Abstract

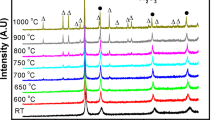

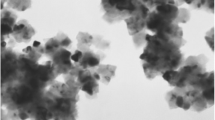

The consolidation of crystalline powders to obtain dense microstructures is typically achieved through a combination of volume and grain boundary diffusion. In situ transmission electron microscopy was utilized to study neck formation between adjacent nickel particles during the early stages of sintering. It was found that the presence of carbon during consolidation of Ni lowers the reduction temperature of nickel oxides on the particle surface and therefore has the potential to accelerate consolidation. In the absence of carbon, the surface oxides remain present during the early stage of sintering and neck formation between particles is limited by self-diffusion of nickel through the oxide layer. This study provides direct experimental evidence that corroborates related earlier hypotheses of self-cleaning on the surface of the nanoparticles that precedes neck formation and growth.

Similar content being viewed by others

References

R.M. German: Sintering Theory and Practice (John Wiley & Sons, Inc., New York, 1996).

S.J.L Kang: Sintering: Densification, Grain Growth, and Microstructure (Elsevier Butterworth-Heinemann, Amsterdam, Netherlands, 2005).

Y.M. Chiang, D.P. Birnie, and W.D. Kingery: Physical Ceramics (John Wiley & Sons, Weinheim, Germany, 1996).

Z.A. Munir and R.M. German: Generalized model for prediction of periodic trends in activation of sintering of refractory metals. High Temp. Sci. 9, 275–283 (1977).

E.A. Olevsky, S. Kandukuri, and L. Froyen: Consolidation enhancement in spark-plasma sintering: Impact of high heating rates. J. Appl. Phys. 102, 114913–114924 (2007).

R. Orrù, R. Licheri, A.M. Locci, A. Cincotti, and G. Cao: Consolidation/synthesis of materials by electric current activated/assisted sintering. Mater. Sci. Eng., R 63, 127–287 (2009).

Z.A. Munir, U. Anselmi-Tamburini, and M. Ohyanagi: The effect of electric field and pressure on the synthesis and consolidation of materials: A review of the spark plasma sintering method. J. Mater. Sci. 41, 763–777 (2006).

W. Chen, U. Anselmi-Tamburini, J.E. Garay, J.R. Groza, and Z.A. Munir: Fundamental investigations on the spark plasma sintering/synthesis process. I. Effect of dc pulsing on reactivity. Mater. Sci. Eng., A 394, 132–138 (2005).

U. Anselmi-Tamburini, J.E. Garay, Z.A. Munir, A. Tacca, F. Maglia, and G. Spinolo: Spark plasma sintering and characterization of bulk nanostructured fully stabilized zirconia: Part I. Densification studies. J. Mater. Res. 19, 3255–3262 (2004).

U. Anselmi-Tamburini, J.E. Garay, and Z.A. Munir: Fundamental investigations on the spark plasma sintering/synthesis process. III. Current effect on reactivity. Mater. Sci. Eng., A 407, 24–30 (2005).

V.Y. Kodash, J.R. Groza, K.C. Cho, B.R. Klotz, and R.J. Dowding: Field-assisted sintering of Ni nanopowders. Mater. Sci. Eng., A 385, 367–371 (2004).

M. Nygren and Z.J. Shen: Novel assemblies via spark plasma sintering. Silicates Industriels 69, 211–218 (2004).

B. Basu, J.H. Lee, and D.Y. Kim: Development of nanocrystalline wear-resistant Y-TZP ceramics. J. Am. Ceram. Soc. 87, 1771–1774 (2004).

M. Yue, J.X. Zhang, W.Q. Liu, and G.P. Wang: Chemical stability and microstructure of Nd-Fe-B magnet prepared by spark plasma sintering. J. Magn. Magn. Mater. 271, 364–368 (2004).

X.L. Su, P.L. Wang, W.W. Chen, Z.J. Shen, M. Nygren, Y.B. Cheng, and D.S. Yan: Optical properties of SPS-ed Y- and (Dy, Y)-alpha-sialon ceramics. J. Mater. Sci. 39, 6257–6262 (2004).

L.J. Zhou, Z. Zhao, A. Zimmermann, F. Aldinger, and M. Nygren: Preparation and properties of lead zirconate stannate titanate sintered by spark plasma sintering. J. Am. Ceram. Soc. 87, 606–611 (2004).

X. Chen, K.A. Khor, S.H. Chan, and L.G. Yu: Overcoming the effect of contaminant in solid oxide fuel cell (SOFC) electrolyte: Spark plasma sintering (SPS) of 0.5 wt% silica-doped yttria- stabilized zirconia (YSZ). Mater. Sci. Eng., A 374, 64–71 (2004).

G. Aldica, V. Khodash, P. Badica, and J.R. Groza: Electrical conduction in initial field assisted sintering stages. J. Optoelectron. Adv. Mater. 9, 3863–3870 (2007).

J.R. Groza, M. Garcia, and J.A. Schneider: Surface effects in field-assisted sintering. J. Mater. Res. 16, 286–292 (2001).

J.R. Groza and A. Zavaliangos: Sintering activation by external electrical field. Mater. Sci. Eng., A 287, 171–177 (2000).

G.Q. Xie, O. Ohashi, N. Yamaguchi, M. Song, K. Mitsuishi, K. Furuya, and T. Noda: Reduction of surface oxide films in Al-Mg alloy powders by pulse electric current sintering. J. Mater. Res. 19, 815–819 (2004).

G.Q. Xie, O. Ohashi, N. Yamaguchi, and A.R. Wang: Effect of surface oxide films on the properties of pulse electric-current sintered metal powders. Metall. Mater. Trans. A 34, 2655–2661 (2003).

N. Sato: Theory for breakdown of anodic oxide films on metals. Electrochim. Acta 16, 1683 (1971).

Z.A. Munir: Analytical treatment of the role of surface oxide layers in the sintering of metals. J. Mater. Sci. 14, 2733–2740 (1979).

M. Tokita: Trends in advanced SPS spark plasma sintering systems and technology. Jpn. Soc. Powder Technol. 30, 790–804 (1993).

D.M. Hulbert, D. Jiang, U. Anselmi-Tamburini, C. Unuvar, and A.K. Mukherjee: Experiments and modeling of spark plasma sintered, functionally graded boron carbide-aluminum composites. Mater. Sci. Eng., A 488, 333–338 (2008).

S.K. Sharma, F.J. Vastola, and P.L. Walker: Reduction of nickel oxide by carbon. 2. Interaction between nickel oxide and natural graphite. Carbon 35, 529–533 (1997).

W. Baukloh and F. Springorum: Reduction of nickel- and copper oxide with solid carbon. Z. Anorg. Allg. Chem. 230, 315–320 (1937).

L.M. Gandia and M. Montes: Effect of thermal treatments on the properties of nickel and cobalt activated charcoal-supported catalysts. J. Catal. 145, 276–288 (1994).

M.A. Asoro, D. Kovar, Y. Shao-Horn, L.F. Allard, and P.J. Ferreira: Coalescence and sintering of Pt nanoparticles: In situ observation by aberration-corrected HAADF STEM. Nanotechnology 21, 025701 (2010).

S.B. Simonsen, I. Chorkendorff, S. Dahl, M. Skoglundh, J. Sehested, and S. Helveg: Ostwald ripening in a Pt/SiO(2) model catalyst studied by in situ TEM. J. Catal. 281, 147–155 (2011).

I. Janowska, M.S. Moldovan, O. Ersen, H. Bulou, K. Chizari, M.J. Ledoux, and P.H. Cuong: High temperature stability of platinum nanoparticles on few-layer graphene investigated by in situ high-resolution transmission electron microscopy. Nano Res. 4, 511–521 (2011).

K. Ida, Y. Sugiyama, Y. Chujyo, M. Tomonari, T. Tokunaga, K. Sasaki, and K. Kuroda: In situ TEM studies of the sintering behavior of copper nanoparticles covered by biopolymer nanoskin. J. Electron Microsc. 59, S75–S80 (2010).

R. Ristau, R. Tiruvalam, P.L. Clasen, E.P. Gorskowski, M.P. Harmer, C.J. Kiely, I. Hussain, and M. Brust: Electron microscopy studies of the thermal stability of gold nanoparticle arrays. Gold Bull. 42, 133–143 (2009).

T.B. Holland, A.M. Thron, C.S. Bonifacio, A.K. Mukherjee, and K. van Benthem: Field assisted sintering of nickel nanoparticles during in situ transmission electron microscopy. Appl. Phys. Lett. 96, 243106 (2010).

M. Hummelgard, R.Y. Zhang, H.E. Nilsson, and H. Olin: Electrical sintering of silver nanoparticle ink studied by in situ TEM probing. PLoS One 6, e30106 (2011).

D.R. Gaskell: Introduction to the Thermodynamics of Materials, 5th ed. (Taylor & Francis, New York, Oxford, 2008).

E.H. Conrad, R.M. Aten, D.S. Kaufman, L.R. Allen, T. Engel, M. Dennijs, and E.K. Riedel: Observation of surface roughening on Ni (115). J. Chem. Phys. 84, 1015–1028 (1986).

P.S. Maiya and J.M. Blakely: Surface self-diffusion and surface energy of nickel. J. Appl. Phys. 38, 698 (1967).

J. Li, S.J. Dillon, and G.S. Rohrer: Relative grain boundary area and energy distributions in nickel. Acta Mater. 57, 4304–4311 (2009).

P. Hassen: Physical Metallurgy, 3rd ed. (Cambridge University Press, Cambridge, UK, 1996).

Acknowledgments

This study was partially funded through UC Davis start-up funds and a young faculty early career award by the U.S. National Science Foundation (DMR-#0955638). M.M. acknowledges financial support from the Japan Student Services Organization (JASSO. T.B.H. and A.K.M. were supported by the Office of Naval Research (Program Manager Dr. L. Kabacoff under Grant No. N00014-10-1-0632

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Matsuno, M., Bonifacio, C.S., Rufner, J.F. et al. In situ transmission electron microscopic investigations of reduction-oxidation reactions during densification of nickel nanoparticles. Journal of Materials Research 27, 2431–2440 (2012). https://doi.org/10.1557/jmr.2012.256

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/jmr.2012.256