Abstract

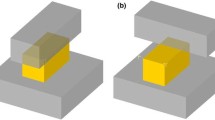

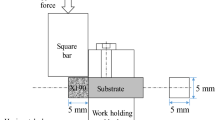

In this paper, 45# steel supports prepared by liquid forging showed excellent performances and the effects of processing techniques on the development of microstructures and mechanical properties of these steel supports were researched. The liquid forging process was simulated and technological parameters were optimized via a ProCAST simulation software. The solidification time, temperature distribution, first principal stress distribution of the 45# steel supports varied with time, temperatures, and position. Two principal parameters, pouring temperature and dwell time, were assessed for their effects on microstructures, mechanical properties, and wear resistance properties of 45# steel supports. Results showed that the optimal pouring temperature of the molten metal and the pressure-holding time were between 1540 °C and 1560 °C and between 35 s and 40 s, respectively. The microstructure, mechanical properties, and fracture behavior of different positions in the support were also discussed, and the central position performed better than the edge because of plastic deformation. Finally, the dynamic solidification process was also investigated and the liquid forging process of 45# steel supports was complex and contained some special metal liquid convection and several plastic deformation stages.

概要

目的

以45#钢支座为典型制件对钢质液态模锻制备工 艺过程进行分析与优化。研究不同工艺参数对制 件组织性能的影响,对制件不同位置的组织性能 进行探讨,优化和改善液态模锻钢制制件性能, 为钢制制件的液态模锻制备提供理论依据。

创新点

1. 利用数值模拟软件模拟分析了钢质液态模锻工 艺过程,为试验分析提供理论依据;2. 对制件不 同位置的组织性能分析,探讨了塑性变形在液态 模锻工艺过程中的影响。

方法

1. 采用ProCAST 模拟软件对45#钢液态模锻的凝 固过程、温度场及应力场的变化进行模拟(图 6~8),并对液态模锻工艺过程进行理论优化; 2. 采用单一变量法,讨论浇注温度和保压时间对 成型件的微观结构、机械性能和耐磨性的影响 (图9~12);3. 研究成型制件不同位置的微观组 织、力学性能和断裂行为(图14,16 和17), 并讨论液态模锻工艺过程中塑性变形对制件组 织性能的影响;4. 探讨分析45#钢支座的动态成 形工艺(图18),并研究45#钢的液态模锻整体 工艺过程。

结论

1. 熔融金属的最佳浇注温度和保压时间分别在 1540~1560 °C 和35~40 s 。2. 在浇注温度为 1540 °C 和保压时间为35 s 时,液态锻造制备的 45#钢支座具有最佳的组织性能;此时支座盘边 缘的抗拉强度、伸长率、维氏硬度和摩擦系数分 别为783.4 MPa、17.1%、242.7 和0.36。3. 45#钢 支座不同位置的组织性能差异不大,但由于塑性 变形的原因,中间位置的性能表现优于边缘位 置。4. 45#钢支座的液态锻造工艺过程相对较复 杂,包含不同的金属液对流和塑性变形;这些特 殊的过程导致45#钢支座的组织性能相对优异。

Similar content being viewed by others

References

Bi GJ, Ng GKL, Teh KM, et al., 2010. Feasibility study on the laser aided additive manufacturing of die inserts for liquid forging. Materials & Design, 31(S1):S112–S116. https://doi.org/10.1016/j.matdes.2009.10.039

Bratu V, Mortici C, Oros C, et al., 2014. Mathematical model of solidification process in steel continuous casting taking into account the convective heat transfer at liquid-solid interface. Computational Materials Science, 94:2–7. https://doi.org/10.1016/j.commatsci.2013.12.033

Cheng YS, Zhang YY, Du ZM, 2010. Liquid forging integral forming technology for aluminum matrix composites with local reinforcement. Special Casting & Nonferrous Alloys, 30(3):231–233 (in Chinese).

Dong J, Li C, Liu CX, et al., 2017. Hot deformation behavior and microstructural evolution of Nb-V-Ti microalloyed ultra-high strength steel. Journal of Materials Research, 32(19):3777–3787. https://doi.org/10.1557/jmr.2017.365

Du ZM, Chen G, Han F, et al., 2011. Homogenization on microstructure and mechanical properties of 2A50 aluminum alloy prepared by liquid forging. Transactions of Nonferrous Metals Society of China, 21(11):2384–2390. https://doi.org/10.1016/S1003-6326(11)61024-8

Escobar DP, de Dafé SSF, Verbeken K, et al., 2016. Effect of the cold rolling reduction on the microstructural characteristics and mechanical behavior of a 0.06%C–17%Mn TRIP/TWIP steel. Steel Research International, 87(1):95–106. https://doi.org/10.1002/srin.201400555

Fang XG, Lü SL, Zhao L, et al., 2016. Microstructure and mechanical properties of a novel Mg-RE-Zn-Y alloy fabricated by Rheo-Squeeze casting. Materials & Design, 94:353–359. https://doi.org/10.1016/j.matdes.2016.01.063

Gao B, Chen XF, Pan ZY, et al., 2019. A high-strength heterogeneous structural dual-phase steel. Journal of Materials Science, 54(19):12898–12910. https://doi.org/10.1007/s10853-019-03785-1

Guo J, Liu LG, Li Q, et al., 2013. Characterization on carbide of a novel steel for cold work roll during solidification process. Materials Characterization, 79:100–109. https://doi.org/10.1016/j.matchar.2013.02.011

Hirt G, Khizhnyakova L, Baadjou R, et al., 2009. Semi-solid forming of aluminium and steel-introduction and overview. In: Hirt G, Kopp R (Eds.), Thixoforming: Semi-solid Metal Processing. Wiley-VCH Verlag GmbH & Co. KGaA, New York, USA, p. 1–27. https://doi.org/10.1002/9783527623969.ch1

Li HJ, Luo SJ, Qi LH, 1992. The stress states of a workpiece in the process of liquid-metal forging. Journal of Materials Processing Technology, 30(3):287–296. https://doi.org/10.1016/0924-0136(92)90221-D

Li JY, Cheng GG, Li LY, et al., 2018. The formation mechanism of Mn-Al-O inclusions in Fe-Cr-Mn stainless steel during continuous casting. Steel Research International, 89(5):1700461. https://doi.org/10.1002/srin.201700461

Li N, Xing SM, Bao PW, 2013. Microstructure and mechanical properties of nodular cast iron produced by melted metal die forging process. Journal of Iron and Steel Research, 20(6):58–62. https://doi.org/10.1016/S1006-706X(13)60112-0

Li SL, Sun WL, Wang HQ, et al., 2011. Study on microstructures and mechanical properties of AlSi9Cu3 aluminum alloy fabricated by liquid forging. Advanced Materials Research, 418–420:353–356. https://doi.org/10.4028/www.scientific.net/amr.418-420.353

Linz M, Rodríguez Ripoll M, Gachot C, et al., 2017. On the competition between plastic deformation and material detachment in Ferritic/Pearlitic steel under boundary lubrication. Wear, 376–377:813–821. https://doi.org/10.1016/j.wear.2017.01.095

Liu FB, Wang JD, Chen DR, et al., 2010. The cavitation erosion of the 45# carbon steels implanted with titanium and nitrogen. Tribology Transactions, 53(2):239–243. https://doi.org/10.1080/10402000903226341

Ma XP, Li DZ, 2016. Multiscale discrete crystal growth in the solidification of 20SiMnMo5 steel. Crystal Growth & Design, 16(6):3163–3169. https://doi.org/10.1021/acs.cgd.5b01804

Mitchell A, 1997. Melting, casting, and forging problems in titanium alloys. JOM, 49(6):40–42. https://doi.org/10.1007/BF02914712

Morin D, Hopperstad OS, Benallal A, 2018. On the description of ductile fracture in metals by the strain localization theory. International Journal of Fracture, 209(1):27–51. https://doi.org/10.1007/s10704-017-0236-9

Murali S, Yong MS, 2010. Liquid forging of thin Al-Si structures. Journal of Materials Processing Technology, 210(10):1276–1281. https://doi.org/10.1016/j.jmatprotec.2010.03.014

Niu CN, LaRosa CR, Miao JS, et al., 2018. Magnetically-driven phase transformation strengthening in high entropy alloys. Nature Communications, 9(1):1363. https://doi.org/10.1038/s41467-018-03846-0

Niu R, Li BK, Liu ZQ, et al., 2018. Melting of moving strip during steel strip feeding in continuous casting process. Steel Research International, 89(5):1700407. https://doi.org/10.1002/srin.201700407

Püttgen W, Hallstedt B, Bleck W, et al., 2007. On the microstructure and properties of 100Cr6 steel processed in the semi-solid state. Acta Materialia, 55(19):6553–6560. https://doi.org/10.1016/j.actamat.2007.08.010

Qin F, Feng W, Wu ST, 2018. Microstructure and Vickershardness of 20CrMnTiH steel during hot compression testing. Ironmaking & Steelmaking, 45(6):537–543. https://doi.org/10.1080/03019233.2017.1297003

Rogal Ł, Dutkiewicz J, 2012. Effect of annealing on microstructure, phase composition and mechanical properties of thixo-cast 100Cr6 steel. Materials Characterization, 68:123–130. https://doi.org/10.1016/j.matchar.2012.03.018

Song GW, Tama BA, Park J, et al., 2019. Temperature control optimization in a steel-making continuous casting process using a multimodal deep learning approach. Steel Research International, 90(12):1900321. https://doi.org/10.1002/srin.201900321

Sosenushkin EN, Frantsuzova LS, Kozlova EM, 2015. Effect of pressure and temperature factors on the solidification of cast iron and its structure in liquid forging. Metal Science and Heat Treatment, 57(5–6):309–316. https://doi.org/10.1007/s11041-015-9881-7

Tsuchiyama T, Yamamoto S, Hata S, et al., 2016. Plastic deformation and dissolution of ε-Cu particles by cold rolling in an over-aged particle dispersion strengthening Fe-2mass%Cu alloy. Acta Materialia, 113:48–55. https://doi.org/10.1016/j.actamat.2016.03.018

Viola E, Marzani A, Fantuzzi N, 2015. Interaction effect of cracks on flutter and divergence instabilities of cracked beams under subtangential forces. Engineering Fracture Mechanics, 151:109–129. https://doi.org/10.1016/j.engfracmech.2015.11.010

Zheng CK, Zhang WW, Zhang DT, et al., 2015. Low cycle fatigue behavior of T4-treated Al-Zn-Mg-Cu alloys prepared by squeeze casting and gravity die casting. Transactions of Nonferrous Metals Society of China, 25(11):3505–3514. https://doi.org/10.1016/S1003-6326(15)63992-9

Author information

Authors and Affiliations

Contributions

Zhi-ming DU and Yong-gen SUN designed the research. Yu-shi QI and Jiao LI processed the corresponding data. Yong-gen SUN wrote the first draft of the manuscript. Li-li CHEN and Li-hua CHEN helped to organize the manuscript. Yong-gen SUN and Zhi-ming DU revised and edited the final version.

Corresponding author

Additional information

Conflict of interest

Yong-gen SUN, Yu-shi QI, Jiao LI, Zhi-ming DU, Li-li CHEN, and Li-hua CHEN declare that they have no conflict of interest.

Project supported by the International Cooperation Project of the Ministry of Science and Technology of China (No. 2014DFR50320) and the National Natural Science Foundation of China (No. 51174064)

Rights and permissions

About this article

Cite this article

Sun, Yg., Qi, Ys., Li, J. et al. Fabrication and performance analyses of 45# steel supports using liquid forging. J. Zhejiang Univ. Sci. A 21, 908–922 (2020). https://doi.org/10.1631/jzus.A2000012

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1631/jzus.A2000012