Abstract

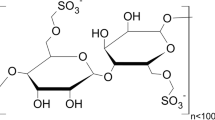

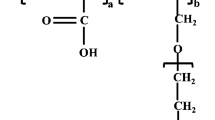

In this study, the effect of sulphonated naphthalene formaldehyde condensate (SNF) and polycarboxylate (PC) superplasticizers on the performance of β-calcium sulphate hemihydrate plaster has been discussed. A considerable improvement in the properties of β-hemihydrate plaster was observed with an increase in superplasticizer content. For 0.6 wt% SNF and PC content, a reduction of 18–20 % in water requirement is obtained and contributes 71–75 % enhancement in the compressive strength of modified pastes as compared to reference sample. The influence of superplasticizers on the hydration characteristics and morphology of the gypsum crystals have been studied using IR, SEM and Electrical Conductivity techniques. These studies indicate a significant influence of superplasticizers on the growth rates of the hydrates and leads to the formation of a dense and well compacted texture of crystals, thereby imparting high strength and better water resistance to the gypsum matrix than the reference material.

Similar content being viewed by others

References

Adjoudj M, Ezziane K, Kadri H, Tien-Tung N, Kaci A (2014) Evaluation of rheological parameters of mortar containing various amounts of mineral addition with polycarboxylate superplasticizer. Constr Build Mater 70:549–559

Arikan M, Sobolev K (2002) The optimization of a gypsum-based composite material. Cem Concr Res 32:1725–1728

Avalos JCR, Ramirez AM, Barcenas JGL, Robles JFP, Guzman EMA, Garcia MEC, Hernandez JG (2005) Flexural behavior and microstructure analysis of a gypsum-SBR composite material. Mater Lett 59:230–233

Bijen J, Van Der Plas C (1992) Polymer-modified glass fibre reinforced gypsum. Mater Struct 25:107–114

BIS 12679 (2005) Specification for by-product gypsum for use in plaster, block and boards. Bureau of Indian Standards, New Delhi

BIS 1288 (2006) Methods of test for mineral gypsum. Bureau of Indian Standards, New Delhi

BIS 2542-Part I, II (2002) Methods of test for gypsum plaster, concrete and products. Bureau of Indian Standards, New Delhi

Cartuxo F, de Brito J, Evangelista L, Jiménez JR, Ledesma EF (2015) Rheological behaviour of concrete made with fine recycled concrete aggregates—influence of the superplasticizer. Constr Build Mater 89:36–47

Colak A (2001) Characteristics of acrylic latex-modified and partially epoxy-impregnated gypsum. Cem Concr Res 31:1539–1547

Dharakumar M, Raghavan A, Saccubai S (1997) Studies on polymer impregnated plaster of paris. J App Polym Sci 63:1243–1249

Eve S, Gomina M, Hamel J, Orange G (2006) Investigation of the setting of polyamide fibre latex-filled plaster composites. J Eur Ceram Soc 26:2541–2546

Garg M, Minocha AK, Jain N (2011) Environment hazard mitigation of waste gypsum and chalk: use in construction materials. Constr Build Mater 25:944–949

Guan B, Ye Q, Zhang J, Lou W, Wu Z (2010) Interaction between α-calcium sulfate hemihydrate and superplasticizer from the point of adsorption characteristics, hydration and hardening process. Cem Concr Res 40:253–259

Izotov VS, Ibragimov RA (2015) Hydration products of portland cement modified with a complex admixture. Inorg Mater 51:187–190

Karni J, Karni E (1995) Gypsum in construction: origin and properties. Mater Struct 28:92–100

Kovler K (1998) Setting and hardening of gypsum-portland cement-silica fume blends, Part 1: temperature and setting expansion. Cem Concr Res 28:423–437

Kovler K (1998) Strength and water absorption for gypsum cement-silica fume blends of improved performance. Adv Cem Res 10:81–92

Lewry AJ, Williamson J (1994) The setting of gypsum plaster, Part I: the hydration of calcium sulphate hemihydrate. J Mater Sci 29:5279–5284

Peng J, Qu J, Zhang J, Chen M, Wan T (2005) Adsorption characteristics of water reducing agents on gypsum surface and its effect on the rheology of gypsum plaster. Cem Concr Res 35:527–531

Pierre A, Lanos C, Estelle P, Perrot A (2015) Rheological properties of calcium sulfate suspensions. Cem Concr Res 76:70–81

Sebok T, Vondruska M (2000) Interaction of anhydrite and melamine-formaldehyde polycondensates in aqueous suspensions. Cem Concr Res 30:993–1003

Singh M, Garg M (1995) Phosphogypsum-fly ash cementitious binder—its hydration and strength development. Cem Concr Res 25:752–758

Singh M, Garg M, Verma CL, Handa SK, Kumar R (1996) An improved process for the purification of phosphogypsum. Constr Build Mater 10:597–600

Stav E, Bentur A (1996) Reactions and early-age properties in in situ polymerized gypsum-acryl amide composites. Mater Struct 29:366–371

Yang J, Liu W, Zhang L, Xiao B (2009) Preparation of load-bearing materials from autoclaved phosphogypsum. Constr Build Mater 23:687–693

Yu QL, Brouwers HJH (2011) Microstructure and mechanical properties of β-hemihydrate produced gypsum: an insight from its hydration process. Constr Build Mater 25:3149–3157

Zhang Y, Kong X (2015) Correlations of the dispersing capability of NSF and PCE types of superplasticizer and their impacts on cement hydration with the adsorption in fresh cement pastes. Cem Concr Res 69:1–9

Acknowledgments

The authors express their sincere thanks to Prof. S.K. Bhattacharyya, Director, CSIR-Central Building Research Institute, Roorkee for his support, encouragement and permission to publish the paper.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Garg, M., Pundir, A. & Singh, R. Modifications in water resistance and engineering properties of β-calcium sulphate hemihydrate plaster-superplasticizer blends. Mater Struct 49, 3253–3263 (2016). https://doi.org/10.1617/s11527-015-0717-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1617/s11527-015-0717-0