Abstract

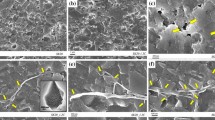

Tantalum carbide (TaC) is an ultrahigh temperature ceramic, where low damage tolerance limits its potential application in propulsion sector. In this respect, current work focuses on enhancing the toughness of TaC based composites via synergistic reinforcement of SiC and carbon nanotubes (CNTs). Spark plasma sintering of TaC, reinforced with 15 vol% SiC and 15 vol% CNT (processed at 1850 °C, 40 MPa, 5 min), has shown enhanced densification from ∼93% (for TaC) to ∼98%. Potential damage of the tubular CNTs to flaky graphite was revealed using transmission electron microscopy, and was supplemented via Raman spectroscopy. SiC addition has enhanced the hardness to ∼19.5 GPa while a decreases to 12.6 GPa was observed with CNT addition when compared to the hardness of TaC (∼15.5 GPa). The increase in the indentation fracture toughness (from 3.1 MPa m1/2 for TaC to 11.4 MPa m1/2) and fracture strength (from ∼23 MPa for TaC to ∼183 MPa) via synergetic reinforcement of SiC and CNT is mainly attributed to energy dissipating mechanisms such as crack branching, CNT bridging, and crack-deflection. In addition, the reduction of interfacial residual tensile-stresses with SiC- and CNT-reinforcement, resulting an overall increase in the fracture energy and toughening, is also established.

Similar content being viewed by others

References

E.K. Storms ed.: Refractory Materials: The Refractory Carbides, A Series of Monographs (Academic Press Inc., New York, 1967).

C. Kim, G. Gottstein, and D.S. Grummon: Plastic flow and dislocation structures in tantalum carbide: Deformation at low and intermediate homologous temperatures. Acta Metall. Mater. 42 (7), 2291 (1994).

G.V. Samonov and R.Y. Petrikina: Sintering of metals, carbides and oxides by Ho pressing. Phys. Sintering 2, 1 (1970).

J.X. Liu, Y.M. Kan, and G.J. Zhang: Pressureless sintering of tantalum carbide ceramics without additives. J. Am. Ceram. Soc. 93 (2), 370 (2010).

E. Khaleghi, Y.S. Lin, M.A. Meyers, and E.A. Olevsky: Spark plasma sintering of tantalum carbide. Scr. Mater. 63 (6), 577 (2010).

W.C. Ruoff and A.L. Yohe: Ultrafine-grain tantalum carbide by high pressure hot pressing. J. Am. Ceram. Soc. 12 (57), 647 (1978).

X. Zhang, G.E. Hilmas, W.G. Fahrenholtz, and D.M. Deason: Hot pressing of tantalum carbide with and without sintering additives. J. Am. Ceram. Soc. 90 (2), 393 (2007).

F. Monteverde: Ultra-high temperature HfB2–SiC ceramics consolidated by hot-pressing and spark plasma sintering. J. Alloys Compd. 428 (1–2), 197 (2007).

X. Zhang, L. Xu, S. Du, C. Liu, J. Han, and W. Han: Spark plasma sintering and hot pressing of ZrB2–SiCW ultra-high temperature ceramics. J. Alloys Compd. 466 (1–2), 241 (2008).

I. Bajpai, K. Balani, and B. Basu: Spark plasma sintered HA-Fe3O4-based multifunctional magnetic biocomposites. J. Am. Ceram. Soc. 96 (7), 2100 (2013).

A.K. Dubey, A. Ea, K. Balani, and B. Basu: Multifunctional properties of multistage spark plasma sintered HA–BaTiO3-based piezobiocomposites for bone replacement applications. J. Am. Ceram. Soc. 96 (12), 3753 (2013).

K. Hackett, S. Verhoef, R.A. Cutler, and D.K. Shetty: Phase constitution and mechanical properties of carbides in the Ta-C system. J. Am. Ceram. Soc. 92 (10), 2404 (2009).

L. Silvestroni, A. Bellosi, C. Melandri, D. Sciti, J.X. Liu, and G.J. Zhang: Microstructure and properties of HfC and TaC-based ceramics obtained by ultrafine powder. J. Eur. Ceram. Soc. 31 (4), 619 (2011).

X. Zhang, G.E. Hilmas, and W.G. Fahrenholtz: Densification, mechanical properties, and oxidation resistance of TaC–TaB2 ceramics. J. Am. Ceram. Soc. 91 (12), 4129 (2008).

S.R. Bakshi, V. Musaramthota, D. Lahiri, V. Singh, S. Seal, and A. Agarwal: Spark plasma sintered tantalum carbide: Effect of pressure and nano-boron carbide addition on microstructure and mechanical properties. Mater. Sci. Eng., A 528 (3), 1287 (2011).

L. Silvestroni and D. Sciti: Effects of MoS additions on the properties of Hf- and Zr-composites produced by pressureless sintering. Scr. Mater. 57 (2), 165 (2007).

A.L. Chamberlain, W.G. Fahrenholtz, G.E. Hilmas, and D.T. Ellerby: High strength ZrB2-based ceramics. J. Am. Ceram. Soc. 87 (6), 1170 (2004).

S. Zhu, W.G. Fahrenholtz, and G.E. Hilmas: Influence of silicon carbide particle size on the microstructure and mechanical properties of zirconium diboride-silicon carbide ceramics. J. Am. Ceram. Soc. 27, 2077 (2007).

L. Liu, F. Ye, Z. Zhang, and Y. Zhou: Microstructure and mechanical properties of the spark plasma sintered TaC/SiC composites. Mater. Sci. Eng., A 529 (25), 479 (2011).

K. Balani, G. Gonzalez, A. Agarwal, R. Hickman, J.S. O’Dell, and S. Seal: Synthesis, microstructural characterization and mechanical property evaluation of vacuum plasma sprayed tantalum carbide. J. Am. Ceram. Soc. 89 (4), 1419 (2006).

S.R. Srinivasa, V. Musaramthota, D.A. Virzi, A.K. Keshri, D. Lahiri, V. Singh, S. Seal, and A. Agarwal: Spark plasma sintered tantalum carbide-carbon nanotube composite: effect of pressure, carbon nanotube length and dispersion technique on microstructure and mechanical properties. Mater. Sci. Eng., A 528 (6), 2538 (2011).

K. Balani, S.R. Bakshi, T. Mungole, and A. Agarwal: Ab-initio molecular modeling of interfaces in tantalum-carbon system. J. Appl. Phys. 111, 063521 (2012).

L. Liu, H. Liu, F. Ye, Z. Zhang, and Y. Zhou: Microstructure and mechanical properties of the spark plasma sintered Ta2C ceramics. Ceram. Int. 38 (6), 4707 (2012).

A. Nieto, D. Lahiri, and A. Agarwal: Graphene nanoplatelets reinforced tantalum carbide consolidated by spark plasma sintering. Mater. Sci. Eng., A 582, 338 (2013).

S.R. Bakshi, K. Balani, and A. Agarwal: Thermal conductivity of plasma-sprayed aluminum oxide—multiwalled carbon nanotube composites. J. Am. Ceram. Soc. 91 (3), 942 (2008).

Y. Chen, K. Balani, and A. Agarwal: Do thermal residual stresses contribute to the improved fracture toughness of carbon nanotube/alumina nanocomposites?Scr. Mater. 66 (6), 347 (2012).

G.R. Anstis, P. Chantiklul, B.R. Lawn, and D.B. Marshall: A critical evaluation of indentation techniques for measuring fracture toughness: I. Dircet crack measurements. J. Am. Ceram. Soc. 64 (9), 533 (1981).

H. Awaji and Y. Sakaida: V-notch technique for single-edge notched beam and chevron notch methods. J. Am. Ceram. Soc. 73 (11), 3522 (1990).

X. Wang, N.P. Padture, and H. Tanaka: Contact-damage-resistant ceramic/single-wall carbon nanotubes and ceramic/graphite composites. Nat. Mater. 3, 539 (2004).

P. Chantikul, G.R. Anstis, B.R. Lawn, and D.B. Marshall: A critical evaluation of indentation techniques for measuring fracture toughness: II. Strength method. J. Am. Ceram. Soc. 64 (9), 539 (1981).

M.H.E-S.A. Albedah and F. Benyahia: Diametral compression test: Validation using finite element analysis. Int. J. Adv. Manuf. Technol. 57 (5–8), 501 (2011).

A.T. Procopio, A. Zavaliangos, and J.C. Cunningham: Analysis of the diametrical compression test and the applicability to plastically deforming materials. J. Mater. Sci. 38 (17), 3629 (2003).

G.B. Yadhukulakrishnan, A. Rahman, S. Karumuri, M.M. Stackpoole, A.K. Kalkan, R.P. Singh, and S.P. Harimkar: Spark plasma sintering of silicon carbide and multi-walled carbon nanotube reinforced zirconium diboride ceramic composite. Mater. Sci. Eng., A 552, 125 (2012).

W.C. Oliver and G.M. Pharr: An improved technique for determining hardness and elastic modulus using load and displacement sensing indentaion experiments. J. Mater. Res. 7 (6), 1564 (1992).

B.R. Kim, K.D. Woo, J.M. Doh, J.K. Yoon, and I.J. Shon: Mechanical properties and rapid consolidation of binderless nanostructured tantalum carbide. Ceram. Int. 35 (8), 3395 (2009).

Y. Chen, K. Balani, and A. Agarwal: Analytical model to evaluate interface characteristics of carbon nanotube reinforced aluminum oxide nanocomposites. Appl. Phys. Lett. 92 (1), 011916 (2008).

J.E. Tercero, S. Namin, D. Lahiri, K. Balani, N. Tsoukias, and A. Agarwal: Effect of carbon nanotube and aluminum oxide addition on plasma-sprayed hydroxyapatite coating’s mechanical properties and biocompatibility. Mater. Sci. Eng., C 29 (7), 2195 (2009).

A.K. Keshri, K. Balani, S.R. Bakshi, V. Singh, T. Laha, S. Seal, and A. Agarwal: Structural transformations in carbon nanotubes during thermal spray processing. Surf. Coat. Technol. 203 (16), 2193 (2009).

T. Zhang, L. Kumari, G.H. Du, W.Z. Li, Q.W. Wang, K. Balani, and A. Agarwal: Mechanical properties of carbon nanotube–alumina nanocomposites synthesized by chemical vapor deposition and spark plasma sintering. Composites, Part A 40 (1), 86 (2009).

V. Singh, R. Diaz, K. Balani, A. Agarwal, and S. Seal: Chromium carbide–CNT nanocomposites with enhanced mechanical properties. Acta Mater. 57 (2), 335 (2009).

C. Lee, X. Wei, J.W. Kysar, and J. Hone: Measurement of the elastic properties and intrinsic strength of monolayer graphene. Science 321 (5887), 385 (2008).

B. Peng, M. Locascio, P. Zapol, S. Li, S.L. Mielke, G.C. Schatz, and H.D. Espinosa: Measurements of near-ultimate strength for multiwalled carbon nanotubes and irradiation-induced crosslinking improvements. Nat. Nanotechnol. 3 (10), 626 (2008).

B.I. Yakobson, C.J. Brabec, and J. Bernholc: Nanomechanics of carbon tubes: Instabilities beyond linear response. Phys. Rev. Lett. 76 (14), 2511 (1996).

S. Zhang, R. Khare, T. Belytschko, K.J. Hsia, S.L. Mielke, and G.C. Schatz: Transition states and minimum energy pathways for the collapse of carbon nanotubes. Phys. Rev. B 73 (075423–075429), 075423 (2006).

L. Muthaswamy, Y. Zheng, R. Vajtai, G. Shehkawat, P. Ajayan, and R.E. Geer: Variation of radial elasticity in multiwalled carbon nanotubes. Nano Lett. 7 (12), 3891 (2007).

Q. Huang, D. Jiang, I.A. Ovid’ko, and A. Mukherjee: High-current-induced damage on carbon nanotubes: The case during spark plasma sintering. Scr. Mater. 63 (12), 1181 (2010).

K. Yang, J. He, Z. Su, J.B. Reppert, M.J. Skove, T.M. Tritt, and A.M. Rao: Inter-tube bonding, graphene formation and anisotropic transport properties in spark plasma sintered multi-wall carbon nanotube arrays. Carbon 48 (3), 756 (2010).

D. Ghosh, G. Subhash, and N. Orlovskaya: Measurement of scratch-induced residual stress within SiC grains in ZrB2–SiC composite using micro-Raman spectroscopy. Acta Mater. 56 (18), 5345 (2008).

J. Watts, G. Hilmas, W.G. Fahrenholtz, D. Brown, and B. Clausen: Measurement of thermal residual stresses in ZrB2–SiC composites. J. Eur. Ceram. Soc. 31 (9), 1811 (2011).

L. Silvestroni, L. Pienti, S. Guicciardi, and D. Sciti: Strength and toughness: The challenging case of TaC-based composites. Composites, Part B 72, 10 (2015).

M. Taya, S. Hayashi, A.S. Kobayashi, and H.S. Yoon: Toughening of a particulate-reinforced ceramic-matrix composite by thermal residual stress. J. Am. Ceram. Soc. 73 (5), 1382 (1990).

ACKNOWLEDGMENTS

Authors acknowledge the financial support received from IITK-Space Technology Cell and ISRO (Indian Space Research Organization), Trivandrum, India. Authors also acknowledge Electron Microscope Facility, MSE Department, IIT Kanpur, and instrumented indentation facility and mechanical testing in Advanced Center for Materials Science, IIT Kanpur. K.B. acknowledges P.K. Kelkar Fellowship, IIT Kanpur.

Author information

Authors and Affiliations

Corresponding author

Supplementary Material

Rights and permissions

About this article

Cite this article

Nisar, A., S, A. & Balani, K. Synergistic reinforcement of carbon nanotubes and silicon carbide for toughening tantalum carbide based ultrahigh temperature ceramic. Journal of Materials Research 31, 682–692 (2016). https://doi.org/10.1557/jmr.2016.65

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/jmr.2016.65