Abstract

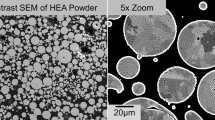

Cold-sprayed high-entropy alloy (HEA) coatings have been generated for the first time. Mechanically alloyed (MA) AlCoCrFeNi powder was chosen as feedstock, owing to the extensive literature on this alloy. Coatings were synthesized under various gas temperature and pressure conditions. Isothermal oxidation was conducted at 1100 °C for 25 h on the coating cold-sprayed at 400 °C and 10 bar on a Ni-base superalloy substrate. The as-sprayed coating retained the MA phases and formed a protective alumina layer upon oxidation. An interdiffusion zone at the interface and unanticipated Mo diffusion from the superalloy substrate into the coating were observed after oxidation. A comprehensive characterization at the coating—substrate interface suggests that diffusion in HEAs is not sluggish. The factors governing the coating’s oxidation are elucidated, and a plausible oxidation mechanism is discussed. These studies are aimed at developing oxidation-resistant HEA coatings for potential applications at high operating temperatures.

Similar content being viewed by others

References

J.W. Yeh, S.K. Chen, S.J. Lin, J.Y. Gan, T.S. Chin, T.T. Shun, C.H. Tsau, and S.Y. Chang: Nanostructured high-entropy alloys with multiple principal elements: Novel alloy design concepts and outcomes. Adv. Eng. Mater. 6, 299 (2004).

B. Cantor, I.T.H. Chang, P. Knight, and A.J.B. Vincent: Microstructural development in equiatomic multicomponent alloys. Mater. Sci. Eng., A 375, 213 (2004).

M.C. Gao, P.K. Liaw, J.W. Yeh, and Y. Zhang: High-Entropy Alloys (Springer International Publishing, Zurich, Switzerland, 2016).

D.B. Miracle and O.N. Senkov: A critical review of high entropy alloys and related concepts. Acta Mater. 122, 488 (2017).

C. Zhang, F. Zhang, S. Chen, and W. Cao: Computational thermodynamics aided high-entropy alloy design. JOM 64, 839 (2012).

W-R. Wang, W-L. Wang, S-C. Wang, Y-C. Tsai, C-H. Lai, and J-W. Yeh: Effects of Al addition on the microstructure and mechanical property of AlxCoCrFeNi high-entropy alloys. Intermetallics 26, 44 (2012).

A. Manzoni, H. Daoud, R. Volkl, U. Glatzel, and N. Wanderka: Phase separation in equiatomic AlCoCrFeNi high-entropy alloy. Ultramicroscopy 132, 212 (2013).

W. Ji, Z. Fu, W. Wang, H. Wang, J. Zhang, Y. Wang, and F. Zhang: Mechanical alloying synthesis and spark plasma sintering consolidation of CoCrFeNiAl high-entropy alloy. J. Alloys Compd. 589, 61 (2014).

S. Uporov, V. Bykov, S. Pryanichnikov, A. Shubin, and N. Uporova: Effect of synthesis route on structure and properties of AlCoCrFeNi high-entropy alloy. Intermetallics 83, 1 (2017).

M. Vaidya, A. Prasad, A. Parakh, and B.S. Murty: Influence of sequence of elemental addition on phase evolution in nanocrystalline AlCoCrFeNi: Novel approach to alloy synthesis using mechanical alloying. Mater. Des. 126, 37 (2017).

V. Shivam, J. Basu, V.K. Pandey, Y. Shadangi, and N.K. Mukhopadhyay: Alloying behaviour, thermal stability and phase evolution in quinary AlCoCrFeNi high entropy alloy. Adv. Powder Technol. 29, 2221 (2018).

Y.P. Wang, B.S. Li, M.X. Ren, C. Yang, and H.Z. Fu: Microstructure and compressive properties of AlCrFeCoNi high entropy alloy. Mater. Sci. Eng., A 491, 154 (2008).

Z. Tang, O.N. Senkov, C.M. Parish, C. Zhang, F. Zhang, L.J. Santodonato, G. Wang, G. Zhao, F. Yang, and P.K. Liaw: Tensile ductility of an AlCoCrFeNi multi-phase high-entropy ally through hot isostatic pressing (HIP) and homogenization. Mater. Sci. Eng., A 647, 229 (2015).

Z.M. Jiao, Z.H. Wang, R.F. Wu, and J.W. Qiao: Strain rate sensitivity of nanoindentation creep in an AlCoCrFeNi high-entropy alloy. Appl. Phys. A 122, 794 (2016).

S. Mohanty, T.N. Maity, S. Mukhopadhyay, S. Sarkar, N.P. Gurao, S. Bhowmick, and K. Biswas: Powder metallurgical processing of equiatomic AlCoCrFeNi high entropy alloy: Microstructure and mechanical properties. Mater. Sci. Eng., A 679, 299 (2017).

E. Ghassemali, R. Sonkusare, K. Biswas, and N.P. Gurao: In situ study of crack initiation and propagation in a dual phase AlCoCrFeNi high entropy alloy. J. Alloys Compd. 710, 539 (2017).

T.M. Butler: Phase stability and oxidation behaviour of Al—Ni—Co—Cr—Fe based high-entropy alloys. Doctoral thesis, University of Alabama, Tuscaloosa, 2016.

J. Dabrowa, G. Cieslak, M. Stygar, K. Mroczka, K. Berent, T. Kulik, and M. Danielewski: Influence of Cu content on high temperature oxidation behaviour of AlCoCrCuxFeNi high entropy alloys (x = 0; 0.5; 1). Intermetallics 84, 52 (2017).

A. Zhang, J. Han, B. Su, and J. Meng: Tribological properties of AlCoCrFeNi high entropy alloy at elevated temperature. Tribology 37, 776 (2017).

P-K. Huang and J-W. Yeh: Inhibition of grain coarsening up to 1000 °C in (AlCrNbSiTiV)N superhard coatings. Scr. Mater. 62, 105 (2010).

A.D. Pogrenbjak, I.V. Yakushchenko, O.V. Bondar, V.M. Beresnev, K. Oyoshi, O.M. Ivasishin, H. Amekura, Y. Takeda, M. Opielak, and C. Kozak: Irradiation resistance, microstructure and mechanical properties of nanostructured (TiZrHfVNbTa)N coatings. J. Alloys Compd. 679, 155 (2016).

C. Huang, Y. Zhang, J. Shen, and R. Vilar: Thermal stability and oxidation resistance of laser clad TiVCrAlSi high entropy alloy coatings on Ti–6Al–4V alloy. Surf. Coat. Technol. 206, 1389 (2011).

N.P. Padture, M. Gell, and E.H. Jordan: Thermal barrier coatings for gas-turbine engine applications. Science 296, 280 (2002).

A.S.M. Ang, C.C. Berndt, M.L. Sesso, A. Anupam, S. Praveen, R.S. Kottada, and B.S. Murty: Plasma-sprayed high entropy alloys: Microstructure and properties of AlCoCrFeNi and MnCoCrFeNi. Metall. Mater. Trans. A 46A, 791 (2015).

A. Moridi, S.M. Hassani-Gangaraj, M. Guagliano, and M. Dao: Cold spray coating: A review of material systems and future perspectives. Surf. Eng. 30, 369 (2014).

A.P. Alkhimov and N. Anatoly: Gas-dynamic spraying method for applying a coating. U.S. Patent No. 5302414, 1994, accessed 24 July, 2018.

H. Assadi, F. Gartner, T. Stoltenhoff, and H. Kreye: Bonding mechanism in cold gas spraying. Acta Mater. 51, 3479 (2003).

T. Stoltenhoff, H. Kreye, and H.J. Richter: An analysis of cold spray process and its coatings. J. Therm. Spray Technol. 11, 542 (2002).

Q. Zhao, G. Ma, H. Wang, G. Li, S. Chen, and Y. Zhou: Review on preparation and application of high-entropy alloy coatings. Mater. Rev. 31, 65 (2017).

S. Yin, W. Li, B. Song, X. Yan, M. Kuang, Y. Xu, K. Wen, and R. Lupoi: Deposition of FeCoNiCrMn high entropy alloy (HEA) coating via cold spraying. J. Mater. Sci. Technol. in press, accepted manuscript (2018). Available at: https://doi.org/10.1016/j.jmst.2018.12.015.

ASM Handbook Volume 3: Alloy Phase Diagrams prepared under the direction of the ASM International Alloy Phase Diagram and Handbook Committees, Metals Park, Ohio (ASM International, 1992).

G. Zhu, Y. Liu, and J. Ye: Early high-temperature oxidation behaviour of Ti(C,N)-based cermets with multi-component AlCoCrFeNi high-entropy alloy binder. Int. J. Refract. Met. Hard Mater. 44, 35 (2014).

A. Kumar, A.K. Swarnakar, and M. Chopkar: Phase evolution and mechanical properties of AlCoCrFeNiSix high-entropy alloys synthesized by mechanical alloying and spark plasma sintering. J. Mater. Eng. Perform. 27, 3304 (2018).

J. Chen, P. Niu, T. Wei, L. Hao, Y. Liu, H. Wang, and Y. Peng: Fabrication and mechanical properties of AlCoNiCrFe high-entropy alloy particle reinforced Cu matrix composites. J. Alloys Compd. 649, 630 (2015).

A. Papyrin, V. Kosarev, S. Klinkov, A. Alkimov, and V. Fomin: Cold Spray Technology (Elsevier, Science, Amsterdam, Netherlands, 2007); ch. 3.

C.S. Tedmon, Jr.: The effect of oxide volatilization on the oxidation kinetics of Cr and Fe—Cr alloys. J. Electrochem. Soc. 113, 766 (1966).

A.G. Evans, D.R. Clarke, and C.G. Levi: The influence of oxides on the performance of advanced gas turbines. J. Eur. Ceram. Soc. 28, 1405 (2008).

C. Wagner: Passivity and inhibition during the oxidation of metals at elevated temperatures. Corros. Sci. 5, 751 (1965).

M.J. Pomeroy: Coatings for gas turbine materials and long-term stability issues. Mater. Des. 26, 223 (2005).

M. Vaidya, K.G. Pradeep, B.S. Murty, G. Wilde, and S.V. Divinki: Bulk tracer diffusion in CoCrFeNi and CoCrFeMnNi high entropy alloys. Acta Mater. 146, 211 (2018).

Q. Li, W. Chen, J. Zhong, L. Zhang, Q. Chen, and Z-K. Liu: On sluggish diffusion in FCC Al—Co—Cr—Fe—Ni high-entropy alloys: An experimental and numerical study. Metals 8, 16 (2018).

N. Kaur, M. Kumar, S.K. Sharma, D.Y. Kim, S. Kumar, N.M. Chavan, S.V. Joshi, N. Singh, and H. Singh: Study of mechanical properties and high temperature oxidation behavior of a novel cold-spray Ni–20Cr coating on boiler steels. Appl. Surf. Sci. 328, 13 (2015).

S. Praveen, A. Anupam, R. Tilak, and R.S. Kottada: Phase evolution and thermal stability of AlCoCrFe high entropy alloy with carbon as unsolicited addition from milling media. Mater. Chem. Phys. 210, 57 (2018).

Acknowledgment

The authors would like to acknowledge the financial support from the Aeronautics Research and Development Board (ARDB), India, via the project “Development of High Entropy Alloy (HEA) coatings as potential bond-coat materials for high temperature turbine engine applications” (sanction # ARDB/GTMAP/01/2031783/M/1/285/D(R&D)). Authors also thank Mr. Ashish Bharadwaj for assistance with the graphics.

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Anupam, A., Kumar, S., Chavan, N.M. et al. First report on cold-sprayed AlCoCrFeNi high-entropy alloy and its isothermal oxidation. Journal of Materials Research 34, 796–806 (2019). https://doi.org/10.1557/jmr.2019.38

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/jmr.2019.38