Abstract

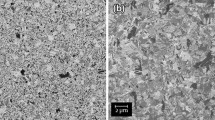

The plane-strain bulge test is used to investigate the mechanical behavior of freestanding electroplated Cu thin films as a function of film thickness and microstructure. The stiffness of the films increases slightly with decreasing film thickness because of changes in the crystallographic texture and the elastic anisotropy of Cu. Experimental stiffness values agree well with values derived from single-crystal elastic constants and the appropriate orientation distribution functions. No modulus deficit is observed. The yield stress of the films varies with film thickness and heat treatment as a result of changes in the grain size of the films. The yield stress follows typical Hall-Petch behavior if twins are counted as distinct grains, indicating that twin boundaries are effective barriers to dislocation motion. The Hall-Petch coefficient is in good agreement with values reported for bulk Cu. Film thickness and crystallographic texture have a negligible effect on the yield stress of the films.

Similar content being viewed by others

References

R.P. Vinci, J.J. Vlassak: Mechanical behavior of thin films. Annu. Rev. Mater. Sci. 26, 431 (1996).

W.D. Nix: Mechanical properties of thin films. Metall. Trans. A 20, 2217 (1989).

E. Arzt: Size effects in materials due to microstructural and dimensional constraints: A comparative review. Acta Mater. 46, 5611 (1998).

N. Triantafyllidis, E.C. Aifantis: A gradient approach to localization of deformation. 1. Hyperelastic materials. J. Elast. 16, 225 (1986).

E.C. Aifantis: Gradient deformation models at nano, micro, and macro scales. J. Eng. Mater. Technol. 121, 189 (1999).

N.A. Fleck, G.M. Muller, M.F. Ashby, J.W. Hutchinson: Strain gradient plasticity: Theory and experiment. Acta Metall. 42, 475 (1994).

N.A. Fleck, J.W. Hutchinson: A reformulation of strain gradient plasticity. J. Mech. Phys. Solids 49, 2245 (2001).

N.A. Fleck, J.W. Hutchinson: Strain gradient plasticity. Adv. Appl. Mech. 33, 295 (1997).

N.A. Fleck, J.W. Hutchinson: A phenomenological theory for strain gradient effects in plasticity. J. Mech. Phys. Solids 41, 1825 (1993).

L. Nicola, Van der E. Giessen, A. Needleman: Discrete dislocation analysis of size effects in thin films. J. Appl. Phys. 93, 5920 (2003).

A. Needleman, Van der E. Giessen: Discrete dislocation and continuum descriptions of plastic flow. Mater. Sci. Eng. A 309, 1 (2001).

G.E. Dieter: Mechanical Metallurgy, 3rd ed. (McGraw-Hill, New York, 1986), p. 287.

F. Spaepen, D.Y.W. Yu: A comparison of the strength of multilayers, thin films and nanocrystalline compacts. Scripta Mater. 50, 729 (2004).

M.A. Haque, M.T.A. Saif: Mechanical behavior of 30-50 mn thick aluminum films under uniaxial tension. Scripta Mater. 47, 863 (2002).

J. Schiotz, Di F.D. Tolla, K.W. Jacobsen: Softening of nanocrystalline metals at very small grain sizes. Nature 391, 561 (1998).

Z.W. Shan, E.A. Stach, J.M.K. Wiezorek, J.A. Knapp, D.M. Follstaedt, S.X. Mao: Grain boundary-mediated plasticity in nanocrystalline nickel. Science 305, 654 (2004).

H.B. Huang, F. Spaepen: Tensile testing of free-standing Cu, Ag and Al thin films and Ag/Cu multilayers. Acta Mater. 48, 3261 (2000).

D.Y.W. Yu, F. Spaepen: The yield strength of thin copper films on Kapton. J. Appl. Phys. 95, 2991 (2004).

A.J. Kalkman, A.H. Verbruggen, G.C.A.M. Janssen: Young’s modulus measurements and grain boundary sliding in freestanding thin metal films. Appl. Phys. Lett. 78, 2673 (2001).

D.T. Read, Y.W. Cheng, R. Geiss: Morphology, microstructure, and mechanical properties of a copper electrodeposit. Microelectron Eng. 75, 63 (2004).

D.T. Read, Y.W. Cheng, R.R. Keller, J.D. McColskey: Tensile properties of free-standing aluminum thin films. Scripta Mater. 45, 583 (2001).

H.D. Espinosa, B.C. Prorok, B. Peng: Plasticity size effects in free-standing submicron polycrystalline FCC films subjected to pure tension. J. Mech. Phys. Solids 52, 667 (2004).

M.A. Haque, M.T.A. Saif: Deformation mechanisms in free-standing nanoscale thin films: A quantitative in situ transmission electron microscope study. Proc. Natl. Acad. Sci. USA 101, 6335 (2004).

Y. Xiang, X. Chen, and J.J. Vlassak: The mechanical properties of electroplated Cu thin films measured by means of the bulge test technique, in Thin Films: Stresses and Mechanical Properties IX edited by C.S. Ozkan, L.B. Freund, R.C. Cammarata, and H. Gao (Mater. Res. Soc. Symp. Proc. 695, Warrendale, PA, 2002), p. 189.

Y. Xiang, J.J. Vlassak, M.T. Perez-Prado, T.Y. Tsui, and A.J. McKerrow: The effects of passivation layer and film thickness on the mechanical behavior of freestanding electroplated Cu thin films with constant microstructure, in Thin Films—Stresses and Mechanical Properties X edited by S.G. Corcoran, Y.C. Joo, N.R. Moody, and Z. Suo (Mater. Res. Soc. Symp. Proc. 795, Warrendale, PA, 2004), p. 417.

H.J. Lee, G. Cornella, J.C. Bravman: Stress relaxation of free-standing aluminum beams for microelectromechanical systems applications. Appl. Phys. Lett. 76, 3415 (2000).

Y. Xiang, X. Chen, J.J. Vlassak: Plane-strain bulge test for thin films. J. Mater. Res. 20, 2360 (2005).

Y. Xiang, J.J. Vlassak: Bauschinger effect in thin metal films. Scripta Mater. 53, 177 (2005).

P.A. Flinn: Measurement and interpretation of stress in copper-films as a function of thermal history. J. Mater. Res. 6, 1498 (1991).

M.D. Thouless, J. Gupta, J.M.E. Harper: Stress development and relaxation in copper-films during thermal cycling. J. Mater. Res. 8, 1845 (1993).

R. Keller, S.P. Baker, E. Arzt: Quantitative analysis of strengthening mechanisms in thin Cu films: Effects of film thickness, grain size, and passivation. J. Mater. Res. 13, 1307 (1998).

R. Spolenak, C.A. Volkert, K. Takahashi, S. Fiorillo, J. Miner, and W.L. Brown: Mechanical properties of electroplated copper thin films, in Thin Films—Stresses and Mechanical Properties VIII edited by R. Vinci, O. Kraft, N. Moody, P. Besser, and E. Shaffer, II (Mater. Res. Soc. Symp. Proc. 594, Warrendale, PA, 2000), p. 63.

L.S. Palatnik, A.I. Llinskii: The strength of vacuum condensates of copper. Sov. Phys. Solid State 3, 2053 (1962).

A. Lawley, S. Schuster: Tensile behavior of copper foils prepared from rolled material. Trans. Metall. Soc. AIME 230, 27 (1964).

I.A. Oding, I.T. Aleksanyan: Mechanical properties of copper films. Sov. Phys. Dokl. 8, 818 (1964).

H. Leidheiser, B.W. Sloope: Mechanical properties of copper films. J. Appl. Phys. 41, 402 (1970).

R.R. Keller, J.M. Phelps, D.T. Read: Tensile and fracture behavior of free-standing copper films. Mater. Sci. Eng. A 214, 42 (1996).

D.T. Read: Tension-tension fatigue of copper thin films. Int. J. Fatigue 20, 203 (1998).

M.T. Perez-Prado, J.J. Vlassak: Microstructural evolution in electroplated Cu thin films. Scripta Mater. 47, 817 (2002).

A. Gangulee: Structure of electroplated and vapor-deposited copper films. J. Appl. Phys. 43, 867 (1972).

I.V. Tomov, D.S. Stoychev, I.B. Vitanova: Recovery and recrystallization of electrodeposited bright copper coatings at room temperature. 2. X-ray investigation of primary recrystallization. J. Appl. Electrochem. 15, 887 (1985).

H. Lee, W.D. Nix, S.S. Wong: Studies of the driving force for room temperature microstructure evolution in electroplated copper films. J. Vac. Sci. Technol. B 22, 2369 (2004).

J.J. Vlassak, W.D. Nix: A new bulge test technique for the determination of Young’s modulus and Poisson’s ratio of thin films. J. Mater. Res. 7, 3242 (1992).

S.H. Hong, K.H. Chung, C.H. Lee: Effects of hot extrusion parameters on the tensile properties and microstructures of SiCw-2124Al composites. Mater. Sci. Eng. A 206, 225 (1996).

H. Gao, L. Zhang, W.D. Nix, C.V. Thompson, E. Arzt: Crack-like grain-boundary diffusion wedges in thin metal films. Acta Mater. 47, 2865 (1999).

Y.C. Joo, S.J. Hwang, H. Park: The effect of grain boundary characteristics on microstructure and stress void evolution in electroplated and sputtered cu films. Mater. Sci. Forum 426–432, 3481 (2003).

C.R. Barrett, W.D. Nix, A.S. Tetelman: The Principles of Engineering Materials (Prentice-Hall, Englewood Cliffs, NJ, 1973).

G. Simmons, H. Wang: Single Crystal Elastic Constants and Calculated Aggregate Properties: A Handbook, 2nd ed. (MIT Press, Cambridge, MA, 1970).

H. Tada, P.C. Paris, G.R. Irwin: The Stress Analysis of Cracks Handbook (Del Research Corporation, Hellertown, PA, 1973).

M.A. Phillips, R. Spolenak, N. Tamura, W.L. Brown, A.A. MacDowell, R.S. Celestre, H.A. Padmore, B.W. Batterman, E. Arzt, J.R. Patel: X-ray microdiffraction: Local stress distributions in polycrystalline and epitaxial thin films. Microelectron. Eng. 75, 117 (2004).

L. Lu, Y.F. Shen, X.H. Chen, L.H. Qian, K. Lu: Ultrahigh strength and high electrical conductivity in copper. Science 304, 422 (2004).

C.J. Youngdahl, J.R. Weertman, R.C. Hugo, H.H. Kung: Deformation behavior in nanocrystalline copper. Scripta Mater. 44, 1475 (2001).

R. Armstrong, I. Codd, R.M. Douthwaite, N.J. Petch: Plastic deformation of polycrystalline aggregates. Philos. Mag. 7, 45 (1962).

H.J. Bunge: Texture Analysis in Materials Science: Mathematical Methods (Butterworths, London, 1982).

U.F. Kocks: Relation between polycrystal deformation and single-crystal deformation. Metall. Trans. 1, 1121 (1970).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Xiang, Y., Tsui, T.Y. & Vlassak, J.J. The mechanical properties of freestanding electroplated Cu thin films. Journal of Materials Research 21, 1607–1618 (2006). https://doi.org/10.1557/jmr.2006.0195

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/jmr.2006.0195