Abstract

Continuum modeling approaches are well established in materials science and engineering of metals. They enable the quantitative investigation of diverse questions related to the improved understanding of mechanics and microstructure evolution of various material classes. Applicable to time and length scales relevant in manufacturing and service, continuum modeling approaches are idely used to study engineering-related phenomena such as recrystallization, strain localization, fracture initiation, and phase transformations. However, focusing on individual physical aspects hampers the wider routine use of continuum modeling tools for many engineering applications. With the advent of multi-physics modeling tools developed with the help of and parametrized by (sub-)micrometer-scale simulations and experiments, a huge variety of applications such as hot rolling, bake-hardening, and case-hardening comes within reach for full-field integrated computational materials engineering. Moreover, the integration of experimentally characterized microstructures and the use of user friendly simulation and evaluation tools render powerful modeling approaches feasible for a broad materials science user community. The state of the art and future trends of mechanical, thermodynamic, and kinetic continuum modeling of metallic materials at the grain scale are outlined in this prospective article.

Similar content being viewed by others

References

F. Roters, P. Eisenlohr, L. Hantcherli, D.D. Tjahjanto, T.R. Bieler, and D. Raabe: Overview of constitutive laws, kinematics, homogenization, and multiscale methods in crystal plasticity finite element modeling: Theory, experiments, applications. Acta Mater. 58, 1152 (2010).

F. Roters, P. Eisenlohr, T.R. Bieler, and D. Raabe: Crystal Plasticity Finite Element Methods in Materials Science and Engineering (Wiley–VCH, Weinheim, 2010).

P.R. Dawson: Crystal plasticity. In Computational Materials Science, edited by D. Raabe (Wiley–VCH, Weinheim, 2005), p. 115.

J.L. Chaboche: Continuum damage mechanics 1. General concepts. J. Appl. Mech. 55, 59 (1988).

G.Z. Voyiadjis (editor): Handbook of Damage Mechanics (Springer, New York, 2015).

C. Miehe, F. Welschinger, and M. Hofacker: Thermodynamically consistent phase-field models of fracture: Variational principles and multi-field FE implementations. Int. J. Numer. Methods Eng. 83, 1273 (2010).

I. Steinbach: Phase-field models in materials science. Model. Simul. Mater. Sci. Eng. 17, 073001 (2009).

N. Provatas and K. Elder: Phase-Field Methods in Materials Science and Engineering (Wiley–VCH, Weinheim, 2010).

N. Moelans, B. Blanpain, and P. Wollants: An introduction to phase-field modeling of microstructure evolution. Calphad 32, 268 (2008).

L.-Q. Chen: Introduction to the phase-field method of microstructure evolution. In Computational Materials Science, edited by D. Raabe (Wiley–VCH, Weinheim, 2005), p. 37.

S. Wolfram, ed.: Theory and applications of cellular automata. In Advanced Series on Complex Systems (World Scientific, Singapore, 1, 1986), p. 485.

H. Hallberg: Approaches to modeling of recrystallization. Metals 1, 16 (2011).

D. Raabe: Cellular automata in materials science with particular reference to recrystallization simulation. Annu. Rev. Mater. Res. 32, 53 (2002).

F. Han, B. Tang, H. Kou, J. Li, and Y. Feng: Cellular automata modeling of static recrystallization based on the curvature driven subgrain growth mechanism. J. Mater. Sci. 48, 7142 (2013).

N. Moelans, F. Wendler, and B. Nestler: Comparative study of two phase-field models for grain growth. Comput. Mater. Sci. 46, 479 (2009).

F.E. Hildebrand and C. Miehe: A phase field model for the formation and evolution of martensitic laminate microstructure at finite strains. Phil. Mag. 92, 4250 (2012).

V.I. Levitas: Phase field approach to martensitic phase transformations with large strains and interface stresses. J. Mech. Phys. Solids 70, 154 (2014).

C. Vannozzi, D. Fiorentino, M. D’Amore, D.S. Rumshitzki, A. Dress, and R. Mauri: Cellular automata model of phase transition in binary mixtures. Ind. Eng. Chem. Res. 45, 2892 (2006).

J.A. Warren, W.C. Carter, and R. Kobayashi: A phase field model of the impingement of solidifying particles. Physica A 261, 159 (1998).

L. Gránásy, T. Pusztai, T. Börzsönyi, G. Tóth, G. Tegze, J.A. Warren, and J.F. Douglas: Phase field theory of crystal nucleation and polycrystalline growth: a review. J. Mater. Res. 21, 309 (2006).

M.B. Cortie: Simulation of metal solidification using a cellular automaton. Metall. Trans. B 24, 1045 (1993).

M. Asle Zaeem, H. Yin, and S.D. Felicelli: Modeling dendritic solidification of Al-3%Cu using cellular automaton and phase-field methods. Appl. Math. Model. 37, 3495 (2013).

J.E. Bishop and H. Lim: Continuum approximations. In Multiscale Materials Modeling for Nanomechanics, edited by C.R. Weinberger and G.J. Tucker (Springer International Publishing, Cham, 2016), p. 89.

L.P. Kadanoff: Statistical Physics. Statics, Dynamics and Renormalization (World Scientific, Singapur, 2011).

M. Koyama, M. Rohwerder, C.C. Tasan, A. Bashir, E. Akiyama, K. Takai, D. Raabe, and K. Tsuzaki: Recent progress in microstructural hydrogen mapping in steels: Quantification, kinetic analysis, and multi-scale characterisation. Mater. Sci. Technol. 33, 1481 (2017).

G. Kugler and R. Turk: Study of the influence of initial microstructure topology on the kinetics of static recrystallization using a cellular automata model. Comput. Mater. Sci. 37, 284 (2006).

J. Pagenkopf, A. Butz, M. Wenk, and D. Helm: Virtual testing of dual-phase steels: Effect of martensite morphology on plastic flow behavior. Mater. Sci. Eng. A 674, 672 (2016).

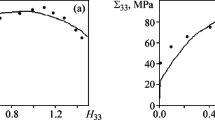

H. Zhang, M. Diehl, F. Roters, and D. Raabe: A virtual laboratory for initial yield surface determination using high resolution crystal plasticity simulations. Int. J. Plas. 80, 111 (2016).

M. Kraska, M. Doig, D. Tikhomirov, D. Raabe, and F. Roters: Virtual material testing for stamping simulations based on polycrystal plasticity. Comput. Mater. Sci. 46, 383 (2009).

F.P.E. Dunne, D. Rugg, and A. Walker: Lengthscale-dependent, elastically anisotropic, physically-based hcp crystal plasticity: Application to cold-dwell fatigue in Ti alloys. Int. J. Plas. 23, 1061 (2007).

M.A. Cuddihy, A. Stapleton, S. Williams, and F.P.E. Dunne: On cold dwell facet fatigue in titanium alloy aero-engine components. Int. J. Fatique 97, 177 (2017).

J.V. Goerler, I. Lopez-Galilea, L. Mujica Roncery, O. Shchyglo, W. Theisen, and I. Steinbach: Topological phase inversion after long-term thermal exposure of nickel-base superalloys: Experiment and phase-field simulation. Acta Mater. 124, 158 (2017).

R.L. Goetz and V. Seetharaman: Static recrystallization kinetics with homogeneous and heterogeneous nucleation using a cellular automata model. Metall. Mater. Trans. A 29, 2307 (1998).

D. Raabe and R.C. Becker: Coupling of a crystal plasticity finite-element model with a probabilistic cellular automaton for simulating primary static recrystallization in aluminium. Model. Simul. Mater. Sci. Eng. 8, 445 (2000).

O. Güvenc, T. Henke, G. Laschet, B. Böttger, M. Apel, M. Bambach, and G. Hirt: Modelling of static recrystallization kinetics by coupling crystal plasticity FEM an multiphase field simulations. Comput. Meth. Mater. Sci. 13, 368 (2003).

F. Han, B. Tang, H. Kou, L. Cheng, J. Li, and Y. Feng: Static recrystallization simulations by coupling cellular automata and crystal plasticity finite element method using a physically based model for nucleation. J. Mater. Sci. 49, 3253 (2014).

H. Lim, F Abdeljawad, S.J. Owen, B.W. Hanks, J.W. Foulk, and C.C. Battaile: Incorporating physically-based microstructures in materials modeling: Bridging phase field and crystal plasticity frameworks. Modelling Simul. Mater. Sci. Eng. 24, 045016 (2016).

H. Moulinec and P. Suquet: A fast numerical method for computing the linear and nonlinear properties of composites. C. R. Acad. Sci. II 318, 1417 (1994).

R.A. Lebensohn: N-site modeling of a 3D viscoplastic polycrystal using fast Fourier transform. Acta Mater. 49, 2723 (2001).

A. Vidyasagar, W.L. Tan, and D.M. Kochmann: Predicting the effective response of bulk polycrystalline ferroelectric ceramics via improved spectral phase field methods. J. Mech. Phys. Solids 106, 133 (2017).

L. Hernández Encinas, S. Hoya White, A. Martín Del Rey, and G. Rodríguez Sánchez: Modelling forest fire spread using hexagonal cellular automata. Appl. Math. Model. 31, 1213 (2007).

C. Reina and S. Conti: Kinematic description of crystal plasticity in the finite kinematic framework: A micromechanical understanding of F=FeFp. J. Mech. Phys. Solids 67, 40 (2014).

G. Abrivard, E.P. Busso, S. Forest, and B. Appolaire: Phase field modelling of grain boundary motion driven by curvature and stored energy gradients. Part I: Theory and numerical implementation. Phil. Mag. 92, 3618 (2012).

G. Abrivard, E.P. Busso, S. Forest, and B. Appolaire: Phase field modelling of grain boundary motion driven by curvature and stored energy gradients. Part II: Application to recrystallisation. Phil. Mag. 92, 3643 (2012).

L. Chen, J. Chen, R.A. Lebensohn, Y.Z. Ji, T.W. Heo, S. Bhattacharyya, K. Chang, S. Mathaudhu, Z.K. Liu, and L.-Q. Chen: An integrated fast Fourier transform-based phase-field and crystal plasticity approach to model recrystallization of three dimensional polycrystals. Comput. Methods Appl. Mech. Eng. 285, 829 (2015).

J. Hiebeler: Recovery and recrystallization during hot deformation in austenitic steel. Ph.D. Thesis, Bochum, 2016.

P. Zhao, T. Song En Low, Y. Wang, and S.R. Niezgoda: An integrated full-field model of concurrent plastic deformation and microstructure evolution: application to 3D simulation of dynamic recrystallization in polycrystalline copper. Int. J. Plas. 80, 38 (2016).

C. Bos, M.G. Mecozzi, and J. Sietsma: A microstructure model for recrystallisation and phase transformation during the dual-phase steel annealing cycle. Comput. Mater. Sci. 48, 692 (2010).

P. Shanthraj, L. Sharma, B. Svendsen, F. Roters, and D. Raabe: A phase field model for damage in elasto-viscoplastic materials. Comput. Methods Appl. Mech. Eng. 312, 167 (2016).

P. Shanthraj, M. Diehl, P. Eisenlohr, F. Roters, and D. Raabe: Spectral solvers for crystal plasticity and multi-physics. In Handbook of Mechanics of Materials, edited by C.-H. Hsueh, S. Schmauder, C.-S. Chen, K. K. Chawla, N. Chawla, W. Chen, and Y. Kagawa (Springer Nature Singapore, Singapore, 2017).

M. Diehl, M. Wicke, P. Shanthraj, F. Roters, A. Brueckner-Foit, and D. Raabe: Coupled crystal plasticity–phase field fracture simulation study on damage evolution around a void: Pore shape versus crystallographic orientation. JOM 69, 872 (2017).

M.R. Bache, F.P.E. Dunne, and C. Madrigal: Experimental and crystal plasticity studies of deformation and crack nucleation in a titanium alloy. J. Strain Anal. Eng. 45, 391 (2010).

C. Schwarze, A. Gupta, T. Hickel, and R. Darvishi Kamachali: Phase-field study of ripening and rearrangement of precipitates under chemomechanical coupling. Phys. Rev. B. 95, 174101 (2017).

D. Raabe and L. Hantcherli: 2D cellular automaton simulation of the recrystallization texture of an IF sheet steel under consideration of Zener pinning. Comput. Mater. Sci. 34, 299 (2005).

A. Gaubert, Y. Le Bouar, and A. Finel: Coupling phase field and viscoplasticity to study rafting in Ni-based superalloys. Phil. Mag. 90, 375 (2010).

C. Reuber, P. Eisenlohr, F. Roters, and D. Raabe: Dislocation density distribution around an indent in single-crystalline nickel: Comparing nonlocal crystal plasticity finite element predictions with experiments. Acta Mater. 71, 333 (2014).

D. Cereceda, M. Diehl, F. Roters, D. Raabe, J.M. Perlado, and J. Marian: Unraveling the temperature dependence of the yield strength in single-crystal Tungsten using atomistically-informed crystal plasticity calculations. Int. J. Plas. 78, 242 (2016).

A. Köster, A. Ma, and A. Hartmaier: Atomistically informed crystal plasticity model for body-centered cubic iron. Acta Mater. 60, 3894 (2012).

S. Queyreau, G. Monnet, and B. Devincre: Slip systems interactions in alpha-iron determined by dislocation dynamics simulations. Int. J. Plas. 25, 361 (2009).

B. Devincre: Dislocation dynamics simulations of slip systems interactions and forest strengthening in ice single crystal. Phil. Mag. 93, 235 (2013).

B. Devincre, L. Kubin, and T. Hoc: Physical analyses of crystal plasticity by DD simulations. Scr. Mater. 54, 741 (2006).

N. Bertin, C.N. Tomé, I.J. Beyerlein, M.R. Barnett, and L. Capolungo: On the strength of dislocation interactions and their effect on latent hardening in pure magnesium. Int. J. Plas. 62, 72 (2014).

M. Stricker: Die Übertragung von mikrostrukturellen Eigenschaften aus der diskreten Versetzungsdynamik in Kontinuumsbeschreibungen. Ph.D. Thesis, Karlsruhe, 2017.

M. Stricker and D. Weygand: Dislocation multiplication mechanisms—glissile junctions and their role on the plastic deformation at the microscale. Acta Mater. 99, 130 (2015).

R.E. Jones, J.A. Zimmerman, and G. Po: Comparison of dislocation density tensor fields derived from discrete dislocation dynamics and crystal plasticity simulations of torsion. J. Mater Sci. Res. 5, 44 (2016).

S. Groh, E.B. Marin, M.F. Horstemeyer, and H.M. Zbib: Multiscale modeling of the plasticity in an aluminum single crystal. Int. J. Plas. 25, 1456 (2009).

S.L. Wong, M. Madivala, U. Prahl, F. Roters, and D. Raabe: A crystal plasticity model for twinning- and transformation-induced plasticity. Acta Mater. 118, 140 (2016).

P. Zhao, C. Shen, J. Li, and Y. Wang: Effect of nonlinear and noncollinear transformation strain pathways in phase-field modeling of nucleation and growth during martensite transformation. NPJ Comput. Mater. 3, 19 (2017).

O. Shchyglo, T. Hammerschmidt, M. Cak, R. Drautz, and I. Steinbach: Atomistically informed extended Gibbs energy description for phase-field simulation of tempering of martensitic steel. Materials 9, 669 (2016).

T. Hickel, U.R. Kattner, and S.G. Fries: Computational thermodynamics: recent developments and future potential and prospects. Phys. Status Solidi (b) 251, (2014). http://onlinelibrary.wiley.co/doi/10.1002/pssb.201470101/full

J. Amodeo, C. Begau, and E. Bitzek: Atomistic simulations of compression tests on Ni3Al nanocubes. Mater. Res. Lett. 2, 140 (2014).

J. Senger, D. Weygand, O. Kraft, and P. Gumbsch: Dislocation microstructure evolution in cyclically twisted microsamples: a discrete dislocation dynamics simulation. Model. Simul. Mater. Sci. Eng. 19, 074004 (2011).

B. Karlsson and B.O. Sundström: Inhomogeneity in plastic deformation of two-phase steels. Mater. Sci. Eng. 16, 161 (1974).

S.-H. Choi, E.-Y. Kim, W. Woo, S.H. Han, and J.H. Kwak: The effect of crystallographic orientation on the micromechanical deformation and failure behaviors of DP980 steel during uniaxial tension. Int. J. Plas. 45, 85 (2013).

L. Wang, R.I. Barabash, Y. Yang, T.R. Bieler, M.A. Crimp, P. Eisenlohr, W. Liu, and G.E. Ice: Experimental characterization and crystal plasticity modeling of heterogeneous deformation in polycrystalline a-Ti. Metall. Mater. Trans. A 42, 626 (2011).

C.C. Tasan, M. Diehl, D. Yan, C. Zambaldi, P. Shanthraj, F. Roters, and D. Raabe: Integrated experimental-numerical analysis of stress and strain partitioning in multi-phase alloys. Acta Mater. 81, 386 (2014).

C. Pinna, Y. Lan, M.F. Kiu, P. Efthymiadis, M. Lopez-Pedrosa, and D. Farrugia: Assessment of crystal plasticity finite element simulations of the hot deformation of metals from local strain and orientation measurements. Int. J. Plas. 73, 24 (2015).

B. Zhu and M. Militzer: 3D phase field modelling of recrystallization in a low-carbon steel. Model. Simul. Mater. Sci. Eng. 20, 085011 (2012).

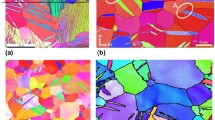

C. Haase, M. Kühbach, L.A. Barrales-Mora, S.L Wong, F. Roters, D.A. Molodov, and G. Gottstein: Recrystallization behavior of a high-manganese steel: Experiments and simulations. Acta Mater. 100, 155 (2015).

R.J. Contieri, M. Zanotello, and R. Caram: Simulation of cp-Ti recrystallization and grain growth by a cellular automata algorithm: Simulated versus experimental results. Mater. Res. 20, 688 (2017).

H. Abdolvand and M.R. Daymond: Multi-scale modeling and experimental study of twin inception and propagation in hexagonal close-packed materials using a crystal plasticity finite element approach. Part I: Average behavior. J. Mech. Phys. Solids 61, 783 (2013).

V.V.C. Wan, M.A. Cuddihy, J. Jiang, D.W. MacLachlan, and F.P.E. Dunne: An hr-EBSD and computational crystal plasticity investigation of microstructural stress distributions and fatigue hotspots in polycrystalline copper. Acta Mater. 115, 45 (2016).

M.A. Groeber and M.A. Jackson: DREAM.3D: A digital representation environment for the analysis of microstructure in 3D. Integr. Mater. Manuf. Innov. 3, 5 (2014).

A. Zeghadi, F. Nguyen, S. Forest, A.-F. Gourgues, and O. Bouaziz: Ensemble averaging stress–strain fields in polycrystalline aggregates with a constrained surface microstructure. Part 1: Anisotropic elastic behaviour. Phil. Mag. 87, 1401 (2007).

A. Zeghadi, S. Forest, A.-F. Gourgues, and O. Bouaziz: Ensemble averaging stress–strain fields in polycrystalline aggregates with a constrained surface microstructure. Part 2: Crystal plasticity. Phil. Mag. 87, 1425 (2007).

M. Diehl, P. Shanthraj, P. Eisenlohr, and F. Roters: Neighborhood influences on stress and strain partitioning in dual-phase microstructures. An investigation on synthetic polycrystals with a robust spectral-based numerical method. Meccanica 51, 429 (2016).

L. Wang, M. Li, J. Almer, T. Bieler, and R. Barabash: Microstructural characterization of polycrystalline materials by synchrotron X-rays. Front. Mater. Sci. 7, 156 (2013).

C. Zhang, H. Li, P. Eisenlohr, W.J. Liu, C.J. Boehlert, M.A. Crimp, and T.R. Bieler: Effect of realistic 3D microstructure in crystal plasticity finite element analysis of polycrystalline Ti-5Al-2.5Sn. Int. J. Plas. 69, 21 (2015).

H. Abdolvand, M. Majkut, J. Oddershede, J.P. Wright, and M.R. Daymond: Study of 3-D stress development in parent and twin pairs of a hexagonal close-packed polycrystal: Part II—crystal plasticity finite element modeling. Acta Mater. 93, 235 (2015).

R. Pokharel, J. Lind, S.F. Li, P. Kenesei, R.A. Lebensohn, R.M. Suter, and A.D. Rollett: In-situ observation of bulk 3D grain evolution during plastic deformation in polycrystalline Cu. Int. J. Plas. 67, 217 (2015).

T.J. Turner, P.A. Shade, J.V. Bernier, S.F. Li, J.C. Schuren, J. Lind, U. Lienert, P. Kenesei, R.M. Suter, B. Blank, and J. Almer: Combined near- and far-field high-energy diffraction microscopy dataset for Ti-7Al tensile specimen elastically loaded in situ. Integr. Mater. Manuf. Innov. 5, 5 (2016).

E. Maire and P.J. Withers: Quantitative X-ray tomography. Int. Mater. Rev. 59, 1 (2014).

S.A. McDonald, P. Reischig, C. Holzner, E.M. Lauridsen, P.J. Withers, A.P. Merkle, and M. Feser: Non-destructive mapping of grain orientations in 3D by laboratory X-ray microscopy. Sci. Rep. 5, 14665 (2015).

S. Zaefferer, S.I. Wright, and D. Raabe: Three-dimensional orientation microscopy in a focused ion beam–scanning electron microscope: A new dimension of microstructure characterization. Metall. Mater. Trans. A 39, 374 (2008).

M. Diehl, D. An, P. Shanthraj, S. Zaefferer, F. Roters, and D. Raabe: Crystal plasticity study on stress and strain partitioning in a measured 3D dual phase steel microstructure. Phys. Mesomech. 20, 311 (2017).

K. Moreland: Diverging color maps for scientific visualization. In Proc. Adv. in Vis. Comut. 5th Int. Symp. Part II, edited by G. Bebis, R. Boyle, B. Parvin, D. Koracin, Y. Kuno, J. Wang, R. Pajarola, P. Lindstrom, A. Hinkenjann, M.L. Encarnação, C.T. Silva, and D. Coming (Springer, Berlin/Heidelberg, 2009), p. 92.

D. Borland and R.M. Taylor: Rainbow color map (still) considered harmful. IEEE Comput. Graph. Appl. 27, 14 (2007).

U. Liedl, S. Traint, and E. Werner: An unexpected feature of the stress–strain diagram of dual-phase steel. Comput. Mater. Sci. 25, 122 (2002).

T.W.J. De Geus, R.H.J. Peerlings, and M.G.D. Geers: Microstructural topology effects on the onset of ductile failure in multi-phase materials—A systematic computational approach. Int. J. Solids Struct. 67, 326 (2015).

S.R. Kalidindi and M. De Graef: Materials data science: Current status and future outlook. Annu. Rev. Mater. Res. 45, 171 (2015).

A. Chowdhury, E. Kautz, B. Yener, and D. Lewis: Image driven machine learning methods for microstructure recognition. Comput. Mater. Sci. 123, 176 (2016).

B.L. DeCost and E.A. Holm: A computer vision approach for automated analysis and classification of microstructural image data. Comput. Mater. Sci. 110, 133 (2015).

S.M. Azimi, D. Britz, M. Engstler, M. Fritz, and F. Mücklich: Advanced steel microstructure classification by deep learning methods (2017). arXiv:1706.06480.

J.A. Gomberg, A.J. Medford, and S.R. Kalidindi: Extracting knowledge from molecular mechanics simulations of grain boundaries using machine learning. Acta Mater. 133, 100 (2017).

M. Folk, G. Heber, Q. Koziol, E. Pourmal, and D. Robinson: An overview of the HDF5 technology suite and its applications. In Proceeding AD ’11 Proceedings of the EDBT/ICDT 2011 Workshop on Array Databases, Uppsala, Sweden–March 25, 2011, pp. 36–47.

M. Jackson, J.P. Simmons, and M. De Graef: MXA: A customizable HDF5-based data format for multi-dimensional data sets. Model. Simul. Mater. Sci. Eng. 18, 065008 (2010).

M.A. Jackson, M.A. Groeber, M.D. Uchic, D.J. Rowenhorst, and M. Graef: H5EBSD: An archival data format for electron back-scatter diffraction data sets. Integr. Mater. Manuf. Innov. 3, 4 (2014).

G.J. Schmitz: Microstructure modeling in integrated computational materials engineering (ICME) settings: Can HDF5 provide the basis for an emerging standard for describing microstructures? JOM 68, 77 (2016).

M. Diehl, P. Eisenlohr, C. Zhang, J. Nastola, P. Shanthraj, and F. Roters: A flexible and efficient output file format for grain-scale multiphysics simulations. Integr. Mater. Manuf. Innov. 6, 83 (2017).

Y. Huang: A user-material subroutine incorporating single crystal plasticity in the ABAQUS finite element program. Technical Report. Cambridge (1991).

F. Roters, P. Eisenlohr, C. Kords, D.D. Tjahjanto, M. Diehl, and D. Raabe: DAMASK: The Düsseldorf advanced material simulation kit for studying crystal plasticity using an FE based or a spectral numerical solver. In Procedia IUTAM: IUTAM Symposium on Linking Scales in Computation: From Microstructure to Macroscale Properties, edited by O. Cazacu (Elsevier, Amsterdam, 3, 2012), p. 3.

J.E. Guyer, D. Wheeler, and J.A. Warren: Fipy: Partial differential equations with python. Comput. Sci. Eng. 11, 6 (2009).

D. Gaston, C. Newman, G. Hansen, and D. Lebrun-Grandié: MOOSE: A parallel computational framework for coupled systems of nonlinear equations. Nucl. Eng. Des. 239, 1768 (2009).

M. Alnæs, J. Blechta, J. Hake, A. Johansson, B. Kehlet, A. Logg, C. Richardson, J. Ring, M. Rognes, and G. Wells: The FEniCS project version 1.5. Arch. Numer. Soft. 3, (2015).

D. Arndt, W. Bangerth, D. Davydov, T. Heister, L. Heltai, M. Kronbichler, M. Maier, J.-P. Pelteret, B. Turcksin, and D. Wells: The deal.II library, version 8.5. J. Numer. Math. (2017).

F. Meier, C. Schwarz, and E. Werner: Crystal-plasticity based thermo-mechanical modeling of Al-components in integrated circuits. Comput. Mater. Sci. 94, 122 (2014).

N. Grilli, K.G.F. Janssens, and H. Van Swygenhoven: Crystal plasticity finite element modelling of low cycle fatigue in fcc metals. J. Mech. Phys. Solids 84, 424 (2015).

A. Ebrahimi and T. Hochrainer: Three-dimensional continuum dislocation dynamics simulations of dislocation structure evolution in bending of a micro-beam. MRS Adv. 1, 1791 (2016).

Acknowledgments

The funding of the TCMPrecipSteel project in the framework of the SPP 1713 “Strong coupling of thermo-chemical and thermo-mechanical states in applied materials” by the Deutsche Forschungsgemeinschaft (DFG) and the support of D. Raabe and F. Roters in writing this article are gratefully acknowledged.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Diehl, M. Review and outlook: mechanical, thermodynamic, and kinetic continuum modeling of metallic materials at the grain scale. MRS Communications 7, 735–746 (2017). https://doi.org/10.1557/mrc.2017.98

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/mrc.2017.98