- 1Systems and Industrial Engineering Technology Research Center, Zhongyuan University of Technology, Zhengzhou, China

- 2Department of Management Science, College of Management, Shenzhen University, Shenzhen, China

The Industry 4.0 concept proposes that new cutting-edge technologies, such as the Internet of Things (IoT), will grow. The acceptance of IoT in the circular economy (CE) is still in its infancy, despite its enormous potential. In the face of growing environmental affairs, IoT based Industry 4.0 technologies are altering CE practices and existing business models, according to the World Economic Forum. This research investigates the function of IoT-based Industry 4.0 in circular CE practices, as well as their impact on economic and environmental performance, which in turn influences overall organizational performance. China-based enterprises provide information for the study, which includes data from 300 companies. Utilizing a structural equation modeling framework known as partial least squares structural equation modeling (PLS-SEM). The major findings are presented in the study: (I) the IoT significantly improves the activities of the CE; (II) the IoT significantly improves the practices of the CE; and (III) the IoT meaningfully advances the practices of CE (green manufacturing, circular design, remanufacturing, and recycling). Moreover, the findings shows that environmentally friendly business practices help enhance environmental performance of firm, while also stimulating their economic performance; and improved environmental performance has a significant positive influence on firm performance. This research lays the groundwork for contributing nations/companies to attain economic and long-term sustainability goals at the same time by incorporating IoT-based Industry 4.0 technology into CE practices.

Introduction

As the globe becomes more unstable, the markets face more difficulties on a daily basis. The stakeholders’ ability to effectively manage their business is hampered when there is a high degree of indecision in the industry. As a result, the significance of ethical business practices (EBP) has been highlighted (Keshri et al., 2020; Yu, 2022). The organization can grow with minimal risks if the kind of business is blatant and clear. IoT technologies and circular economy (CE) are also encouraging businesses to become more environmentally friendly and efficient (Mohammadzadeh et al., 2018). As a result, businesses are incorporating CE and IoT into their operations to support EBP.

There is a slew of recent reviews in the literature examining the role that digital technologies (DTs) play in advancing CE (Sattarian et al., 2019). Industry 4.0 technologies, such as cyber-physical structures, Internet of Things (IoT), radio-frequency identification (RFID), cloud manufacturing, and stabilizing manufacturing have all been examined in these studies as well as architectural layers involved in data gathering, integrating, and analyzing (Astill et al., 2019). This research has directed the growth of appropriate application settings for DTs in the context of CE’s lifecycle management, digital transformations, supply chain management, and so on (Aggarwal et al., 2021). To name just a few, there have been numerous studies into product-service structures that focus on things like intelligent ways of making and reusing products and services as well as how to keep them in good working order and how to recycle them.

The CE has received increasing attention recently from academics, stakeholders, policymakers, and so on; though the body of information on this matter is still in its infancy and even the literature does not have a complete definition for the CE (Lezoche et al., 2020). For the time being, the CE is most commonly defined as “a system restorative and regenerative by design” by the Ellen MacArthur Foundation, which purposes to maintain components, products, and materials at their maximum usefulness and value at all times (Kurniawan et al., 2021). Industrial environmentalism, blue economy, biomimicry, and Cradle-to-Cradle are just a few of the other fields of study that support the concept of CE (Müller et al., 2021). Contrary to the linear economy, which typically involves manufacturers using raw materials to make products, selling them to consumers, and then disposing of the waste, the CE takes a more circular approach. Through the use of multiple closed-loop cycles for product reuse, remanufacturing, and recycling, the CE aims at facilitating economic growth while minimizing negative impacts on the environment.

The CE’s theoretical foundations can now be applied more easily to real-world economic initiatives thanks to new technologies like the IoT (Liu and Zhang, 2020). Numerous studies have looked at the effects of IoT and digitalization on the development and implementation of CE in the last few years, with varying results. The Ellen MacArthur Foundation, which has made significant efforts to stimulate the CE, has just released two reports on the subject.

More than 14 trillion dollars will be generated by the IoT by 2024, according to the authors (Kawaguchi, 2019; Roy and Roy, 2019; Lezoche et al., 2020) who predicted that 34 billion devices would be fitted in several areas such as smart grid, city infrastructure, housing/home-based mechanization and carriage, industrial methods and healthcare (Zafari et al., 2019). The IoT provides devices with sensors that allow them to communicate and contribute to information set-ups (Yu et al., 2016). With IoT, even stand-alone products can be smart and linked, and materials can be tracked. IoT also helps collect and manage waste from end-of-life products (Ahamad et al., 2021). Reuse, remanufacturing, and recycling are all made possible as a result. Firms and organizations would be able to amass enormous amounts of facts in a brief period of time using this new technology. Because of its ability to track and monitor product activity, IoT is a valuable resource for manufacturers who can use it to improve technical support (Supardianto et al., 2019). The IoT has the capacity to improve renovation and end-of-life processes. It is critical for any business to keep tabs on the progress of its products, say (Pal and Yasar, 2020). Consequently, the IoT could be a valuable tool for companies to monitor their product’s status, usage, and position in real-time throughout their product lifecycle. As a result, manufacturing executives can learn more about how their customers use and implement their products, allowing for a more personal relationship. As a result, manufacturers and their customers will have more fruitful interactions.

The IoT can greatly benefit from integrating with other fields, such as computer engineering. Limited resources can be used for longer periods, assets can be used more effectively, and natural capital can be regenerated for consumption with greater effectiveness and efficiency when CE is implemented. It has also been found in the literature that the IoT is an excellent tool for promoting the use of circular plans and business models in businesses and organizations (Elavarasan et al., 2021). Using IoT to track a product’s status and condition, as well as how it is being used and where it is, is an effective way to implement a circular strategy based on increasing usage (Stich et al., 2020). In the economic cycle, the IoT can act as an assisting enabler by properly organizing previous knowledge about the circumstances, sites, functioning, and quality over time of assets. A number of CE innovators have found practical solutions to resource-related issues using this technology (Zhao et al., 2019). As an outcome, CE models may be useful in extracting value from the enormous amounts of data generated by the IoT. To put it simply, the IoT refers to a wide range of technologies that allow various devices to be connected and monitored via a network of data. Physical objects like actuators, smart machines, sensors, and tags can form an IoT network and communicate with each other in order to exchange data and generate new information that will increase the value of the network.

The IoT is built on three pillars: identification, communication, and interaction. When objects are able to sense and communicate with their surroundings, they aid in the understanding of the complexity and the appropriate response (Bhattarai and Kumar Jha, 2019). CE can benefit greatly from IoT, which is one of the most important factors. No matter how much progress is made in DTs, the current linear economy will never be able to address the critical problems with natural resources. Even when the economy is linked to DTS, it offers a podium for re-thinking its schemes and certifying CE. New business models will be able to be scaled more effectively if CE common codes are combined with IoT and cloud technologies.

An evaluation model for the impact of IoT on CE in order to achieve sustainable business practices has been developed in light of this. The seminal articles are used to identify and assess the concepts of sustainable business practices, CE, and IoT. IoT becomes increasingly important as the organization strives to be more environmentally friendly through its use of CE operations. In addition, the guiding principles of a company’s business operations have a substantial influence on the quality of its products and services (Khan et al., 2021a). In addition, a company’s functioning and practices reveal its principled side, which comprises employee involvement, environmental well-being, and customer satisfaction from their products or services (Hopkins, 2021). Thus, the work suggested a CE-IoT model that included elements from CE, and IoT. The model calculates the aspects that impact a company’s decision to adopt CE-IoT. In the above context, the research question is as follows: In a VUCA world, how can we model the adoption intention of CE-IoT in the food processing industry?

In order to find an answer, the variables were chosen from a preexisting literature review and statistically validated using the Churchill approach. In order to assess the food processing industry’s interest in implementing CE-IoT, several relevant factors were considered. The study is notable for a number of reasons. First and foremost, this is inventive work that pools various methods and endorses a placement framework that integrates CE, and IoT factors into a single platform. Herein lies the research’s greatest contribution. This study’s unique contribution is that all of the factors were classified using an Artificial Neural Network (ANN) to ensure its robustness as a mechanism for testing the CE-IoT. Third, the use of ANN-based cataloging in the food processing industry perspective advances the adoption of CE-IoT at the strategic level.

The following is a description of the paper’s organizational structure: section “Theoretical Frameworks and Hypothesis” discusses the theoretical framework as well as the development of hypotheses. Section “Research Methods and Data” discusses data sources as well as research methodologies. Section “Results Analysis and Findings” contains a description of the findings as well as a discussion. Section “Discussion” is comprised of conclusions and managerial ramifications of the findings.

Theoretical Frameworks and Hypothesis

Many people look at this topic from two different angles when debating the link between environmental stewardship and economic growth. The first step is the win-lose game, in which strategic options with environmental ambitions and real economic implications are weighed against one another. When all parties involved are satisfied, a win–win partnership is achieved. It is futile to assume a zero-sum game and neglect the opportunity to “grow the pie” for all contributors (Chen et al., 2020). Other actions may be more expensive and not be rewarded because of the current economic system, whereas certain environmental sustainability programs pay both participants.

Many investigators and experts from a wide range of disciplines have recently studied how businesses might incorporate environmental challenges into their operations by adopting frameworks such as ecological foot-printing, triple-bottom-line, business ecology, and life cycle management (Li et al., 2020). We may learn from these theoretical frameworks about how to combine ecological, financial, and social problems into our business strategies. They do not fundamentally replace each other, but rather explain various aspects of the same phenomenon. To describe stewardship of the social, economic, and environmental realms, a more comprehensive approach is needed. The study adheres to two consistent theoretical frameworks: ecological modernization theory (EMT) (Bag et al., 2021) and practice-based perspective theory (PBV) (Rejeb et al., 2020).

Economic expansion, according to the EMT, has led to environmental concerns, which can be alleviated by increasing resource efficiency through technological innovation, such as green supply chain techniques. It is in this context that environmental protection is no longer a “problem,” but rather an “opportunity,” which supports concepts like “ecologizing economy” (Tiwari and Khan, 2020) and “economizing ecology” (Pieroni et al., 2021). With this goal in mind, the Public Benefit Corporation teaches supply chain strategies that are environmentally friendly (Koistinen et al., 2022). Bag et al. (2021) popularized PBV, which is an extended form of the mainstream resource-based view theory (RBV) The adoption of “an established activity or collection of activities that other organizations may execute” (as defined by PBV) causes variances in enterprises’ performance, as explained by PBV (Ntsondé and Aggeri, 2021).

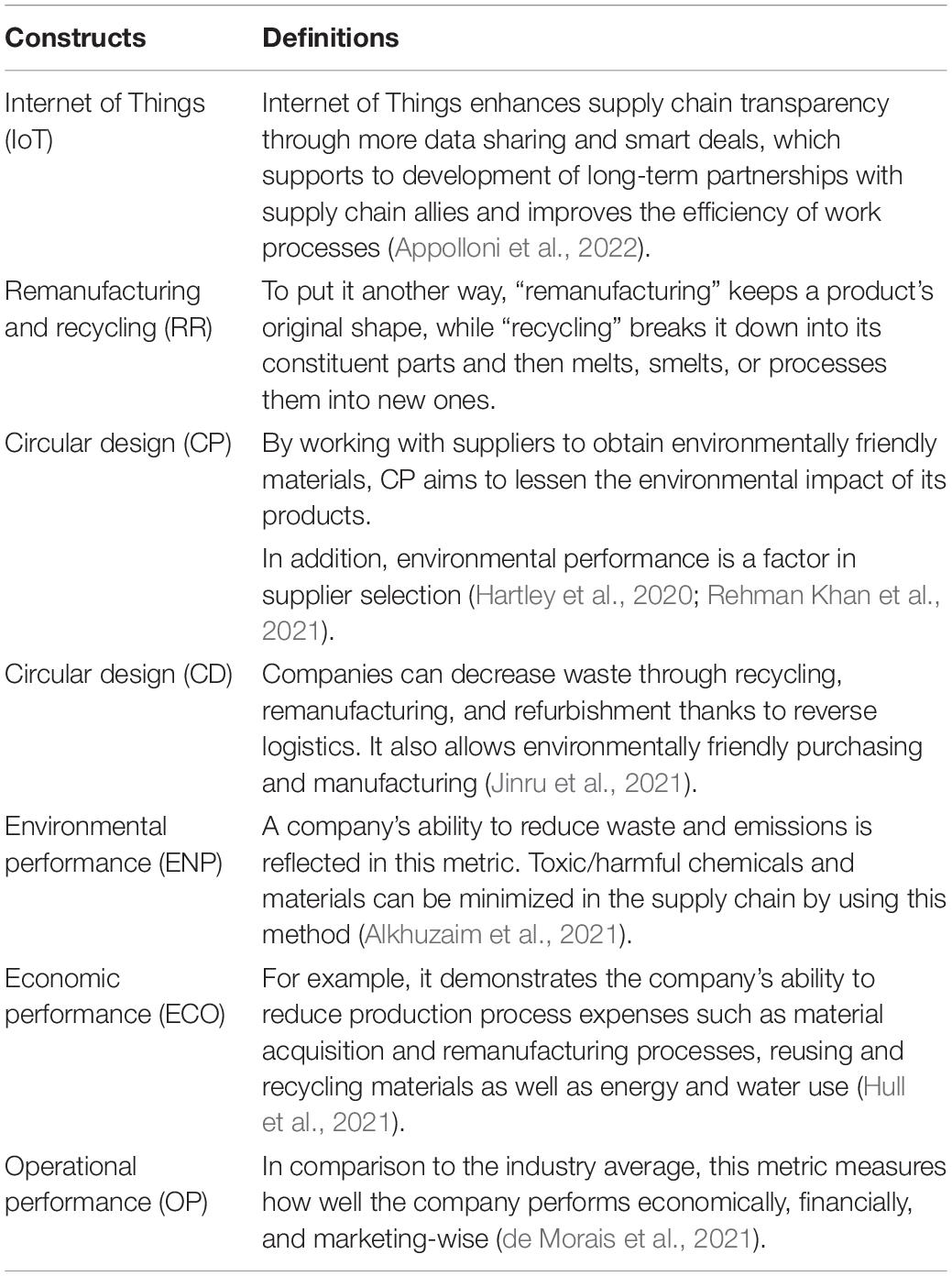

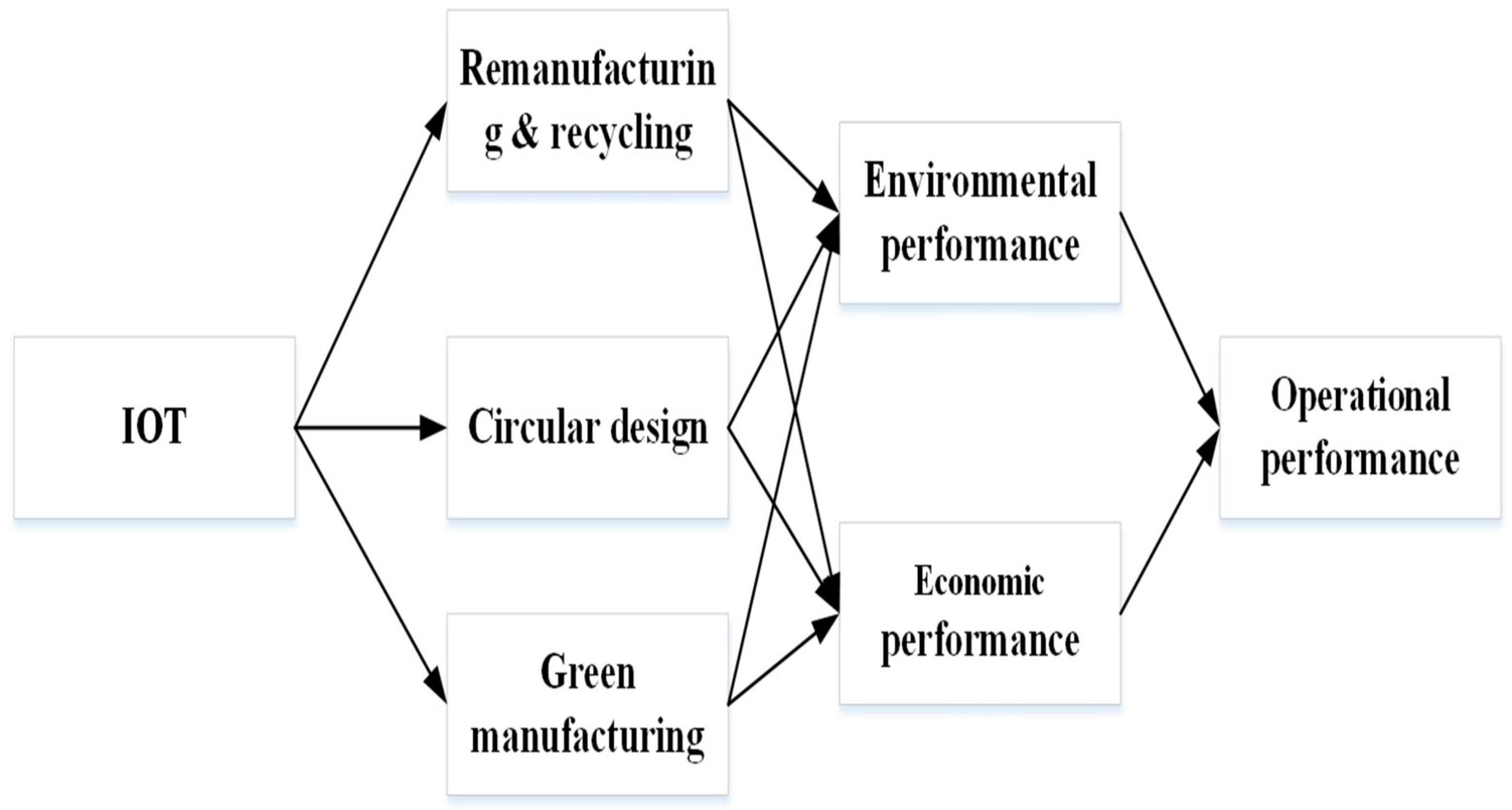

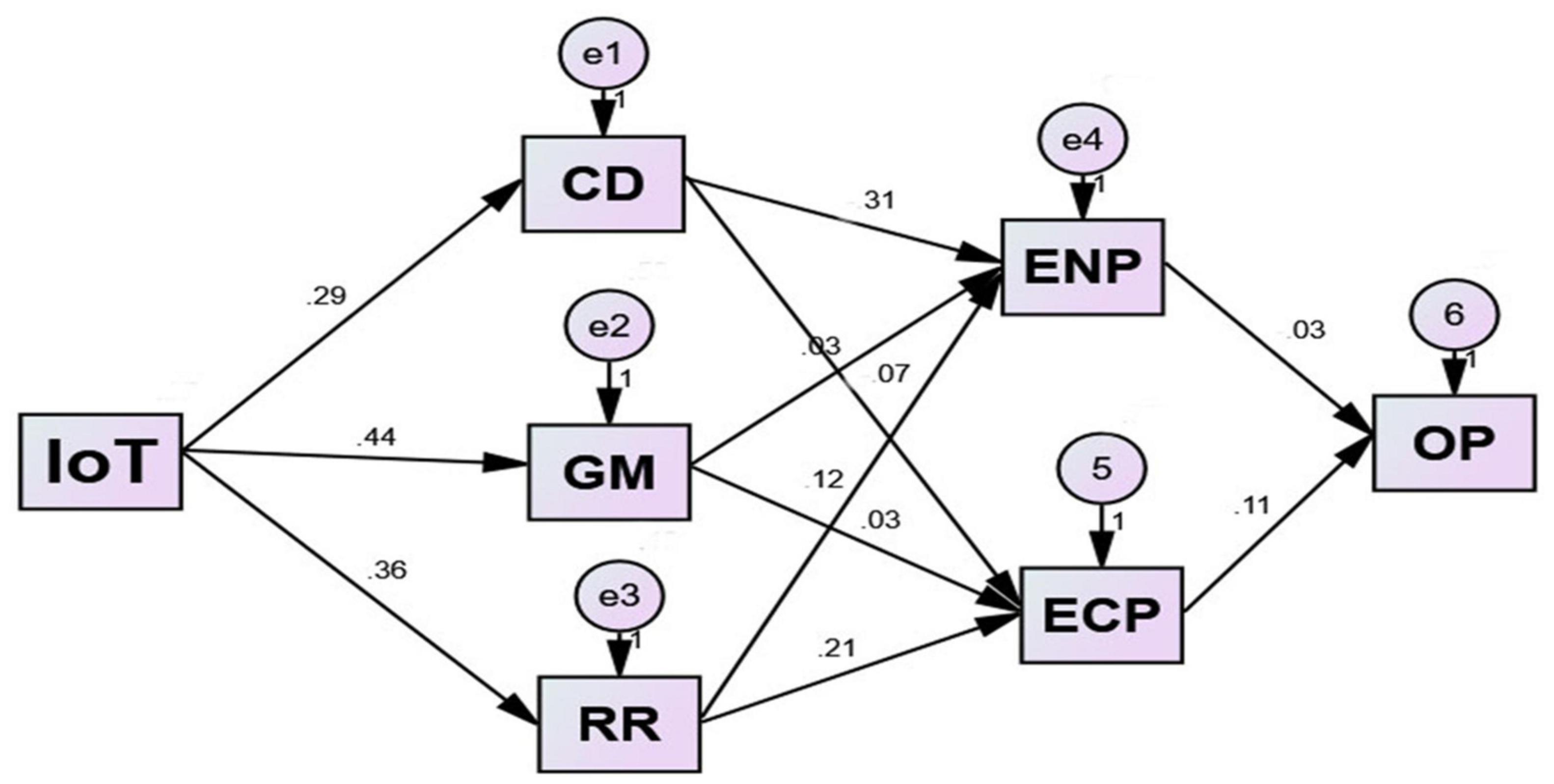

We built an inclusive SEM framework around eco-environmental practices (circular purchasing, recycling, remanufacturing, and circular design) based on the theoretical foundations of environmental transformation and resource-based view, which are driven by IoT in the context of Industry 4.0, and finally lead to entire firm performance. Table 1 explains the definition and constructions of the term. The study’s conceptual framework can be seen in Figure 1.

Industry 4.0 and the Circular Economy

Ecological economics emphasizes the concept of product manufacturing, use, and recycling in order to create sustainable development for future generations at the micro and macro levels. Accordingly, today’s industries are focused on a circular operating model instead of linear economic models in order to make the process more efficient and sustainable. These kinds of conditions necessitate an approach that prioritizes zero waste, resulting in improved usage of materials, energy, and scarce resources (Grafström and Aasma, 2021). CE is a common term for this occurrence. Manufacturing, construction, electronics, automotive, and apparel industries have seen a rise in the use of computer-aided design (CAD) (Ionescu, 2021; Lăzăroiu et al., 2021; Nica et al., 2021; Vătămănescu et al., 2021). The impact of CE on the food processing industry, on the other hand, is largely unexplored. The CE has also failed to fully benefit several industries as a result of a slower rate of adoption. Everyday challenges like technological, organizational, and regulatory standards are to blame for this (Kumar et al., 2021). Centobelli et al. (2021), on the other hand, looked at several works and emphasized the necessity of creating a comprehensive evaluation framework for CE in the industry. As previously mentioned, Gupta et al. (2021) emphasized the difficulty of evaluating CE at the firm level and the need for a thorough approach to understanding CE implementation. As a result, the study’s focus was on determining whether the food processing industry has any interest in implementing CE procedures.

Internet of Things and Circular Economy

Key CE enablers include DTs, in particular those associated with Industry 4.0. Many companies can share data in their supply chains and track their products using these technologies (Singhai and Sushil, 2021). They can help these companies retain the value of their products more effectively. To ensure a smooth transition to CE, the IoT is considered an important technology (Cheng and Wang, 2021). The IoT can be used to extend the lifecycle of products, according to a number of researchers. In addition, the literature shows that the IoT has the potential to affect a wide range of CE issues.

The IoT is a new paradigm in which objects can sense and communicate with each other, allowing for new ways of exchanging information between them. IoT’s theoretical potential to support the transition to CE has been highlighted in some recent reports published recently (Thomasian and Adashi, 2021). It raises the profile of assets in a particular industry, which has ramifications for CE. Manufacturers, for example, will have access to information about the current and future conditions of their products. Based on the actual performance and usage, they can then offer certain products or services (Kovacova and Lãzãroiu, 2021; Popescu et al., 2021; Rogers and Katarina, 2021). In addition, if products are connected to the IoT, they can be monitored throughout their lifecycles; this helps companies that use circular business models make better decisions (Quan et al., 2021). Maintenance, reusing, remanufacturing, and recycling are all described as possible outcomes of IoT implementation in the CE sector in the literature. According to Pagoropoulos and his colleagues, the IoT can be used to monitor people’s health and the actions of connected products. Based on these arguments, we propose the following hypotheses:

H1: The Internet of Things has a significant and positive effect on green manufacturing (GM).

H2: The Internet of Things has a significant and positive effect on recycling and remanufacturing (RR).

H3: The Internet of Things has a significant and positive effect on circular design (CD).

Internet of Things Applications in Circular Economy and Environmental Performance

Resource flow management can be made easier in the transition to a CE by leveraging the IoT technology. In order to connect stakeholders from all points of the value chain, the IoT collects data generated by various sensors, such as smart meters (Khalil et al., 2021; Sulich and Sołoducho-Pelc, 2021; Pervez et al., 2022). Aside from providing real-time data, the IoT shows the impact of specific actions taken by stakeholders (Nica and Stehel, 2021; Novak et al., 2021). It is thus possible to develop and use CE models based on IoT-captured data in order to evaluate particular items throughout their lives, such as smartphones (Zając and Avdiushchenko, 2020). The concept of a smart CE has recently been discussed by scholars and practitioners and is facilitated by essential technologies such as the IoT. There is a smart circular strategy framework for manufacturing organizations leveraging IoT that is utilized to align activities across the CE and information systems (Sarfraz et al., 2020a,b). The IoT’s ability to collect data has led to its widespread use by the CE in the development and implementation of systems (Ding et al., 2020; Kurniawan et al., 2021).

There have been a few examples of how IoT can be used in CE to improve sustainability. For instance, an IoT-based sustainable CE technique from Indonesia for a smart waste management system was introduced by Husgafvel et al. (2022). In order to attain sustainability in smart cities, IoT technology has also been applied in garbage management (Khan et al., 2021b; Kristensen et al., 2021; Su and Urban, 2021; Belhadi et al., 2022). Data-driven decision-making models may be possible because of IoT technology’s data-collecting efficiencies and high levels of data exchange, according to a recent report. An agent-based IoT platform that encourages citizen participation in recycling tasks through gamification mechanisms was proposed by Yalçın and Foxon (2021). In light of the aforementioned research, we have come up with the following hypotheses:

H4: Circular design has a positive effect on the environmental performance of the firm.

H5: Remanufacturing and recycling has a positive effect on the environmental performance of the firm.

H6: Green manufacturing has a positive effect on the environmental performance of the firm.

Internet of Things Applications in Circular Economy and Economic Performance

It is important to consider the costs and benefits of new technology before jumping on the bandwagon of innovations. In recent policy work, the IoT has been overlooked. There have been studies done in the past to try to figure out how the Internet affects research productivity, the value of the knowledge it provides, and the role it plays in fostering entrepreneurship (Su and Urban, 2021). New technologies can have a significant impact on productivity, which is a crucial driver of economic growth. The IoT is the primary focus of this study (IoT).

To get a sense of how the IoT will affect the economy, it is helpful to go back and review the history of how ICT has influenced economic growth. During the last three decades of research, a period that has seen a revolution in information technology, Yu et al. (2021) famously advocated this topic in the field of economics. There have been two main approaches taken by economists to the problem: micro and macro. If you are interested in how different types of assets affect output or labor productivity, growth accounting is a dynamic technique that looks at how those assets are linked to each other. Data at the country or industry level is typically used to make this determination (Iqbal et al., 2021; Liu K. et al., 2021; Liu Z. et al., 2021; Yumei et al., 2021). Regression analysis may be used to uncover causal effects in econometrics by incorporating heterogeneity and time into the equation. When it comes to measuring the influence of new technology, the econometric approach demands a lot of data over a lengthy period, which might be difficult. As a result, we use the growth accounting method. Based on the findings cited above, we propose the following theories as possible answers:

H7: Circular design has a positive effect on the economic performance of the firm.

H8: Remanufacturing and recycling has a positive effect on the economic performance of the firm.

H9: Green manufacturing has a positive effect on the economic performance of the firm.

Internet of Things Applications in Circular Economy and Operational Performance

Internet of Things-based I4.0 was originally discussed in the industrial industry in 2011. Several researchers, including myself, provided some initial guidance on how to implement I4.0. However, there is still a need for systematic research into how I4.0 will affect future industries’ operations management. As a result, there are few studies on I4.0’s contributions to operations management that discuss the framework or practical implications of those contributions. All operations management activities could benefit from the automation of procedures brought about by I4.0 technologies (Liu K. et al., 2021; Lv et al., 2021, 2022; Yang et al., 2021). Real-time information on operating units, such as material flow, customer demand, and inventory position of SC echelons, are some examples of applications.

It is possible to share operational resources utilizing cloud manufacturing technology and the IoT. Design, manufacturing, and assembly participants in the supply chain can all benefit from a centralized service platform in the cloud. Another technology made possible by I4.0’s cloud services is additive manufacturing. From a management standpoint, though, I4.0 and sustainability play a vital role in today’s operating system. In conjunction with one other, they have the potential to advance a more environmentally friendly society (Pieroni et al., 2021). Sustainability and the IoT may be able to address environmental and economic concerns in enterprises’ operations management simultaneously. The green design of products and processes, as well as environmentally friendly supply chain operations, play a role in sustainable operations that are ecologically affected. Jinru et al. (2021) have proposed a classification of environmentally sustainable operations that includes (a) design of the environment, (b) cleaner production, and (c) green supply chain management (GSCM). For environmentally friendly operations, Huang et al. (2021) recommended implementing the 3Rs (reduce, reuse, and recycle). As a result, the connections between environmentally sustainable operations and Industry 4.0 are important, given the role that technology plays in making environmentally sustainable operations excellence judgments.

H10: Environmental performance has a positive effect on the operational activities of the firm.

H11: Economic performance has a positive effect on the operational activities of the firm.

Research Methods and Data

Research Methods

Multiple associations between manifest and latent variables were examined simultaneously using a survey and structural equation modeling as a method of multivariate data analysis. In this section, we describe the research instrument design and the sample size, and then we describe the survey process itself. For the data analysis, we used partial least squares structural equation modeling (PLS-SEM) version 6.0 software, which can handle a wide range of both direct and moderated effects (Upadhyay et al., 2021). In order to measure the five concepts of interest, we developed the survey using existing scales that operationalize the variables of interest (economic performance, environmental performance, operational performance, IoT based on I4.0, green design, recycling and remanufacturing, and green manufacturing). The data was gathered from Chinese food industries. To collect primary data, a structured questionnaire was used. A 5-point Likert scale was used to build the instrument. A multiple-item, 5-point Likert-type scale (1 = “Strongly Disagree”; 2 = “Disagree”; 3 = “Neutral”; 4 = “Agree”; 5 = “Strongly Agree”) was used. The study’s conceptual framework is depicted in Figure 1.

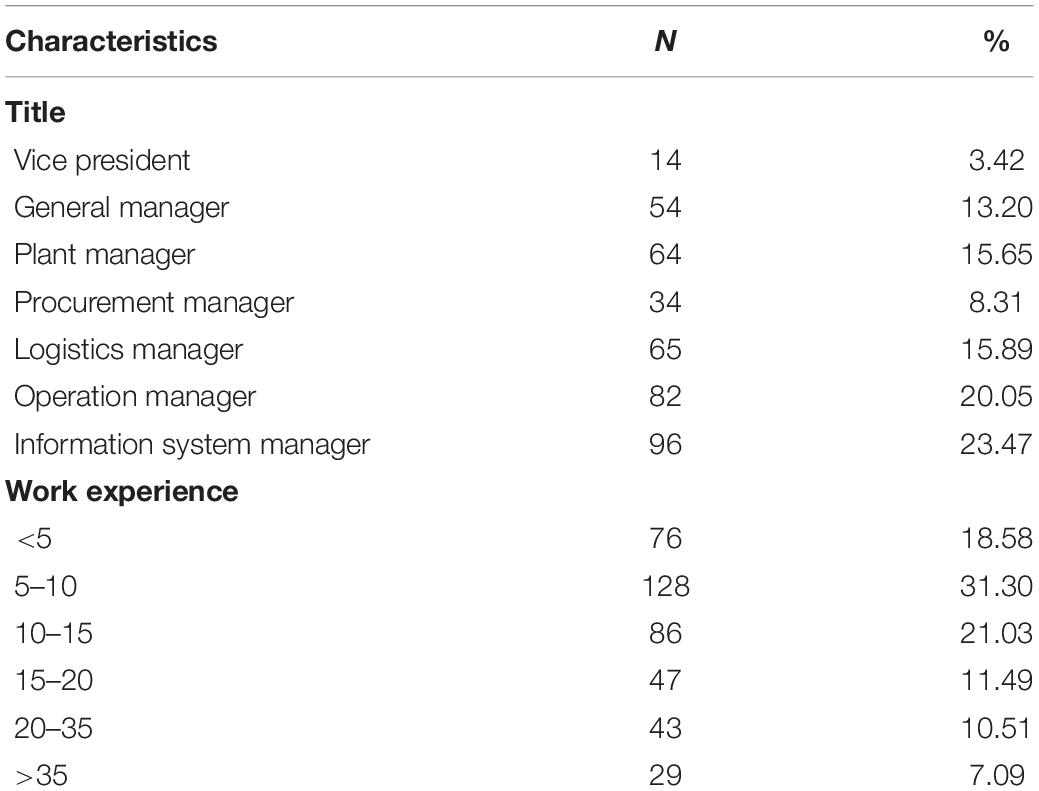

Researchers used data gathered from Chinese companies in the summer of 2019 to combine IoT based Industry 4.0 applications with CE principles to improve organizational performance. The primary goal of the survey is to look into how companies’ performance can be improved through the use of Industry 4.0 technologies and CE principles. The data gathering process was followed in the current investigation. Respondents’ socioeconomic status was shown in Table 2. We sent out 600 questionnaires throughout the summer of 2021. The total number of completed questionnaires received was 447, of which 38 were deemed insufficiently complete. In order to do further research, we incorporated all 409 remaining questions in our sample. Although the sample size was sufficient to use PLS-SEM to test hypotheses, only 67% of those who participated in the survey responded (Bag et al., 2021). Table 2 presents the demographic profile of the participants

Data Analysis

The statistical software package SPSS 25 with AMOS 24 was used to analyze the respondents’ data. For SEM, Sharma et al. (2021) recommend a sample size of at least 200. Therefore, our sample of 409 exceeds the recommended value. Additionally, maximum likelihood estimation was used and is commonly used with sample sizes greater than 300 observations.

Results Analysis and Findings

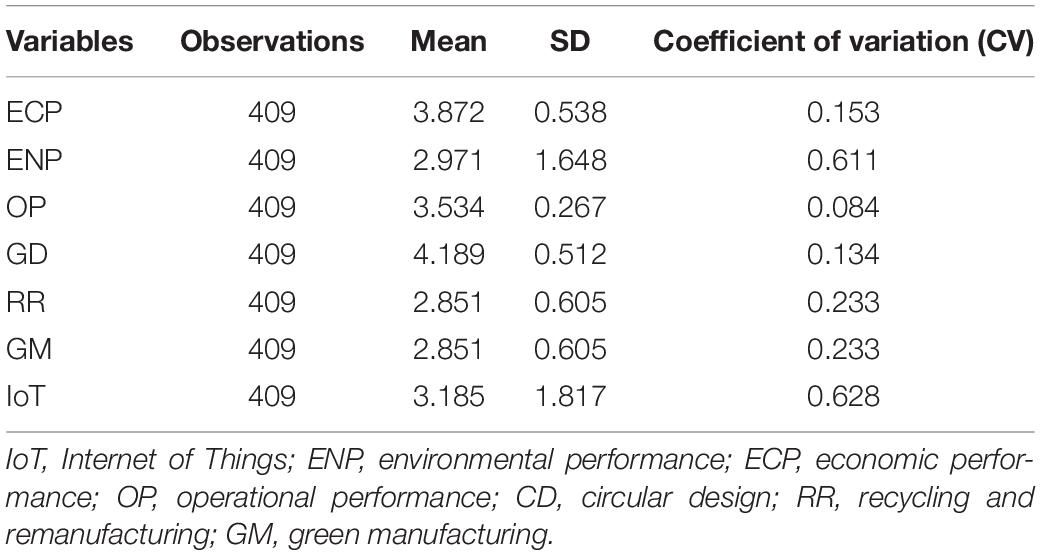

Descriptive Statistics

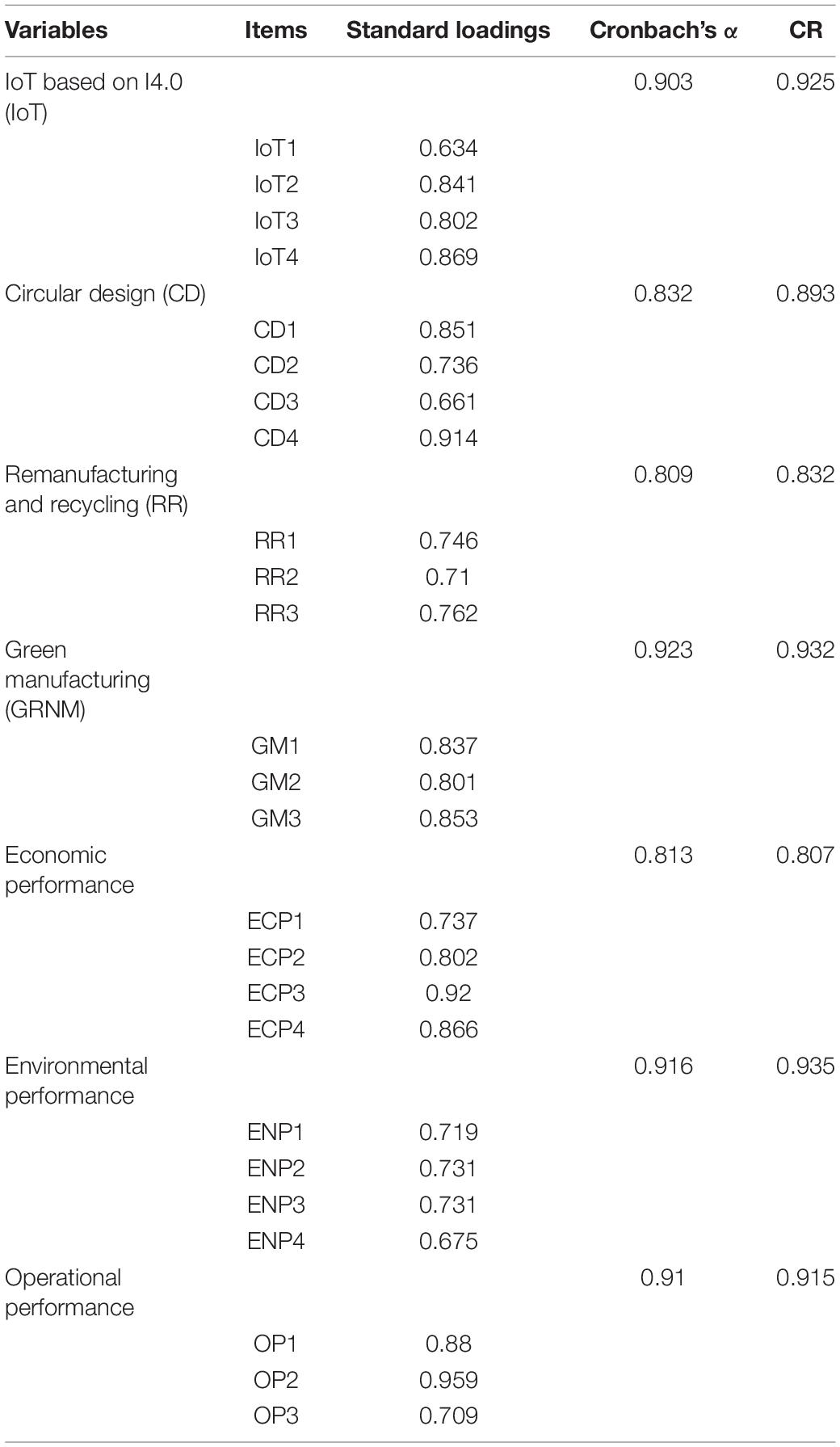

Statistics such as average, variance, and coefficient of determination are shown in Table 3. After compiling demographic information, we tested the measurement model and survey instrument for convergent validity, reliability and discriminant validity. When looking for collinearity, variance inflation factors (VIFs) are employed. F-square values indicate the level of significance of each construct in the model by calculating the variance explained by each independent variable. When it came time to conduct SEM analysis, the hypothesized associations from the measurement model were re-sampled and examined. Based on the idea that the theoretical foundations of interrelated measures are statistically related, convergent validity is defined. The degree to which two variables should be correlated is known as convergent validity. Table 3 displayed the Cronbach’s alpha (CA), average extracted variance (AVE), and composite reliability (CR). Reliability and validity were found to be in line with established standards.

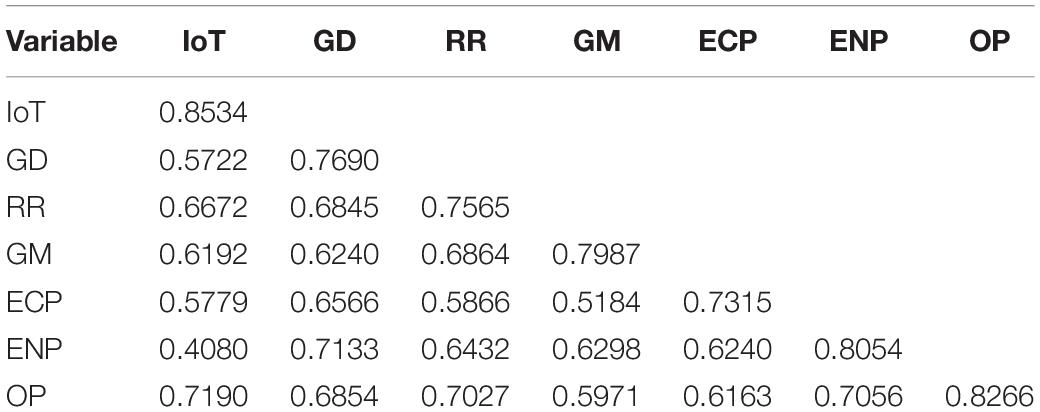

The Fornell and Larcher criterion is used to check discriminant validity. The results are presented in Table 4. The higher values in the diagonal indicate the discriminant validity. If the square root of the average variance extracted is greater than the square root of other bivariate relations, this specifies the discrimination is valid. Discriminant validity boosts the relationships between items and their respective constructs that are stronger than others.

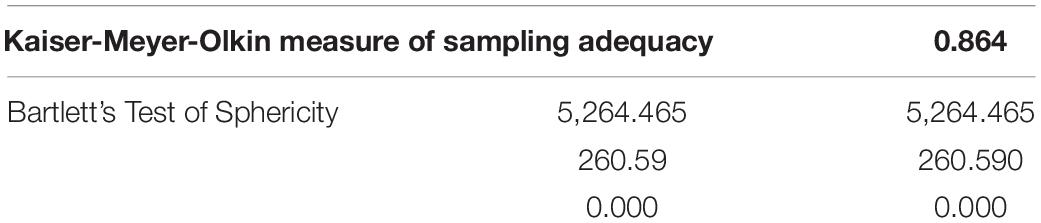

Exploratory Factor Analysis

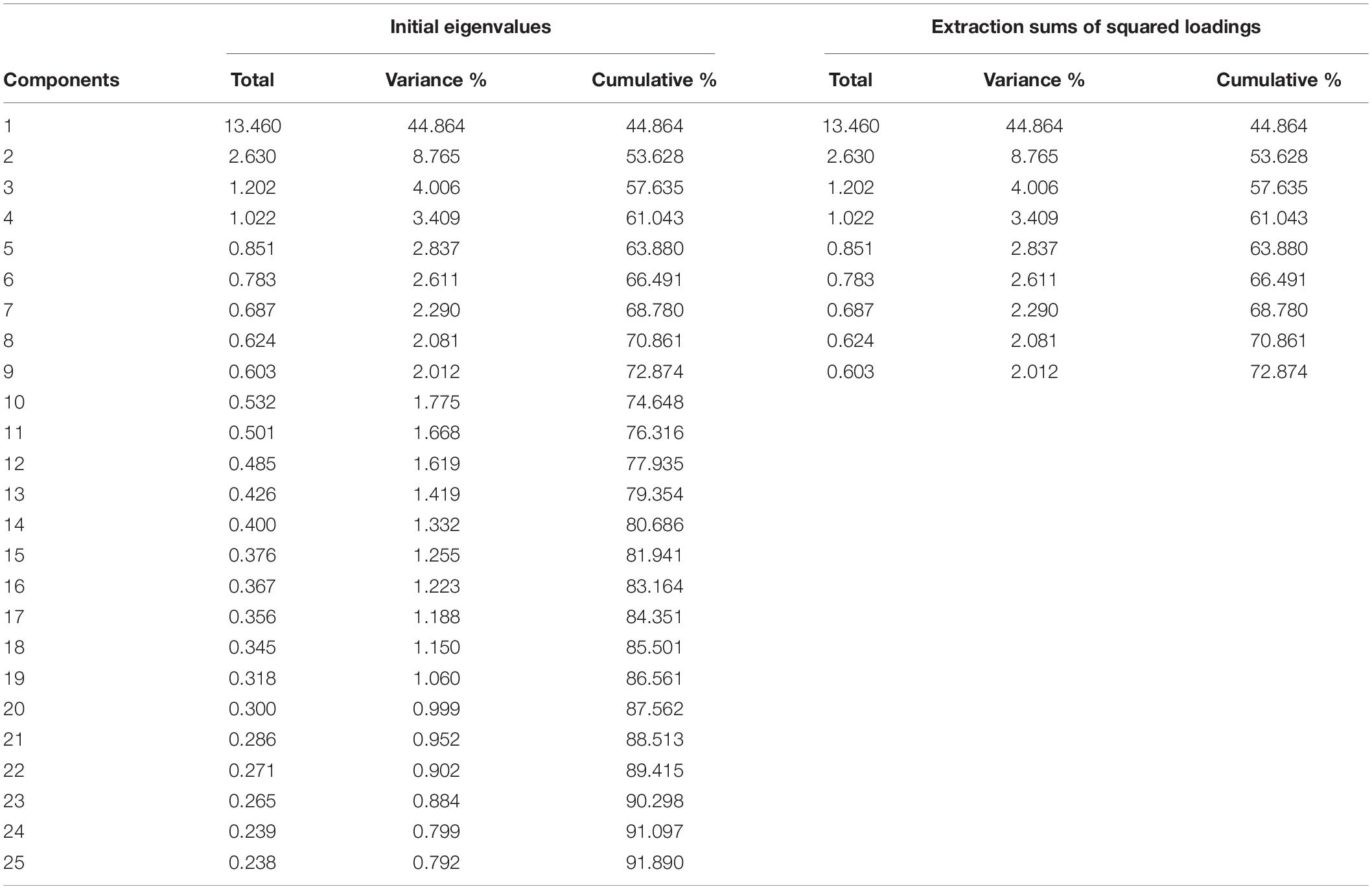

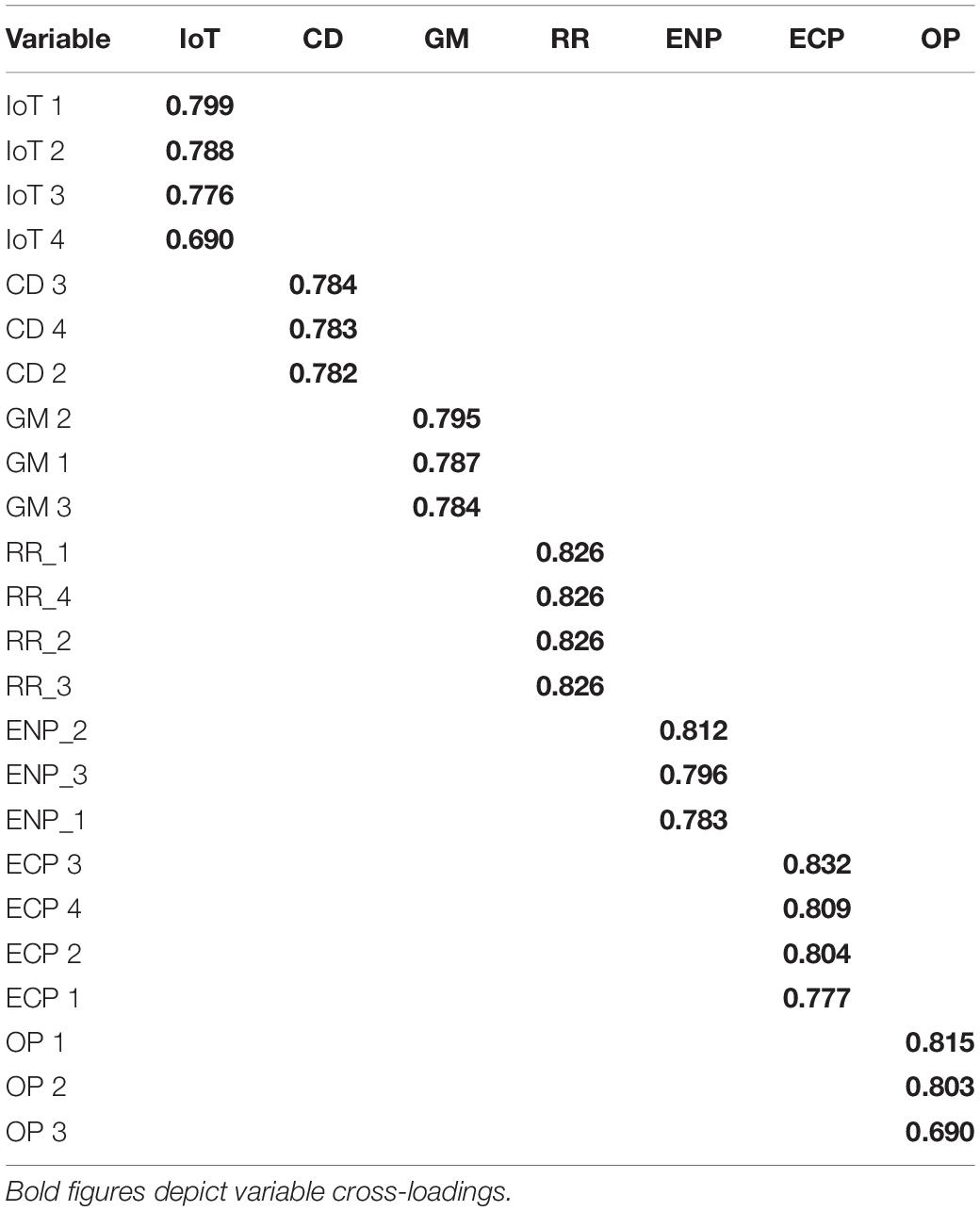

Previous Industry 4.0 and supply chain management studies have employed the exploratory factor analysis (EFA) method. One of EFA’s primary functions is discovering the structural relationships among several variables. Table 5 shows that the KMO value is 0.87, which is higher than the 0.60 suggested minimum (Camana et al., 2021). The outcome of Bartlett’s Test of Sphericity was also relevant in light of the resources examined in this research. This means that EFA can be used with these resources. Table 6 depicts the rotated component matrix after it has been rotated. It reveals that 25 materials were categorized into seven different categories. Factor loadings exceeded 0.50% in all cases. The eigenvalues were all greater than or equal to 1.00.

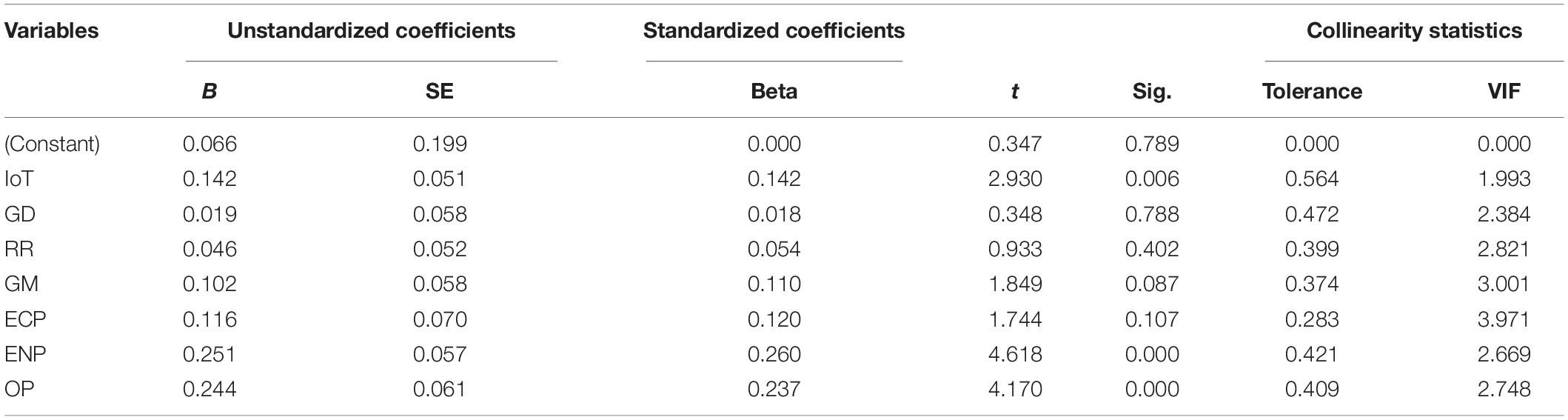

Multicollinearity Test

The VIF is a common measure used to assess the multicollinearity between independent variables. Belhadi et al. (2021) recommend a VIF score below 5.0 to demonstrate that multicollinearity is not an issue among the independent variables. Table 7 below lists the results of the multicollinearity test. The VIF scores range between 1.993 and 3.971 falling within the acceptable range for VIF scores.

Common Method Bias

Harman’s single factor test was conducted to ensure that the model is free from common method bias. The SPSS software package was used to derive the result by conducting an un-rotated, single-factor constraint factor analysis. As demonstrated in Table 8, the highest variance explained by one factor was 47.225%. This is below the 50% cutoff point indicating that no concern with common method bias exists.

Analysis of Factor Loadings

Convergent validity is measured through the factor loadings and cross-loadings of the survey items. Table 9 lists the results of the factor analysis. Hair et al. (2012) recommend that the factor loadings should be at a level of 0.5 or greater. All survey items that fell below the recommended level were removed from the study. The remaining 23 survey items all met the acceptable level of validity and explained 76.709% of the variance in the dependent construct.

Structural Equation Model

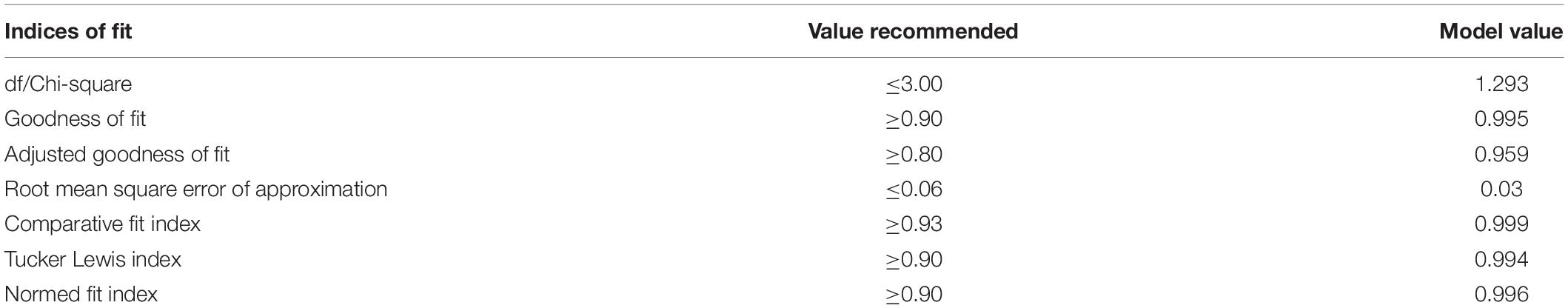

SPSS AMOS 24 was utilized to evaluate the proposed research model. To test the overall goodness of fit of the proposed research model, the measures of df/Chi-square, goodness of fit, adjusted goodness of fit, root mean square error of approximation, comparative fit index, Tucker Lewis index, and normed fit index were employed. Table 10 reveals that all the goodness of fit indices falls within their acceptable levels. This reveals that the proposed research model exhibited a good fit with the data.

Hypothesis Testing

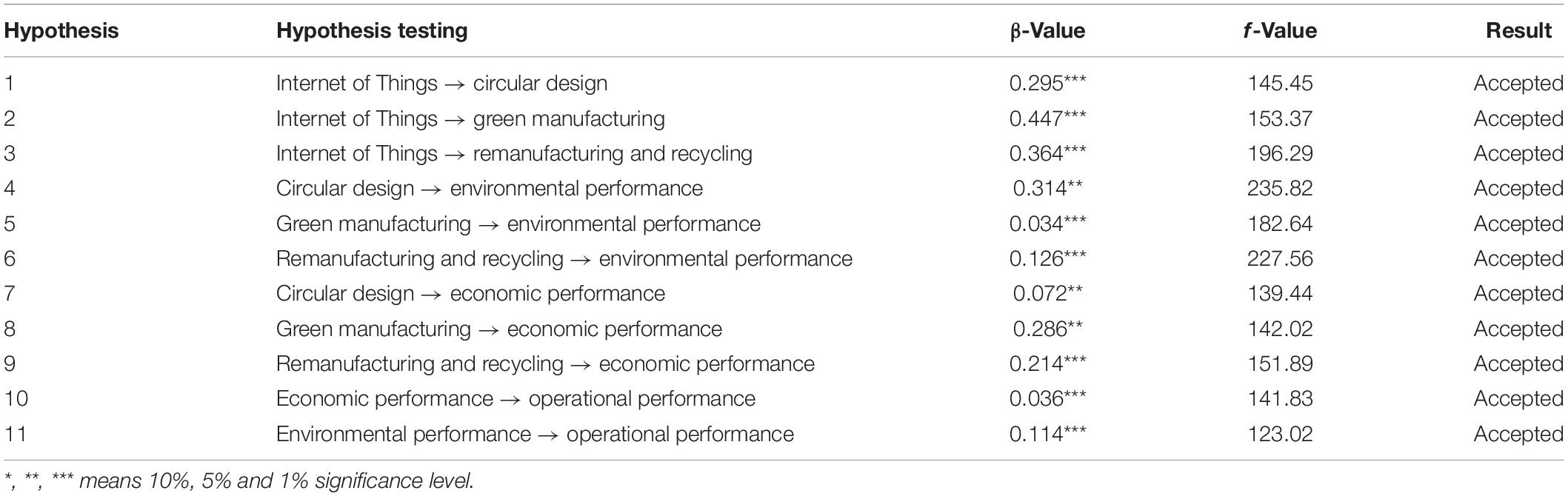

Table 11 and Figure 2 below show the properties of the causal paths including the standardized path coefficients.

Discussion

The findings show that all of the hypothesized relationships proposed in the model are significant. The IoT based Industry 4.0 technology has a substantial impact on the CE in all of its components, as may be deduced from Table 10. Circular design can be improved by a 0.295% increase in IoT usage for every one percent rise in IoT. Green manufacturing is also benefiting from IoT, as a 1% growth in the IoT would raise it by 0.447%. An increase of 1% in IoT’s impact on recycling and remanufacturing will result in an additional 0.364% increase in these processes. Researchers such as Chen et al. (2020) have also investigated this association in previous studies. To implement the CE effectively, it is important to focus on the technical aspects of this new paradigm, as large-scale automation and digitization have occurred in the fourth industrial revolution. The IoT, first presented by Flynn and Hacking (2019), has become a key component of Industry 4.0. There are numerous ways in which IoT might help the CE: it is transparent, decentralized, peer-to-peer data synchronization, smart contracting, and data immutability. Monitoring apparent environmental and social circumstances that might be causing health, environmental, and safety hazards is an essential application focus for the BCT, like Adams et al. (2018) claim. Circular economies have a good impact on both the environment and the economy, and this influence is only growing. A total of 0.292, 0.215, and 0.262% of environmental performance are influenced by eco-friendly design, eco-friendly manufacturing, and recycling and remanufacturing. Ymeri et al. (2020) found that pollution in the environment is directly linked to the use of fossil fuels and energy in the production and distribution of goods. Additional emphasis was placed on green manufacturing and environmentally friendly transportation systems to reduce their negative impact on the environment and society. As stated by Soo et al. (2021), the CE or GSCM improves resource efficiency and safeguards the environment. Circular economies have been proposed by Han and Trimi (2022), and this is one of their central claims, which they analyze further in this research by looking at the effect that environmental performance and economic performance have on organizational performance.

Eco-friendly design and manufacturing contribute 0.314, 0.034, and 0.126% to the economy’s performance, respectively. Remanufacturing and recycling goods can save billions of dollars each year, according to Ghadimi et al. (2019). Most organizations, according to Çalık (2021), only engage in green activities that increase their profits and help them enter the export market. The results show that a 1% increase in environmental performance might result in a 0.114% increase in operational performance, proving the link between environmental and economic performance. Kolla et al. (2019) investigated the data obtained from Chinese enterprises to evaluate the effectiveness of activities related to GSCM. They concluded that the organizations’ goals and profitability are boosted by sustainability. As a result, environmental and economic performance improve the company’s performance by 0.036 and 0.114%, respectively. Kumar et al. (2021) observed that green practices have the potential to improve a company’s overall performance, but the lack of support from high management can quickly result in a disastrous GSCM project. Gupta et al. (2021) found that economic considerations have an impact on an organization’s performance.

Conclusion

The IoT and the CE are two hot issues that will have a significant impact on business and society. One of the first studies to look at how IoT can help the CE. Industrial case studies are used to examine potential and identify application gaps for future research and practice.

They are all representative of their respective industries. All of the cases have claimed the benefits of IoT for their supply chains and the CE in general. Adoption has been mainly at the demonstration and piloting stages so far, nevertheless, Interoperability problems, security concerns, and stability issues with IoT systems are still present. Even though industrial trends remain good and preliminary results show that industry leaders such as Walmart and Toyota mimic one another’s behavior, the majority of smaller businesses are skeptical and reluctant to embrace this technological transformation. As a result of these tensions, there is a risk of increased overhead, technological investment, and a lack of immediate financial rewards. Small, risk-taking businesses are more likely to adopt new technologies than larger ones.

With IoT, businesses may expect a more transparent, decentralized, and secure transaction process as well as the potential for increased efficiency and responsiveness. In the long run, these attributes will have a positive impact on the economy, society, and the environment.

Decentralization and digitalization can help the CE by improving supply chain procedures in each industrial sector that are lacking in transparency, precision, and security – all of which can benefit from decentralization and digitalization. The adoption of IoT for various CE procedures varies significantly among industries, as we have seen. The case studies that have been provided allow us to understand how many firms from various industries have progressed toward the use of IoT. CE implementation dimensions and their case scenarios can also be viewed in this way. This study’s findings may help clarify how IoT can be used in cases of CE. Additionally, managers, policymakers, and CE coordinators can use real illustrative instances to identify the practical gaps that organizations can focus on when they attempt to use their CE practices with IoT.

An examination into whether IoT-based solutions may benefit businesses and industries in the CE is needed. A good place to start researching industries and organizations is by identifying the most critical operational principles and sector-specific difficulties that IoTs and CE are currently confronted with. Legal framework and relationship requirements, application scale, and infrastructure needs can all be included in this list of principles. Further investigation should be done into the supply chain activities and features that can be improved by a IoT-powered solution. In a IoT ecosystem, procurement, shipping, and logistics may have a higher impact on CE than internal processes. IoT may not be necessary for every situation, and basic or even classic digital solutions may suffice in many scenarios.

Our exploratory inquiry has reached its limits. In order to support a large-scale investment in IoT and CE links, the data from the case studies is insufficient. There is a need for more evidence. It is essential to include business cases and long-term observations into IoT in the CE environment in order to maximize its efficacy. IoT’s role in today’s supply chains is defined by the process of creating, implementing, and enforcing essential IoT characteristics.

The IoT offers a wide range of applications, each of which requires a large amount of infrastructure. So, it is with the methods of continuing education. Both fields have a large number of potential applications and connections. In this relationship, there are both opportunities and challenges. Because significant sectors have already embraced and implemented the technology at such a rapid pace, more concrete evidence is needed. It is also necessary to conduct a more rigorous analysis of the potential of IoT in a CE environment. That is why we believe that our work sets the groundwork for major advancement in both domains.

Data Availability Statement

The raw data supporting the conclusions of this article will be made available by the authors, without undue reservation.

Author Contributions

Both authors listed have made a substantial, direct, and intellectual contribution to the work, and approved it for publication.

Funding

This study was supported by the Key Research Institute of Humanities and Social Sciences at Universities of Henan.

Conflict of Interest

The authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

Publisher’s Note

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article, or claim that may be made by its manufacturer, is not guaranteed or endorsed by the publisher.

References

Adams, R., Kewell, B., and Parry, G. (2018). “Blockchain for Good? Digital Ledger Technology and Sustainable Development Goals,” in Handbook of Sustainability and Social Science Research. World Sustainability Series, eds W. Leal Filho, R. Marans, and J. Callewaert (Cham: Springer).

Aggarwal, B. K., Gupta, A., Goyal, D., Gupta, P., Bansal, B., and Barak, D. D. (2021). A review on investigating the role of block-chain in cyber security. Mater. Today Proc. doi: 10.1016/j.matpr.2021.10.124

Ahamad, S., Gupta, P., Bikash Acharjee, P., Padma Kiran, K., Khan, Z., and Faez Hasan, M. (2021). The role of block chain technology and Internet of Things (IoT) to protect financial transactions in crypto currency market. Mater. Today Proc. doi: 10.1016/j.matpr.2021.11.405

Alkhuzaim, L., Zhu, Q., and Sarkis, J. (2021). Evaluating Emergy Analysis at the Nexus of Circular Economy and Sustainable Supply Chain Management. Sustain. Prod. Consum. 25, 413–424. doi: 10.1016/j.spc.2020.11.022

Appolloni, A., Chiappetta Jabbour, C. J., D’Adamo, I., Gastaldi, M., and Settembre-Blundo, D. (2022). Green recovery in the mature manufacturing industry: the role of the green-circular premium and sustainability certification in innovative efforts. Ecol. Econ. 193:107311. doi: 10.1016/J.ECOLECON.2021.107311

Astill, J., Dara, R. A., Campbell, M., Farber, J. M., Fraser, E. D. G., Sharif, S., et al. (2019). Transparency in food supply chains: a review of enabling technology solutions. Trends Food Sci. Technol. 91, 240–247. doi: 10.1016/j.tifs.2019.07.024

Bag, S., Pretorius, J. H. C., Gupta, S., and Dwivedi, Y. K. (2021). Role of institutional pressures and resources in the adoption of big data analytics powered artificial intelligence, sustainable manufacturing practices and circular economy capabilities. Technol. Forecast. Soc. Change 163:120420. doi: 10.1016/j.techfore.2020.120420

Belhadi, A., Kamble, S. S., Chiappetta Jabbour, C. J., Mani, V., Khan, S. A. R., and Touriki, F. E. (2022). A self-assessment tool for evaluating the integration of circular economy and industry 4.0 principles in closed-loop supply chains. Int. J. Prod. Econ. 245:108372. doi: 10.1016/J.IJPE.2021.108372

Belhadi, A., Kamble, S. S., Chiappetta Jabbour, C. J., Mani, V., Rehman Khan, S. A., and Touriki, F. E. (2021). A self-assessment tool for evaluating the integration of circular economy and industry 4.0 principles in closed-loop supply chains. Int. J. Prod. Econ. 245:108372. doi: 10.1016/j.ijpe.2021.108372

Bhattarai, N., and Kumar Jha, R. (2019). Rooftop Farming: an Alternative To Conventional Farming For Urban Sustainability. Malaysian J. Sustain. Agric. 3, 39–43. doi: 10.26480/mjsa.01.2019.39.43

Çalık, A. (2021). A novel Pythagorean fuzzy AHP and fuzzy TOPSIS methodology for green supplier selection in the Industry 4.0 era. Soft Comput. 25, 2253–2265. doi: 10.1007/S00500-020-05294-9/TABLES/11

Camana, D., Manzardo, A., Toniolo, S., Gallo, F., and Scipioni, A. (2021). Assessing environmental sustainability of local waste management policies in Italy from a circular economy perspective. An overview of existing tools. Sustain. Prod. Consum. 27, 613–629. doi: 10.1016/j.spc.2021.01.029

Centobelli, P., Cerchione, R., Vecchio, P., Del, Oropallo, E., and Secundo, G. (2021). Blockchain technology for bridging trust, traceability and transparency in circular supply chain. Inf. Manag 103508. doi: 10.1016/j.im.2021.103508

Chen, T. L., Kim, H., Pan, S. Y., Tseng, P. C., Lin, Y. P., and Chiang, P. C. (2020). Implementation of green chemistry principles in circular economy system towards sustainable development goals: challenges and perspectives. Sci. Total Environ. 716:136998. doi: 10.1016/J.SCITOTENV.2020.136998

Cheng, F., and Wang, Y. (2021). Research and application of 3D visualization and Internet of Things technology in urban land use efficiency management. Displays 69:102050. doi: 10.1016/j.displa.2021.102050

de Morais, L. H. L., Pinto, D. C., and Cruz-Jesus, F. (2021). Circular economy engagement: altruism, status, and cultural orientation as drivers for sustainable consumption. Sustain. Prod. Consum. 27, 523–533. doi: 10.1016/j.spc.2021.01.019

Ding, L. L., Lei, L., Wang, L., and Zhang, L. F. (2020). Assessing industrial circular economy performance and its dynamic evolution: an extended Malmquist index based on cooperative game network DEA. Sci. Total Environ. 731:139001. doi: 10.1016/j.scitotenv.2020.139001

Elavarasan, R. M., Pugazhendhi, R., Shafiullah, G. M., Irfan, M., and Anvari-Moghaddam, A. (2021). A hover view over effectual approaches on pandemic management for sustainable cities – The endowment of prospective technologies with revitalization strategies. Sustain. Cities Soc. 68:102789. doi: 10.1016/j.scs.2021.102789

Flynn, A., and Hacking, N. (2019). Setting standards for a circular economy: a challenge too far for neoliberal environmental governance? J. Clean. Prod. 212, 1256–1267. doi: 10.1016/j.jclepro.2018.11.257

Ghadimi, P., Wang, C., Lim, M. K., and Heavey, C. (2019). Intelligent sustainable supplier selection using multi-agent technology: theory and application for Industry 4.0 supply chains. Comput. Ind. Eng. 127, 588–600. doi: 10.1016/j.cie.2018.10.050

Grafström, J., and Aasma, S. (2021). Breaking circular economy barriers. J. Clean. Prod. 292:126002. doi: 10.1016/j.jclepro.2021.126002

Gupta, H., Kumar, A., and Wasan, P. (2021). Industry 4.0, cleaner production and circular economy: an integrative framework for evaluating ethical and sustainable business performance of manufacturing organizations. J. Clean. Prod. 295:126253. doi: 10.1016/j.jclepro.2021.126253

Hair, J. F., Sarstedt, M., Ringle, C. M., and Mena, J. A. (2012). An assessment of the use of partial least squares structural equation modeling in marketing research. J. Acad. Mark. Sci. 40, 414–433. doi: 10.1007/S11747-011-0261-6/TABLES/5

Han, H., and Trimi, S. (2022). Towards a data science platform for improving SME collaboration through Industry 4.0 technologies. Technol. Forecast. Soc. Change 174:121242. doi: 10.1016/j.techfore.2021.121242

Hartley, K., van Santen, R., and Kirchherr, J. (2020). Policies for transitioning towards a circular economy: expectations from the European Union (EU). Resour. Conserv. Recycl. 155:104634. doi: 10.1016/j.resconrec.2019.104634

Hopkins, J. L. (2021). An investigation into emerging industry 4.0 technologies as drivers of supply chain innovation in Australia. Comput. Ind. 125:103323. doi: 10.1016/j.compind.2020.103323

Huang, Y.-F., Azevedo, S. G., Lin, T.-J., Cheng, C.-S., and Lin, C.-T. (2021). Exploring the decisive barriers to achieve circular economy: strategies for the textile innovation in Taiwan. Sustain. Prod. Consum. 27, 1406–1423. doi: 10.1016/j.spc.2021.03.007

Hull, C. E., Millette, S., and Williams, E. (2021). Challenges and opportunities in building circular-economy incubators: stakeholder perspectives in Trinidad and Tobago. J. Clean. Prod. 296:126412. doi: 10.1016/j.jclepro.2021.126412

Husgafvel, R., Linkosalmi, L., Sakaguchi, D., and Hughes, M. (2022). “. How to advance sustainable and circular economy-oriented public procurement—A review of the operational environment and a case study from the Kymenlaakso region in Finland,” in Circular Economy and Sustainability, eds A. Stefanakis and I. Nikolaou (Amsterdam: Elsevier), 227–277. doi: 10.1016/b978-0-12-819817-9.00015-6

Ionescu, L. (2021). Big Data Analytics Tools and Machine Learning Algorithms in Cloud-based Accounting Information Systems. Anal. Metaphys. 20:102. doi: 10.22381/am2020217

Iqbal, W., Tang, Y. M., Lijun, M., Chau, K. Y., Xuan, W., and Fatima, A. (2021). Energy policy paradox on environmental performance: the moderating role of renewable energy patents. J. Environ. Manage. 297:113230. doi: 10.1016/j.jenvman.2021.113230

Jinru, L., Changbiao, Z., Ahmad, B., Irfan, M., and Nazir, R. (2021). How do green financing and green logistics affect the circular economy in the pandemic situation: key mediating role of sustainable production. Econ. Res. Istraz doi: 10.1080/1331677X.2021.2004437

Kawaguchi, N. (2019). Application of Blockchain to Supply Chain: flexible Blockchain Technology. Procedia Comput. Sci. 164, 143–148. doi: 10.1016/j.procs.2019.12.166

Keshri, A. K., Mishra, B. K., and Rukhaiyar, B. P. (2020). When rumors create chaos in e-commerce. Chaos, Solitons and Fractals 131:109497. doi: 10.1016/j.chaos.2019.109497

Khalil, M., Khawaja, K. F., and Sarfraz, M. (2021). The adoption of blockchain technology in the financial sector during the era of fourth industrial revolution: a moderated mediated model. Qual. Quant* 1–18. doi: 10.1007/s11135-021-01229-0

Khan, S. A. R., Ponce, P., Tanveer, M., Aguirre-Padilla, N., Mahmood, H., and Shah, S. A. A. (2021a). Technological Innovation and Circular Economy Practices: business Strategies to Mitigate the Effects of COVID-19. Sustain 13:8479. doi: 10.3390/SU13158479

Khan, S. A. R., Razzaq, A., Yu, Z., and Miller, S. (2021b). Industry 4.0 and circular economy practices: a new era business strategies for environmental sustainability. Bus. Strateg. Environ. 30, 4001–4014. doi: 10.1002/BSE.2853

Koistinen, K., Onkila, T., Teerikangas, S., Mäkelä, M., Sarja, M., and Valkjärvi, M. (2022). Bold ambition, blunted agency? Examining top management perspectives on a circular economy transition in Finland.. Energy Res. Soc. Sci. 86:102451. doi: 10.1016/J.ERSS.2021.102451

Kolla, S., Minufekr, M., and Plapper, P. (2019). Deriving essential components of lean and industry 4.0 assessment model for manufacturing SMEs. Procedia. CIRP 81, 753–758. doi: 10.1016/j.procir.2019.03.189

Kovacova, M., and Lãzãroiu, G. (2021). Sustainable organizational performance, cyber-physical production networks, and deep learning-assisted smart process planning in industry 4.0-based manufacturing systems. Econ. Manag. Financ. Mark. 16, 41–54. doi: 10.22381/emfm16320212

Kristensen, H. S., Mosgaard, M. A., and Remmen, A. (2021). Circular public procurement practices in Danish municipalities. J. Clean. Prod. 281:124962. doi: 10.1016/j.jclepro.2020.124962

Kumar, S., Raut, R. D., Nayal, K., Kraus, S., Yadav, V. S., and Narkhede, B. E. (2021). To identify industry 4.0 and circular economy adoption barriers in the agriculture supply chain by using ISM-ANP. J. Clean. Prod. 293:126023. doi: 10.1016/j.jclepro.2021.126023

Kurniawan, T. A., Lo, W., Singh, D., Othman, M. H. D., Avtar, R., Hwang, G. H., et al. (2021). A societal transition of MSW management in Xiamen (China) toward a circular economy through integrated waste recycling and technological digitization. Environ. Pollut. 277:116741. doi: 10.1016/j.envpol.2021.116741

Lăzăroiu, G., Kliestik, T., and Novak, A. (2021). Internet of things smart devices, industrial artificial intelligence, and real-time sensor networks in sustainable cyber-physical production systems. J. Self-Governance Manag. Econ. 9, 20–30. doi: 10.22381/JSME9120212

Lezoche, M., Hernandez, J. E., Alemany Díaz, M., del, M. E., Panetto, H., and Kacprzyk, J. (2020). Agri-food 4.0: a survey of the supply chains and technologies for the future agriculture. Comput. Ind. 117:103187. doi: 10.1016/j.compind.2020.103187

Li, Y., Dai, J., and Cui, L. (2020). The impact of digital technologies on economic and environmental performance in the context of industry 4.0: a moderated mediation model. Int. J. Prod. Econ. 229:107777. doi: 10.1016/J.IJPE.2020.107777

Liu, K., Ke, F., Huang, X., Yu, R., Lin, F., Wu, Y., et al. (2021). DeepBAN: a Temporal Convolution-Based Communication Framework for Dynamic WBANs. IEEE Trans. Commun. 69, 6675–6690. doi: 10.1109/TCOMM.2021.3094581

Liu, Y., and Zhang, S. (2020). Information security and storage of Internet of Things based on block chains. Futur. Gener. Comput. Syst. 106, 296–303. doi: 10.1016/j.future.2020.01.023

Liu, Z., Tang, Y. M., Chau, K. Y., Chien, F., Iqbal, W., and Sadiq, M. (2021). Incorporating strategic petroleum reserve and welfare losses: a way forward for the policy development of crude oil resources in South Asia. Resour. Policy 74:102309. doi: 10.1016/j.resourpol.2021.102309

Lv, Z., Chen, D., Lou, R., and Song, H. (2021). Industrial Security Solution for Virtual Reality. IEEE Internet Things J. 8, 6273–6281. doi: 10.1109/JIOT.2020.3004469

Lv, Z., Guo, J., and Lv, H. (2022). Safety Poka Yoke in Zero-Defect Manufacturing Based on Digital Twins. IEEE Trans. Ind. Informatics* doi: 10.1109/TII.2021.3139897

Mohammadzadeh, A. K., Ghafoori, S., Mohammadian, A., Mohammadkazemi, R., Mahbanooei, B., and Ghasemi, R. (2018). A Fuzzy Analytic Network Process (FANP) approach for prioritizing internet of things challenges in Iran. Technol. Soc. 53, 124–134. doi: 10.1016/j.techsoc.2018.01.007

Müller, J. M., Buliga, O., and Voigt, K.-I. (2021). The role of absorptive capacity and innovation strategy in the design of industry 4.0 business Models - A comparison between SMEs and large enterprises. Eur. Manag. J. 39, 333–343. doi: 10.1016/j.emj.2020.01.002

Nica, E., Stan, C. I, Luţan, A. G., and Oaşa, R. (2021). Internet of things-based real-time production logistics, sustainable industrial value creation, and artificial intelligence-driven big data analytics in cyber-physical smart manufacturing systems. Econ. Manag. Financ. Mark 16, 52–62. doi: 10.22381/EMFM16120215

Nica, E., and Stehel, V. (2021). Internet of things sensing networks, artificial intelligence-based decision-making algorithms, and real-time process monitoring in sustainable industry 4.0. J. Self-Governance Manag. Econ. 9, 35–47. doi: 10.22381/jsme9320213

Novak, A., Bennett, D., and Economics, T. K. (2021). Product Decision-Making Information Systems, Real-Time Sensor Networks, and Artificial Intelligence-driven Big Data Analytics in Sustainable Industry 4.0. Econ. Manag. Financ. Mark 16:62. doi: 10.22381/emfm16220213

Ntsondé, J., and Aggeri, F. (2021). Stimulating innovation and creating new markets – The potential of circular public procurement. J. Clean. Prod. 308:127303. doi: 10.1016/j.jclepro.2021.127303

Pal, K., and Yasar, A.-U.-H. (2020). Internet of Things and Blockchain Technology in Apparel Manufacturing Supply Chain Data Management. Procedia Comput. Sci. 170, 450–457. doi: 10.1016/j.procs.2020.03.088

Pervez, T., Khawaja, K. F., and Sarfraz, M. (2022). An empirical investigation of value co-creation on customer loyalty: mediating role of customer trust. Int. J. Econ. Bus. Res. 23, 56–67. doi: 10.1504/IJEBR.2022.119349

Pieroni, M. P. P., McAloone, T. C., and Pigosso, D. C. A. (2021). Circular economy business model innovation: sectorial patterns within manufacturing companies. J. Clean. Prod. 286:124921. doi: 10.1016/j.jclepro.2020.124921

Popescu, G. H., Petreanu, S., Alexandru, B., and Corpodean, H. (2021). Internet of things-based real-time production logistics, cyber-physical process monitoring systems, and industrial artificial intelligence in sustainable smart manufacturing. J. Self-Governance Manag. Econ. 9, 52–62. doi: 10.22381/JSME9220215

Quan, F., Mingming, Z., Hu, S., and Yuhang, C. (2021). Research on data fusion scheme of power internet of things based on cloud and NFV. Procedia Comput. Sci. 183, 115–119. doi: 10.1016/j.procs.2021.02.038

Rehman Khan, S. A., Yu, Z., Sarwat, S., Godil, D. I., Amin, S., and Shujaat, S. (2021). The role of block chain technology in circular economy practices to improve organisational performance. Int. J. Logist. Res. Appl doi: 10.1080/13675567.2021.1872512

Rejeb, A., Simske, S., Rejeb, K., Treiblmaier, H., and Zailani, S. (2020). Internet of Things research in supply chain management and logistics: a bibliometric analysis. Internet Things 12:100318. doi: 10.1016/J.IOT.2020.100318

Rogers, S., and Katarina, Z. (2021). Big Data-driven Algorithmic Governance in Sustainable Smart Manufacturing: robotic Process and Cognitive Automation Technologies. Anal. Metaphys 20:130. doi: 10.22381/am2020219

Roy, M., and Roy, A. (2019). Nexus of Internet of Things (IoT) and Big Data: roadmap for Smart Management Systems (SMgS). IEEE Eng. Manag. Rev. 47, 53–65. doi: 10.1109/EMR.2019.2915961

Sarfraz, M., He, B., and Shah, S. G. M. (2020a). Elucidating the effectiveness of cognitive CEO on corporate environmental performance: the mediating role of corporate innovation. Environ. Sci. Pollut. Res. 27, 45938–45948. doi: 10.1007/S11356-020-10496-7/TABLES/6

Sarfraz, M., Shah, S. G. M., Ivascu, L., and Qureshi, M. A. A. (2020b). Explicating the impact of hierarchical CEO succession on small-medium enterprises’ performance and cash holdings. Int. J. Financ. Econ 26, 2289. doi: 10.1002/ijfe.2289

Sattarian, M., Rezazadeh, J., Farahbakhsh, R., and Bagheri, A. (2019). Indoor navigation systems based on data mining techniques in internet of things: a survey. Wirel. Networks 25, 1385–1402. doi: 10.1007/s11276-018-1766-4

Sharma, H. B., Vanapalli, K. R., Samal, B., Cheela, V. R. S., Dubey, B. K., and Bhattacharya, J. (2021). Circular economy approach in solid waste management system to achieve UN-SDGs: solutions for post-COVID recovery. Sci. Total Environ. 800:149605. doi: 10.1016/j.scitotenv.2021.149605

Singhai, R., and Sushil, R. (2021). An investigation of various security and privacy issues in Internet of Things. Mater. Today Proc doi: 10.1016/j.matpr.2021.07.259

Soo, V. K., Doolan, M., Compston, P., Duflou, J. R., Peeters, J., and Umeda, Y. (2021). The influence of end-of-life regulation on vehicle material circularity: a comparison of Europe. Japan, Australia and the US. Resour. Conserv. Recycl. 168:105294. doi: 10.1016/j.resconrec.2020.105294

Stich, V., Zeller, V., Hicking, J., and Kraut, A. (2020). Measures for a successful digital transformation of SMEs. Procedia CIRP 93, 286–291. doi: 10.1016/j.procir.2020.03.023

Su, C., and Urban, F. (2021). Circular economy for clean energy transitions: a new opportunity under the COVID-19 pandemic. Appl. Energy 289:116666. doi: 10.1016/j.apenergy.2021.116666

Sulich, A., and Sołoducho-Pelc, L. (2021). The circular economy and the Green Jobs creation. Environ. Sci. Pollut. Res. 29, 14231–14247. doi: 10.1007/S11356-021-16562-Y/TABLES/9

Supardianto, Ferdiana, R., and Sulistyo, S. (2019). The Role of Information Technology Usage on Startup Financial Management and Taxation. Procedia Comput. Sci. 161, 1308–1315. doi: 10.1016/j.procs.2019.11.246

Thomasian, N. M., and Adashi, E. Y. (2021). Cybersecurity in the Internet of Medical Things. Heal. Policy Technol. 10:100549. doi: 10.1016/j.hlpt.2021.100549

Tiwari, K., and Khan, M. S. (2020). Sustainability accounting and reporting in the industry 4.0. J. Clean. Prod. 258:120783. doi: 10.1016/J.JCLEPRO.2020.120783

Upadhyay, A., Mukhuty, S., Kumar, V., and Kazancoglu, Y. (2021). Blockchain technology and the circular economy: implications for sustainability and social responsibility. J. Clean. Prod. 293:126130. doi: 10.1016/j.jclepro.2021.126130

Vătămănescu, E. M., Dabija, D. C., Gazzola, P., Cegarro-Navarro, J. G., and Buzzi, T. (2021). Before and after the outbreak of Covid-19: linking fashion companies’ corporate social responsibility approach to consumers’ demand for sustainable products. J. Clean. Prod. 321:128945. doi: 10.1016/J.JCLEPRO.2021.128945

Yalçın, N. G., and Foxon, T. J. (2021). A systemic approach to transitions towards circular economy: the case of Brighton and Hove. Clean. Environ. Syst. 3:100038. doi: 10.1016/j.cesys.2021.100038

Yang, L., Xiong, Z., Liu, G., Hu, Y., Zhang, X., and Qiu, M. (2021). An Analytical Model of Page Dissemination for Efficient Big Data Transmission of C-ITS. IEEE Trans. Intell. Transp. Syst doi: 10.1109/TITS.2021.3134557

Ymeri, P., Musliu, A., Shkodra, J., Miftari, I., and Fogarassy, C. (2020). Analysis of income determinants among rural households in Kosovo. 42, Soc. Econ. doi: 10.1556/204.2020.00021

Yu, B. (2022). The Impact of the Internet on Industrial Green Productivity: evidence from China. Technol. Forecast. Soc. Change 177:121527. doi: 10.1016/j.techfore.2022.121527

Yu, L., Tao, S., Gao, W., Zhang, G., and Lin, K. (2016). “Intelligent farm relaxation for smart city based on Internet of Things: Management system and service model,” in IoTBD 2016 - Proceedings of the International Conference on Internet of Things and Big Data. (Beijing: China Agriculture University), 159–166. doi: 10.5220/0005874001590166

Yu, Z., Khan, S. A. R., and Umar, M. (2021). Circular economy practices and industry 4.0 technologies: a strategic move of automobile industry. Bus. Strateg. Environ. 31, 796–809. doi: 10.1002/bse.2918

Yumei, H., Iqbal, W., Irfan, M., and Fatima, A. (2021). The dynamics of public spending on sustainable green economy: role of technological innovation and industrial structure effects. Environ. Sci. Pollut. Res. 1, 1–19. doi: 10.1007/s11356-021-17407-4

Zafari, F., Gkelias, A., and Leung, K. K. (2019). A Survey of Indoor Localization Systems and Technologies. IEEE Commun. Surv. Tutorials 21, 2568–2599. doi: 10.1109/COMST.2019.2911558

Zając, P., and Avdiushchenko, A. (2020). The impact of converting waste into resources on the regional economy, evidence from Poland. Ecol. Modell. 437:109299. doi: 10.1016/j.ecolmodel.2020.109299

Keywords: Internet of Things, Industry 4.0, sustainable business practices, circular economy, environmental sustainability

Citation: Sun X and Wang X (2022) Modeling and Analyzing the Impact of the Internet of Things-Based Industry 4.0 on Circular Economy Practices for Sustainable Development: Evidence From the Food Processing Industry of China. Front. Psychol. 13:866361. doi: 10.3389/fpsyg.2022.866361

Received: 31 January 2022; Accepted: 23 February 2022;

Published: 25 April 2022.

Edited by:

Muddassar Sarfraz, University of Putra Malaysia, MalaysiaReviewed by:

Luminita Ionescu, Spiru Haret University, RomaniaJakub Horák, Institute of Technology and Business, Czechia

Copyright © 2022 Sun and Wang. This is an open-access article distributed under the terms of the Creative Commons Attribution License (CC BY). The use, distribution or reproduction in other forums is permitted, provided the original author(s) and the copyright owner(s) are credited and that the original publication in this journal is cited, in accordance with accepted academic practice. No use, distribution or reproduction is permitted which does not comply with these terms.

*Correspondence: Xiaoli Sun, 6138@zut.edu.cn

Xiaoli Sun1*

Xiaoli Sun1* Xuan Wang

Xuan Wang