Abstract

The relationship between hardness and flow stress in glassy polymers is examined. Materials studied include poly(methylmethacrylate), polystyrene, and polycarbonate. Properties are strongly rate dependent, so broadband nanoindentation creep (BNC) is used to measure hardness across a broad range of indentation strain rates (10−4 to 10 s−1). Molybdenum (Mo) is also studied to serve as a “control” whose rate-dependent hardness properties have been measured previously and whose flow stress, unlike the polymers, is pressure insensitive. The BNC hardness data are converted to uniaxial flow stress using two methods based on the usual Tabor–Marsh–Johnson correlation. With both methods the resulting BNC-derived uniaxial flow stress data agree closely with literature compression uniaxial flow stress data for all materials. For the polymers, the BNC hardness data depend on initial rate of loading, indicating that the measured properties are path dependent. Path dependence is not detected in Mo.

Similar content being viewed by others

References

R.F. Boyer: Dependence of mechanical properties on molecular motion in polymers. Polym. Eng. Sci. 8(3), 161 (1968).

A.S. Argon: A theory for the low-temperature plastic deformation of glassy polymers. Philos. Mag. 28(4), 839 (1973).

A.E. Mayr, W.D. Cook, and G.H. Edward: Yielding behaviour in model epoxy thermosets—I. Effect of strain rate and composition. Polymer 39, 3719 (1998).

D. Rana, V. Sauvant, and J.L. Halary: Molecular analysis of yielding in pure and antiplasticized epoxy-amine thermosets. J. Mater. Sci. 37(24), 5267 (2002).

L. Lin and A.S. Argon: Rate mechanism of plasticity in the crystalline component of semicrystalline nylon 6. Macromolecules 27(23), 6903 (1994).

N.W.J. Brooks, R.A. Duckett, and I.M. Ward: Temperature and strain-rate dependence of yield stress of polyethylene. J. Polym. Sci., Part B: Polym. Phys. 36(12), 2177 (1998).

T. Kazmierczak, A. Galeski, and A.S. Argon: Plastic deformation of polyethylene crystals as a function of crystal thickness and compression rate. Polymer 46(21), 8926 (2005).

A. Strojny, X. Xia, A. Tsou, and W.W. Gerberich: Techniques and considerations for nanoindentation measurements of polymer thin film constitutive properties. J. Adhes. Sci. Technol. 12, 1299 (1998).

O.L. Warren and T.J. Wyrobek: Nanomechanical property screening of combinatorial thin-film libraries by nanoindentation. Meas. Sci. Technol. 16(1), 100 (2005).

D.M. Ebenstein and L.A. Pruitt: Nanoindentation of biological materials. Nano Today 1(3), 26 (2006).

J.E. Jakes, C.R. Frihart, and D.S. Stone: Creep properties of micron-size domains in ethylene glycol modified wood across 4½ decades in strain rate, in Mechanics of Biological and Biomedical Materials, edited by K. Katti, C. Hellmich, U.G.K. Wegst, and R. Narayan (Mater. Res. Soc. Symp. Proc. 1132, Warrendale, PA, 2009), 1132-Z07-21.

W. Rostoker and J.O. Galante: Indentation creep of polymers for human joint applications. J. Biomed. Mater. Res. 13(5), 825 (1979).

M. Takahashi, M.C. Shen, R.B. Taylor, and A.V. Tobolsky: Master curves for some amorphous polymers. J. Appl. Polym. Sci. 8(4), 1548 (1964).

S.N.G. Chu and J.C.M. Li: Impression creep; a new creep test. J. Mater. Sci. 12(11), 2200 (1977).

J. Chen, G.A. Bell, D. Hanshan, J.F. Smith, and B.D. Beake: A study of low temperature mechanical properties and creep behaviour of polypropylene using a new sub-ambient temperature nanoindentation test platform. J. Phys. D: Appl. Phys. 43(42), 425404 (2010).

M.L. Oyen: Sensitivity of polymer nanoindentation creep measurements to experimental variables. Acta Mater. 55(11), 3633 (2007).

Fischer-A.C. Cripps: A simple phenomenological approach to nanoindentation creep. Mater. Sci. Eng., A 385(1–2), 74 (2004).

H. Li and A.H.W. Ngan: Size effects of nanoindentation creep. J. Mater. Res. 19(2), 513 (2004).

G. Constantinides, C.A. Tweedie, D.M. Holbrook, P. Barragan, J.F. Smith, and Van K.J. Vliet: Quantifying deformation and energy dissipation of polymeric surfaces under localized impact. Mater. Sci. Eng., A 489, 403 (2008).

A. Jager and R. Lackner: Identification of viscoelastic model parameters by means of cyclic nanoindentation testing. Int. J. Mater. Res. 99, 829 (2008).

H. Lu, B. Wang, J. Ma, G. Huang, and H. Viswanathan: Measurement of creep compliance of solid polymers by nanoindentation. Mech. Time-Depend. Mater. 7, 189 (2003).

M.L. Oyen: Spherical indentation creep following ramp loading. J. Mater. Res. 20(8), 2094 (2005).

M.L. Oyen: Relating viscoelastic nanoindentation creep and load relaxation experiments. Int. J. Mater. Res. 99, 823 (2008).

C.A. Tweedie and Van K.J. Vliet: Contact creep compliance of viscoelastic materials via nanoindentation. J. Mater. Res. 21(6), 1576 (2006).

M.R. Vanlandingham, N.K. Chang, P.L. Drzal, C.C. White, and S.H. Chang: Viscoelastic characterization of polymers using instrumented indentation. I. Quasi-static testing. J. Polym. Sci., Part B: Polym. Phys. 43, 1794 (2005).

B. Beake: Modelling indentation creep of polymers: A phenomenological approach. J. Phys. D: Appl. Phys. 39, 4478 (2006).

C.Y. Zhang, Y.W. Zhang, K.Y. Zeng, and L. Shen: Characterization of mechanical properties of polymers by nanoindentation tests. Philos. Mag. 86, 4487 (2006).

J.E. Jakes, R.S. Lakes, and D.S. Stone: Broadband nanoindentation of glassy polymers: Part I. Viscoelasticity. J. Mater. Res. 27(2), 463 (2011).

A.A. Elmustafa, S. Kose, and D.S. Stone: The strain-rate sensitivity of the hardness in indentation creep. J. Mater. Res. 22(4), 926 (2007).

J.B. Puthoff, J.E. Jakes, H. Cao, and D.S. Stone: Investigation of thermally activated deformation in amorphous PMMA and Zr-Cu-Al bulk metallic glasses with broadband nanoindentation creep. J. Mater. Res. 24(3), 1279 (2009).

D.S. Stone and K.B. Yoder: Division of the hardness of molybdenum into rate-dependent and rate-independent components. J. Mater. Res. 9(10), 2524 (1994).

K.B. Yoder, A.A. Elmustafa, J.C. Lin, R.A. Hoffman, and D.S. Stone: Activation analysis of deformation in evaporated molybdenum thin films. J. Phys. D: Appl. Phys. 36, 884 (2003).

M.F. Doerner and W.D. Nix: A method for interpreting the data from depth-sensing indentation instruments. J. Mater. Res. 1(4), 601 (1986).

D.S. Stone, J.E. Jakes, J.B. Puthoff, and A.A. Elmustafa: Analysis of indentation creep. J. Mater. Res. 25(4), 611 (2010).

J.E. Jakes, C.R. Frihart, J.F. Beecher, R.J. Moon, P.J. Resto, Z.H. Melgarejo, O.M. Surez, H. Baumgart, A.A. Elmustafa, and D.S. Stone: Nanoindentation near the edge. J. Mater. Res. 24(3), 1016 (2009).

J.E. Jakes, C.R. Frihart, J.F. Beecher, R.J. Moon, and D.S. Stone: Experimental method to account for structural compliance in nanoindentation measurements. J. Mater. Res. 23(4), 1113 (2008).

Q. Ma and D.R. Clarke: Size dependent hardness of silver single crystals. J. Mater. Res. 10(4), 853 (1995).

W.D. Nix and H. Gao: Indentation size effects in crystalline materials: A law for strain gradient plasticity. J. Mech. Phys. Solids 46(3), 411 (1998).

C.A. Tweedie, G. Constantinides, K.E. Lehman, D.J. Brill, G.S. Blackman, and Van K.J. Vliet: Enhanced stiffness of amorphous polymer surfaces under confinement of localized contact loads. Adv. Mater. 19(18), 2540 (2007).

E. Amitay-Sadovsky, B. Ward, G.A. Somorjai, and K. Komvopoulos: Nanomechanical properties and morphology of thick polyurethane films under contact pressure and stretching. J. Appl. Phys. 91, 375 (2002).

Fischer-A.C. Cripps: Significance of a local temperature rise in nanoindentation testing. J. Mater. Sci. 39(18), 5849 (2004).

G. Swallowe and S. Lee: Quasi-static and dynamic compressive behaviour of poly(methyl methacrylate) and polystyrene at temperatures from 293 K to 363 K. J. Mater. Sci. 41(19), 6280 (2006).

N.A. Fleck, W.J. Stronge, and J.H. Liu: High strain-rate shear response of polycarbonate and polymethyl methacrylate. Proc. R. Soc. London, Ser. A. 429, 459 (1990).

J. Richeton, S. Ahzi, K.S. Vecchio, F.C. Jiang, and R.R. Adharapurapu: Influence of temperature and strain rate on the mechanical behavior of three amorphous polymers: Characterization and modeling of the compressive yield stress. Int. J. Solids Struct. 43(7–8), 2318 (2006).

T.L. Briggs and J.D. Campbell: The effect of strain rate and temperature on the yield and flow of polycrystalline niobium and molybdenum. Acta Metall. 20(5), 711 (1972).

B.N. Lucas and W.C. Oliver: Indentation power-law creep of high-purity indium. Metall. Mater. Trans. A 30(3), 601 (1999).

D. Tabor: A simple theory of static and dynamic hardness. Proc. R. Soc. London, Ser. A 192, 247 (1948).

D. Tabor: The hardness of solids. Rev. Phys. Technol. 1(3), 145 (1970).

D.M. Marsh: Plastic flow in glass. Proc. R. Soc. London, Ser. A 279(1378), 420 (1964).

K.L. Johnson: Correlation of indentation experiments. J. Mech. Phys. Solids 18(2), 115 (1970).

K.L. Johnson: Contact Mechanics (Cambridge University Press, Cambridge, United Kingdom, 1985), p. 452.

G. Kermouche, J.L. Loubet, and J.M. Bergheau: Cone indentation of time-dependent materials: The effects of the indentation strain rate. Mech. Mater. 39, 24 (2007).

G. Kermouche, J.L. Loubet, and J.M. Bergheau: A new index to estimate the strain rate sensitivity of glassy polymers using conical/pyramidal indentation. Philos. Mag. 86, 5667 (2006).

I.N. Sneddon: Relation between load and penetration in axisymmetric Boussinesq problem for punch of arbitrary profile. Int. J. Eng. Sci. 3, 47 (1965).

L.A. Davis and C.A. Pampillo: Deformation of polyethylene at high pressure. J. Appl. Phys. 42, 4659 (1971).

L.A. Davis and C.A. Pampillo: Kinetics of deformation of PTFE at high pressure. J. Appl. Phys. 43, 4285 (1972).

K.D. Pae, J.A. Sauer, and A.A. Silano: Shear deformation under hydrostatic pressure of polytetrafluoroethylene and polycarbonate, in Proceedings of the Sixth International Conference on High-Pressure Science and Technology, Boulder, CO, edited by K.D. Timmerhaus and M.S. Barber (1979), pp. 512–518.

I.W. Chen: Implications of transformation plasticity in ZrO2-containing ceramics: II. Elastic-plastic indentation. J. Am. Ceram. Soc. 69, 189 (1986).

P. Bardia and R. Narasimhan: Characterisation of pressure-sensitive yielding in polymers. Strain 42, 187 (2006).

V. Keryvin: Indentation as a probe for pressure sensitivity of metallic glasses. J. Phys. Condens. Matter 20(11), 114119 (2008).

M.-Q. Le and S.-S. Kim: Element analysis of instrumented sharp indentations into pressure-sensitive materials. J. Mater. Sci. Technol. 23(2), 277 (2007).

R. Narasimhan: Analysis of indentation of pressure sensitive plastic solids using the expanding cavity model. Mech. Mater. 36(7), 633 (2004).

ACKNOWLEDGMENTS

This work was supported by Cooperative Research and Development Agreement 10-RD-111111129-027 between Hysitron, Inc. and Forest Products Laboratory. Research was sponsored by the National Science Foundation (Award CMMI-0824719 to D.S. Stone).

Author information

Authors and Affiliations

Corresponding author

Appendix

Appendix

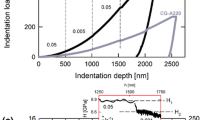

We obtain the continuous area-time curves in Fig. 4 by fitting continuous curves to the discrete area-time measurements also shown in the figure. Rather than relying on arbitrary functions like polynomials, power laws, or decaying exponentials to generate continuous area-time curves, we employ another approach that utilizes the nanoindentation load-depth-time traces. The method does a better job of capturing the trend of the data over a wide range of strain rate and has been validated and improved using finite element analysis.34 With this method it is assumed that \({A^{1/2}} \propto h_p^{{\xi _p}}\) at constant load. The power law exponent ζp is used as a fitting parameter to fit the continuous area-time curve to the discrete experimental data. During the creep hold, hp is estimated using

where P is the instantaneous load (ideally, P = P0 although in a real experiment P varies a small amount). The superscripts “0” refer to the values of the parameters at the end of the creep hold and \(h_p^0 = h_t^0 - {P^0}{\left( {{A^0}} \right)^{1/2}}\). Eeff is given by

where Es and Ed are Young’s moduli and vs and vd are Poisson’s ratios of specimen and indenter, respectively, and β ≈ 1.23.36E* is the usual modulus encountered in Hertz contact problems. Equation (A1) is obtained from a theoretical analysis. However, for polymers Eeff lacks uniqueness because of viscoelasticity, so the polymers do not strictly conform to the theory. In practice, this discrepancy does not present a problem because ζp is calculated using a representative value of Eeff and in the end the continuous area-time curve is insensitive to the choice of Eeff. Figure A1 shows ln (A0)1/2 versus ln \(h_p^0\) from experiments with different creep hold times at fixed load. The slopes of the curves correspond to ζp. Rather than forming straight lines, the data must be approximated as parabolas

Data used to calculate ?p for PMMA, PS, and PC. For each material, data include indents with creep hold times that vary from 0.01 to100 s and load times that vary from 0.01 to 100 s. The 0.01-s load time data were fit to Eq. (A3), and these fits were differentiated to calculate ?p. The coefficients for the fit and the values of Eeff used to calculate hp are given in the embedded table.

in which case ζp = X1 + 2X2 ln \(h_p^0\). Previously34 we had not been able to reliably detect that ζp varies with depth. However, our measurement methods are now better, and the finite element analyses neglected viscoelastic deformation, so it should come as no surprise that ζp is not a constant for the polymers.

Because ζp depends on hp, it is not straightforward to calculate hp using Eq. (A1). Therefore, to account for variation in ζp in Eq. (A1) we divide the raw depth-load-time data into 100 equal segments on a log(time) scale so that for each segment, ζp is approximately constant. We then analyze each segment separately starting with the final segment of the creep hold, where A = A0 and \({h_p} = h_p^0\) are known, and work backward to the beginning of the creep hold.

Rights and permissions

About this article

Cite this article

Joseph, J.E., Lakes, R.S. & Stone, D.S. Broadband nanoindentation of glassy polymers: Part II. Viscoplasticity. Journal of Materials Research 27, 475–484 (2012). https://doi.org/10.1557/jmr.2011.364

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/jmr.2011.364