Abstract

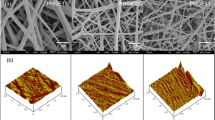

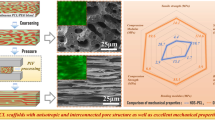

Three dimensional scaffolds (3D) are promising for future nanoscale materials and tissue engineering applications being that they have architecture and mechanical properties similar to natural tissue. In this work, poly(lactic acid) fibers were prepared via electrospinnig with average diameters of 2580 nm. Using Enzymatic Surface-Initiated polymerization (ESIP), poly(3-hydroxybutyrate) were coated on poly(lactic acid) fibers. This provides an alternative method to enzymatic surface modification of fibers. ESIP of PHB produces a granular film providing surface topography and increases mechanical properties of PLA fibers alone. When using covalent approaches, PHB granules provide surface topography of 200-500 nm with a polydisperse coverage area. Compressive modulus measurements of PLA and PHB/PLA scaffolds were 25 kPa and 73 kPa, respectively. The percent crystallinity of PLA and PHB/PLA scaffolds was 17% and 30%, respectively. This rough topography, in addition to the crystallinity of the scaffold, facilitates Soas-2 osteoblast cell attachment. We have observed attachment of the osteoblast cells along the length of the oriented PLA and PHB/PLA composite scaffolds with different morphologies, rounded and stretched, throughout a depth of 90 µm.

Similar content being viewed by others

References

Doshi, J., Reneker, D.H. Electrospinning process and applications of Electrospun Fibers. J. Electrostat. 1995, 35, 2/3, 151–160.

Chen,G.Q. and Wu, Q. The Application of Polyhydroxyalkanoates as tissue engineering materials. Biomaterials. 2005, 26, 6565–6578.

Williams, SF., Martin, DP., Horowitz, DM., Peoples OP. PHA applications: addressing the price of performance issue I. Tissue Engineering. Int. J. Bio. Macro. 1999, 25, 111–121.

Freir, T., Kunze, C., Nischan, C., Kramer, S., Sternberg, K., Sass, M., Hopt, UT., Schmitz, KP. In vitro and in vivo degradation studies for development of biodegradable patch based on poly(3-hydroxybutyrate). Biomaterials. 2002, 23(13), 2649–2657.

Zhao, K., Deng, Y., Chen, C.J., Chen, G.Q. Polyhydroxyalkanoates (PHA) scaffolds with good mechanical properties and biocompatibility. Biomaterials. 2003, 24, 1041–1045.

Pruker, O., Rueche, J. Polymer Layers through Self-Assembled Monolayers of Initiators. Langmuir. 1998, 14, 6893–6898.

Jordan,R., Ulman, A., Kang, J.F., Rafailovich, M.H., Sokolov, J. Surface-Initiated Anionic Polymerization of Styrenes by means of Self-Assembled Monolayers. JACS. 1999, 121, 1016–1022.

Reith, L.R., Moore, D.R., Lobkovsky, E.B., Coates, G.W. Single-site-B-Diiminate Zince catalysts for the Ring-opening Polymerization of B-Butyrolactone and B-Valerolactone to Poly(3-hydroxyalkanoates. J.Am. Chem. Soc. 2002, 124, 15239–15248.

Matyjaszewski, K., Miller, P.J., Shukla, N., Immaraporn, B., Gelman, A., Luokala, B.B., Siclovan, T.M., Kickelbick, G., Vallant, T., Hoffman, H., Pakula, T. Polymers at Interfaces: Using Atomic Transfer Radical Polymerization in the controlled growth of homopolymers and Block copolymers from Silicon Surfaces in the absence of Untethred Sacrificial Initiators. Macromolecules. 1999, 32, 8716–8724.

Kim, Y-R., Paik, H.-j., Ober, C.K., Coates, G.W., Batt, C. A. Enzymatic Surface-Initiated Polymerization: A Novel Approach for the In-Situ Solid-Phase Synthesis of Biocompatible Polymer Poly(3-hydroxybutyrate). Biomacromolecules. 2004, 5, 889–894.

Li, D., Frey, M., Joo, Y. Characterization of nanofibrous membranes with capillary flow porometry. Journal of Membrane Sci. 2006, 286, 104–114.

Kim, Y.R., Nanoengineering of Solid Surfaces Using an In Vitro Synthesized Biological Polymer, Cornell University, Ithaca. 2003.

Yan, L., Marzolin, C., Terfort, A, Whitesides, G.M. Formation and Reaction of Interchain Carboxylic Anhydrides Groups on Self-Assembled Monolayers of Gold. Langmuir. 1997, 13, 6704.

Koyama, N. and Doi, Y. Miscibility of binary blends of poly[(R )-3-hydroxybutryric acid] and poly[(S)-lactic acid. Polymer. 1997, 38(7), 1589–1593.

Niamsiri, N., Bergkvist, M., Delamarre, S., Cady, N., Coates, G.W., Ober, C.K., Batt, C.A. Insight in the role of bovine serum albumin for promoting the in situ surface growth of polyhydroxybutyrate (PHB) on patterned surfaces via enzymatic surface-intitated polymerization. Colliods and Surfaces B: Biointerfaces. 2007, 60, 68–70

Ouchi, T., Miyazaki, H., Arimura, H., Tasaka, F., Hamada, A., Ohya, Y., J. Polym. Sci., Part A: Polym. Chem. 2002, 40, 1218.

Wang, Y.W., Wu, Q., Chen, J., Chen, G.Q. Evaluation of three dimensional scaffolds made of blends of hydroxyapaptite and poly(3-hydroxybutyrate-co-3-hydroxyhexanoate) for bone reconstruction. Biomaterials. 2005, 26, 899–904.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Mendenhall, J., Li, D., Frey, M. et al. Piezoelectric Poly(3-hydroxybutyrate)-Poly(lactic acid) Three Dimensional Scaffolds for Bone Tissue Engineering. MRS Online Proceedings Library 1025, 1203 (2007). https://doi.org/10.1557/PROC-1025-B12-03

Received:

Accepted:

Published:

DOI: https://doi.org/10.1557/PROC-1025-B12-03