Abstract

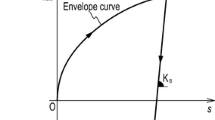

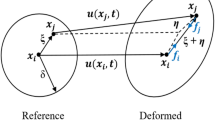

The objective of this paper is to develop a tool for the numerical analysis of full-scale ECC structures. For this purpose, a macroscopic cyclic constitutive model for engineered cementitious composite (ECC) materials is developed based on the response of the material at the stress–strain level under different loading regimes. Various features specific to ECC material such as the unloading and reloading characteristics, different backbone curves in tension and compression, and residual strains are taken into account in the model development. The input parameters are limited to those that can be obtained from conventional monotonic compression and tension tests, thus facilitating its use with minimum information. The model is first validated at the stress–strain level and then implemented into fiber-based finite element analysis software for structural level simulation. The results from simulation of ECC members under cyclic and static time history loading are compared to experimental data for model validation at the structural level. Finally, a parametric study is conducted at the member level to investigate the effect of ECC tensile strength and ductility on the structural level response metrics: stiffness, strength, ductility, and energy dissipation capacity. It is observed that the structural level response metrics change considerably depending on the material properties. With its sensitivity to the main behavioral features of ECC, its simplicity, and its sufficient accuracy, the model is suited for use in predicting the behavior of ECC structures under monotonic, cyclic, and dynamic loading scenarios.

Similar content being viewed by others

References

Li VC (1992) Performance driven design of fiber reinforced cementitious composites. In: Swamy RN (ed) 4th International symposium on fiber reinforced concrete, Chapman and Hall, pp 12–30

Li VC (1992) Postcrack scaling relations for fiber reinforced cementitious composites. J Mater Civ Eng 4(1):41–57

Li VC, Leung CKY (1992) Steady-state and multiple cracking of short random fiber composites. J Eng Mech 118(11):2246–2264

Li VC, Wu HC (1992) Conditions for pseudo strain-hardening in fiber reinforced brittle matrix composites. J Appl Mech Rev 45(8):390–398

Li VC, Wang S, Wu C (2001) Tensile strain-hardening behavior of polyvinyl alcohol engineered cementitious composite (PVA-ECC). ACI Mater J 98(6):483–492

Berard A (1874) Improvement in Artificial Stone, U.S. Patent No. 157 903

Naaman AE (1972) A statistical theory of strength for fiber reinforced concrete. PhD Thesis, Civil Engineering, Massachusetts Institute of Technology, Boston, Massachusetts, USA

Hannant DJ (1978) Fibre cements and fibre concretes. Wiley, New York

Kelly A (1972) Reinforcement of structural materials by long strong fibres. Metall Mater Trans B 3(9):2313–2325

Lankard DR (1985) Slurry infiltrated fiber concrete (SIFCON): properties and applications. In: Young JF (ed) Symposium on very high strength cement based materials, vol 42. Materials Research Society, Pittsburgh, pp 277–286

Naaman A (2007) Tensile strain-hardening FRC composites: historical evolution since the 1960. In: Grosse U (ed) Advances in construction materials 2007. Springer, Berlin, pp 181–202

Billington SL, Yoon JK (2004) Cyclic response of unbonded posttensioned precast columns with ductile fiber-reinforced concrete. J Bridge Eng ASCE 9:353

Fischer G, Li VC (2002) Effect of matrix ductility on deformation behavior of steel-reinforced ECC flexural members under reversed cyclic loading conditions. ACI Struct J 99(6):781–790

Fischer G, Li VC (2003) Deformation behavior of fiber-reinforced polymer reinforced engineered cementitious composite (ECC) flexural members under reversed cyclic loading conditions. ACI Struct J 100(1):25–35

Fischer G, Li VC (2003) Intrinsic response control of moment-resisting frames utilizing advanced composite materials and structural elements. ACI Struct J 100(2):166–176

Fukuyama H, Matsuzaki Y, Nakano K, Sato Y (1999) Structural performance of beam elements with PVA-ECC. In: Reinhardt HW, Naaman AE (eds) High performance fiber reinforced cement composites 3 (HPFRCC 3). RILEM Publications s.a.r.l., Cachan Cedex, France, pp 531–542

Gencturk B (2011) Multi-objective optimal seismic design of building using advanced engineering materials. PhD thesis, Department of Civil and Environmental Engineering, University of Illinois at Urbana-Champaign, Urbana

Kabele P (2002) Equivalent continuum model of multiple cracking. Eng Mech 9(1/2):75–90

Han TS, Feenstra PH, Billington SL (2003) Simulation of highly ductile fiber-reinforced cement-based composite components under cyclic loading. ACI Struct J 100(6):749–757

Lee WK, Billington SL (2008) Simulation of self-centring fibre-reinforced concrete columns. Eng Comput Mech 161(2):77–84

Lee WK (2007) Simulation and performance-based earthquake engineering assessment of self-centering post-tensioned concrete bridge systems. PhD thesis, Department of Civil and Environmental Engineering, Stanford University, Palo Alto

Li VC (2006) Bendable composites—ductile concrete for structures. Structure Magazine, July, 45–48

Fukuyama H, Suwada H, Ilseung Y (2002) HPFRCC damper for structural control. In: JCI international workshop on ductile fiber reinforced cementitious composites (DFRCC): application and evaluation, Japan Concrete Institute, Takayama, Japan, 21–22 October

Kesner KE, Billington SL (2004) Tension, compression and cyclic testing of engineered cementitious composite materials. Technical report MCEER-04-0002. Multidisciplinary Center for Earthquake Engineering Research

Yankelevsky DZ, Reinhardt HW (1989) Uniaxial behavior of concrete in cyclic tension. J Struct Eng 115(1):166–182

Karsan ID, Jirsa JO (1969) Behavior of concrete under compressive loadings. J Struct Div ASCE 95(ST12):2543–2563

Bahn BY, Hsu CTT (1998) Stress-strain behavior of concrete under cyclic loading. ACI Mater J 95(2):178–193

Mander JB, Priestley MJN, Park R (1988) Theoretical stress-strain model for confined concrete. J Struct Eng 114(8):1804–1826

Sinha BP, Gerstle KH, Tulin LG (1964) Stress-strain relations for concrete under cyclic loading. J Am Concr Inst 61(2):195–211

Martínez-Rueda JE, Elnashai AS (1997) Confined concrete model under cyclic load. Mater Struct 30(3):139–147

Palermo D, Vecchio FJ (2003) Compression field modeling of reinforced concrete subjected to reversed loading: formulation. ACI Struct J 100(5):616–625

Sakai J, Kawashima K, Asce M (2006) Unloading and reloading stress–strain model for confined concrete. J Struct Eng 132:112–122

Sima JF, Roca P, Molins C (2008) Cyclic constitutive model for concrete. Eng Struct 30(3):695–706

Saenz LP (1964) Discussion of equation for the stress-strain curve of concrete by Desayi and Krishnan. ACI J 61(9):1229–1235

Chang GA, Mander JB (1994) Seismic energy based fatigue damage analysis of bridge columns: part 1—evaluation of seismic capacity. Technical report NCEER-94-0006. National Center for Earthquake Engineering Research, State University of New York at Buffalo, Buffalo

Sato Y, Fukuyama H, Suwada H (2001) A proposal of tension-compression cyclic loading test method for ductile cementitious materials. J Struct Constr Eng 539:7–12 (in Japanese)

Elnashai AS, Papanikolaou VK, Lee D (2010) ZEUS NL—a system for inelastic analysis of structures. User’s manual. Mid-America Earthquake (MAE) Center, Department of Civil and Environmental Engineering, University of Illinois at Urbana-Champaign, Urbana

Izzuddin BA, Elnasahi AS (1993) Adaptive space frame analysis, part II: a distributed plasticity approach. In: Proceedings of the institution of civil engineers, structures and buildings, vol 99, pp 317–326

Lepech MD (2006) A paradigm for integrated structures and materials design for sustainable transportation infrastructure. PhD thesis, Civil Engineering, University of Michigan

Yang EH, Yang Y, Li VC (2007) Use of high volumes of fly ash to improve ECC mechanical properties and material greenness. ACI Mater J 104(6):620–628

Park R (1988) Ductility evaluation from laboratory and analytical testing. In: 9th World conference on earthquake engineering, vol VIII, Tokyo-Kyoto, Japan, pp 605–616

Acknowledgments

This research was funded by the Mid-America Earthquake (MAE) Center. The MAE Center is a graduated National Science Foundation Engineering Research Center, which was funded under National Science Foundation Grant EEC-9701785. The funding for ECC member tests was provided by the George E. Brown, Jr. Network for Earthquake Engineering Simulation (NEES) facility in the Department of Civil and Environmental Engineering at the University of Illinois at Urbana-Champaign through the following grants by the National Science Foundation: CMMI-0927178 and CMMI-0530737. The stress–strain level test data was provided by Professor Sarah Billington and Dr. Hiroshi Fukuyama. The ECC columns were cast at Stanford University in collaboration with Professors Michael Lepech and Sarah Billington. The data from testing of ECC columns is used for structural level validation of the ECC constitutive model. The authors are thankful for the support of Professors Sarah Billington and Michael Lepech and Dr. Hiroshi Fukuyama.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Gencturk, B., Elnashai, A.S. Numerical modeling and analysis of ECC structures. Mater Struct 46, 663–682 (2013). https://doi.org/10.1617/s11527-012-9924-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1617/s11527-012-9924-0