Abstract

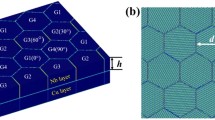

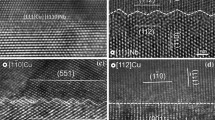

In this work, the deformation mechanisms underlying the room temperature deformation of the pseudomorphic body centered cubic (BCC) Mg phase in Mg/Nb nanolayered composites are studied. Nanolayered composites comprised of 50% volume fraction of Mg and Nb were synthesized using physical vapor deposition with the individual layer thicknesses h of 5, 6.7, and 50 nm. At the lower layer thicknesses of h = 5 and 6.7 nm, Mg has undergone a phase transition from HCP to BCC such that it formed a coherent interface with the adjoining Nb phase. Micropillar compression testing normal and parallel to the interface plane shows that the BCC Mg nanolayered composite is much stronger and can sustain higher strains to failure than the HCP Mg nanolayered composite. A crystal plasticity model incorporating confined layer slip is presented and applied to link the observed anisotropy and hardening in the deformation response to the underlying slip mechanisms.

Similar content being viewed by others

References

D. Van Heerden, D. Josell, and D. Shechtman: The formation of f.c.c. titanium in titanium–aluminum multilayers. Acta Mater. 44, 297 (1996).

R. Banerjee, X.D. Zhang, S.A. Dregia, and H.L. Fraser: Phase stability in Al/Ti multilayers. Acta Mater. 47, 1153 (1999).

H. Wormeester, E. Hüger, and E. Bauer: Hcp and bcc Cu and Pd films. Phys. Rev. Lett. 77, 1540 (1996).

J.Q. Zheng, J.B. Ketterson, and G.P. Felcher: Synthesis of layered crystals of titanium silver. J. Appl. Phys. 53, 3624 (1982).

R. Ahuja and H.L. Fraser: Microstructural transitions in titanium–aluminum thin film multilayers. J. Electron. Mater. 23, 1027 (1994).

R. Banerjee, R. Ahuja, and H.L. Fraser: Dimensionally induced structural transformations in titanium–aluminum multilayers. Phys. Rev. Lett. 76, 3778 (1996).

J. Chakraborty, K. Kumar, R. Ranjan, S.G. Chowdhury, and S.R. Singh: Thickness-dependent fcc–hcp phase transformation in polycrystalline titanium thin films. Acta Mater. 59, 2615 (2011).

S.A. Dregia, R. Banerjee, and H.L. Fraser: Polymorphic phase stability in thin multilayers. Scr. Mater. 39, 217 (1998).

W.P. Lowe and T.H. Geballe: NbZr multilayers. I. Structure and superconductivity. Phys. Rev. B 29, 4961 (1984).

J.Y. Zhang, P. Zhang, X. Zhang, R.H. Wang, G. Liu, G.J. Zhang, and J. Sun: Mechanical properties of fcc/fcc Cu/Nb nanostructured multilayers. Mater. Sci. Eng., A 545, 118 (2012).

M.D. Uchic, P.A. Shade, and D.M. Dimiduk: Plasticity of micrometer-scale single crystals in compression. Annu. Rev. Mater. Res. 39, 361 (2009).

N.A. Mara, D. Bhattacharyya, P. Dickerson, R.G. Hoagland, and A. Misra: Deformability of ultrahigh strength 5 nm Cu/Nb nanolayered composites. Appl. Phys. Lett. 92, 231901 (2008).

M.A. Monclús, S.J. Zheng, J.R. Mayeur, I.J. Beyerlein, N.A. Mara, T. Polcar, J. Llorca, and J.M. Molina-Aldareguía: Optimum high temperature strength of two-dimensional nanocomposites. APL Mater. 1, 052103 (2013).

J. Snel, M.A. Monclús, M. Castillo-Rodríguez, N. Mara, I.J. Beyerlein, J. Llorca, and J.M. Molina-Aldareguía: Deformation mechanism map of Cu/Nb nanoscale metallic multilayers as a function of temperature and layer thickness. JOM 69, 239–259 (2017).

J.Y. Zhang, S. Lei, Y. Liu, J.J. Niu, Y. Chen, G. Liu, X. Zhang, and J. Sun: Length scale-dependent deformation behavior of nanolayered Cu/Zr micropillars. Acta Mater. 60, 1610 (2012).

R. Raghavan, J.M. Wheeler, T.P. Harzer, V. Chawla, S. Djaziri, K. Thomas, B. Philippi, C. Kirchlechner, B.N. Jaya, J. Wehrs, J. Michler, and G. Dehm: Transition from shear to stress-assisted diffusion of copper–chromium nanolayered thin films at elevated temperatures. Acta Mater. 100, 73 (2015).

N.A. Mara and I.J. Beyerlein: Interface-dominant multilayers fabricated by severe plastic deformation: Stability under extreme conditions. Curr. Opin. Solid State Mater. Sci. 19, 265 (2015).

N.A. Mara, D. Bhattacharyya, R.G. Hoagland, and A. Misra: Tensile behavior of 40 nm Cu/Nb nanoscale multilayers. Scr. Mater. 58, 874 (2008).

W. Han, M.J. Demkowicz, N.A. Mara, E. Fu, S. Sinha, A.D. Rollett, Y. Wang, J.S. Carpenter, I.J. Beyerlein, and A. Misra: Design of radiation tolerant materials via interface engineering. Adv. Mater. 25, 6975 (2013).

W.Z. Han, A. Misra, N.A. Mara, T.C. Germann, J.K. Baldwin, T. Shimada, and S.N. Luo: Role of interfaces in shock-induced plasticity in Cu/Nb nanolaminates. Philos. Mag. 91, 4172 (2011).

A. Misra, R.G. Hoagland, and H. Kung: Thermal stability of self-supported nanolayered Cu/Nb films. Philos. Mag. 84, 1021 (2004).

A. Misra and R.G. Hoagland: Effects of elevated temperature annealing on the structure and hardness of copper/niobium nanolayered films. J. Mater. Res. 20, 2046 (2005).

M. Knezevic and D.J. Savage: A high-performance computational framework for fast crystal plasticity simulations. Comput. Mater. Sci. 83, 101 (2014).

S. Subedi, I.J. Beyerlein, R. LeSar, and A.D. Rollett: Strength of nanoscale metallic multilayers. Scr. Mater. (2017).

S.J. Zheng, J. Wang, J.S. Carpenter, W.M. Mook, P.O. Dickerson, N.A. Mara, and I.J. Beyerlein: Plastic instability mechanisms in bimetallic nanolayered composites. Acta Mater. 79, 282 (2014).

N. Li, J. Wang, A. Misra, and J.Y. Huang: Direct observations of confined layer slip in Cu/Nb multilayers. Microsc. Microanal. 18, 1155 (2012).

N. Li, N.A. Mara, J. Wang, P. Dickerson, J.Y. Huang, and A. Misra: Ex situ and in situ measurements of the shear strength of interfaces in metallic multilayers. Scr. Mater. 67, 479 (2012).

K. Hattar, A. Misra, M.R.F. Dosanjh, P. Dickerson, I.M. Robertson, and R.G. Hoagland: Direct observation of crack propagation in copper–niobium multilayers. J. Eng. Mater. Technol. 134, 021014 (2012).

S. Pathak, N. Velisavljevic, J.K. Baldwin, M. Jain, S. Zheng, N.A. Mara, and I.J. Beyerlein: Strong, ductile, and thermally stable bcc-Mg nanolaminates. Sci. Rep. 7, 8264 (2017).

B.L. Mordike and T. Ebert: Magnesium: Properties–applications–potential. Mater. Sci. Eng., A 302, 37 (2001).

T.M. Pollock: Weight loss with magnesium alloys. Science 328, 986 (2010).

I.J. Beyerlein, R.J. McCabe, and C.N. Tomé: Effect of microstructure on the nucleation of deformation twins in polycrystalline high-purity magnesium: A multi-scale modeling study. J. Mech. Phys. Solid. 59, 988 (2011).

G. Proust, C.N. Tomé, A. Jain, and S.R. Agnew: Modeling the effect of twinning and detwinning during strain-path changes of magnesium alloy AZ31. Int. J. Plast. 25, 861 (2009).

M. Ardeljan, I.J. Beyerlein, B.A. McWilliams, and M. Knezevic: Strain rate and temperature sensitive multi-level crystal plasticity model for large plastic deformation behavior: Application to AZ31 magnesium alloy. Int. J. Plast. 83, 90 (2016).

E. Kelley and W. Hosford: Plane-strain compression of magnesium and magnesium alloy crystals. Trans. Metall. Soc. AIME 242, 5 (1968).

F. Kabirian, A.S. Khan, and T. Gnäupel-Herlod: Visco-plastic modeling of mechanical responses and texture evolution in extruded AZ31 magnesium alloy for various loading conditions. Int. J. Plast. 68, 1 (2015).

A.S. Khan, A. Pandey, T. Gnäupel-Herold, and R.K. Mishra: Mechanical response and texture evolution of AZ31 alloy at large strains for different strain rates and temperatures. Int. J. Plast. 27, 688 (2011).

K. Ishikawa, H. Watanabe, and T. Mukai: High strain rate deformation behavior of an AZ91 magnesium alloy at elevated temperatures. Mater. Lett. 59, 1511 (2005).

H. Watanabe and K. Ishikawa: Effect of texture on high temperature deformation behavior at high strain rates in a Mg–3Al–1Zn alloy. Mater. Sci. Eng., A 523, 304 (2009).

M. Arul Kumar, I.J. Beyerlein, and C.N. Tomé: A measure of plastic anisotropy for hexagonal close packed metals: Application to alloying effects on the formability of Mg. J. Alloys Compd. 695, 1488 (2017).

M. Arul Kumar, I.J. Beyerlein, R.A. Lebensohn, and C.N. Tomé: Role of alloying elements on twin growth and twin transmission in magnesium alloys. Mater. Sci. Eng., A 706, 295 (2017).

A. Junkaew, B. Ham, X. Zhang, and R. Arróyave: Tailoring the formation of metastable Mg through interfacial engineering: A phase stability analysis. Calphad 45, 145 (2014).

A. Kumar, I.J. Beyerlein, and J. Wang: First-principles study of the structure of Mg/Nb multilayers. Appl. Phys. Lett. 105, 071602 (2014).

A.L. Oppedal, H. El Kadiri, C.N. Tomé, G.C. Kaschner, S.C. Vogel, J.C. Baird, and M.F. Horstemeyer: Effect of dislocation transmutation on modeling hardening mechanisms by twinning in magnesium. Int. J. Plast. 30–31, 41 (2012).

R. Hielscher and H. Schaeben: A novel pole figure inversion method: Specification of the MTEX algorithm. J. Appl. Crystallogr. 41, 1024 (2008).

B. Ham and X. Zhang: High strength Mg/Nb nanolayer composites. Mater. Sci. Eng., A 528, 2028 (2011).

A. Junkaew, B. Ham, X. Zhang, A. Talapatra, and R. Arróyave: Stabilization of bcc Mg in thin films at ambient pressure: Experimental evidence and ab initio calculations. Mater. Res. Lett. 1, 161 (2013).

Y. Chen, S. Shao, X.Y. Liu, S.K. Yadav, N. Li, N. Mara, and J. Wang: Misfit dislocation patterns of Mg–Nb interfaces. Acta Mater. 126, 552 (2017).

K.M. Youssef, Y.B. Wang, X.Z. Liao, S.N. Mathaudhu, L.J. Kecskés, Y.T. Zhu, and C.C. Koch: High hardness in a nanocrystalline Mg97Y2Zn1 alloy. Mater. Sci. Eng., A 528, 7494 (2011).

E.N. Popova, V.V. Popov, E.P. Romanov, and V.P. Pilyugin: Thermal stability of nanocrystalline Nb produced by severe plastic deformation. Phys. Met. Metallogr. 101, 52 (2006).

H. Yu, Y. Xin, M. Wang, and Q. Liu: Hall–Petch relationship in Mg alloys: A review. J. Mater. Sci. Technol. 34, 248 (2018).

F.E. Hauser, P.R. Landon, and J.E. Dorn: Fracture of magnesium alloys at low temperature. Trans. Am. Inst. Min. Metall. Eng. 48, 589 (1956).

N. Ono, R. Nowak, and S. Miura: Effect of deformation temperature on Hall–Petch relationship registered for polycrystalline magnesium. Mater. Lett. 58, 39 (2004).

Z.C. Cordero, B.E. Knight, and C.A. Schuh: Six decades of the Hall–Petch effect—A survey of grain-size strengthening studies on pure metals. Int. Mater. Rev. 61, 495 (2016).

Y. Gao and H. Bei: Strength statistics of single crystals and metallic glasses under small stressed volumes. Prog. Mater. Sci. 82, 118 (2016).

J.A. El-Awady, C. Woodward, D.M. Dimiduk, and N.M. Ghoniem: Effects of focused ion beam induced damage on the plasticity of micropillars. Phys. Rev. B 80, 104104 (2009).

Q. Yu, L. Qi, R.K. Mishra, J. Li, and A.M. Minor: Reducing deformation anisotropy to achieve ultrahigh strength and ductility in Mg at the nanoscale. Proc. Natl. Acad. Sci. U.S.A. 110, 13289 (2013).

Y.T. Zhu, X.Z. Liao, and X.L. Wu: Deformation twinning in bulk nanocrystalline metals: Experimental observations. JOM 60, 60 (2008).

M. Lentz, M. Risse, N. Schaefer, W. Reimers, and I.J. Beyerlein: Strength and ductility with \(\left\{ {10\bar 11} \right\} - \left\{ {10\bar 12} \right\}\) double twinning in a magnesium alloy. Nat. Commun. 7, 11068 (2016)

T. Nizolek, N.A. Mara, I.J. Beyerlein, J.T. Avallone, and T.M. Pollock: Enhanced plasticity via kinking in cubic metallic nanolaminates. Adv. Eng. Mater. 17, 781 (2015).

T.J. Nizolek, M.R. Begley, R.J. McCabe, J.T. Avallone, N.A. Mara, I.J. Beyerlein, and T.M. Pollock: Strain fields induced by kink band propagation in Cu–Nb nanolaminate composites. Acta Mater. 133, 303 (2017).

R. Zhang, J. Wang, I. Beyerlein, and T. Germann: Twinning in bcc metals under shock loading: A challenge to empirical potentials. Philos. Mag. Lett. 91, 731 (2011).

A. Kumar, B.M. Morrow, R.J. McCabe, and I.J. Beyerlein: An atomic-scale modeling and experimental study of 〈c + a〉 dislocations in Mg. Mater. Sci. Eng., A 695, 270 (2017).

G. Lu, N. Kioussis, V.V. Bulatov, and E. Kaxiras: Generalized stacking fault energy surface and dislocation properties of aluminum. Phys. Rev. B 62, 3099 (2000).

V. Vítek: Intrinsic stacking faults in body-centred cubic crystals. Philos. Mag. 18, 773 (1968).

J. Frenkel: Zur Theorie der Elastizitätsgrenze und der Festigkeit kristallinischer Körper. Z. Phys. 37, 572 (1926).

J.P. Perdew, K. Burke, and M. Ernzerhof: Generalized gradient approximation made simple. Phys. Rev. Lett. 77, 3865 (1996).

G.V. Sin’ko and N.A. Smirnov: Ab initio. Phys. Rev. B 80, 104113 (2009).

A. Kumar, J. Wang, and C.N. Tomé: First-principles study of energy and atomic solubility of twinning-associated boundaries in hexagonal metals. Acta Mater. 85, 144 (2015).

M.E. Straumanis and S. Zyszczynski: Lattice parameters, thermal expansion coefficients and densities of Nb, and of solid solutions Nb–O and Nb–N–O and their defect structure. J. Appl. Crystallogr. 3, 1 (1970).

L.J. Slutsky and C.W. Garland: Elastic constants of magnesium from 4.2° K to 300° K. Phys. Rev. 107, 972 (1957).

A. Kumar, M.A. Kumar, and I.J. Beyerlein: First-principles study of crystallographic slip modes in ω-Zr. Sci. Rep. 7, 8932 (2017).

M. Ardeljan, D.J. Savage, A. Kumar, I.J. Beyerlein, and M. Knezevic: The plasticity of highly oriented nano-layered Zr/Nb composites. Acta Mater. 115, 189 (2016).

B. Joós and M.S. Duesbery: The peierls stress of dislocations: An analytic formula. Phys. Rev. Lett. 78, 266 (1997).

M. Knezevic, B. Drach, M. Ardeljan, and I.J. Beyerlein: Three dimensional predictions of grain scale plasticity and grain boundaries using crystal plasticity finite element models. Comput. Meth. Appl. Mech. Eng. 277, 239–259 (2014).

M. Ardeljan, M. Knezevic, T. Nizolek, I.J. Beyerlein, N.A. Mara, and T.M. Pollock: A study of microstructure-driven strain localizations in two-phase polycrystalline HCP/BCC composites using a multi-scale model. Int. J. Plast. 74, 35 (2015).

M. Ardeljan, I.J. Beyerlein, and M. Knezevic: A dislocation density based crystal plasticity finite element model: Application to a two-phase polycrystalline HCP/BCC composites. J. Mech. Phys. Solid. 66, 16 (2014).

D.I. Bolef: Elastic constants of single crystals of the bcc transition elements V, Nb, and Ta. J. Appl. Phys. 32, 100 (1961).

J.W. Christian and S. Mahajan: Deformation twinning. Prog. Mater. Sci. 39, 1 (1995).

M.H. Yoo: Slip, twinning, and fracture in hexagonal close-packed metals. Metall. Mater. Trans. A 12, 409 (1981).

P.G. Partridge: The crystallography and deformation modes of hexagonal close-packed metals. Metall. Rev. 12, 169 (1967).

H. Yoshinaga, T. Obara, and S. Morozumi: Twinning deformation in magnesium compressed along the C-axis. Mater. Sci. Eng. 12, 255 (1973).

M. Ardeljan, R.J. McCabe, I.J. Beyerlein, and M. Knezevic: Explicit incorporation of deformation twins into crystal plasticity finite element models. Comput. Meth. Appl. Mech. Eng. 295, 396 (2015).

A. Misra, J.P. Hirth, and R.G. Hoagland: Length-scale-dependent deformation mechanisms in incoherent metallic multilayered composites. Acta Mater. 53, 4817 (2005).

A. Misra, M. Verdier, H. Kung, J.D. Embury, and J.P. Hirth: Deformation mechanism maps for polycrystalline metallic multiplayers. Scr. Mater. 41, 973 (1999).

W.D. Nix: Mechanical properties of thin films. Metall. Mater. Trans. A 20, 2217 (1989).

J.D. Embury and J.P. Hirth: On dislocation storage and the mechanical response of fine scale microstructures. Acta Metall. Mater. 42, 2051 (1994).

R.G. Hoagland, R.J. Kurtz, and C.H. Henager: Slip resistance of interfaces and the strength of metallic multilayer composites. Scr. Mater. 50, 775 (2004).

R.G. Hoagland, T.E. Mitchell, J.P. Hirth, and H. Kung: On the strengthening effects of interfaces in multilayer fee metallic composites. Philos. Mag. A 82, 643 (2002).

Y. Shen and P.M. Anderson: Transmission of a screw dislocation across a coherent, non-slipping interface. J. Mech. Phys. Solid. 55, 956 (2007).

Y. Zeng, A. Hunter, I.J. Beyerlein, and M. Koslowski: A phase field dislocation dynamics model for a bicrystal interface system: An investigation into dislocation slip transmission across cube-on-cube interfaces. Int. J. Plast. 79, 293 (2016).

J. Wang, R.G. Hoagland, J.P. Hirth, and A. Misra: Atomistic simulations of the shear strength and sliding mechanisms of copper–niobium interfaces. Acta Mater. 56, 3109 (2008).

R.F. Zhang, T.C. Germann, X.Y. Liu, J. Wang, and I.J. Beyerlein: Layer size effect on the shock compression behavior of fcc–bcc nanolaminates. Acta Mater. 79, 74 (2014).

S. Huang, I.J. Beyerlein, and C. Zhou: Nanograin size effects on the strength of biphase nanolayered composites. Sci. Rep. 7, 11251 (2017).

J.R. Mayeur, I.J. Beyerlein, C.A. Bronkhorst, and H.M. Mourad: Incorporating interface affected zones into crystal plasticity. Int. J. Plast. 65, 206 (2015).

ACKNOWLEDGMENTS

M.A., M.K., M.J., and S.P., acknowledge funding from the National Science Foundation (NSF) - Civil, Mechanical and Manufacturing Innovation (CMMI) Early Concept Grants for Exploratory Research (EAGER) Grant No. 1541918. I.J.B. gratefully acknowledges support from a CMMI-MEP Grant No. 1727495. S.P. would also like to gratefully acknowledge support from the University of Nevada, Reno Research Enhancement Grant 2017 for this work. A.K. would like to acknowledge LANL LDRD Program No. 20170680ER for financial support. We acknowledge support from the Center for Scientific Computing from the CNSI, MRL: an NSF MRSEC (DMR-1121053). Part of the research was performed at the Center for Integrated Nanotechnologies, an Office of Science User Facility operated for the U.S. Department of Energy, Office of Science. Los Alamos National Laboratory is operated by Los Alamos National Security, LLC, for the National Nuclear Security Administration of the U.S. Department of Energy under Contract No. DE-AC52-06NA25396. The authors acknowledge M. Jahedi for XRD texture measurements.

Author information

Authors and Affiliations

Corresponding author

Additional information

This paper has been selected as an Invited Feature Paper.

Rights and permissions

About this article

Cite this article

Ardeljan, M., Knezevic, M., Jain, M. et al. Room temperature deformation mechanisms of Mg/Nb nanolayered composites. Journal of Materials Research 33, 1311–1332 (2018). https://doi.org/10.1557/jmr.2018.107

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/jmr.2018.107