Abstract

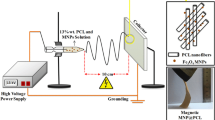

When nanoparticles and nanofibers combined at the nanoscale, they could create new features in the material and therefore new areas of use. In this study, polyvinylpyrrolidone (PVP) nanofibers containing carbon nanoparticles produced by dense medium plasma technology have been fabricated via electrospinning technique for the first time, a new class of nanocomposite mat material has been prepared and evaluated for medical devices. A dense medium plasma technique is used for nanoparticles synthesis, which is novel, cost-efficient, and fast technology when is compared with other common nanoparticles synthesis techniques. Carbon based nanoparticles are synthesized from an arc sustained in benzene (purity, 99.5%) between iron electrodes by the lab-made dense medium plasma system. The study first mentions the production of nanoparticles by a pressure of 8 bar argon gas for glow discharge in a period of 9 seconds using a 0.5 cm electrode distance in a liquid environment (volume of benzene: 30 ml). Then, separated carbon nanoparticles are integrated with the PVP nanofibers produced by the electrospinning method. Processing parameters of PVP nanofibers containing carbon nanoparticle (nanocomposites) are optimized with various conditions such as polymer concentration: 7.8-8.0 %w/v, ratio of nanoparticle to polymer solution: 1-3.9 mg /ml, distance of electrode: 10-25 cm, processing time: 5-30 min. All samples are characterized by contact angle measurements, scanning electron microscopy and transmission electron microscopy. At the same time, electrical conductivity of nanocomposite mats are tested for foreseeing usage in biomedical application. Results showed that carbon nanoparticles have diameters in 25 ± 5.4 nm. New nanocomposite material production is proven by transmission electron microscopy. It is a super hydrophilic mat material (static contact angle is lower than 10°). According to the optimization of processing parameters, the diameters of nanocomposite fibers reach down to 150 ±75 nm., Nanocomposite mat resistance is found to be dramatically higher than that for the bare PVP nanofiber mat resistance. According to these results, usage in biomedical application of new material was discussed. It has a great potential to use as biocompatible, light, insulator new material.

Similar content being viewed by others

References

R. Vasita and D.S. Katti, International Journal of Nanomedicine 1, 15–30 (2006).

Z. M Huang, Y. Z. Zhang, M. Kotaki, and S. Ramakrishna, Composites Science and Technology 63,2223–2253 (2003).

W. J. Li, C. T. Laurencin, E. J. Caterson, R. S. Tuan, and F. K. Ko, Journal of Biomedical Materials Research, P. A. 60, 613–621 (2002).

S. Li, M. M. Lin, M. S. Toprak, D. K. Kim and M. Muhammed, Nano Reviews 1, 5214–5232 (2010).

W. K. Son, J. H. Youk, W. H. Park, Carbohydrate Polymers, 430–434 (2006).

V. Subramanian, E. E. Wolf, and P. V. Kamat, Journal of the American Chemical Society 126, 4943–4950 (2004).

S. Agarwal, J. H. Wendorff and A. Greiner, Polymer 49, 5603–5621 (2008)

W. E. Teo, R. İnai and S. Ramaksihna, Science and Technology of Advanced Materials 12, 1–19 (2011).

N. A. M. Barakat, M.F. Abadir, F. A. Sheikh, M. A. Kanjwal, S. J. Park, H. Y. Kim, Chemical Engineering Journal, 156, 487–495 (2010).

Y. Ma, S. Manolache, F. Denes, D, D.H. Thamm, I.D. Kurzman, D.M. Vail, J. Biomater. Sci. Polymer Edn, 15 (8), 1033–1049 (2004).

M. Afzali, A. Mostafavi, and T. Shamspur, Materials Science and Engineering, C 68, 789–797. (2016).

Y. Liu, H. Huang, L. Wang, D. Cai, B. Liu, D. Wang, Q. Li, and T. Wang, Sensors and Actuators B: Chemical 223, 730–737. (2016).

A.E. Deniz, H.A. Vural, B. Ortaç, and T. Uyar, Materials Letters 65, 2941–2943. (2011).

J. Quirós, J.P. Borges, K. Boltes, I. Rodea-Palomares, and R. Rosal, Journal of Hazardous Materials 299, 298–305 (2015).

T. Tański, W. Matysiak, Ł. Krzemiński, P. Jarka, and K. Gołombek, Applied Surface Science 424, 184–189 (2017).

K. Nasouri, A.M Shoushtari, and M.R.M. Mojtahedi, Polymer Composites 38, 2026–2034 (2017).

F. Barzegar, A. Bello, M. Fabiane, S. Khamlich, D. Momodu, F. Taghizadeh, J. Dangbegnon, and N. Manyala, Journal of Physics and Chemistry of Solids 77, 139–145 (2015).

F. Müller, C.A. Ferreira, D. S. Azambuja, C. Aleman, E. Armelin, Journal of Physical Chemistry 118, 1102–1112 (2014).

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Serdaroğlu, D.Ç., Korkusuz, H.K., Karakaya, M. et al. Nanoparticle Embedded Nanofiber Synthesis and Evaluation of Usability on Biomedical Applications. MRS Advances 3, 233–240 (2018). https://doi.org/10.1557/adv.2018.200

Published:

Issue Date:

DOI: https://doi.org/10.1557/adv.2018.200