Abstract

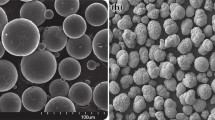

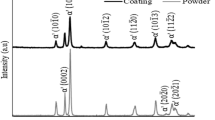

The microstructure, phase composition, and chemical composition of vacuum plasma-sprayed Ti-6Al-4V alloys were examined in detail using a variety of techniques, including x-ray diffraction, x-ray photoelectron spectroscopy, and transmission electron microscopy. The observed chemistry and structure were related to the conditions under which the deposit was formed and the phase equilibria in the Ti alloy system. The porosity of the deposit was in the range of 3 to 5%. A slight decrease in the Al content and a slight increase in the amount of oxygen and hydrogen was found relative to the starting powder. Within individual splats, a columnar solidification structure can be seen. However, the as-deposited material is ≥90% α′ martensite that is present in the form of fine lathes on the order of 500 nm in width surrounded by residual β-phase. This herringbone structure obscures to some extent the preexisting columnar structure of the as-solidified β-phase. The material fails at low elongations (∼1%) when tested in tension, with a macroscopic stress-strain curve, which appears to be quite brittle. Examination of the fracture surface, however, reveals a ductile failure mode within individual splats, which is consistent with the structure described above. Sections perpendicular to the fracture surface show that failure occurs at the weak splat boundaries through the development and growth of voids between splats.

Similar content being viewed by others

References

Y.Y. Zhao, P.S. Grant, and B. Cantor, Modeling and Experimental Analysis of Vacuum Plasma Spraying: Part I. Prediction of Initial Plasma Properties at Plasma Gun Exit, Model. Simul. Mater. Sci. Eng., Vol 8, 2000, p 497–513

Y.Y. Zhao, P.S. Grant, and B. Cantor, Modeling and Experimental Analysis of Vacuum Plasma Spraying: Part II. Prediction of Temperatures and Velocities of Plasma Gases and Ti Particles in a Plasma Jet, Model. Simul. Mater. Sci. Eng., Vol 8, 2000, p 515–540

T. McKechine, Near-Net Shape Spray Forming-Metals, Thermal Spray Coatings: Research, Design, and Applications, C. Berndt and T.F. Bernecki, Ed., ASM International, 2000, p 1105–1116

R.P. Krepski, Thermal Spray Coating Applications in the Chemical Process Industries, Vol 42, MTI Publication, Georgetown, PA, 1993

S. Sampath and H. Herman, Rapid Solidification and Microstructure Development During Plasma Spray deposition, J. Thermal Spray Technol, Vol 5 (No. 4), 1996, p 445–456

H.D. Steffens and M. Dvork, Structure and Electrochemical Behavior of Vacuum Plasma Sprayed Titanium and Plasma Beam Alloyed Titanium Coatings, Thermal Spray Research and Applications, C. Berndt and T.F. Bernecki, Ed., ASM International, 1991, p 207–210

S. Malinov, W. Sha, Z. Guo, C.C. Tang, and A.E. Long, Synchrotron X-Ray Diffraction Study of the Phase Transformations in Titanium Alloys, Mater. Charact., Vol 48, 2002, p 279–295

B.D. Cullity, Elements of X-ray Diffraction, 2nd ed., Addison-Wesley Publishing Co., Reading, MA, 1978

R. Boyer, G. Welsch, and E.W. Collings, Ed., Materials Properties Handbook: Titanium Alloys, 2nd ed., ASM International, 1998, p 12–48

K. Oi, H. Terashima, and K. Suzuki, Control of Microstructure in Ti-6Al-4V Castparts, Metallurgy and Technology of Practical Titanium Alloys, S. Fujishiro, D. Eylon, and T. Kishi, Ed., The Minerals Metals & Materials Society, Warrendale, PA, 1994, p 219–224

K. Mills, Ed., Metals Handbook: Fractography, 9th ed., ASM International, 1987, p 441–455

S. Sampath and H. Herman, Microstructure of Vacuum Plasma Sprayed Coating, Thermal Spray Technology-New Ideas and Processes, D.L. Houck, Ed., ASM International, 1989, p 1–7

J.A. Hines, J.O. Peters, and G. Lutjering, Microcrack Propagation in Ti-6Al-4V Alloys, Fatigue Behavior of Titanium Alloys, R. Boyer and D. Eylon, Ed., The Minerals Metals & Materials Society, Warrendale, PA, 1999, p 15–22

R.R. Holmes and D.H. Burns, Vacuum Plasma Spray Forming NAR-loy-Z and Inconel Components for Liquid Rocket Engines, Thermal Spray Research and Applications, T.F. Bernecki, Ed., ASM International, 1991, p 363–368

H.R. Salimijazi, T.W. Coyle, J. Mostaghimi, and L. Leblanc, Microstructural Formation of VPSF Ti-6Al-4V Alloys, Thermal Spray 2003: Advancing the Science and Applying the Technology, B.R. Marple and C. Moreau, Ed., May 5–8, 2003 (Orlando, FL), ASM International, 2003, p 611–616

L. Leblanc, H. R. Salimijazi, J. Mostaghimi, and T.W. Coyle, On Vacuum Plasma Spray Forming of Ti-6Al-4V, Thermal Spray 2003: Advancing the Science and Applying the Technology, B.R. Marple and C. Moreau, Ed., May 5–8, 2003 (Orlando, FL), ASM International, 2003, p 603–609

T.A. Brzezinski, S. Grenier, M.E. Smagoriski, and G.E. Kim, Vacuum Plasma Spray Deposition of Spherical Plasma Atomized Ti-6Al 4V, Thermal Spray Coatings: Research, Design, and Applications, C. Berndt and T.F. Bernecki, Ed., ASM International, 2000, p 935–939

F.H. Froes and D. Eylon, Powder Metallurgy of Ti Alloys, Titanium Technology, F.H. Froes, D. Eylon, and H.B. Bomberger, Ed., Titanium Development Association, Dayton, OH, 1985, p 49–58

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Salimijazi, H.R., Coyle, T.W., Mostaghimi, J. et al. Microstructure and failure mechanism in As-deposited, vacuum plasma-sprayed Ti-6Al-4V alloy. J Therm Spray Tech 14, 215–223 (2005). https://doi.org/10.1361/10599630523773

Received:

Revised:

Issue Date:

DOI: https://doi.org/10.1361/10599630523773