Abstract

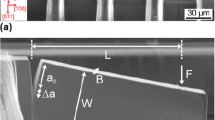

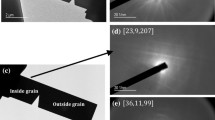

An analysis of size effects and doping on the strength of ultrananocrystalline diamond (UNCD) thin films is presented. The doping was achieved by the addition of nitrogen gas to the Ar/CH4 microwave plasma. The strength data, obtained by means of the membrane deflection experiment (MDE) were interpreted using Weibull statistics. The validity and predictive capability of the theory were examined in conjunction with detailed fractographic and transmission electron microscopy microstructural analysis. The Weibull parameters were estimated nonlinear regression based on 480 tests when the specimen volume varied from 500 to 16,000 μm3. Both undoped and doped UNCD films exhibited a decrease in strength with an increase in specimen size. A significant drop in strength was measured when the films were doped with nitrogen. Such a drop was almost independent of the percentage of doping. The results also showed that one can predict the fracture strength of a component possessing any arbitrary volume to within ±3%. Moreover, the failure mode of UNCD was found to be volume controlled. We also report changes in Young’s modulus as a function of doping for n-doped UNCD thin films.

Similar content being viewed by others

References

W. Weibull: A statistical theory of the strength of materials. Proc. R. Swedish Inst. Eng. Res. 151, 1 (1939).

W. Weibull: A statistical distribution function of wide applicability. J. Appl. Mech. 18, 293 (1951).

J. Bagdahn, W.N. Sharpe Jr., and O. Jadaan: Fracture strength of polysilicon at stress concentrations. J. Microelectromech. Syst. 12, 302 (2003).

W.N. Sharpe Jr., K.M. Jackson, J.H. Kevin, and Z. Xie: Effect of specimen size on Young’s modulus and fracture strength of polysilicon. J. Microelectromech. Syst. 10, 317 (2001).

D.A. LaVan, T. Tsuchiya, G. Coles, W.G. Knauss, I. Chasiotis, and D. Read: Cross comparison of direct strength testing techniques on polysilicon films, in Mechanical Properties of Structural Films, edited by C. Muhlstein and S.B. Brown (American Society for Testing and Materials, West Conshohocken, PA, 2001).

D.A. LaVan, K. Jackson, S.J. Glass, T.A. Friedmann, J.P. Sullivan, and T. Buchheit: Direct tension and fracture toughness testing using the lateral force capabilities of a nanomechanical test system, in Mechanical Properties of Structural Films, edited by C. Muhlstein and S.B. Brown (American Society for Testing and Materials, West Conshohocken, PA, 2001).

K.M. Jackson, J. Dunning, C.A. Zorman, M. Mehregany, and W.N. Sharpe Jr.: Mechanical properties of epitaxial 3C silicon carbide thin films. J. Microelectromech. Syst. 14, 664 (2005).

H.D. Espinosa, B. Peng, B.C. Prorok, N. Moldovan, O. Auciello, J.A. Carlisle, D.M. Gruen, and D.C. Mancini: Fracture strength of ultrananocrystalline diamond thin films—Identification of Weibull parameters. J. Appl. Phys. 94, 6076 (2003).

H.D. Espinosa, B.C. Prorok, B. Peng, K.H. Kim, N. Moldovan, O. Auciello, J.A. Carlisle, D.M. Gruen, and D.C. Mancini: Mechanical properties of ultrananocrystalline diamond thin films relevant to MEMS/NEMS devices. Experimental Mechanics 43, 256 (2003).

I. Chasiotis and W.G. Knauss: The mechanical strength of polysilicon films: Part 1. The influence of fabrication governed surface conditions. J. Mech. Phys. Solids 51, 1553 (2003).

I. Chasiotis and W.G. Knauss: The mechanical strength of polysilicon films: Part 2. Size effects associated with elliptical and circular perforations. J. Mech. Phys. Solids 51, 1551 (2003).

K.S. Chen, A. Ayon, and S.M. Spearing: Controlling and testing the fracture strength of silicon on the mesoscale. J. Am. Ceram. Soc. 83, 1476 (2000).

T. Tsuchiya, J. Sakata, and Y. Taga: Tensile strength and fracture toughness of surface micromachined polycrystalline silicon thin films prepared under various conditions, in Thin-Films—Stresses and Mechanical Properties VII, edited by R.C. Cammarata, M. Nastasi, E.P. Busso and W.C. Oliver (Mater. Res. Soc. Symp. Proc. 505, Warrendale, PA, 1998), pp. 285–290.

D.T. Read, J.D. McColskey, R. Geiss, and Y.W. Cheng: Microtensile testing of thin films in the optical and scanning electron microscopes, in Characterization and Metrology for ULSI Technology, edited by D.G. Seiler and A.C. Diebold (AIP Conference Proceedings 683, 2003), pp. 353–356.

D.M. Gruen: Nanocrystalline diamond films. Ann. Rev. Mater. Sci. 29, 211 (1999).

D. Zhou, T.G. McCauley, L.C. Qin, A.R. Krauss, and D.M. Gruen: Synthesis of nanocrystalline diamond thin film from an Ar–CH4 microwave plasma. J. Appl. Phys. 83, 540 (1998).

O. Auciello, J. Birrell, J.A. Carlisle, J.E. Gerbi, X. Xiao, B. Peng, and H.D. Espinosa: Materials science and fabrication processes for a new MEMS technology based on ultrananocrystalline diamond thin films. J. Phys. Condens. Matter 16, R539 (2004).

A.V. Sumant, D.S. Grierson, J.E. Gerbi, J. Birrell, U.D. Lanke, O. Auciello, J.A. Carlisle, and R.W. Carpick: Toward the ultimate tribological interface: surface chemistry and nanotribology of ultrananocrystalline diamond. Adv. Mater. 17, 1039 (2005).

A. Erdemir, G.R. Fenske, A.R. Krauss, D.M. Gruen, T. McCauley, and R.T. Csencsits: Tribological properties of nanocrystalline diamond films. Surf. Coat. Technol. 120, 565 (1999).

A.R. Krauss, O. Auciello, M.Q. Ding, D.M. Gruen, Y. Huang, V.V. Zhirnov, E.I. Givargizov, A. Breskin, R. Chechen, E. Shefer, V. Konov, S. Pimenov, A. Karabutov, A. Rakhimov, and N. Suetin: Electron field emissions for ultrananocrystalline diamond films. J. Appl. Phys. 89, 2958 (2001).

B. Bhattacharyya, O. Auciello, J. Birrell, J.A. Carlisle, L.A. Curtiss, A.N. Goyette, D.M. Gruen, A.R. Krauss, J. Schlueter, A. Suman, and P. Zapol: Synthesis and characterization of highly-conducting nitrogen doped ultrananocrystalline diamond films. Appl. Phys. Lett. 79, 1441 (2001).

J. Birrell, J.A. Carlisle, O. Auciello, D.M. Gruen, and J.M. Gibson: Morphology and electronic structure in nitrogen-doped ultrananocrystalline diamond. Appl. Phys. Lett. 81, 2235 (2002).

W. Yang, O. Auciello, J.E. Butler, W. Cai, J.A. Carlisle, J.E. Gerbi, D.M. Gruen, T. Knickerbocker, T.L. Lasseter, J.N. Russell, L.M. Smith, and R.J. Hamers: DNA-modified nanocrystalline diamond thin-films as stable, biologically active substrates. Nat. Mater. 1, 253 (2002).

K.H. Kim, N. Moldovan, C. Ke, H.D. Espinosa, X. Xiao, J.A. Carlisle, and O. Auciello: Novel ultrananocrystalline diamond probes for high-resolution low-wear nanolithographic techniques. Small 1, 866 (2005).

H.D. Espinosa, B.C. Prorok, and M. Fisher: A methodology for determining mechanical properties of freestanding thin films and MEMS materials. J. Mech. Phys. Solids 51, 47 (2003).

W. Weibull: The phenomenon of rupture in solids. Proc. R. Swedish Inst. Eng. Res. 153, 1 (1939).

Z.P. Bazant, Y. Zhou, D. Novak, and I.M. Daniel: Size effect on flexural strength of fiber-composite laminates. J. Eng. Mater. Technol. 126, 29 (2004).

C.A. Johnson and W.T. Tucker: Advanced statistical concepts of fracture in brittle materials. Eng. Mater. Handbook, Ceram. Glasses 4, 709 (1991).

N. Pugno, B. Peng, and H.D. Espinosa: Prediction of strength in MEMS components with defects—A novel experimental-theoretical approach. Int. J. Solid Struct. 42, 647 (2005).

H.D. Espinosa and B. Peng: A new methodology to investigate fracture toughness of freestanding MEMS and advanced materials in thin film form. J. Microelectromech. Syst. 14, 153 (2005).

Author information

Authors and Affiliations

Corresponding author

Additional information

This author was an editor of this journal during the review and decision stage. For the JMR policy on review and publication of articles authored by editors, please refer to http://www.mrs.org/jmr_policy.

Rights and permissions

About this article

Cite this article

Peng, B., Li, C., Moldovan, N. et al. Fracture size effect in ultrananocrystalline diamond: Applicability of Weibull theory. Journal of Materials Research 22, 913–925 (2007). https://doi.org/10.1557/jmr.2007.0137

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/jmr.2007.0137