Abstract

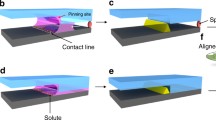

We have developed a soft lithography-based process to create microscale patterns of silica on a diverse array of substrates. A sacrificial polymer layer was first patterned using a micromolding technique. A peptide was adsorbed on the substrate and the sacrificial layer was removed. The patterned peptide template then catalyzed the deposition of silica from a silicic acid solution. With this procedure, we have created both continuous and discontinuous silica patterns on metallic, ceramic, and polymer substrates.

Similar content being viewed by others

References

C.C. Perry and T. Keeling-Tucker: Biosilicification: The role of the inorganic matrix., J. Biol. Inorg. Chem. 5, 537 (2000).

D.E. Morse: Silicon biotechnology: Harnessing biological silica production to construct new materials. Trends Biotechnol. 17, 230 (1999).

R. Tacke: Milestones in the biochemistry of silicon: From basic research to biotechnological applications. Angew. Chem. Int. Ed. 38, 3015 (1999).

E.G. Vrieling, T.P.M. Beelen, R.A. van Santen, and W.W.C. Gieskes: Diatom silicon biomineralization as an inspirational source of new approaches to silica production., J. Biotechnol. 70, 39 (1999).

N. Poulsen, M. Sumper, and N. Kröger: Biosilica formation in diatoms: Characterization of native silaffin-2 and its role in silica morphogenesis. Proc. Nat. Acad. Sci. USA. 100, 12075 (2003).

N. Kröger, R. Deutzmann, C. Bergsdorf, and M. Sumper: Species-specific polyamines from diatoms control silica morphology. Proc. Nat. Acad. Sci. USA. 97, 14133 (2000).

K. Shimizu, J. Cha, G.D. Stucky, and D.E. Morse: Silicatein a: Cathepsin L-like protein in sponge biosilica. Proc. Natl. Acad. Sci. USA. 95, 6234 (1998).

N. Kröger, R. Deutzmann, and M. Sumper: Polycationic peptides from diatom biosilica that direct silica nanosphere formation. Science 286, 1129 (1999).

J.N. Cha, K. Shimizu, Y. Zhou, S.C. Christiansen, B.F. Chmelka, G.D. Stucky, and D.E. Morse: Silicatein filaments and subunits from a marine sponge direct the polymerization of silica and silicones in vitro. Proc. Natl. Acad. Sci. USA. 96, 361 (1999).

S.V. Patwardhan and S.J. Clarson: Silicification and biosilicification: Part 1. Formation of silica structures utilizing a cationically charged synthetic polymer at neutral pH and under ambient conditions. Polym. Bull. 48, 367 (2002).

S.V. Patwardhan, N. Mukherjee, and S.J. Clarson: Effect of process parameters on the polymer mediated synthesis of silica at neutral pH. Silicon Chem. 1, 47 (2002).

S.V. Patwardhan, N. Mukherjee, and S.J. Clarson: The use of poly-L-lysine to form novel silica morphologies and the role of polypeptides in biosilicification. J. Inorg. Organomet. Polym. 11, 193 (2001).

F. Rodríguez, D.D. Glawe, R.R. Naik, K.P. Hallinan, and M. O. Stone: Study of the chemical and physical influences upon in vitro peptide-mediated silica formation. Biomacromolecules 5, 261 (2004).

T. Coradin and J. Livage: Effect of some amino acids and peptides on silicic acid polymerization. Colloids Surf., B 21, 329 (2001).

T. Coradin, O. Durupthy, and J. Livage: Interactions of amino-containing peptides with sodium silicate and colloidal silica: A biomimetic approach of silicification. Langmuir 18, 2331 (2002).

Y. Xia and G.M. Whitesides: Soft lithography. Angew. Chem. Int. Ed. 37, 550 (1998).

A. Bernard, J.P. Renault, B. Michel, H.R. Bosshard, and E. Delamarche: Microcontact printing of proteins. Adv. Mater. 12, 1067 (2000).

A. Fang, H. Ng, X. Su, and S.F.Y. Li: Soft-lithography-mediated submicrometer patterning of self-assembled monolayer of hemoglobin on ITO surfaces. Langmuir 16, 5221 (2000).

J. Aizenberg, A.J. Black, and G.M. Whitesides: Oriented growth of calcite controlled by self-assembled monolayers of functional-ized alkanethiols supported on gold and silver. J. Am. Chem. Soc. 121, 4500 (1999).

J. Aizenberg, A.J. Black, and G.M. Whitesides: Control of crystal nucleation by patterned self-assembled monolayers. Nature 398, 495 (1999).

R.T. Butler, N.J. Ferrell, and D.J. Hansford: Spatial and geometrical control of silicification using a patterned poly-L-lysine template. Appl. Surf. Sci. 252, 7337 (2006).

E.A. Coffman, A.V. Melechko, D.P. Allison, M.L. Simpson, and M.J. Doktycz: Surface patterning of silica nanostructures using bio-inspired templates and directed synthesis. Langmuir 20, 8431 (2004).

D.J. Kim, K. Lee, T.G. Lee, H.K. Shon, W. Kim, H. Paik, and I.S. Choi: Biomimetic micropatterning of silica by surface-initiated polymerization and microcontact printing. Small 1, 992 (2005).

J. Guan, A. Chakrapani, and D.J. Hansford: Polymer microparticles fabricated by soft lithography. Chem. Mater. 17, 6227 (2005).

J. Guan, N. Ferrell, L.J. Lee, and D.J. Hansford: Fabrication of polymeric microparticles for drug delivery by soft lithography. Biomaterials 27, 4034 (2006).

N. Ferrell, J. Woodard, and D. Hansford: Fabrication of polymer microstructures for MEMS: Sacrificial layer micromolding and patterned substrate micromolding. Biomed. Microdevices 9, 815 (2007).

R.J. Jackman, D.C. Duffy, E. Ostuni, N.D. Willmore, and G.M. Whitesides: Fabricating large arrays of microwells with arbitrary dimensions and filling them using discontinuous dewet-ting. Anal. Chem. 70, 2280 (1998).

N. Ferrell and D. Hansford: Fabrication of micro and nanoscale polymer structures by soft lithography and spin dewetting. Macromol. Rapid Commun. 28, 966 (2007).

L.L. Brott, R.R. Naik, D.J. Pikas, S.M. Kirkpatrick, D.W. Tomlin, P.W. Whitlock, S.J. Clarson, and M.O. Stone: Ultrafast holographic nanopatterning of biocatalytically formed silica. Nature 413, 291 (2001).

K.H. Sandhage, M.B. Dickerson, P.M. Huseman, M.A. Caranna, J.D. Clifton, T.A. Bull, T.J. Heibel, W.R. Overton, and M.E.A. Schoenwaelder: Novel, bioclastic route to self-assembled, 3D, chemically tailored meso/nanostructures: Shape-preserving reactive conversion of biosilica (diatom) microshells. Adv. Mater. 14, 429 (2002).

Author information

Authors and Affiliations

Corresponding author

Additional information

This paper was selected as an Outstanding Symposium Paper for the 2007 MRS Spring Meeting, Symposium T Proceedings, Vol. 10008E.

Rights and permissions

About this article

Cite this article

Butler, R., Ferrell, N., Hansford, D. et al. Soft lithography-mediated microscale patterning of silica on diverse substrates. Journal of Materials Research 24, 1632–1638 (2009). https://doi.org/10.1557/jmr.2009.0200

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/jmr.2009.0200