Abstract

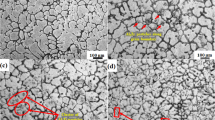

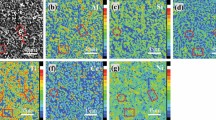

As a promising reinforcement of aluminum alloy, in situ formed Al3Ti particles have attracted more attention in the fabrication of aluminum matrix composites. In our research, in situ Al3Ti/7075 alloy composites were fabricated by adding K2TiF6 salt powders into molten 7075 alloy at 750 °C via casting method. The formation of in situ Al3Ti particles and their effects on the microstructure and mechanical properties of 7075 alloy, including hardness, ultimate tensile strength (UTS), and yield strength (YS), were investigated. The results showed that in situ formed Al3Ti particles were rod-like in morphology, with the average length and width of 15 µm and 5 µm, respectively. Due to the nucleating effect of Al3Ti particles, α-Al crystals of 7075 alloy transferred from dendritic to equiaxed structure in morphology, the size of which decreased obviously as well. Compared with 7075 alloy, the hardness, UTS, and YS of in situ Al3Ti/7075 alloy were improved by 14.3%, 18.1%, and 25.8%, respectively.

Similar content being viewed by others

References

S.C. Tjong and Z.Y. Ma: Microstructural and mechanical characteristics of in situ metal matrix composites. Mater. Sci. Eng. R29, 49–113 (2000).

Z.Q. Yang, L.L. He, J. Chen, H.T. Cong, and H.Q. Ye: Microstructure and thermal stability of an ultrafine Al/Al2O3 composite. J. Mater. Res. 18, 272–278 (2003).

L.G. Chen, K.H. Shue, S.Y. Chang, and S.J. Lin: Squeeze casting of SiCp/Al-alloy composites with various contents of reinforcements. J. Mater. Res. 17, 376–385 (2002).

Z.W. Liu, Q.Y. Han, and J.G. Li: A developed method for producing in situ TiC/Al composites by using quick preheating treatment and ultrasonic vibration. Composites Part B 43, 2429–2433 (2012).

Z.Y. Xiu, G.Q. Chen, G.H. Wu, W.S. Yang, and Y.M. Liu: Effect of volume fraction on microstructure and mechanical properties of Si3N4/Al composites. Trans. Nonferrous Met. Soc. China 21, s285–s289 (2011).

Y.Q. Liu, H.T. Cong, and H.M. Cheng: Thermal properties of nanocrystalline Al composites reinforced by AlN nanoparticles. J. Mater. Res. 24, 24–31 (2009).

T.X. Fan, G. Yang, and D. Zhang: Thermodynamic effect of alloying addition on in-situ reinforced TiB2/Al composites. Metall. Mater. Trans. A36, 225–233 (2005).

Z.W. Liu, Q.Y. Han, and J.G. Li: Formation of small blocky Al3Ti particles via direct reaction between solid Ti powders and liquid Al. Metall. Mater. Trans. A43, 4460–4463 (2012).

Z.W. Liu, Q.Y. Han, and J.G. Li: Fabrication of in situ Al3Ti/Al composites by using ultrasound assisted direct reaction between solid Ti powders and liquid Al. Powder Technol. 247, 55–59 (2013).

R.N. Wright, B.H. Rabin, and W.H. McFerran: Combustion synthesis of cubic Al3Ti alloys. J. Mater. Res. 7, 2733–2738 (1992).

Q. Zhang, B.L. Xiao, W.G. Wang, and Z.Y. Ma: Reactive mechanism and mechanical properties of in situ composites fabricated from an Al-TiO2 system by friction stir processing. Acta Mater. 60, 7090–7103 (2012).

M.X. Zhang, P.M. Kelly, M.A. Easton, and J.A. Taylor: Crystallographic study of grain refinement in aluminum alloys using the edge-to-edge matching model. Acta Mater. 53, 1427–1438 (2005).

D.H. St. John and L.M. Hogan: Metallography and growth crystallography of Al3Ti in Al-Ti alloys up to 5 wt% Ti. J. Cryst. Growth 46, 387–398 (1979).

K.A. Jackson: Structure of solid-liquid interfaces and crystal growth. In Interfaces Conference, Butterworths and Australian Institute of Metals: Melbourne, 1969.

G.K. Sigworth: The grain refining of aluminum and phase relationships in the Al-Ti-B System. Metall. Trans. A15, 277–282 (1984).

J.X. Li and A.P. Wu: Principle of Materials Processing (Peking University Press, Beijing, 2005).

G.R. Li, H.M. Wang, Y.T. Zhao, D.B. Chen, G. Chen, and X.N. Chen: Microstructure of in situ Al3Ti/6351 Al composites fabricated with electromagnetic stirring and fluxes. Trans. Nonferrous Met. Soc. China 20, 577–583 (2010).

X.M. Wang, A. Jha, and R. Brydson: In situ fabrication of Al3Ti particle reinforced aluminum alloy metal-matrix composites. Mater. Sci. Eng. A364, 339–345 (2004).

G.K. Sigworth: Communication on mechanism of grain refinement in aluminum. Scr. Mater. 34, 919–922 (1995).

F. Wang, Z.L. Liu, D. Qiu, J.A. Taylor, M.A. Easton, and M-X. Zhang: Revisiting the role of peritectics in grain refinement of Al alloys. Acta Mater. 61, 360–370 (2013).

J. Zhang and Y.C. Zhou: Microstructure, mechanical, and electrical properties of Cu-Ti3AlC2 and in situ Cu-TiCx composites. J. Mater. Res. 23, 924–932 (2008).

S.V. Kamat, J.P. Hirth, and R. Mehrabian: Mechanical properties of particulate-reinforced aluminum-matrix composites. Acta Metall. 37, 2395–2402 (1989).

V.C. Nardone and K.M. Prewo: On the strength of discontinuous silicon carbide reinforced aluminum composites. Scr. Metall. 20, 43–48 (1986).

W.F. Smith and J. Hashemi: Foundations of Materials Science and Engineering, 5th ed.; McGraw-Hill Companies, Inc., New York, 2010.

ACKNOWLEDGMENTS

The authors are very grateful to the New Material Institute of Shandong Academy of Sciences for proving experimental equipment for this research. The authors also acknowledge Xu Wang, Jianhua Wu, Yunteng Liu, Haihua Zhuang, Jixue Zhou, and Chengwei Zhan from the New Material Institute for their help in this research.

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Liu, Z., Rakita, M., Wang, X. et al. In situ formed Al3Ti particles in Al alloy matrix and their effects on the microstructure and mechanical properties of 7075 alloy. Journal of Materials Research 29, 1354–1361 (2014). https://doi.org/10.1557/jmr.2014.123

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/jmr.2014.123