Abstract

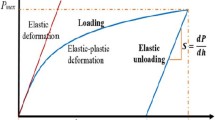

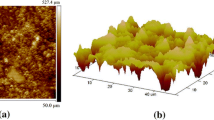

In this study, we propose an energy-based method to extract the nanomechanical properties such as indentation modulus and hardness for cementitious materials within the framework of contact mechanics that relies on more accurate and realistic interpretation of the load–displacement data. Such interpretation allows us to evaluate both the initial unloading stiffness and the hardness—two main input parameters for the Sneddon’s solution to indentation of an elastic half-space—directly as the functions of indentation works. Specifically, we show that while the initial unloading stiffness may be expressed in terms of normalized elastic work, the hardness may be evaluated from the total work done using the modified work-of-indentation approach. Results from nanoindentation on hardened cement paste show that the proposed energy-based method provides the indentation modulus and the hardness in agreement with the Oliver and Pharr method for all the nanomechanical phases of the paste considered. Two main advantages associated with the proposed method include: it circumvents the need of fitting the unloading response by a power-law and computing the area of contact between indenter and specimen. As the method described herein is simple and easy to use, it could be employed as a potential alternative to the conventional Oliver and Pharr method for a heterogeneous material like cement paste.

Similar content being viewed by others

References

Bernard O, Ulm F-J, Lemarchand E (2003) A multiscale micromechanics-hydration model for the early-age elastic properties of cement based materials. Cem Concr Res 33(9):1293–1309

Constantinides G, Ulm F-J (2004) The effect of two types of C-S-H on the elasticity of cement-based materials: results from nanoindentation and micromechanical modeling. Cem Concr Res 34(1):67–80

Oliver WC, Pharr GM (1992) An improved technique for determining hardness and elastic modulus using load and displacement sensing indentation experiments. J Mater Res 7(6):1564–1583

Oliver WC, Pharr GM (2004) Measurement of hardness and elastic modulus by instrumented indentations: advances in understanding and refinements to methodology. J Mater Res 19(1):3–20

Doerner MF, Nix WD (1986) A method for interpreting the data from depth-sensing indentation instruments. J Mater Res 1(4):601–609

Sneddon IN (1965) The relation between load and penetration in the axisymmetric Boussinesq problem for a punch of arbitrary profile. Int J Eng Sci 3(1):47–57

Oliver WC (2001) Alternative technique for analyzing instrumented indentation data. J Mater Res 16(11):3202–3206

Velez K, Maximilien S, Damidot D, Fantozzi G, Sorrentino F (2001) Determination by nanoindentation of elastic modulus and hardness of pure constituents of Portland cement clinker. Cem Concr Res 31(4):555–561

Sarris E, Constantinides G (2013) Finite element modeling of nanoindentation on C-S-H: effect of pile-up and contact friction. Cem Concr Compos 36:78–84

Pharr GM (1998) Measurement of mechanical properties by ultra-low load indentation. Mater Sci Eng A 253(1–2):151–159

Constantinides G, Ulm F-J (2003) On the use of nanoindentation for cementitious materials. Mater Struct 36(3):191–196

Konsta-Gdoutos MS, Metaxa ZS, Shah SP (2010) Highly dispersed carbon nanotube reinforced cement based materials. Cem Concr Res 40(7):1052–1059

Abu Al-Rub RK, Tyson BM, Yazdanbakhsh A, Grasley Z (2012) Mechanical properties of nanocomposites cement incorporating surface-treated and untreated carbon nanotubes and carbon nanofibres. J Nanomech Micromech ASCE 2(1):1–6

Cheng YT, Cheng CM (1998) Relationships between hardness, elastic modulus and the work of indentation. Appl Phys Lett 73(5):614–616

Dao M, Chollacoop N, Van Vliet KJ, Venkatesh TA, Suresh S (2001) Computational modeling of the forward and reverse problems in instrumented sharp indentation. Acta Mater 49(19):3899–3918

Tho KK, Swaddiwudhipong S, Liu ZS, Zeng K, Hua J (2004) Uniqueness of reverse analysis from conical indentation tests. J Mater Res 19(8):2498–2502

Alkorta J, Martinez-Esnaola JM, Gil Sevillano J (2005) Absence of one-to-one correspondence between elastoplastic properties and sharp-indentation load-penetration data. J Mater Res 20(2):432–437

Malzbender J (2005) Comment on the determination of mechanical properties from the energy dissipated during indentation. J Mater Res 20(5):1090–1092

Chen J, Bull SJ (2009) Relation between the ratio of elastic work to the total work of indentation and the ratio of hardness to Young’s modulus for a perfect conical tip. J Mater Res 24(3):590–598

Hainsworth SV, Chandler HW, Page TF (1996) Analysis of nanoindentation load-displacement loading curves. J Mater Res 11(8):1987–1995

Jha KK, Suksawang N, Agarwal A (2010) Analytical method for the determination of indenter constants used in the analysis of nanoindentation loading curves. Scripta Mater 63(3):281–284

Malzbender J, de With G, den Toonder J (2000) The P–h2 relationship in indentation. J Mater Res 15(5):1209–1212

Stilwell NA, Tabor D (1961) Elastic recovery of conical indentations. Phys Proc Soc Lond 78(2):169–179

Tuck JR, Korsunsky AM, Davidson RI, Bull SJ, Elliott DM (2000) Modeling of the hardness of electroplated nickel coatings on copper substrate. Surf Coat Technol 127(1):1–8

Zhou L, Yao Y (2007) Single crystal bulk material micro/nano indentation hardness testing by nanoindentation instrument and AFM. Mater Sci Eng A 460–461:95–110

Gong J, Miao H, Peng Z (2004) Analysis of the nanoindentation data measured with a Berkovich indenter for brittle materials: effect of the residual contact stress. Acta Mater 52(3):785–793

Jha KK, Suksawang N, Lahiri D, Agarwal A (2012) Energy-based analysis of nanoindentation curves for cementitious materials. ACI Mater J 109(1):81–90

Marx V, Blake H (1997) A critical investigation of the unloading behavior of sharp indentation. Acta Mater 45(9):3791–3800

Sawa T, Tanaka K (2001) Simplified method for analyzing nanoindentation data and evaluating performance of nanoindentation instruments. J Mater Res 16(11):3084–3096

VanLandingham MR, Villarrubia JS, Guthrie WF, Meyers GF (2001) Nanoindentation of polymers: an overview. Macromol Symp 167:15–45

Tranchida D, Piccarolo S (2005) On the use of the nanoindentation unloading curve to measure Young’s modulus of polymers on nanometer scale. Macromol Rapid Commun 26(22):1800–1804

Jha KK (2012) An energy-based nanomechanical properties evaluation method for cementitious materials. PhD Dissertation submitted to Florida International University, Miami

Pharr GM, Oliver WC, Brotzen FR (1992) On the generality of the relationship among contact stiffness, contact area, and elastic modulus during indentation. J Mater Res 7(3):613–617

Hay JC, Bolshakov A, Pharr GM (1999) A critical examination of the fundamental relations used in the analysis of nanoindentation data. J Mater Res 14(6):2296–2305

King RB (1987) Elastic analysis of some punch problems for a layered medium. Int J Solids Struct 23(12):1657–1664

Strader JH, Shim S, Bei H, Oliver WC, Pharr GM (2006) An experimental evaluation of the constant β relating the contact stiffness to the contact area in nanoindentation. Philos Mag 86(33–35):5285–5298

Meza JM, Abbes F, Troyon M (2008) Penetration depth and tip radius dependence on the correction factor in nanoindentation measurement. J Mater Res 23(3):725–731

Xu Z-H, Li X (2008) Effects of indenter geometry and material properties on the correction factor of Sneddon’s relationship for nanoindentation of elastic and elasto-plastic materials. Acta Mater 56(6):1399–1405

Martin M, Troyon M (2002) Fundamental relations used in nanoindentation: critical examination based on experimental measurements. J Mater Res 17(9):2227–2234

Attaf MT (2003) New ceramics related investigation of the indentation energy concept. Mater Lett 57(30):4684–4693

Attaf MT (2003) A unified aspect of power-law correlations for Berkovich hardness testing of ceramics. Mater Lett 57(30):4627–4638

Miller M, Bobko C, Vandamme M, Ulm F-J (2008) Surface roughness criteria for cement paste nanoindentation. Cem Concr Res 38(4):467–476

Mondal P, Shah SP, Marks L (2007) A reliable technique to determine the local mechanical properties at the nanoscale for cementitious materials. Cem Concr Res 37(10):1440–1444

Davydov D, Jirasek M, Kopecky L (2011) Critical aspects of nano-indentation technique in application to hardened cement paste. Cem Concr Res 41(1):20–29

Constantinides G, Ravi Chandran KS, Ulm F-J, Van Vliet KJ (2006) Grid indentation analysis of composite microstructure and mechanics: principles and validation. Mater Sci Eng A 430(1–2):189–202

Constantinides G, Ulm F-J (2007) The nanogranular nature of C-S-H. J Mech Phys Solids 55(1):64–90

Zhu W, Hughes JJ, Bicanic N, Pierce CJ (2007) Nanoindentation mapping of mechanical properties of cement paste and natural rocks. Mater Charact 58(11–12):1189–1198

Mondal P, Shah SP, Marks LD (2008) Nanoscale characterization of cementitious materials. ACI Mater J 105(2):174–179

Vandamme M, Ulm F-J, Fonollosa P (2010) Nanogranular packing of C-S-H at substochiometric conditions. Cem Concr Res 40(1):14–26

Jha KK, Suksawang N, Lahiri D, Agarwal A (2013) Evaluating initial unloading stiffness from elastic work-of-indentation measured in a nanoindentation experiment. J Mater Res 28(6):789–797

Attaf MT (2004) New formulation of the nanomechanical quantities using the β-material concept and the indentation function. Mater Lett 58(6):889–894

Beegan D, Chowdhury S, Laugier MT (2005) Work of indentation methods for determining copper film hardness. Surf Coat Technol 192(1):57–63

Khan MK, Hainsworth SV, Fitzpatrick ME, Edwards L (2009) Application of the work of indentation approach for the characterization of aluminum 2024-T351 and Al cladding by nanoindentation. J Mater Sci 44(4):1006–1015

Cao Y, Xue Z, Chen X, Raabe D (2008) Correlation between the flow stress and the nominal indentation hardness of soft metals. Scripta Mater 59(5):518–521

Ma D, Ong CW, Zhang T (2009) An instrumented indentation method for Young’s modulus measurement with accuracy estimation. Exp Mech 49(5):719–729

Nemecek J (2009) Creep effects in nanoindentation of hydrated phases of cement pastes. Mater Charact 60(9):1028–1034

Acknowledgments

KKJ acknowledges the financial support from the University Graduate School, Florida International University in the form of Dissertation Year Fellowship. The authors would like to acknowledge the support extended by Mr. Neal Ricks, Manager, Advanced Materials Engineering Research Institute (AMERI) at Florida International University in preparing the samples for nanoindentation. Likewise, we would like to acknowledge Ms. Barbara Avila, Territory Manager, Titan America for providing us fresh cement for sample preparation. A.A. acknowledges funding from the Office of Naval Research DURIP program (N00014-06-0675).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Jha, K.K., Suksawang, N., Lahiri, D. et al. A novel energy-based method to evaluate indentation modulus and hardness of cementitious materials from nanoindentation load–displacement data. Mater Struct 48, 2915–2927 (2015). https://doi.org/10.1617/s11527-014-0367-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1617/s11527-014-0367-7