Abstract

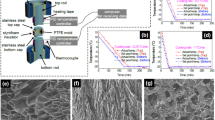

Microcellular injection molding, a process capable of mass-producing complex plastic parts, and particle leaching methods were combined to fabricate porous thermoplastic polyurethane tissue engineering scaffolds. Water soluble polyvinyl alcohol (PVOH) and sodium chloride (NaCl) were used as porogens to improve the porosity and interconnectivity as well as the hydrophilicity of the scaffolds. It was found in the study that the microcellular injection molding process was effective at producing high pore density and porosity. The addition of PVOH decreased the pore diameter and increased the pore density. Furthermore, scaffolds with NaCl and PVOH porogens showed more interconnected pores. The 3T3 fibroblast cell culture was used to confirm the biocompatibility of the scaffolds. Residual PVOH content after leaching increased the hydrophilicity of the scaffolds and further improved cell adhesion and proliferation. The resulting scaffolds offer an alternative scalable tissue scaffold fabrication method for soft tissue scaffold production.

Similar content being viewed by others

References

X.W. Wang, P. Lin, Q.H. Yao, and C.Y. Chen: Development of small-diameter vascular grafts. World J. Surg. 31, 682 (2007).

D.W. Jang, T.H. Nguyen, S.K. Sarkar, and B.T. Lee: Microwave sintering and in vitro study of defect-free stable porous multilayered HAp-ZrO2 artificial bone scaffold. Sci. Technol. Adv. Mat. 13, (2012).

B. Li, J.M. Davidson, and S.A. Guelcher: The effect of the local delivery of platelet-derived growth factor from reactive two-component polyurethane scaffolds on the healing in rat skin excisional wounds. Biomaterials 30, 3486 (2009).

Z.C. Tian, Y.L. Zhu, J.J. Qiu, H.F. Guan, L.Y. Li, S.C. Zheng, X.H. Dong, and J. Xiao: Synthesis and characterization of UPPE-PLGA-rhBMP2 scaffolds for bone regeneration. J. Huazhong U. Sci.-Med. 32, 563 (2012).

A.M. Rosado and L.P. Brewster: Regeneration: Letting the scaffold do the work. J. Surg. Res. 180, 49 (2013).

Y.Z. Zhang, J. Venugopal, Z.M. Huang, C.T. Lim, and S. Ramakrishna: Characterization of the surface biocompatibility of the electrospun PCL-collagen nanofibers using fibroblasts. Biomacromolecules 6, 2583 (2005).

S.F. Yang, K.F. Leong, Z.H. Du, and C.K. Chua: The design of scaffolds for use in tissue engineering. Part 1. Traditional factors. Tissue Eng. 7, 679 (2001).

B. Gupta, S. Patra, and A.R. Ray: Preparation of porous polycaprolactone tubular matrix by salt leaching process. J. Appl. Polym. Sci. 126, 1505 (2012).

J.K. Sherwood, S.L. Riley, R. Palazzolo, S.C. Brown, D.C. Monkhouse, M. Coates, L.G. Griffith, L.K. Landeen, and A. Ratcliffe: A three-dimensional osteochondral composite scaffold for articular cartilage repair. Biomaterials 23, 4739 (2002).

X.X. Shao, D.W. Hutmacher, S.T. Ho, J.C.H. Goh, and E.H. Lee: Evaluation of a hybrid scaffold/cell construct in repair of high-load-bearing osteochondral defects in rabbits. Biomaterials 27, 1071 (2006).

D. Odedra, L. Chiu, L. Reis, F. Rask, K. Chiang, and M. Radisic: Cardiac tissue engineering. In Biomaterials for Tissue Engineering Applications: A Review of the Past and Future Trends, J.A. Burdick and R.L. Mauck ed.; Springer, New York, 2011; p. 421.

X.H. Liu and P.X. Ma: Polymeric scaffolds for bone tissue engineering. Ann. Biomed. Eng. 32, 477 (2004).

L. Ghasemi-Mobarakeh, M.P. Prabhakaran, M. Morshed, M.H. Nasr-Esfahani, and S. Ramakrishna: Bio-functionalized PCL nanofibrous scaffolds for nerve tissue engineering. Mat. Sci. Eng. C-Mater. 30, 1129 (2010).

L. Shor, E.D. Yildirim, S. Guceri, and W. Sun: Precision extruding deposition for freeform fabrication of PCL and PCL-HA tissue scaffolds. Biological and Medical Physics. Biomedical Engineering, (Springer-Verlag, New York, 2010); p. 91.

A. Yeo, W.J. Wong, and S.H. Teoh: Surface modification of PCL-TCP scaffolds in rabbit calvaria defects: Evaluation of scaffold degradation profile, biomechanical properties and bone healing patterns. J. Biomed. Mater. Res. A 93, 1358 (2010).

D. Ajami-Henriquez, M. Rodriguez, M. Sabino, R.V. Castillo, A.J. Muller, A. Boschetti-de-Fierro, C. Abetz, V. Abetz, and P. Dubois: Evaluation of cell affinity on poly(L-lactide) and poly(epsilon-caprolactone) blends and on PLLA-b-PCL diblock copolymer surfaces. J. Biomed. Mater. Res. A 87, 405 (2008).

M. Navarro, C. Aparicio, M. Charles-Harris, M.P. Ginebra, E. Engel, and J.A. Planell: Development of a biodegradable composite scaffold for bone tissue engineering: Physicochemical, topographical, mechanical, degradation, and biological properties. Adv. Polym. Sci. 200, 209 (2006).

A. Nieponice, L. Soletti, J.J. Guan, Y. Hong, B. Gharaibeh, T.M. Maul, J. Huard, W.R. Wagner, and D.A. Vorp: In Vivo assessment of a tissue-engineered vascular graft combining a biodegradable elastomeric scaffold and muscle-derived stem cells in a rat model. Tissue Eng. Pt. A 16, 1215 (2010).

C. Danielsson, S. Ruault, M. Simonet, P. Neuenschwander, and P. Frey: Polyesterurethane foam scaffold for smooth muscle cell tissue engineering. Biomaterials 27, 1410 (2006).

T. Hentschel and H. Munstedt: Thermoplastic polyurethane — the material used for the Erlanger silver catheter. Infection 27, S43 (1999).

P.B. Maurus and C.C. Kaeding: Bioabsorbable implant material review. Oper. Techn. Sport. Med. 12, 158 (2004).

N. Lamba, K. Woodhouse, and S. Cooper: Polyurethanes in Biomedical Applications (CRC Press, New York, 1998).

C. Huang, R. Chen, Q.F. Ke, Y. Morsi, K.H. Zhang, and X.M. Mo: Electrospun collagen-chitosan-TPU nanofibrous scaffolds for tissue engineered tubular grafts. Colloid Surface B 82, 307 (2011).

D.K. Dempsey, C.J. Schwartz, R.S. Ward, A.V. Iyer, J.P. Parakka, and E.M. Cosgriff-Hernandez: Micropatterning of electrospun polyurethane fibers through control of surface topography. Macromol. Mater. Eng. 295, 990 (2010).

C.A. Martinez-Perez, P.E. Garcia-Casillas, P. Romero, A. Martinez-Villafane, A.D. Moller, and J. Romero-Garcia: Porous biodegradable polyurethane scaffolds prepared by thermally induced phase separation. J. Adv. Mater.-Covina 1, 5 (2006).

D. Sin, X.G. Miao, G. Liu, F. Wei, G. Chadwick, C. Yan, and T. Friis: Polyurethane (PU) scaffolds prepared by solvent casting/particulate leaching (SCPL) combined with centrifugation. Mat. Sci. Eng. C 30, 78 (2010).

K. He and X.H. Wang: Rapid prototyping of tubular polyurethane and cell/hydrogel constructs. J. Bioact. Compat. Pol. 26, 363 (2011).

S. Ito, K. Matsunaga, M. Tajima, and Y. Yoshida: Generation of microcellular polyurethane with supercritical carbon dioxide. J. Appl. Polym. Sci. 106, 3581 (2007).

S. Leicher, J. Will, H. Haugen, and E. Wintermantel: MuCell (R) technology for injection molding: A processing method for polyether-urethane scaffolds. J. Mater. Sci. 40, 4613 (2005).

L.J. Gerhardt, C.W. Manke, and E. Gulari: Rheology of polydimethylsiloxane swollen with supercritical carbon dioxide. J. Polym. Sci. Pol. Phys. 35, 523 (1997).

L.B. Wu, D.Y. Jing, and J.D. Ding: A “room-temperature” injection molding/particulate leaching approach for fabrication of biodegradable three-dimensional porous scaffolds. Biomaterials 27, 185 (2006).

S.J. Liu, C.L. Hsueh, S.W.N. Ueng, S.S. Lin, and J.K. Chen: Manufacture of solvent-free polylactic-glycolic acid (PLGA) scaffolds for tissue engineering. Asia-Pac. J. Chem. Eng. 4, 154 (2009).

A. Kramschuster and L.S. Turng: An injection molding process for manufacturing highly porous and interconnected biodegradable polymer matrices for use as tissue engineering scaffolds. J. Biomed. Mater. Res. B. 92, 366 (2010).

H.E. Naguib and C.B. Park: Strategies for achieving ultra low-density polypropylene foams. Polym. Eng. Sci. 42, 1481 (2002).

P.J. Gong and M. Ohshima: The effect of interfacial miscibility on the cell morphology of polyethylene terephthalate/bisphenol a polycarbonate blend foams. J. Polym. Sci. Pol. Phys. 50, 1173 (2012).

S.N. Leung, C.B. Park, and H. Li: Numerical simulation of polymeric foaming processes using modified nucleation theory. Plast. Rubber Compos. 35, 93 (2006).

S.H. Oh, S.G. Kang, E.S. Kim, S.H. Cho, and J.H. Lee: Fabrication and characterization of hydrophilic poly(lactic-co-glycolic acid)/poly(vinyl alcohol) blend cell scaffolds by melt-molding particulate-leaching method. Biomaterials 24, 4011 (2003).

F.J. O’Brien, B.A. Harley, I.V. Yannas, and L.J. Gibson: The effect of pore size on cell adhesion in collagen-GAG scaffolds. Biomaterials 26, 433 (2005).

ACKNOWLEDGMENTS

The authors would like to acknowledge the financial support of the Wisconsin Institute for Discovery (WID), the China Scholarship Council, the National Nature Science Foundation of China (No.51073061, No.21174044), the Guangdong Nature Science Foundation (No. S2013020013855, No. 9151064101000066), and the National Basic Research Development Program 973 (No. 2012CB025902) in China.

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Mi, HY., Jing, X., Salick, M.R. et al. Fabrication of thermoplastic polyurethane tissue engineering scaffold by combining microcellular injection molding and particle leaching. Journal of Materials Research 29, 911–922 (2014). https://doi.org/10.1557/jmr.2014.67

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/jmr.2014.67