Abstract

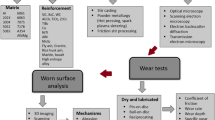

The friction and wear behaviors of reciprocatingly extruded AA 6061-SiC composites form the focal point of this study. To find the optimum way for refining the grains of the matrix, reciprocating extrusion (RE), as a deformation processes, is conducted and found to be feasible. Accordingly, RE has been applied on SiC particles reinforced AA 6061 matrix composite. Using the RE passes as a base, wear behaviors of the composites have been investigated at ambient temperature under dry and lubricated forms. Optical microscopy, transmission electron microscopy and scanning electron microscopy techniques were used to reveal the effect of the RE passes on the microstructure of the materials. As a result, it is found that there is a clear relationship between the weight loss, wear resistance and hardness of the samples. As the load and the number of passes increase, the weight loss in the samples increases. The worn surfaces of the reinforced composites have commonly adhesive and abrasive type of wear.

Similar content being viewed by others

References

M.B. Karamıs, F.N. Sarı, and V. Erturun: Friction and wear behaviors of reciprocatingly extruded Al–SiC composite. J. Mater. Process. Technol. 212, 2578 (2012).

M.B. Karamıs, V. Erturun, and F.N. Sarı: Investigation on effects of reciprocating extrusion process on microstructure of AA 6061 based composites. Mater. Sci. Technol. 28, 1379 (2012).

M.R. Shankar, B.C. Rao, S. Lee, S. Chandrasekar, A.H. King, and W.D. Compton: Severe plastic deformation (SPD) of titanium at near-ambient temperature. Acta Mater. 54, 3691 (2006).

Z.M. Zhang, C.J. Xu, X.F. Guo, and S.Z. Jia: Reciprocating extrusion of in situ Mg2Si reinforced Mg-Al based composite. Acta Metall. Sin. (Engl. Lett.) 21, 169 (2008).

Y. Dou, Y. Liu, Y. Liu, Z. Xiong, and Q. Xia: Friction and wear behaviors of B4C/6061Al composite. Mater. Des. 60, 669 (2014).

R. Deaquino-Lara, N. Soltani, A. Bahrami, E. Gutiérrez-Castañeda, E. García-Sánchez, and M.A.L. Hernandez-Rodríguez: Tribological characterization of Al 7075–graphite composites fabricated by mechanical alloying and hot extrusion. Mater. Des. 67, 224 (2015).

M. Walczak, D. Pieniak, M. Zwierzchowski, M. Walczak, D. Pieniak, and M. Zwierzchowski: The tribological characteristics of SiC particle reinforced aluminium composites. Arch. Civ. Mech. Eng. 15, 116 (2015).

R.J. Mustafa: Abrasive wear of continuous fibre reinforced Al and Al-alloy metal matrix composites. Jordan J. Mech. Ind. Eng. 4, 246 (2010).

A. Abdollahi, A. Alizadeh, and H.R. Baharvandi: Dry sliding tribological behavior and mechanical properties of Al2024–5 wt.%B4C nanocomposite produced by mechanical milling and hot extrusion. Mater. Des. 55, 471 (2014).

U. Soy, A. Demir, and F. Findik: Friction and wear behaviors of Al-SiC-B4C composites produced by pressure infiltration method. Ind. Lubr. Tribol. 63, 387 (2011).

R. Jamaati, M. Naseri, and M.R. Toroghinejad: Wear behavior of nanostructured Al/Al2O3 composite fabricated via accumulative roll bonding (ARB) process. Mater. Des. 59, 540 (2014).

N. Altinkok, İ. Özsert, and F. Findik: Dry sliding wear behavior of Al2O3/SiC particle reinforced aluminium based MMCs fabricated by stir casting method. Acta Phys. Pol., A 124, 11 (2013).

F. Nair and M. B. Karamis: Effects of reinforcement particle size in MMCs on extrusion die wear. Wear 265, 1741 (2008).

J.K. Thompson, W. Li, S.J. Park, A. Antonyraj, R.M. German, and F. Findik: Utilisation of silicon rubber to characterise tool surface quality during die compaction. Powder Metall. 52, 238 (2009).

H. Zhu, C. Jar, J. Song, J. Zhao, J. Li, and Z. Xie: High temperature dry sliding friction and wear behavior of aluminum matrix composites (Al3Zr+α-Al2O3)/Al. Tribol. Int. 48, 78 (2012).

U. Ozsarac, F. Findik, and M. Durman: The wear behaviour investigation of sliding bearings with a designed testing machine. Mater. Des. 28, 345 (2007).

J. An, C. Dong, and Q.Y. Zhang: Improvement of the wear behavior of stircast Al–Si–Pb alloys by hot extrusion. Tribol. Int. 36, 25 (2003).

Q.B. Nguyen, Y.H.M. Sim, M. Gupta, and C.Y.H. Lim: Tribology characteristics of magnesium alloy AZ31 band its composites. Tribol. Int. 82, 464 (2015).

C.S. Ramesh, R. Keshavamurthy, and G.J. Naveen: Effect of extrusion ratio on wear behaviour of hot extruded Al6061–SiCp (Ni–P coated) composites. Wear 271, 1868 (2011).

W. Theisen and M. Karlsohn: Hot direct extrusion-A novel method to produce abrasion-resistant metal-matrix composites. Wear 263, 896 (2007).

F. Yang, L. Peng, and K. Okazaki: Micro-indentation of aluminum processed by equal channel angular extrusion. J. Mater. Res. 19, 1243 (2004).

G.G. Yapici, I. Karaman, Z.P. Luo, H.J. Maier, and Y.I. Chumlyakov: Microstructural refinement and deformation twinning during severe plastic deformation of 316L stainless steel at high temperatures. J. Mater. Res. 19, 2268 (2004).

H. Watanabe, H. Somekawa, and K. Higashi: Fine-grain processing by equal channel angular extrusion of rapidly quenched bulk Mg–Y–Zn alloy. J. Mater. Res. 20, 93 (2005).

N.V. Thuong, H. Zuhailawati, A.A. Seman, T.D. Huy, and B.K. Dhindaw: Microstructural evolution and wear characteristics of equal channel angular pressing processed semi-solid cast hypoeutectic aluminum alloys. Mater. Des. 67, 448 (2015).

E. Koraman, M. Baydoğan, S. Sayılgan, and A. Kalkanlı: Dry sliding wear behaviour of Al–Fe–Si–V alloys at elevated temperatures. Wear 322, 101 (2015).

ACKNOWLEDGMENTS

The authors acknowledge the financial support of Erciyes University (Project No. FBD-09668) and the Scientific and Technological Research Council of Turkey (TUBİTAK) (Project No. 108M562)

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Erturun, V., Karamış, M.B. The effects of a reciprocating extrusion process on the friction and wear behaviors of AA 6061/SiC composites. Journal of Materials Research 31, 388–395 (2016). https://doi.org/10.1557/jmr.2016.10

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/jmr.2016.10