd |

| A8 | 1015 | 2-Carene | C10H16 | nd | 0.11 ± 0 | nd | 0.07 ± 0 | 0.09 ± 0 | nd |

| A9 | 1023 | Cymene | C10H16 | nd | 0.14 ± 0 | nd | 0.24 ± 0.02 | 0.39 ± 0.01 | 0.7 ± 0.02 |

| A10 | 1027 | d-Limonene | C10H16 | nd | 10.57 ± 0.09 | 38.89 ± 1.67 | nd | 1.9 ± 0.03 | 9.84 ± 0.09 |

| A11 | 1038 | trans-.beta.-Ocimene | C10H16 | nd | nd | 0.16 ± 0.02 | 0.16 ± 0 | 0.41 ± 0.01 | 0.64 ± 0.02 |

| A12 | 1048 | β-Ocimene | C10H16 | nd | 4.62 ± 0.04 | 0.1 ± 0.01 | 1 ± 0.03 | 2.5 ± 0.01 | 5.35 ± 0.04 |

| A13 | 1057 | γ-Terpinene | C10H16 | 0.12 ± 0.02 | 0.25 ± 0 | 0.26 ± 0.01 | 0.17 ± 0.01 | 0.29 ± 0.01 | 0.39 ± 0.01 |

| A14 | 1070 | 4-Carene | C10H16 | nd | nd | nd | 0.15±0.01 | nd | nd |

| A15 | 1087 | Terpinolene | C10H16 | nd | nd | nd | nd | 0.27 ± 0.01 | 0.63 ± 0.01 |

| A16 | 1130 | 2,4,6-Octatriene, 2,6-dimethyl- | C10H16 | nd | nd | nd | nd | nd | 0.5 ± 0.02 |

| A17 | 1255 | 3-Carene | C10H16 | nd | nd | 0.14 ± 0.01 | nd | nd | 0.79 ± 0.03 |

| A18 | 1349 | α-Cubebene | C15H24 | nd | nd | nd | 0.4 ± 0.01 | 0.43 ± 0.02 | 0.52 ± 0.02 |

| A19 | 1375 | α-Copaene | C15H24 | 0.13 ± 0.01 | 1.07 ± 0.12 | 1.09 ± 0.65 | 0.75 ± 0.01 | 1.15 ± 0.02 | 0.95 ± 0.02 |

| A20 | 1385 | (+)-3-Carene | C10H16 | nd | nd | nd | nd | nd | 0.33 ± 0.02 |

| A21 | 1389 | Bicyclosesquiphellandrene | C15H24 | nd | nd | nd | nd | 0.4 ± 0.01 | nd |

| A22 | 1392 | β-Elemene | C15H24 | nd | nd | 1.16 ± 0.13 | nd | nd | nd |

| A23 | 1419 | β-Caryophyllene | C15H24 | 5.53 ± 0.23 | 6.41 ± 0.06 | 9.11 ± 0.37 | 5.84 ± 0.06 | 5.58 ± 0.02 | 5.57 ± 0.1 |

| A24 | 1438 | α-Guaiene | C15H24 | nd | nd | nd | nd | nd | 0.16 ± 0.01 |

| A25 | 1453 | Humulene | C15H24 | 3.04 ± 0.98 | 0.77 ± 0.01 | 0.88 ± 0.06 | 4.33 ± 0.68 | 1.76 ± 0.01 | 1.43 ± 0.03 |

| A26 | 1481 | β-Copaene | C15H24 | nd | nd | nd | 0.08 ± 0 | 2.74 ± 0.01 | nd |

| A27 | 1497 | Bicyclogermacrene | C15H24 | nd | nd | nd | 4.15 ± 0.04 | 5.28 ± 0.07 | 2.41 ± 0.07 |

| A28 | 1500 | α-Muurolene | C15H24 | nd | nd | nd | nd | 0.22 ± 0.01 | 0.13 ± 0.01 |

| A29 | 1506 | Cedrene | C15H24 | nd | nd | nd | nd | nd | 0.1 ± 0 |

| A30 | 1509 | α-Farnesene | C15H24 | nd | nd | nd | 0.13 ± 0 | 0.16 ± 0.01 | 0.16 ± 0.01 |

| A31 | 1516 | α-selinene | C15H24 | nd | 0.11 ± 0 | 0.11 ± 0.01 | nd | nd | nd |

| A32 | 1575 | γ-Muurolene | C15H24 | nd | nd | nd | nd | 1.09 ± 0.03 | nd |

| A33 | 1582 | Alloaromadendrene | C15H24 | nd | nd | 0.03 ± 0 | 0.08 ± 0.03 | 0.65 ± 0.07 | 0.51 ± 0.12 |

| A34 | 1644 | copaene | C15H24 | nd | nd | nd | 0.06 ± 0.01 | 0.12 ± 0 | nd |

| A35 | 1652 | β-Panasinsene | C15H24 | nd | 0.14 ± 0 | nd | nd | nd | nd |

| A36 | 1722 | β-Bisabolene | C15H24 | nd | nd | 0.05 ± 0.01 | nd | 4.13 ± 0.04 | nd |

| A37 | 1849 | β-Farnesene | C15H24 | nd | 0.55 ± 0.02 | 0.04 ± 0.01 | nd | 0.04 ± 0 | 0.59 ± 0.07 |

| Ketones | |||||||||

| B1 | 987 | 6-Methyl-5-hepten-2-one | C8H14O | 1.2 ± 0.13 | 2.01 ± 0.02 | 1.55 ± 0.08 | 0.39 ± 0.04 | 0.33 ± 0.01 | 0.13 ± 0.01 |

| B2 | 1145 | Camphor | C10H16O | 0.28 ± 0.03 | 0.22 ± 0.01 | 0.23 ± 0.09 | 20.6 ± 0.3 | 17.59 ± 0.4 | 18.03 ± 0.67 |

| B3 | 1183 | Pulegone | C10H16O | nd | 1 ± 0.01 | nd | nd | nd | nd |

| B4 | 1823 | Isoshyobunone | C15H24O | nd | nd | nd | nd | 0.04 ± 0.01 | nd |

| Alcohols | |||||||||

| C1 | 1029 | Eucalyptol | C10H18O | 1.43 ± 0.15 | 2.99 ± 0.03 | nd | 2.17 ± 0.02 | 2.53 ± 0.02 | nd |

| C2 | 1100 | Linalool | C10H18O | 3.74 ± 0.37 | nd | 3.17 ± 0.04 | 21.31 ± 0.28 | 18.57 ± 0.18 | 14.89 ± 0.17 |

| C3 | 1107 | 1,5,7-Octatrien-3-ol, 3,7-dimethyl | C10H16O | nd | nd | nd | nd | 0.21 ± 0.01 | nd |

| C4 | 1143 | Isopulegol | C10H18O | 0.1 ± 0.01 | 0.11 ± 0.01 | nd | 0.04 ± 0 | nd | nd |

| C5 | 1164 | endo-Borneol | C10H18O | 0.3±0.03 | 0.33±0.01 | 0.07 ± 0 | 0.6 ± 0.01 | 0.54 ± 0.01 | 0.24 ±0.14 |

| C6 | 1165 | Verbenol | C10H16O | nd | 0.86 ± 0.01 | nd | nd | 0.29 ± 0.01 | nd |

| C7 | 1190 | Terpinen-4-ol | C10H18O | 2.98 ± 0.12 | 3.19 ± 0.02 | 0.79 ± 0.05 | 2.64 ± 0.05 | 2.64 ± 0.02 | 1.14 ± 0.02 |

| C8 | 1218 | Carveol | C10H16O | nd | 0.3 ± 0.03 | nd | nd | nd | nd |

| C9 | 1228 | 2,6-Octadien-1-ol, 3,7-dimethyl- | C10H18O | 0.63 ± 0.06 | 1.12 ± 0.06 | nd | nd | nd | nd |

| C10 | 1229 | Citronellol | C10H20O | nd | nd | nd | 0.41 ± 0.1 | 1.12 ± 0.02 | 0.4 ± 0.02 |

| C11 | 1256 | Geraniol | C10H18O | 0.99 ± 0.06 | 1.66 ± 0.05 | nd | 0.71 ± 0.01 | 1.76 ± 0.57 | nd |

| C12 | 1610 | .tau.-Cadinol | C15H26O | nd | nd | nd | 0.49 ± 0.05 | nd | nd |

| C13 | 1640 | Muurolol | C15H26O | nd | nd | nd | nd | 0.71 ± 0.01 | nd |

| C14 | 1648 | α-Cadinol | C15H26O | nd | nd | nd | 0.6 ± 0.03 | nd | nd |

| C15 | 1655 | Nerolidol | C15H26O | nd | nd | 0.14 ± 0.02 | nd | nd | nd |

| Aldehydes | |||||||||

| D1 | 1154 | Citronellal | C10H18O | 0.48 ± 0.06 | 0.62 ± 0.01 | 0.21 ± 0.01 | nd | 0.46 ± 0.01 | 0.29 ± 0.01 |

| D2 | 1241 | 2,6-Octadienal, 3,7-dimethyl-, (Z) | C10H16O | 6.09 ± 0.54 | 11.32 ± 0.13 | 0.72 ± 0.04 | 0.52 ± 0.04 | nd | 1.1 ± 0.03 |

| D3 | 1272 | Citral | C10H16O | 7.96 ± 0.72 | 11.85 ± 0.12 | 1.09 ± 0.03 | 0.62 ± 0.02 | 5.77 ± 0.03 | 1.74 ± 0.04 |

| D4 | 1740 | 2,6,10-Dodecatrienal, 3,7,11-trimethyl- | C15H24O | nd | nd | nd | 0.58 ± 0.02 | 0.2 ± 0.01 | nd |

| Esters | |||||||||

| E1 | 1193 | Methyl salicylate | C8H8O3 | nd | nd | 0.04±0.01 | nd | nd | nd |

| E2 | 1213 | Acetic acid, octyl ester | C10H20O2 | nd | nd | nd | 0.12 ± 0.01 | 0.17 ± 0.01 | 0.17 ± 0.01 |

| E3 | 1285 | Bornyl acetate | C12H20O2 | nd | nd | nd | 0.63 ± 0.1 | 0.52 ± 0.01 | 0.55 ± 0.01 |

| E4 | 1297 | Decanoic acid, methyl ester | C11H22O2 | 0.34 ± 0.02 | nd | nd | 0.55 ± 0.03 | nd | nd |

| E5 | 1324 | 2,6-Octadienoic acid, 3,7-dimethyl-, methyl ester | C11H18O2 | nd | nd | nd | nd | 0.17 ± 0.01 | 0.11 ± 0.01 |

| E6 | 1370 | 2,6-Octadien-1-ol, 3,7-dimethyl-acetate, (Z)- | C12H20O2 | nd | nd | nd | 0.07 ± 0 | nd | nd |

| E7 | 1381 | 2-Propenoic acid, 3-phenyl-, methyl ester | C10H10O2 | nd | nd | nd | 0.42 ± 0.01 | 0.33 ± 0 | 0.14 ± 0.01 |

| E8 | 1385 | lavandulyl acetate | C12H20O2 | nd | nd | nd | nd | 0.64 ± 0.01 | nd |

| E9 | 1387 | Geranyl acetate | C12H20O2 | nd | nd | nd | 0.78 ± 0.02 | nd | nd |

| E10 | 1661 | Dodecanoic acid, methyl ester | C12H26O2 | 0.71 ± 0.05 | nd | nd | nd | nd | nd |

| Acids | |||||||||

| F1 | 1360 | Geranic acid | C10H16O2 | nd | nd | 0.17 ± 0.02 | nd | nd | nd |

| F2 | 1391 | n-Decanoic acid | C10H20O2 | 15.64 ± 1.51 | 9.29 ± 0.45 | 0.34 ± 0.02 | 14.85 ± 0.6 | nd | nd |

| F3 | 1582 | Dodecanoic acid | C12H24O2 | 32.9 ± 0.6 | 13.27 ± 0.36 | 1.89 ± 1.03 | 3.85 ± 0.31 | nd | nd |

| Others | |||||||||

| G1 | 1053 | Cyclopentene, 1-methyl- | C6H10 | nd | 0.13 ± 0.01 | nd | nd | nd | nd |

| G2 | 1197 | Estragole | C10H12O | nd | nd | 0.04 ± 0.02 | nd | nd | nd |

| G3 | 1223 | Cyclohexene, 3,3,5-trimethyl- | C9H16 | nd | 0.73 ± 0.03 | nd | nd | nd | nd |

| G4 | 1285 | Anethole | C10H12O | 0.34 ± 0.03 | 0.77 ± 0.01 | 0.6 ± 0.02 | nd | nd | nd |

| G5 | 1287 | Safrole | C10H10O2 | nd | nd | nd | 0.1 ± 0.09 | 0.23 ± 0.01 | nd |

| G6 | 1326 | Eugenol | C10H12O2 | 0.12 ± 0.01 | 0.15 ± 0.07 | nd | nd | nd | nd |

| G7 | 1336 | 1,5,5-Trimethyl-6-methylene-cyclohexene | C10H16 | nd | nd | nd | nd | 0.51±0.06 | 2.04 ± 0.05 |

| G8 | 1354 | 2,6-Octadiene, 2,6-dimethyl- | C10H18 | nd | nd | nd | 0.38 ± 0 | 0.43 ± 0.03 | 0.32 ± 0.01 |

| G9 | 1392 | Cyclohexane, 1-ethenyl-1-methyl-2,4-bis(1-methylethenyl)- | C15H24 | nd | nd | nd | nd | 0.44 ± 0.01 | nd |

| G10 | 1405 | Methyleugenol | C11H14O2 | nd | nd | nd | 0.71 ± 0.03 | 0.11 ± 0 | nd |

| G11 | 1439 | Ethanone, 1-(2-hydroxy-4-methoxyphenyl)- | C9H10O3 | nd | nd | nd | nd | 0.17 ± 0.01 | nd |

| G12 | 1448 | trans-Isoeugenol | C10H12O2 | nd | nd | nd | nd | 0.23 ± 0.01 | 0.11 ± 0.01 |

| G13 | 1485 | Naphthalene, decahydro-4a-methyl-1-methylene-7-(1-methylethenyl)- | C15H24 | nd | nd | nd | 0.69 ± 0.01 | 0.79 ± 0.01 | nd |

| G14 | 1513 | Naphthalene, 1,2,4a,5,6,8a-hexahydro-4,7-dimethyl-1-(1-methylethyl)- | C15H24 | nd | nd | nd | 0.31 ± 0 | 0.3 ± 0 | 0.81 ± 0.03 |

| G15 | 1523 | Naphthalene, 1,2,3,5,6,8a-hexahydro-4,7-dimethyl-1-(1-methylethyl)- | C15H24 | nd | nd | nd | 1.59 ± 0.02 | 1.58 ± 0.01 | 0.06 ± 0.01 |

| G16 | 1652 | Naphthalene, 1,2,4a,5,6,8a-hexahydro-4,7-dimethyl-1-(1-methylethyl)- | C15H24 | nd | nd | nd | nd | 1.4 ± 0.01 | nd |

| G17 | 1669 | Caryophyllene oxide | C15H24O | 4.93 ± 0.27 | 0.25 ± 0.01 | 1.47 ± 0.09 | nd | nd | nd |

| Codes | Odor | DF a | |

|---|---|---|---|

| Litsea cubeba | Piper cubeba | ||

| A1 | pine, turpentine | 4 | 2 |

| A4 | pine, resin, turpentine | 4 | 6 |

| A6 | turpentine, mint, spice | 0 | 2 |

| A10 | lemon, citrus, mint | 6 | 6 |

| A12 | herb | 4 | 6 |

| A13 | turpentine | 4 | 4 |

| A18 | herb | 0 | 4 |

| A23 | wood, herb | 2 | 2 |

| B2 | camphor wood | 2 | 6 |

| C2 | flower, lavender | 2 | 8 |

| C8 | turpentine, nutmeg | 4 | 4 |

| D3 | lemon, fruit | 6 | 4 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cheng, H.; Chen, J.; Watkins, P.J.; Chen, S.; Wu, D.; Liu, D.; Ye, X. Discrimination of Aroma Characteristics for Cubeb Berries by Sensomics Approach with Chemometrics. Molecules 2018, 23, 1627. https://doi.org/10.3390/molecules23071627

Cheng H, Chen J, Watkins PJ, Chen S, Wu D, Liu D, Ye X. Discrimination of Aroma Characteristics for Cubeb Berries by Sensomics Approach with Chemometrics. Molecules. 2018; 23(7):1627. https://doi.org/10.3390/molecules23071627

Chicago/Turabian StyleCheng, Huan, Jianle Chen, Peter J. Watkins, Shiguo Chen, Dan Wu, Donghong Liu, and Xingqian Ye. 2018. "Discrimination of Aroma Characteristics for Cubeb Berries by Sensomics Approach with Chemometrics" Molecules 23, no. 7: 1627. https://doi.org/10.3390/molecules23071627