Abstract

The design of the disc brake friction unit is proposed, the basis for the creation of which is a combination of friction materials with different properties. As a criterion for the structural formation of a friction unit of a disc brake, it is proposed to use the initial equality of linear wear rates for all brake linings made of friction materials with different properties. It is shown that the use of a friction unit based on combined friction materials makes it possible to achieve new disc brake characteristics, compared to its traditional design. It is concluded that the proposed solution is promising.

Similar content being viewed by others

REFERENCES

Ehlers, H.-R., et al., Potential and limits of opportunities of the block brake, Glasers Ann., 2002, nos. 6–7, pp. 290–300.

Moiseenko, M.A., Analysis of the loading of parts of high-speed railway carriage disc brakes, Sovrem. Probl. Nauki Obraz., 2012, no. 2. http://science-education.ru/ru/article/view?id=5906. Accessed April 21, 2019.

Osenin, Yu.Yu., Douma Mansur Al-Makhdi, Osenin, Yu.I., Sergienko, O.V., Sosnov, I.I., and Chesnokov, A.V., Providing the stability of the coefficient of friction of a vehicle disk brake under extreme operating conditions, J. Frict. Wear, 2016, vol. 37, no. 3, pp. 230–236.

Khebda, M. And Chichinadze, A.V., Spravochnik po tribotekhnike. Tom 1. Teoreticheskie osnovy (Handbook on Tribotechnics, Vol. 1: Theory), Moscow: Mashinostroenie, 1989.

Radkevich, M.M., Formation of the deformation center in conditions of deformational-thermal processing, Metalloobrabotka, 2005, no. 6 (30), pp. 24–27.

Krylov, V.I., et al., Tormoznoe oborudovanie zheleznodorozhnogo podvizhnogo sostava: spravochnik (Break Equipment for Railway Stock: Handbook), Moscow: Transport, 1989.

Kragel’skii, I.V. and Mikhin, N.M., Uzly treniya mashin: Spravochnik (Machine Friction Joints: Handbook), Moscow: Mashinostroenie, 1984.

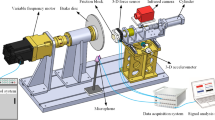

Osenin, Yu.Yu., Sosnov, I.I., Sergienko, O.V., and Bugaenko, V.V., Testing stands of disk brakes for high-speed railway stocks, Visn. Skhidnoukr. Nats. Univ. im. V. Dalya, 2013, no. 2-2, pp. 99–103.

Starchenko, V.N., Gurin, V.A., Bykadorov, V.P., and Shapran, E.N., Friction materials based on carbon-carbon and carbon-asbestos fibers for brake devices, Zhelezn. Dorogi Mira, 2006, no. 2, pp. 38–42.

Author information

Authors and Affiliations

Corresponding author

About this article

Cite this article

Osenin, Y.I., Sosnov, I.I., Chesnokov, A.V. et al. Friction Unit of a Disc Brake Based on a Combination of Friction Materials. J. Frict. Wear 40, 293–296 (2019). https://doi.org/10.3103/S1068366619040093

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.3103/S1068366619040093