Abstract

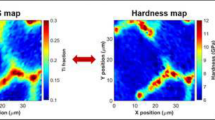

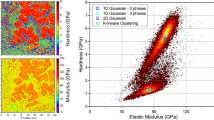

Titanium alloys are widely used in additive manufacturing, but their complex microstructures and related micromechanical properties have not been fully explored. Here, we employ high-speed nanoindentation mapping, electron probe microanalysis, and electron backscatter diffraction to characterize as-deposited and heat-treated Ti–6Al–2Zr–Mo–V alloys. Our results show the correlations between mechanical contrasts (hardness and elastic modulus) and phase contrasts (α and β). The hardness and elastic modulus of the α and β phases are increased due to the element redistribution after annealing (Al diffuses from β to α; Mo and V diffuse from α to β). We use a K-means clustering algorithm to analyze the nanoindentation dataset and correlate the mechanical property maps to the distribution of α and β phases. Our study employs the emerging high-speed nanoindentation mapping to give a better understanding of the microstructure–mechanical property relationship of additive manufactured multiphase alloys across length scales.

Graphic abstract

Similar content being viewed by others

Data availability

The datasets generated during and/or analyzed during the current study are available from the corresponding author on reasonable request.

References

L. Xing-wu, S. Ai-xue, W. Zhang, C. Jun-peng, M. Ji-min, TA15 titanium alloy and its applying prospects on airframe. Titan. Ind. Prog. 20(4), 90 (2003)

L. Yang, B.-Y. Wang, J.-G. Lin, H.-J. Zhao, W.-Y. Ma, Ductile fracture behavior of TA15 titanium alloy at elevated temperatures. Int. J. Miner. Metall. Mater. 22(10), 1082 (2015)

C. Liu, X. Liu, Fatigue crack propagation behavior in FZ and HAZ of TA15 titanium alloy welds. Fail Anal Prev. 2(1), 10 (2007)

Z.Y. Liu, B. He, T.Y. Lyu, Y. Zou, A Review on Additive manufacturing of titanium alloys for aerospace applications: directed energy deposition and beyond Ti-6Al-4V. JOM. (in press)

J. Li, H.M. Wang, Aging response of laser melting deposited Ti–6Al–2Zr–1Mo–1V alloy. Mater. Sci. Eng. A 560, 193 (2013)

R. Chen, C. Tan, Z. You, Z. Li, S. Zhang, Z. Nie, X. Yu, X. Zhao, Effect of α phase on high-strain rate deformation behavior of laser melting deposited Ti-6.5Al-1Mo-1V-2Zr titanium alloy. Mater. Sci. Eng. A 750, 81 (2019)

Y. Chong, G. Deng, J. Yi, A. Shibata, N. Tsuji, On the strain hardening abilities of α+β titanium alloys: thse roles of strain partitioning and interface length density. J. Alloys Compd. 811, 152040 (2019)

K. Wang, Z. Yan, Y. Zhou, S. Wei, X. Wang, R. Xin, Q. Liu, Slip initiation in interlayered β and corresponding slip transfer during compression of a lamellar-structure titanium alloy. Results Phys. 18, 103276 (2020)

E.D. Hintsala, U. Hangen, D.D. Stauffer, High-throughput nanoindentation for statistical and spatial property determination. Jom 70(4), 494 (2018)

W.C. Oliver, G.M. Pharr, An improved technique for determining hardness and elastic modulus using load and displacement sensing indentation experiments. J. Mater. Res. 7(6), 1564 (2011)

B. Vignesh, W.C. Oliver, G.S. Kumar, P.S. Phani, Critical assessment of high speed nanoindentation mapping technique and data deconvolution on thermal barrier coatings. Mater. Des. 181, 108084 (2019)

J.J. Roa, P. Sudharshan Phani, W.C. Oliver, L. Llanes, Mapping of mechanical properties at microstructural length scale in WC-Co cemented carbides: assessment of hardness and elastic modulus by means of high speed massive nanoindentation and statistical analysis. Int. J. Refractory Met. Hard Mater. 75, 211 (2018)

H. Besharatloo, M. Carpio, J.-M. Cabrera, A.M. Mateo, G. Fargas, J.M. Wheeler, J.J. Roa, L. Llanes, Novel mechanical characterization of austenite and ferrite phases within duplex stainless steel. Metals 10(10), 1352 (2020)

H. Besharatloo, S. Gordon, T. Rodriguez-Suarez, A. Can, W. Oliver, L. Llanes, J. Roa, Small-scale mechanical properties of constitutive phases within a polycrystalline cubic boron nitride composite. J. Eur. Ceram. Soc. 39(16), 5181 (2019)

H. Besharatloo, M. De Nicolas, J. Roa, M. Dios, A. Mateo, B. Ferrari, E. Gordo, L. Llanes, Assessment of mechanical properties at microstructural length scale of Ti (C, N)–FeNi ceramic-metal composites by means of massive nanoindentation and statistical analysis. Ceram. Int. 45(16), 20202 (2019)

C. Tromas, N. Ouabadi, V. Gauthier-Brunet, M. Jaouen, S. Dubois, Mechanical properties of nanolaminate Ti3SnC2 carbide determined by nanohardness cartography. J. Am. Ceram. Soc. 93(2), 330 (2010)

J.M. Wheeler, Mechanical phase mapping of the Taza meteorite using correlated high-speed nanoindentation and EDX. J. Mater. Res. 1 (2020).

Y. Xiao, H. Besharatloo, B. Gan, X. Maeder, R. Spolenak, J.M. Wheeler, Combinatorial investigation of Al–Cu intermetallics using small-scale mechanical testing. J. Alloys Compd. 822, 153536 (2020)

H. Sun, X. Chu, Z. Liu, A. Gisele, Y. Zou, Selective laser melting of maraging steels using recycled powders: a comprehensive microstructural and mechanical investigation. Metall. Mater. Trans. A 52(5), 1714–1722 (2021)

H.X. Chen, Z.Y. Liu, X. Chen, Y. Zou, Laser deposition of graded γ-TiAl/Ti2AlNb alloys: microstructure and nanomechanical characterization of the transition zone. J. Alloys Compd. (in press)

H. Gardner, P. Gopon, C. Magazzeni, A. Radecka, K. Fox, D. Rugg, J. Wade, D. Armstrong, M. Moody, P. Bagot, Quantifying the effect of oxygen on micro-mechanical properties of a near-alpha titanium alloy. J. Mater. Res. 1 (2021).

C.M. Magazzeni, H.M. Gardner, I. Howe, P. Gopon, J.C. Waite, D. Rugg, D.E. Armstrong, A.J. Wilkinson, Nanoindentation in multi-modal map combinations: a correlative approach to local mechanical property assessment. J. Mater. Res. 1 (2021).

C.M. Liu, X.J. Tian, H.B. Tang, H.M. Wang, Microstructural characterization of laser melting deposited Ti–5Al-5Mo–5V–1Cr–1Fe near β titanium alloy. J. Alloys Compd. 572, 17 (2013)

C.M. Liu, H.M. Wang, X.J. Tian, H.B. Tang, D. Liu, Microstructure and tensile properties of laser melting deposited Ti–5Al–5Mo–5V–1Cr–1Fe near β titanium alloy. Mater. Sci. Eng. A 586, 323 (2013)

J. Ruzic, S. Emura, X. Ji, I. Watanabe, Mo segregation and distribution in Ti–Mo alloy investigated using nanoindentation. Mater. Sci. Eng. A 718, 48 (2018)

S. Huang, J. Zhang, Y. Ma, S. Zhang, S.S. Youssef, M. Qi, H. Wang, J. Qiu, D. Xu, J. Lei, R. Yang, Influence of thermal treatment on element partitioning in α+β titanium alloy. J. Alloys Compd. 791, 575 (2019)

X. Gao, W. Zeng, S. Zhang, Q. Wang, A study of epitaxial growth behaviors of equiaxed alpha phase at different cooling rates in near alpha titanium alloy. Acta Mater. 122, 298 (2017)

M. Brieseck, W. Lengauer, B. Gneiß, K. Wagner, S. Wagner, A straightforward method for analysing the grain-size distribution in tungsten carbide-cobalt hardmetals. Microchim. Acta 168(3–4), 309 (2010)

G.E. Lloyd, Atomic number and crystallographic contrast images with the SEM: a review of backscattered electron techniques. Miner. Mag. 51(359), 3 (1987)

P. Barriobero-Vila, G. Requena, T. Buslaps, M. Alfeld, U. Boesenberg, Role of element partitioning on the α–β phase transformation kinetics of a bi-modal Ti–6Al–6V–2Sn alloy during continuous heating. J. Alloys Compd. 626, 330 (2015)

P.S. Phani, W. Oliver, A critical assessment of the effect of indentation spacing on the measurement of hardness and modulus using instrumented indentation testing. Mater. Des. 164, 107563 (2019)

T. Britton, H. Liang, F. Dunne, A. Wilkinson, The effect of crystal orientation on the indentation response of commercially pure titanium: experiments and simulations. Proc. R. Soc. A 466(2115), 695 (2010)

L. Zeng, H. Chen, X. Li, L. Lei, G. Zhang, Influence of alloy element partitioning on strength of primary α phase in Ti-6Al-4V alloy. J. Mater. Sci. Technol. 34(5), 782 (2018)

C. Zambaldi, Y. Yang, T.R. Bieler, D. Raabe, Orientation informed nanoindentation of [alpha]-titanium: indentation pileup in hexagonal metals deforming by prismatic slip. J. Mater. Res. 27(1), 356 (2012)

G. Viswanathan, E. Lee, D.M. Maher, S. Banerjee, H.L. Fraser, Direct observations and analyses of dislocation substructures in the α phase of an α/β Ti-alloy formed by nanoindentation. Acta Mater. 53(19), 5101 (2005)

T.-S. Jun, G. Sernicola, F.P. Dunne, T.B. Britton, Local deformation mechanisms of two-phase Ti alloy. Mater. Sci. Eng. A 649, 39 (2016)

G. Constantinides, K.R. Chandran, F.-J. Ulm, K. Van Vliet, Grid indentation analysis of composite microstructure and mechanics: principles and validation. Mater. Sci. Eng. A 430(1–2), 189 (2006)

C. Dichtl, Z. Zhang, H. Gardner, P. Bagot, A. Radecka, D. Dye, M. Thomas, R. Sandala, J.Q. da Fonseca, M. Preuss, Element segregation and α2 formation in primary α of a near-α Ti-alloy. Mater. Charact. 164, 110327 (2020)

G. Lütjering, S. Weissmann, Mechanical properties of age-hardened titanium-aluminum alloys. Acta Metall. 18(7), 785 (1970)

A. Radecka, J. Coakley, V. Vorontsov, T. Martin, P. Bagot, M. Moody, D. Rugg, D. Dye, Precipitation of the ordered α2 phase in a near-α titanium alloy. Scr. Mater. 117, 81 (2016)

C. Leyens, M. Peters, Titanium and Titanium Alloys: Fundamentals and Applications (Wiley, Chichester, 2003).

T. Li, M. Ahmed, G. Sha, R. Shi, G. Casillas, H.-W. Yen, Y. Wang, E.V. Pereloma, J.M. Cairney, The influence of partitioning on the growth of intragranular α in near-β Ti alloys. J. Alloys Compd. 643, 212 (2015)

Y. Liu, L. Chen, H. Tang, C.T. Liu, B. Liu, B. Huang, Design of powder metallurgy titanium alloys and composites. Mater. Sci. Eng. A 418(1–2), 25 (2006)

A.K. Jain, M.N. Murty, P.J. Flynn, Data clustering: a review. ACM Comput. Surv. (CSUR) 31(3), 264 (1999)

J.A. Hartigan, M.A. Wong, Algorithm AS 136: A k-means clustering algorithm. J. R. Stat. Soc. C 28(1), 100 (1979)

X. Li, Z. Liu, S. Cui, C. Luo, C. Li, Z. Zhuang, Predicting the effective mechanical property of heterogeneous materials by image based modeling and deep learning. Comput. Methods Appl. Mech. Eng. 347, 735 (2019)

H. Li, X. Sun, H. Yang, A three-dimensional cellular automata-crystal plasticity finite element model for predicting the multiscale interaction among heterogeneous deformation, DRX microstructural evolution and mechanical responses in titanium alloys. Int. J. Plast. 87, 154 (2016)

Acknowledgments

Z. L., J. Z., and Y. Z.acknowledge the financial support from the Natural Sciences and Engineering Research Council of Canada (NSERC Discovery Grant # RGPIN-2018-05731) and Dean’s Spark Assistant Professorship in the Faculty of Applied Science & Engineering at the University of Toronto. The authors acknowledge the technical support from Ontario Centre for the Characterization of Advanced Materials (OCCAM) in the University of Toronto and Dr. Yujie Meng at KLA Instruments Group. Z. L. also acknowledges the China Scholarship Council for a graduate fellowship (No.201907980002).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Liu, Z., Zhang, J., He, B. et al. High-speed nanoindentation mapping of a near-alpha titanium alloy made by additive manufacturing. Journal of Materials Research 36, 2223–2234 (2021). https://doi.org/10.1557/s43578-021-00204-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/s43578-021-00204-7