Abstract

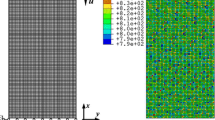

The quasi-static compressive deformation behavior of a Vitreloy 1 bulk metallic glass (BMG) with an aspect ratio of 0.25 was investigated. It is found that the friction and the confinement at the specimen–loading platen interface will cause the dramatic increase in the compressive load, leading to higher compressive strength. In particular, the BMG specimens show great plastic-deformation ability, and plenty of interacted, deflected, wavy, or branched shear bands were observed on the surfaces after plastic deformation. The formation of the strongly interacted, deflected, wavy, or branched shear bands can be attributed to the triaxial stress state in the glassy specimens with a very small aspect ratio.

Similar content being viewed by others

References

A. Inoue: Stabilization of metallic supercooled liquid and bulk amorphous alloys. Acta Mater. 48, 279 (2000).

J.F. Löffler: Bulk metallic glasses. Intermetallics. 11, 529 (2003).

W.H. Wang, C. Dong, and C.H. Shek: Bulk metallic glasses. Mater. Sci. Eng. R 44, 45 (2004).

A.I. Salimon, M.F. Ashby, Y. Brechet, and A.L. Greer: Bulk metallic glasses: What are they good for? Mater. Sci. Eng., A 375–377, 385 (2004).

H.A. Bruck, T. Christman, A.J. Rosakis, and W.L. Johnson: Quasi-static constitutive behavior of Zr41.25Ti13.75Ni10Cu12.5Be22.5 bulk amorphous-alloys. Scripta Metall. Mater. 30, 429 (1994).

H.A. Bruck, A.J. Rosakis, and W.L. Johnson: The dynamic compressive behavior of beryllium bearing bulk metallic glasses. J. Mater. Res. 11, 503 (1996).

H. Choi-Yimhoi-Yim and W.L. Johnson: Bulk metallic glass matrix composites. Appl. Phys. Lett. 71, 3808 (1997).

R.D. Conner, R.B. Dandliker, and W.L. Johnson: Mechanical properties of tungsten and steel fiber reinforced Zr41.25Ti13.75Cu12.5Ni10Be22.5 metallic glass matrix composites. Acta Mater. 46, 6089 (1998).

D.H. Bae, M.H. Lee, D.H. Kim, and D.J. Sordelet: Plasticity in Ni59Zr20Ti16Si2Sn3 metallic glass matrix composites containing brass fibers synthesized by warm extrusion of powders. Appl. Phys. Lett. 83, 2312 (2003).

C.C. Hays, C.P. Kim, and W.L. Johnson: Microstructure controlled shear band pattern formation and enhanced plasticity of bulk metallic glasses containing in situ formed ductile phase dendrite dispersions. Phys. Rev. Lett. 84, 2901 (2000).

G. He, J. Eckert, and W. Löser: Stability, phase transformation and deformation behavior of Ti-base metallic glass and composites. Acta Mater. 51, 1621 (2003).

F.F. Wu, Z.F. Zhang, A. Peker, S.X. Mao, J. Das, and J. Eckert: Strength asymmetry of ductile dendrites reinforced Zr- and Ti-based composites. J. Mater. Res. 21, 2331 (2006).

R.D. Conner, Y. Li, W.D. Nix, and W.L. Johnson: Shear band spacing under bending of Zr-based metallic glass plates. Acta Mater. 52, 2429 (2004).

Z.F. Zhang, H. Zhang, X.F. Pan, J. Das, and J. Eckert: Effect of aspect ratio on the compressive deformation and fracture behaviour of Zr-based bulk metallic glass. Philos. Mag. Lett. 85, 513 (2005).

H. Bei, S. Xie, and E.P. George: Softening caused by profuse shear banding in a bulk metallic glass. Phys. Rev. Lett. 96, 105503 (2006).

A.H. Brothers and D.C. Dunand: Syntactic bulk metallic glass foam. Appl. Phys. Lett. 84, 1108 (2004).

A.H. Brothers and D.C. Dunand: Plasticity and damage in cellular amorphous metals. Acta Mater. 53, 4427 (2005).

Y. Yokoyama, K. Yamano, K. Fukaura, H. Sunada, and A. Inoue: Enhancement of ductility and plasticity of Zr55Cu30Al10Ni5 bulk glassy alloy by cold rolling. Mater. Trans. 42, 623 (2001).

L.A. Davis and S. Kavesh: Deformation and fracture of an amorphous metallic alloy at high pressure. J. Mater. Sci. 10, 453 (1975).

J.J. Lewandowski and P. Lowhaphandu: Effects of hydrostatic pressure on the flow and fracture of a bulk amorphous metal. Philos. Mag. A 82, 3427 (2002).

J. Lu and G. Ravichandran: Pressure-dependent flow behavior of Zr41.2Ti13.8Cu12.5Ni10Be22.5 bulk metallic glass. J. Mater. Res. 18, 2039 (2003).

G.P. Sunny, V. Prakash, and J.J. Lewandowski: Results from a novel insert design for high strain-rate compression of a bulk metallic glass, in Proceedings of the 2006 International Mechanical Engineering Conference and Exposition (American Society of Mechanical Engineers, New York, NY, 2006).

G.P. Sunny, F. Yuan, J.J. Lewandowski, and V. Prakash: Dynamic stress-strain response of a Zr-based bulk metallic glass, in Proceedings of the 2005 SEM Annual Conference and Exposition on Experimental and Applied Mechanics (Society of Experimental Mechanics, Bethel, CT, 2005).

G. Subhash, R.J. Dowding, and L.J. Kecskes: Characterization of uniaxial compressive response of bulk amorphous Zr-Ti-Cu-Ni-Be alloy. Mater. Sci. Eng., A 334, 33 (2002).

J. Lu, G. Ravichandran, and W.L. Johnson: Deformation behavior of the Zr41.2Ti13.8Cu12.5Ni10Be22.5 bulk metallic glass over a wide range of strain-rates and temperatures. Acta Mater. 51, 3429 (2003).

Z.F. Zhang, J. Eckert, and L. Schultz: Difference in compressive and tensile fracture mechanisms of Zr59Cu20Al10Ni8Ti3 bulk metallic glass. Acta Mater. 51, 1167 (2003).

Z.F. Zhang, D. Brunner, C. Scheu, and M. Rühle: Deformation and fracture mechanisms of Al2O3/Nb/Al2O3 composites under compression. Z. Metallkd. 96, 62 (2005).

B. Avitzur: Handbook of Metal Forming (John Wiley & Sons, New York, 1983).

H. Chen, Y. He, G.J. Shiflet, and S.J. Poon: Deformation-induced nanocrystal formation in shear bands of amorphous-alloys. Nature 367, 541 (1994).

Z.F. Zhang, H. Zhang, B.L. Shen, A. Inoue, and J. Eckert: Shear fracture and fragmentation mechanisms of bulk metallic glasses. Philos. Mag. Lett. 86, 643 (2006).

Z.F. Zhang and J. Eckert: Unified tensile fracture criterion. Phys. Rev. Lett. 94, 094301 (2005).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Wu, F.F., Zhang, Z.F. & Mao, S.X. Compressive properties of bulk metallic glass with small aspect ratio. Journal of Materials Research 22, 501–507 (2007). https://doi.org/10.1557/jmr.2007.0064

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/jmr.2007.0064