Abstract

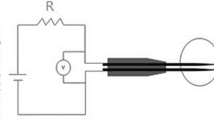

In order to overcome the inconvenience of manual bubble counting, a bubble counter based on photoelectric technique aiming for automatically detecting and measuring minute gas leakage of cryogenic valves is proposed. Experiments have been conducted on a self-built apparatus, testing the performance with different gas inlet strategies (bottom gas-inlet strategy and side gas-inlet strategy) and the influence of gas pipe length (0, 1, 2, 4, 6, 8, 10 m) and leakage rate (around 10, 20, 30, 40 bubbles/min) on first bubble time and bubble rate. A buffer of 110 cm3 is inserted between leakage source and gas pipe to simulate the downstream cavum adjacent to the valve clack. Based on analyzing the experimental data, experiential parameters have also been summarized to guide leakage detection and measurement for engineering applications. A practical system has already been successfully applied in a cryogenic testing apparatus for cryogenic valves.

Similar content being viewed by others

References

ANSI/ASTM, 2005. Standard Test Method for Leaks Using Bubble Emission Techniques. ANSI/ASTM E515-05.

British Standards, 1984. Specification for Valves for Cryogenic Service. BS 6364.

Genenger, B., Lohrengel, B., 1992. Measuring device for gas/liquid flow. Chemical Engineering and Processing, 31(2):87–96. [doi:10.1016/0255-2701(92)85003-K]

Gong, Q.C., Liu, C.L., Wang, Y.H., 2005. Study and design of a new leak-detect system based on ultrasonic. Chinese Hydraulics & Pneumatics, (3):75–77 (in Chinese).

Jenkins, W.A., 1952. A bubble counter for vacuum systems. Vacuum, 2(1):65–66. [doi:10.1016/0042-207X(52)90231-5]

Jia, L.X., Moslemian, D., Chow, W.L., 1992. Cryogenic leak testing of tube fittings/valves. Cryogenics, 32(9):833–839. [doi:10.1016/0011-2275(92)90318-5]

Juds, S.M., 1988. Photoelectric Sensors and Controls: Selection and Application. M. Dekker, New York.

Mahoney, D.G., Ruiz, G.E., Farmer, J.W., Pflanz, T.L., Hall, W.D., Parsons, R.F., 1997. Sealed Parts Leak Testing Method and Apparatus for Helium Spectrometer Leak Detection. US Patent 5625141.

Tang, Y.S., Wu, X.D., Li, F., Wan, L.X., Xing, W., 2002. Research and design of high precision micro air leakage detector. Chinese Journal of Scientific Instrument, 23(5):59–62 (in Chinese).

Veenstra, T.T., Venhorst, G.C.F., Burger, J.F., Holland, H.J., ter Brake, H.J.M., Sirbi, A., Rogalla, H., 2007. Development of a stainless steel check valve for cryogenic applications. Cryogenics, 47(2):121–126. [doi:10.1016/j.cryogenics.2006.10.004]

Weilert, M., Hahn, I., Barmatz, M., Higham, D., Frodsham, G., 2001. Progress on a small multi-cycling cryogenic fluid flow valve. Cryogenics, 41(11–12):813–816. [doi:10.1016/S0011-2275(01)00172-2]

Zhu, S.Y., 2000. A discussion about leakage criterion for valve seat test. Valve, (5):36–38 (in Chinese).

Author information

Authors and Affiliations

Corresponding author

Additional information

Project (Nos. 50776075 and 50536040) supported by the National Natural Science Foundation of China

Rights and permissions

About this article

Cite this article

Jin, T., Xu, B., Tang, K. et al. Bubble counter based on photoelectric technique for leakage detection of cryogenic valves. J. Zhejiang Univ. Sci. A 9, 88–92 (2008). https://doi.org/10.1631/jzus.A071430

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1631/jzus.A071430