Abstract

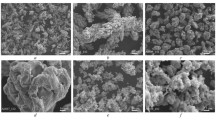

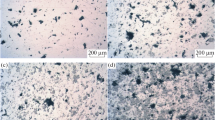

We investigated improvements to the mechanical properties of iron matrix composites for the case where the surfaces of the reinforcing particles are coated with copper and a hybrid mixture of different types of reinforcing ceramic particles (hybrid particles mixture) is used. Copper coating on the surfaces of SiC, TiC, and TiN particles can eliminate interfacial defects to significantly improve the composites’ mechanical properties. The addition of uncoated hybrid particles mixture has little effect on the tensile strength improvement of composites compared with composites reinforced by monolithic particles, whereas copper-coated hybrid reinforcement has a significant effect. Any composite reinforced with copper-coated hybrid particles mixture will always have higher strength than that reinforced with monolithic particles. Our findings suggest that the load transfer between the matrix and reinforcing particles improved because of different elastic moduli, coefficients of thermal expansion and reaction heats of different types of reinforcing particles.

Similar content being viewed by others

References

Z. Mei, Y. Yan, and K. Cui: Effect of matrix composition on the microstructure of in situ synthesized TiC particulate reinforced iron-based composites. Mater. Lett. 57 (21), 3175 (2003).

F. Akhtara and S.J. Guo: Microstructure, mechanical and fretting wear properties of TiC-stainless steel composites. Mater. Charact. 59 (1), 84 (2008).

L. Zhong, Y. Xu, M. Hojamberdiev, J. Wang, and J. Wang: In situ fabrication of titanium carbide particulates-reinforced iron matrix composites. Mater. Des. 32 (7), 3790 (2011).

C.S. Ramesha and C.K. Srinivas: Friction and wear behavior of laser-sintered iron-silicon carbide composites. J. Mater. Process. Technol. 209 (14), 5429 (2009).

E. Pagounis and V.K. Lindroos: Processing and properties of particulate reinforced steel matrix composites. Mater. Sci. Eng., A 246 (1–2), 221 (1998).

T.R. Prabhu, V.K. Varma, and S. Vedantam: Effect of reinforcement type, size, and volume fraction on the tribological behavior of Fe matrix composites at high sliding speed conditions. Wear 309, 247 (2014).

T.R. Prabhu, V.K. Varma, and S. Vedantam: Effect of SiC volume fraction and size on dry sliding wear of Fe/SiC/graphite hybrid composites for high sliding speed applications. Wear 309, 1 (2014).

Q. Cen, Y. Jiang, R. Zhou, Y. Xu, and J. Wang: Study on in situ synthesis of TiC particle reinforced iron matrix composite. J. Mater. Eng. Perform. 20 (8), 1447 (2011).

I.A. Ibrahim, F.A. Mohamed, and E.J. Lavernia: Particulate reinforced metal matrix composites—A review. J. Mater. Sci. 26, 1137 (1991).

S. Weber and W. Theisen: Sintering of high wear resistant metal matrix composites. Adv. Eng. Mater. 9 (3), 165 (2007).

J. Li, B.Y. Zong, Y. Wang, and W. Zhuang: Experiment and modeling of mechanical properties on iron matrix composites reinforced by different types of ceramic particles. Mater. Sci. Eng., A 527 (29–30), 7545 (2010).

W. Zhuang, B.Y. Zong, Y. Wang, and Y. Yang: Processing and properties of SiCp/Fe composites by resistance sintering with a novel dynamic temperature control. J. Compos. Mater. 47 (8), 1001 (2013).

B. Song, S. Dong, P. Coddeta, G. Zhou, O. Sheng, H. Liao, and C. Coddeta: Microstructure and tensile behavior of hybrid nano-micro SiC reinforced iron matrix composites produced by selective laser melting. J. Alloys Compd. 579, 415 (2013).

S. Chakthin, N. Poolthong, and R. Tongsri: Effect of reaction between Fe and carbide particles on mechanical properties of Fe-base composite. Adv. Mater. Res. 55–57, 357 (2008).

V.S. Aigbodion and S.B. Hassan: Effects of silicon carbide reinforcement on microstructure and properties of cast Al–Si–Fe/SiC particulate composites. Mater. Sci. Eng., A 447 (1–2), 355 (2007).

E. Pagounis, M. Talvitieb, and V.K. Lindroosa: Influence of the metal/ceramic interface on the microstructure and mechanical properties of HIPed iron-based composites. Compos. Sci. Technol. 56 (11), 1329 (1996).

J. Pelleg: Reactions in the matrix and interface of the Fe–SiC metal matrix composite system. Mater. Sci. Eng., A 269 (1–2), 225 (1999).

W. Tang, Z. Zheng, H. Ding, and Z. Jin: Control of the interface reaction between silicon carbide and iron. Mater. Chem. Phys. 80 (1), 360 (2003).

N. Chawla and K.K. Chawla: Metal Matrix Composites (Springer-Verlag Inc., New York, 2005); pp. 113, 187.

F. Kretz, Z. Gacsi, J. Kovacs, and T. Pieczonka: The electroless deposition of nickel on SiC particles for aluminum matrix composites. Surf. Coat. Technol. 180–181, 575 (2004).

D. Yi, P. Yu, B. Hu, H. Liu, B. Wang, and Y. Jiang: Preparation of nickel-coated titanium carbide particulates and their use in the production of reinforced iron matrix composites. Mater. Des. 52, 572 (2013).

Y. Zhang, B.Y. Zong, J. Jin, and X. Cao: Electroless copper plating on particulate reinforcements and the effects on mechanical properties of SiCp/Fe composite. Surf. Eng. 31, 232 (2015).

S. Hao and J. Xie: Tensile properties and strengthening mechanisms of SiCp-reinforced aluminum matrix composites as a function of relative particle size ratio. J. Mater. Res. 28 (15), 2047 (2013).

M. Razavi, M.S. Yaghmaee, M.R. Rahimipour, and S.S.R. Tousi: The effect of production method on properties of Fe–TiC composite. Int. J. Miner. Process. 94 (3–4), 97 (2010).

D. Zhou, F. Qiu, and Q. Jiang: Simultaneously increasing the strength and ductility of nano-sized TiN particle reinforced Al–Cu matrix composites. Mater. Sci. Eng., A 596, 98 (2014).

Z. Wang, M. Song, C. Sun, and Y. He: Effects of particle size and distribution on the mechanical properties of SiC reinforced Al–Cu alloy composites. Mater. Sci. Eng., A 528 (3), 1131 (2011).

K. Petersen, A.S. Pedersen, N. Pryds, K.A. Thorsen, and J.L. List: The effect of particles in different sizes on the mechanical properties of spray formed steel composites. Mater. Sci. Eng., A 326 (1), 40 (2002).

M. Rahimian, N. Ehsani, N. Parvin, and H. Baharvandi: The effect of particle size, sintering temperature and sintering time on the properties of Al–Al2O3 composites made by powder metallurgy. J. Mater. Process. Technol. 209 (14), 5387 (2009).

K. Das and T.K. Bandyopadhyay: Synthesis and characterization of zirconium carbide-reinforced iron-based composite. Mater. Sci. Eng., A 379 (1–2), 83 (2004).

A. Ahmadi, M.R. Toroghinejad, and A. Najafizadeh: Evaluation of microstructure and mechanical properties of Al/Al2O3/SiC hybrid composite fabricated by accumulative roll bonding process. Mater. Des. 53, 13 (2014).

X. Chen, C. Yang, L. Guan, and B. Yan: TiB2/Al2O3 ceramic particle reinforced aluminum fabricated by spray deposition. Mater. Sci. Eng., A 496 (1–2), 52 (2008).

D. Zhao, X. Liu, Y. Pan, X. Bian, and X. Liu: Microstructure and mechanical properties of in situ synthesized (TiB2+Al2O3)/Al–Cu composites. J. Mater. Process. Technol. 189 (1–3), 237 (2007).

W. Zhuang, B.Y. Zong, Y. Zhang, and X. Cao: Effects of mechanical impact metal coating on properties and microstructure of SiCp/Fe composites. J. Northeast Univ. 34 (5), 663 (2013).

D. Ye and J. Hu: Practical Inorganic Thermodynamic Data Handbook, 2nd ed. (Metallurgical Industry Press, Beijing, 2002).

B.Y. Zong, F. Zhang, G. Wang, and L. Zuo: Strengthening mechanism of load sharing of particulate reinforcements in a metal matrix composite. J. Mater. Sci. 42 (12), 4215 (2007).

A. Rajabi, M.J. Ghazali, and A.R. Daud: Chemical composition, microstructure and sintering temperature modifications on mechanical properties of TiC-based cermet—A review. Mater. Des. 67, 95 (2015).

J. Huang, M. Lee, H. Lu, and D. Lii: Microstructure, fracture behavior and mechanical properties of TiN/Si3N4 composites. Mater. Chem. Phys. 45 (3), 203 (1996).

ACKNOWLEDGMENT

This work was financially supported by Northeastern University Young Talent Start-up Funding (No. 01270021814101/024), National Natural Science Foundation of China (Grant Nos. 51171040, U1302272, and 51301035) and the National High Technology Research and Development Program of China (Grant No. 2013AA031601).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Cao, X., Jin, J., Zhang, Y. et al. Mechanical properties of iron matrix composites reinforced by copper-coated hybrid ceramic particles. Journal of Materials Research 30, 2360–2368 (2015). https://doi.org/10.1557/jmr.2015.208

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/jmr.2015.208