Relation Between Adhesion Properties and Microscopic Characterization of Polyphosphoric Acid Composite SBS Modified Asphalt Binder

- 1National and Provincial Joint Engineering Laboratory of Road and Bridge Disaster Prevention and Control, Lanzhou Jiaotong University, Lanzhou, China

- 2Gansu Province Highway Traffic Construction Group Co., Ltd., Lanzhou, China

- 3Gansu Provincial Transportation Research Institute Group Co., Ltd., Lanzhou, China

The purpose of this study was to investigate the adhesive properties of polyphosphoric acid compounded SBS (PPA/SBS) modified asphalt. Three base asphalt binders, one SBS, one dibutyl phthalate (DBP), one furfural extraction oil, and two polyphosphoric acids (PPA), were used to produce the modified binders. The adhesive properties tested in this study included contact angle, cohesive work, adhesive work, and peak area ratio. Cohesive work and adhesive work indicators were calculated from the contact angle, the contact angle between PPA/SBS modified asphalt and three liquids (distilled water, glycerin, formamide) were tested by the contact angle tester, and the peak area ratio of the microscopic adhesion performance index by AFM. The relation between the microscopic adhesion performance characterization method (peak area ratio) and the macroscopic adhesion performance index (cohesive work, adhesion work) was established. The test results indicated that the PPA/SBS modified asphalt had the highest cohesive work and adhesion work under the conditions of 0.5% PPA, 1% DBP, 1.5% extracted oil, and 3.5% SBS, which was clearly greater than the original SBS modified asphalt, while the peak area ratio was consistent with the cohesive work and adhesive work, in which the correlation coefficient between the peak area ratio and cohesive work was 0.77788, and that between the peak area ratio and adhesion work was 0.87203. We recommend adopting the peak area ratio to characterize PPA/SBS modified asphalt’s microscopic adhesion properties.

Introduction

Asphalt pavement is the primary material used in high-grade pavement, most of which is distributed in regions with cold winters and hot summers. Asphalt materials require the properties of high and low temperature performance, requirements that ordinary base asphalt cannot meet (Zhang et al., 2016). As part of the implementation of the strategic highway research program (SHRP) binder specification, various properties of asphalt binder can be improved significantly by adding modifiers such as polymer and rubber powder (Wang et al., 2018a; Wang et al., 2018b). Among them, SBS modified asphalt is used widely because of its good high temperature stability and low temperature crack resistance (Liang et al., 2015). However, with the rise in oil and polymer prices, the price of polymer modified asphalt has increased (Cai et al., 2018). Thus, the application of a cheap polyphosphoric acid (PPA) modifier in road asphalt modification has attracted the attention of domestic and foreign scholars gradually, and many researchers have carried out the preparation process, and identified PPA modified asphalt’s microstructure and modification mechanism, and have drawn many useful conclusions that has laid the foundation for PPA modified asphalt’s further development (Bishara et al., 2003; Romagosa and Martin, 2009; Fee and Maldonado, 2010; Yan et al., 2013; Wang et al., 2017). Previous studies have shown that PPA reduces the modification cost to a certain extent and improves SBS modified asphalt’s high-temperature performance significantly (Baumgardner, 2006; Kodrat et al., 2007; Jiang et al., 2019). However, it has been reported that PPA can react with asphalt only when it contains polymer with a high dielectric constant (Masson, 2008). Therefore, some scholars have proposed that a certain amount of SBS modifier can be added to improve the PPA’s related properties (Aflaki and Hajikarimi, 2012; Zegeye et al., 2012).

Research on PPA/SBS modified asphalt’s high and low temperature rheological properties and chemical composition changes has been conducted commonly (Jiang et al., 2012; Zegeye et al., 2012; Alam and Hossain, 2017), but there is little research on its water sensitivity. As an early road surface disease of asphalt pavement, water damage shortens the pavement’s service life and affects road safety seriously. In recent years, researchers at home and abroad have believed that the mechanism of water damage consists primarily of cohesive and adhesion failure (Kvasnak and West, 2009; Howson et al., 2010), largely by using the adhesion properties of asphalt and aggregate to appraise the asphalt mixture’s water stability. The evaluation methods include the bitumen bond strength test, boiling water test, freeze-thaw splitting experiment, Hamburg Wheel Tracking Device (HWTD) experiment, and so on (Reinke et al., 2010; Park et al., 2017; Gang et al., 2018). However, these experiments on the adhesion between the asphalt and aggregate are macro experiments, which are influenced greatly by subjective factors and result in inconsistent research results, while no explanation has been given of the mechanism from the micro level. To study the adhesion of asphalt and aggregate from the microscopic aspect quantitatively, the surface free energy (SFE) theory and atomic force microscopy (AFM) have been used constantly over the years, and proven to be a powerful way to study asphalt materials’ adhesion properties quantitatively.

Ji et al. studied asphalt mixture system’s adhesiveness in the presence and absence of water through the surface free energy theory, and found that this method is feasible (Ji et al., 2017). Moraes et al. compared the asphalt bonding strength (ABS) test with the surface energy test, and found that different asphalt samples’ ABS has a good correlation with the surface energy index, indicating that the surface energy test’s use can measure the water stability between asphalt and aggregate effectively (Moraes et al., 2017). In addition, AFM, as an auxiliary verification method, not only detects asphalt binders’ nanoscopic adhesion characteristics, but also provides a new and better research method to understand asphalt’s microstructure and mechanical properties accurately. Guo et al. investigated the interfacial interaction between asphalt and aggregate with the AFM test, and found that the influence thickness is approximately 1 µm (Guo et al., 2017). Ma et al. used the AFM test to investigate the change in asphalt binder’s bond performance after aging and regeneration, and found a very good correlation between the AFM and macro test results. In addition, AFM can be used to characterize the asphalt’s bonding properties better after aging and regeneration (Ma et al., 2019). Li et al. used the force-distance curve of the AFM experiment to investigate the influence of the original material composition on SBS modified asphalt’s nano adhesion properties, which showed that AFM can be used to study the water stability between asphalt and aggregate quantitatively (Li et al., 2019). A large number of studies has shown that both the surface energy and AFM tests can characterize the adhesion of asphalt and the adhesion between asphalt and aggregate quantitatively. However, few scholars have given attention to the change in PPA/SBS modified asphalt’s adhesion and adhesion performance.

In this paper, different raw materials’ influence on the adhesion performance of PPA/SBS modified asphalt was studied by the surface energy theory and AFM test. The PPA/SBS modified asphalt’s water damage resistance was characterized by adhesion work and cohesion work, and its nano adhesion properties were characterized through the peak area ratio. At the same time, the correlation between the surface energy test results and AFM test results was analyzed to promote the application of AFM technology by characterizing the PPA/SBS modified asphalt’s adhesion properties.

Materials and Experimental Methods

Raw Materials

base asphalt

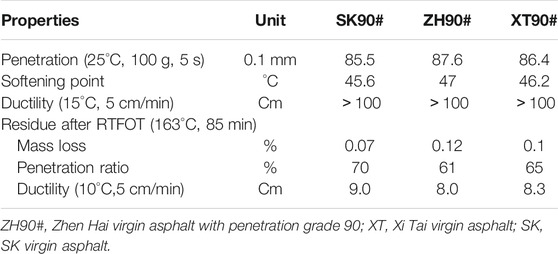

The Gansu Luqiao Construction Group Co., Ltd. supplied the three base asphalts used, and Table 1 shows the base asphalt binders’ performance.

(2) SBS modifier

SBS modifier consists of two molecular structures: Linear and star-shaped. In this paper, SBS modified asphalt was prepared with the 1,301 linear SBS modifier used commonly in Gansu. The primary physical indices are displayed in Table 2.

(3) Polyphosphoric acid (PPA)

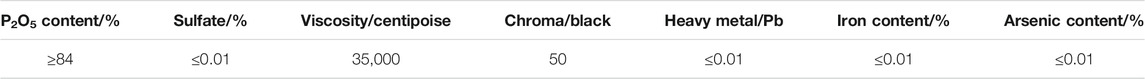

In this paper, the PPA Shanghai Zhanyun provided was used to improve the asphalt’s high temperature properties. Its main technical performance indices are shown in Table 3.

(4) Furfural extraction oil

Extracted oil was used to improve the compatibility of SBS and asphalt, thereby enhancing SBS modified asphalt’s low-temperature plasticity and ductility. The main technical indicators are shown in Table 4.

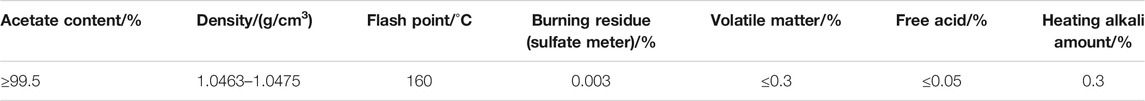

(5) Dibutyl phthalate (DBP)

To prevent the low temperature properties of PPA in the matrix asphalt deteriorating in the modification process, DBP provided by Wuxi was used to improve its low temperature performance. The principal technical indicators are shown in Table 5.

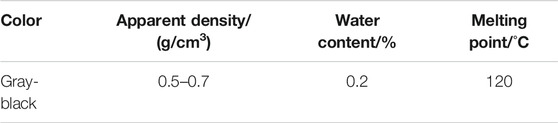

(6) Stabilizer

In addition, to avoid phase separation in SBS modified asphalt and increase its storage stability, a certain amount of high-quality stabilizer Gansu Provincial Road Surface Engineering Technology Research Center provided was added when preparing the SBS modified asphalt. The major physical indicators are shown in Table 6.

Sample Preparation

Preparation of PPA/SBS modified asphalt

PPA/SBS modified asphalt is made with a high-speed shearing machine. The specific test procedure was as follows (Li et al., 2021): 1) The matrix asphalt was heated to 140°C, and a certain amount of extracted oil was added and stirred evenly; 2) The evenly mixed asphalt was placed in the heating device and heated to 160°C, and the required amount of DBP was added and stirred uniformly; 3) the temperature was raised rapidly to approximately 175°C, SBS modifier was added, and the mixture was stirred thoroughly and allowed to swell for approximately 10 min; 4) the set content of PPA in the swollen modified asphalt was heated, and placed under a high-speed shearing machine to control and stabilize the temperature at approximately 175°C at 5000 r/min, and was sheared for 30 min; 5) the stabilizer was set and stirring continued for 10 min; 6) the modified asphalt was developed continuously for 2.5 h to obtain the compound asphalt required for the test.

(2) Preparation of contact angle sample preparation

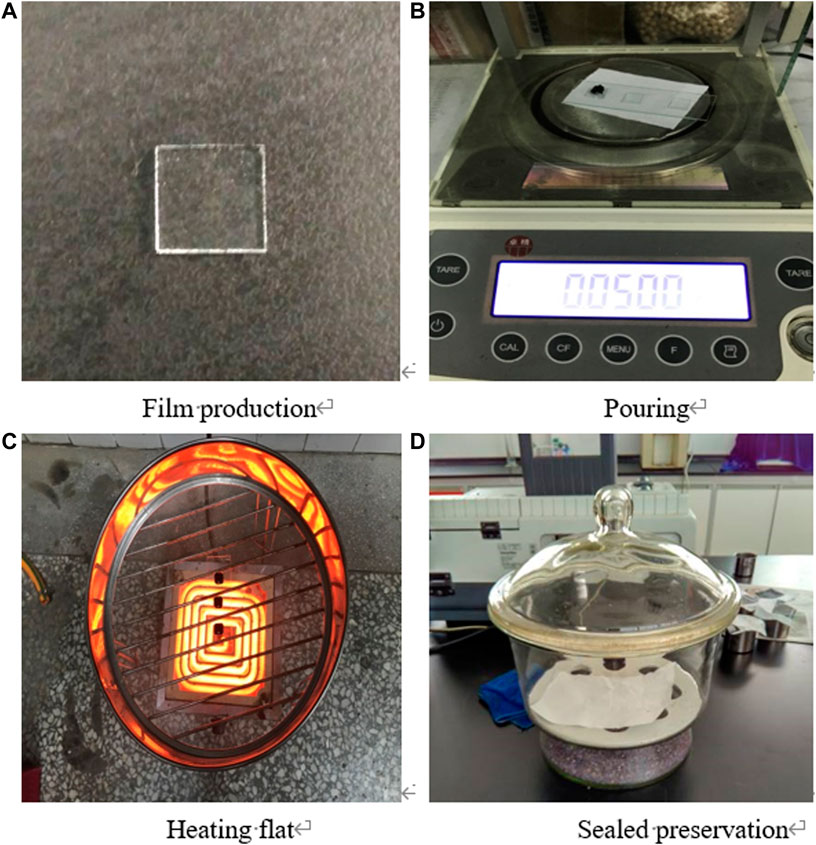

The asphalt samples were prepared by the drop method. First, the asphalt binder was heated and weighed and 1.5 ± 0.1 g was placed on the slide. Thereafter, it was placed on a horizontal heating frame and heated for 5 min to form a uniform asphalt film. Finally, the asphalt sample was placed in a drying dish for 12 h (Li et al., 2021).

(3) AFM sample preparation

The preparation process of the AFM sample was as follows: First, 0.05g of the fluid state asphalt mixture was weighed onto a 1 cm × 1 cm glass slide, and then placed on a leveled and high-rise heating frame, at a temperature of approximately 163°C and heated continuously until a smooth horizontal asphalt test surface was obtained. It was moved to room temperature to cool, and then placed in a sealed dry container horizontally for approximately 24h to obtain an AFM sample. The preparation process is shown in Figure 1.

FIGURE 1. AFM sample preparation process. (A) Film production. (B) Pouring. (B) Heating flat. (D) Sealed preservation.

Sample Test

Contact angle test

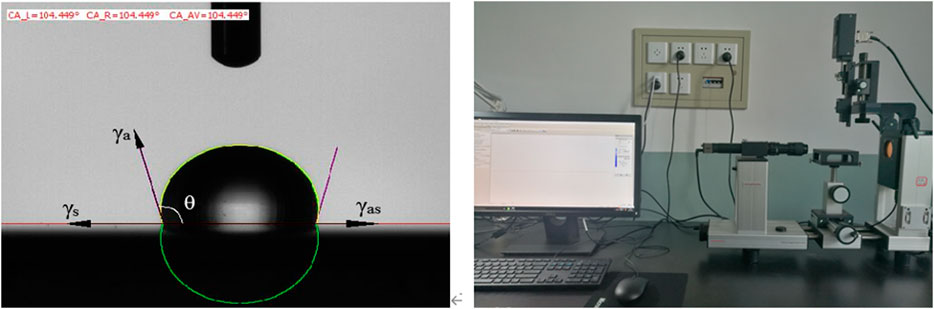

A contact angle test is required to calculate PPA/SBS modified asphalt’s adhesion performance index (cohesive work and adhesion work) (Li et al., 2021). Figure 2 shows the contact angle formed between the liquid and the asphalt sample. In addition, it shows the test instrument for the contact angle.

FIGURE 2. Schematic representation of the contact angle formed between a probe liquid and an asphalt surface and drop shape analyser (OCA25).

PPA/SBS modified asphalt’s adhesion performance indices can be calculated from the contact angle test results; for the detailed calculation process, refer to Li et al. (Li et al., 2021). The calculation equation is shown in Eqs (1), (2):

in which γp is the polar component, γd is the dispersion component, γ+ is the Lewis acid component, γ− is the Lewis base component, γa is the bitumen surface energy, γs is the aggregate surface energy, and γas is the interface energy between the bitumen and the aggregate contact surface.

(2) AFM test

In this paper, Bruce’s Icon-type atomic force microscope and Bugdet Sensors Tap300Al-G probe were used to test the asphalt samples’ morphology and mechanical indices in the peak force light mode (PFT QNM). The probe elastic constant was 1 Hz, scanning frequency was 1.0 Hz, scanning range was 20 um × 20 um, resolution was 512 × 512, and test temperature was 25°C, as shown in Figure 3.

Results and Discussion

Raw Materials’ Influence on PPA/SBS Modified Asphalt’s Adhesion Characteristics

Matrix asphalt/PPA type

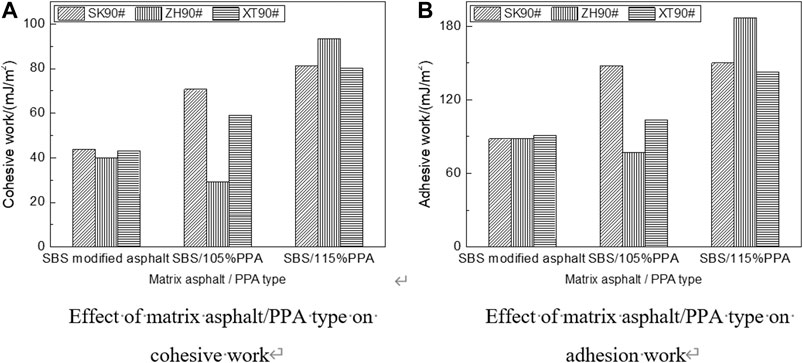

The adhesion performance indices (cohesive work and adhesion work) of PPA/SBS modified asphalt prepared from three kinds of base asphalt (SK90# and ZH90# and XT90#) and PPA type (105% PPA and 115% PPA) are shown in Figure 4.

FIGURE 4. Effect of matrix asphalt/PPA type on PPA/SBS modified asphalt’s adhesion characteristics, (A) Effect of matrix asphalt/PPA type on cohesive work, (B) Effect of matrix asphalt/PPA type on adhesion work.

As illustrated in Figure 4, both the base asphalt and the type of PPA influence PPA/SBS modified asphalt’s adhesion work and cohesive work. Among them, when the base asphalt is SK asphalt, and the PPA is 105%, the PPA/SBS modified asphalt’s adhesion and cohesion effects improved. The results indicated that different types of raw materials have different effects on PPA/SBS modified asphalt’s adhesion properties, and types of asphalt and PPA with good performance should be chosen when selecting raw materials.

(2) Different dosages

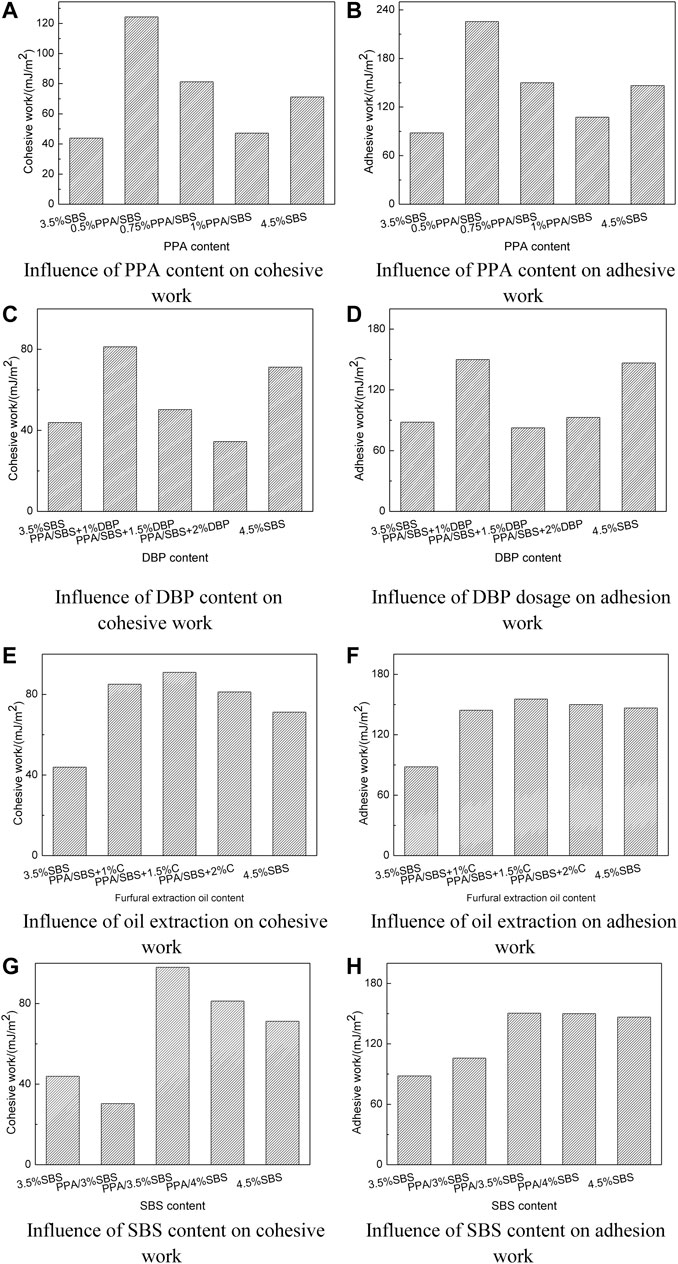

The adhesion performance index (adhesive work and adhesion work) of PPA/SBS modified asphalt prepared with various PPA dosages (0.5, 0.75, and 1.0%), DBP content (1, 1.5, and 2.0%), oil extraction amounts (1, 1.5, and 2.0%), and SBS content (3, 3.5, and 4.0%) is shown in Figure 5.

FIGURE 5. Effect of the raw materials’ content on PPA/SBS modified asphalt’s adhesion characteristics. (A) Influence of PPA content on cohesive work. (B) Influence of PPA content on adhesive work. (C) Influence of DBP content on cohesive work. (D) Influence of DBP dosage on adhesion work. (E) Influence of oil extraction on cohesive work. (F) Influence of oil extraction on adhesion work. (G) Influence of SBS content on cohesive work. (H) Influence of SBS content on adhesion work.

Figure 5 shows that compared to 3.5% SBS modified asphalt, the cohesion work and adhesive work PPA/SBS modified asphalt provided increased, which indicates that after adding PPA, PPA, and SBS modified asphalt reacted and consumed energy, resulting in a change in the SBS modified asphalt’s molecular network structure, which improved its bonding performance (Liang et al., 2017). However, as the PPA and DBP dosage increased, the cohesive work and adhesive work decreased, and as the furfural extract oil and SBS dosage increased, the cohesion work and adhesion work increased first and then decreased, indicating that when PPA, DBP, furfural extract oil, and SBS are within a certain range, the PPA/SBS modified asphalt’s adhesiveness and cohesiveness will increase, but beyond this range, they will decrease. Moreover, with 0.5% PPA content, 1% DBP content, 1.5% furfural extract oil content, and 3.5% SBS modifier content, the cohesion work and adhesion work were the largest, even more than the actual production of high content SBS modified asphalt, and the adhesion properties also improved significantly. These results indicated that under this condition, the PPA/SBS modified asphalt has good cohesiveness and adhesiveness with the aggregate and its water damage resistance is the greatest.

Raw Materials’ Effect on PPA/SBS Modified Asphalt’s Peak Area Ratio

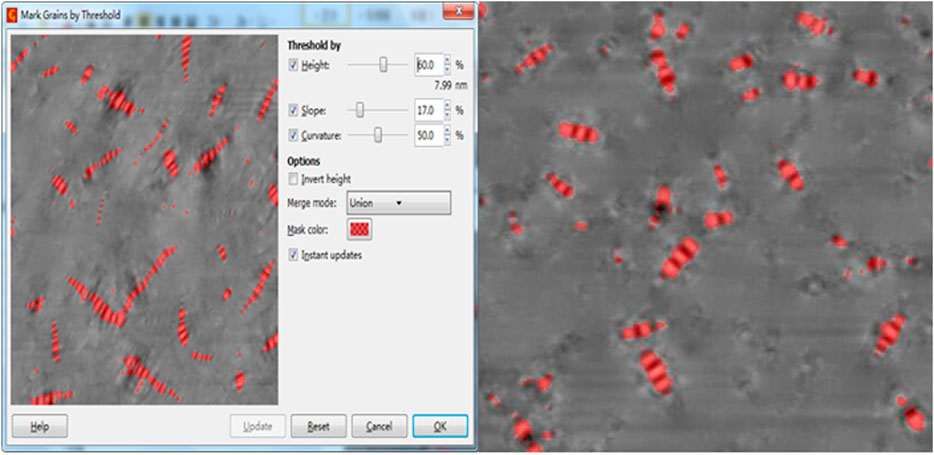

Gwyddion is a professional scanning microscope image processing software, in which the Grains Mark function can distinguish the microstructure according to the height. In this paper, Gwyddion was used to mark the matrix phase and the “honeycomb” structure according to the height of different phases, as shown in Figure 6. The area of the marked protrusion was calculated, and the ratio of the area of the entire scanning area (900 μm2) was obtained, which is the peak area ratio.

FIGURE 6. Labeled asphalt topography. (A) Gwyddion software “honeycomb” structure marker. (B) Mark “honeycomb” structure.

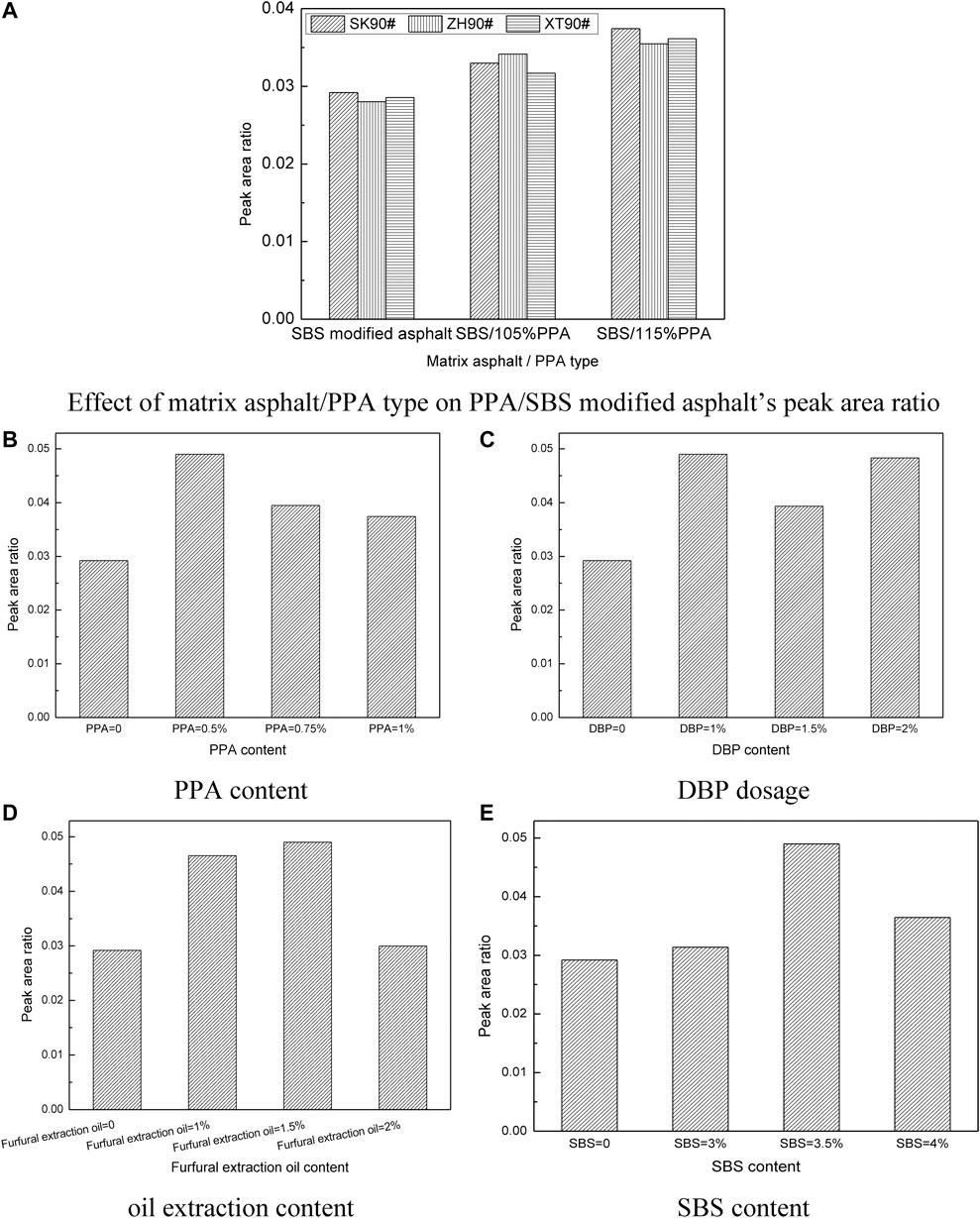

The atomic force microscope was used to explore the original materials’ effect on the PPA/SBS modified asphalt’s microstructure, and their effect on the PPA/SBS modified asphalt’s peak area ratio was studied further. The results are shown in Figure 7.

FIGURE 7. Effect of raw material content on PPA/SBS modified asphalt’s peak area ratio. (A) Effect of matrix asphalt/PPA type on PPA/SBS modified asphalt’s peak area ratio. (B) PPA content. (C) DBP dosage. (D) oil extraction content. (E) SBS content.

Figure 7A shows different matrix asphalt types and different PPA types’ effect on the PPA/SBS modified asphalt’s peak area ratio. The analysis chart shows that the peak area ratio was SK base asphalt > XT base asphalt > ZH base asphalt, which is the same as the matrix asphalt without SBS modifier, indicating that the addition of SBS modifier has no effect on the “honeycomb” structure. After PPA was added to the SBS modified asphalt, the three matrix asphalts’ peak area ratio increased, and the peak area ratio of 115% PPA to 105% PPA was larger, indicating that the appropriate amount of PPA increased the SBS modified asphalt’s peak. The area ratio was the same as the change trend in the adhesion properties index of the SBS modified asphalt with the matrix asphalt and PPA type.

Figure 7B shows that as the PPA content increased, the peak area ratio increased first and then decreased, and the peak occurred when the dosage was 0.5%, indicating that PPA/SBS is 0.5% PPA/SBS. Further, the modified asphalt had a greater effect. Figure 7C illustrates that the peak area ratio was highest when the DBP dosage was 1%. As the amount of doping continued to increase, the peak area ratio decreased sharply. When the amount was too high, the peak area ratio was as well. The increase indicated that the change in the amount of DBP causes a “honeycomb” structure change. It can also be seen in Figure 7D that the effect of the amount of extracted oil on the peak area ratio increased first and then decreased, indicating that the “honeycomb” structure changed. This may be attributable to the formation of the asphalt component after the oil was extracted, and when the number of light components was too great, the “honeycomb” area decreased gradually. Figure 7E shows that the effect of the increase in SBS dosage on the peak area ratio also increased first and then decreased, indicating that a moderate amount of SBS content and asphalt molecules form a relatively stable spatial network structure, making asphaltenes more dispersed, and resulting in an increase in the honeycomb area ratio.

Relation Between Adhesion Performance Index and Peak Area Ratio

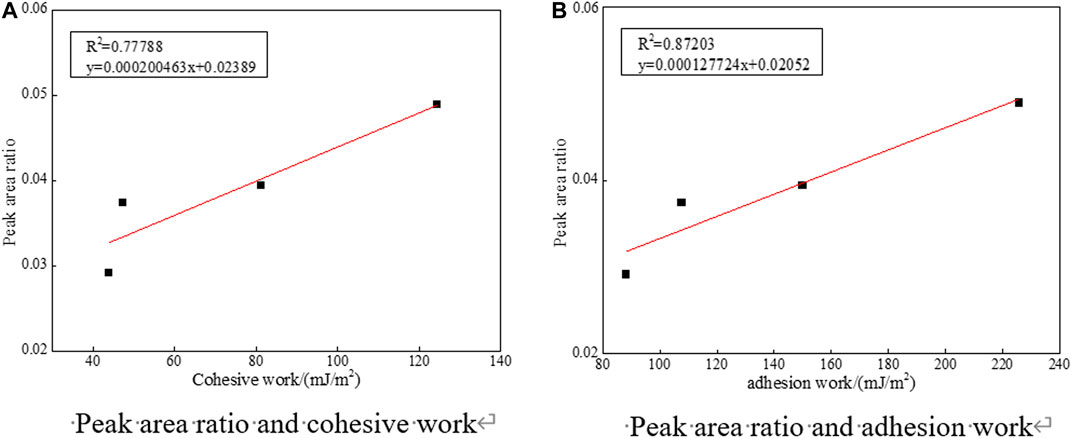

Based on the previous discussion of the raw material types and dosages’ influence on the PPA/SBS modified asphalt’s adhesive performance, taking the influence of PPA content on the PPA/SBS modified asphalt’s bond properties as an example, the relation between the microscopic bond performance characterization method and the macro bond performance was established; the results are shown in Figure 8.

FIGURE 8. Relation between macroscopic adhesion properties and micro-adhesion performance characterization methods. (A) Peak area ratio and cohesive work. (B) Peak area ratio and adhesion work.

Figure 8 shows that the PPA/SBS modified asphalt micro adhesive property characterization method (peak area ratio) and macroscopic adhesion performance index (viscoaggregation work and adhesion work) were correlated positively, but for the microscopic adhesion properties, the correlation coefficient between the characterization method and the macroscopic adhesion performance index was small. The correlation coefficient between the peak area ratio and macroscopic adhesion performance index was better, and the coefficients of cohesion work and adhesion work were 0.77788 and 0.87203, respectively. Further, the correlation coefficient of modified asphalt with more polyphosphoric acid improved significantly. It was proven fully that PPA can disperse the “honeycomb” structure between SBS modified asphalt and form a relatively stable spatial reticular structure with SBS, making the peak area ratio change trend of PPA/SBS modified asphalt closer to the results of the macro bond performance index. The peak area ratio is considered the evaluation index of the PPA/SBS modified asphalt’s micro-adhesion properties.

Conclusion

In this paper, PPA/SBS modified asphalt’s adhesion work and cohesion work were studied by the surface energy theory, and its peak area ratio was studied with the AFM test; the correlation between the two indices was analyzed, and the specific conclusions are as follows:

As the PPA and DBP content increased, the PPA/SBS modified asphalt’s cohesive work, adhesive work, and peak area ratio showed a decreasing trend.

As the amount of oil extracted and SBS increased, the PPA/SBS modified asphalt’s cohesive work, adhesive work, and peak area ratio increased first and then decreased.

PPA/SBS modified asphalt’s cohesive work, adhesion work, and peak area comparison showed that 3.5% SBS modified asphalt demonstrated an increasing trend. The PPA/SBS modified asphalt had the largest cohesive work, adhesion work, and peak area compared with SBS modified asphalt with a 0.5% PPA dosage, 1% DBP dosage, 1.5% furfural extract oil dosage, and 3.5% SBS modifier dosage.

The correlation coefficient between PPA/SBS modified asphalt’s peak area ratio and macroscopic adhesion performance index was the highest. The peak area ratio is considered to characterize PPA/SBS modified asphalt’s micro-adhesive properties.

Data Availability Statement

The original contributions presented in the study are included in the article/Supplementary Material, further inquiries can be directed to the corresponding author.

Author Contributions

LL: Conceptualization, Methodology, Data curation, Writing-original draft. ZL: Validation, Data curation, Writing-review and editing. YW: Writing-review and editing. XL: Validation, Writing-review and editing. BL: Investigation, Writing-review and editing.

Funding

The research work reported in this paper was supported by the National Natural Science Foundation of China (Grant Nos. 51668038 and 51868042), Industry Support and Guidance Project by University and College in Gansu Province (No. 2020C-13), the Distinguished Young Scholars Fund of Gansu Province (No. 1606RJDA318).

Acknowledgments

The authors gratefully acknowledge many important contributions from the researchers of all reports cited in our paper.

Conflict of Interest

Author YW was employed by the company Gansu Province Highway Traffic Construction Group Co., Ltd. Author XL was employed by the company Gansu Provincial Transportation Research Institute Group Co., Ltd.

The remaining authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

References

Aflaki, S., and Hajikarimi, P. (2012). Implementing viscoelastic rheological methods to evaluate low temperature performance of modified asphalt binders. Constr. Build. Mater. 36, 110–118. doi:10.1016/j.conbuildmat.2012.04.076

Alam, S., and Hossain, Z. (2017). Changes in fractional compositions of PPA and SBS modified asphalt binders. Constr. Build. Mater. 152, 386–393. doi:10.1016/j.conbuildmat.2017.07.021

Baumgardner, G. (2006). “Appropriate application of chemical Modification.”in Presented at the meeting of the association of modified asphalt producers annual meeting, Wisconsin Rapids, WI, November 4–November 6, 2006. America.

Bishara, S. W., King, G. N., Mahoney, D., and Reynolds, R. L. (2003). Modification of binder with acid. advantages and disadvantages. J. Transp. Res. Rec. 2, 37–45.

Cai, L., Shi, X., and Xue, J. (2018). Laboratory evaluation of composed modified asphalt binder and mixture containing nano-silica/rock asphalt/SBS. Constr. Build. Mater. 172,.204–211. doi:10.1016/j.conbuildmat.2018.03.187

Fee, D., Maldonado, R., Reinke, G., and Romagosa, H. 2010). Polyphosphoric acid modification of asphalt. Transp. Res. Rec. 2179, 49–57. doi:10.3141/2179-06

Gang, H., Wang, P., and Liu, B. S. (2018). Study on the performance of polyphosphoric acid modified asphalt. West. Transp. Sci. Technol. (06), 5–10. doi:10.16339/j.cnki.hdxbzkb.2017.05.013

Guo, M., Tan, Y., Yu, J., Hou, Y., and Wang, L. (2017). A direct characterization of interfacial interaction between asphalt binder and mineral fillers by atomic force microscopy. Mater. Struct. 50 (2), 141. doi:10.1617/s11527-017-1015-9

Howson, J., Masad, E., Amit, B., Little, D., and Lytton, R. (2010). Comprehensive analysis of surface free energy of asphalts and aggregates and the effects of changes in pH. Constr. Build. Mater. 25 (5). doi:10.1016/j.conbuildmat.2010.11.098

Ji, J., Yao, H., Liu, L., Suo, Z., Peng, Z., Yang, X., et al. (2017). Adhesion evaluation of asphalt-aggregate interface using surface free energy method. Appl. Sci. 7 (2), 156. doi:10.3390/app7020156

Jiang, X., Li, P., Ding, Z., Yang, L., and Zhao, J. (2019). Investigations on viscosity and flow behavior of polyphosphoric acid (PPA) modified asphalt at high temperatures. Constr. Build. Mater. 228, 116610. doi:10.1016/j.conbuildmat.2019.07.336

Kodrat, I., Sohn, D., and Simon, A. M. (2007). Hesp. comparison of polyphosphoric acid-modified asphalt binders with straight and polymer-modified materials. Transport. Res. Rec. (1), 1998. 10.3141/1998-06

Kvasnak, A. N., and West, R. C. (2009). “Case study of warm-mix asphalt moisture susceptibility in birmingham, Alabama,” in Transportation Research Board 88th Annual Meeting, Washington, DC, January 11–January 15, 2009.

Li, B., Cui, Y., Liu, X., Li, H., and Li, X. (2019). Effect of material composition on nano-adhesive characteristics of styrene-butadiene-styrene copolymer-modified bitumen using atomic force microscope technology. Int. J. Adhes. Adhes. 89, 168–173. doi:10.1016/j.ijadhadh.2019.01.002

Li, B., Li, X., Kundwa, M. J., Li, Z., and Wei, D. (2021). Evaluation of the adhesion characteristics of material composition for polyphosphoric acid and SBS modified bitumen based on surface free energy theory. Constr. Build. Mater. 266 (PB), 121022. doi:10.1016/j.conbuildmat.2020.121022

Liang, M., Liang, P., Fan, W., Qian, C., Xin, X., Shi, J., et al. (2015). Thermo-rheological behavior and compatibility of modified asphalt with various styrene-butadiene structures in SBS copolymers. Mater. Des. 88, 177–185. doi:10.1016/j.matdes.2015.09.002

Liang, P., Liang, M., Fan, W., Zhang, Y., Qian, C., and Ren, S. (2017). Improving thermo-rheological behavior and compatibility of SBR modified asphalt by addition of polyphosphoric acid (PPA). Constr. Build. Mater. 139, 183–192. doi:10.1016/j.conbuildmat.2017.02.065

Ma, W., Huang, T., Guo, S., Yang, C., Ding, Y., and Hu, C. (2019). Atomic force microscope study of the aging/rejuvenating effect on asphalt morphology and adhesion performance. Constr. Build. Mater. 205, 642–655. doi:10.1016/j.conbuildmat.2019.01.151

Masson, J.-F. (2008). Brief review of the chemistry of polyphosphoric acid (PPA) and bitumen. Energy Fuels 22 (4), 2637–2640. doi:10.1021/ef800120x

Moraes, R., Velasquez, R., and Hussain, B. (2017). Using bond strength and surface energy to estimate moisture resistance of asphalt-aggregate systems. Constr. Build. Mater. 130, 156–170. doi:10.1016/j.conbuildmat.2016.10.043

Park, D. W., Seo, W. J., Kim, J., and Vo, H. V. (2017). Evaluation of moisture susceptibility of asphalt mixture using liquid anti-stripping agents. Constr. Build. Mater. 144, 399–405. doi:10.1016/j.conbuildmat.2017.03.214

Reinke, G., Glidden, S., Herlitzka, D., and Veglahn, S. (2010). “PPA modified binders and mixtures: Aggregate and binder interactions, rutting and moisture sensitivity of mixtures,” in Asphalt Paving Technilogists-Proceedings of the Technical Sessions, Sacramento, CA, March 7–March 10, 2010, 719

Romagosa, H., and Martin, J. V. (2009). “Best practices for PPA modification of asphalt,” in Presented at the 2009 PPA Workshop, Minneapolis, MN, April 7–April 8, 2009.

Wang, J., Yuan, J., Xiao, F., Li, Z., Wang, J., and Xu, Z. (2018a). Performance investigation and sustainability evaluation of multiple-polymer asphalt mixtures in airfield pavement. J. Clean. Prod. 189. doi:10.1016/j.jclepro.2018.03.208

Wang, L., Wang, Z., and Li, C. (2017). High temperature rheological properties of polyphosphoric acid modified asphalt. Acta Mater. Compos. Sin. 34 (7), 1610–1616. doi:10.13801/j.cnki.fhclxb.20160921.001

Wang, T., Xiao, F., Zhu, X., Huang, B., Wang, J., and Amirkhanian, S. (2018b). Energy consumption and environmental impact of rubberized asphalt pavement. J. Clean. Prod. 180, 139–158. doi:10.1016/j.jclepro.2018.01.086

Yan, K., Zhang, H., and Xu, H. (2013). Effect of polyphosphoric acid on physical properties, chemical composition and morphology of bitumen. Constr. Build. Mater. 47, 92–98. doi:10.1016/j.conbuildmat.2013.05.004

Zegeye, E. T., Moon, K. H., Turos, M., Clyne, T. R., and Marasteanu, M. O. (2012). Low temperature fracture properties of polyphosphoric acid modified asphalt mixtures. J. Mater. Civ. Eng. 24 (8).doi:10.1061/(asce)mt.1943-5533.0000488

Keywords: polyphosphoric acid compounded SBS modified asphalt, surface free energy theory, atomic force microscopy, adhesion properties, peak area ratio

Citation: Li L, Li Z, Wang Y, Li X and Li B (2021) Relation Between Adhesion Properties and Microscopic Characterization of Polyphosphoric Acid Composite SBS Modified Asphalt Binder. Front. Mater. 8:633439. doi: 10.3389/fmats.2021.633439

Received: 25 November 2020; Accepted: 06 January 2021;

Published: 02 March 2021.

Edited by:

Zhanping You, Michigan Technological University, United StatesReviewed by:

Ali Behnood, Purdue University, United StatesPouria Hajikarimi, Amirkabir University of Technology, Iran

Copyright © 2021 Li, Li, Wang, Li and Li. This is an open-access article distributed under the terms of the Creative Commons Attribution License (CC BY). The use, distribution or reproduction in other forums is permitted, provided the original author(s) and the copyright owner(s) are credited and that the original publication in this journal is cited, in accordance with accepted academic practice. No use, distribution or reproduction is permitted which does not comply with these terms.

*Correspondence: Bo Li, libo@mail.lzjtu.cn

Liangying Li1

Liangying Li1  Bo Li

Bo Li